Do you need to know more about beta machine and fabrication york pa? If yes, then you are in the right place. Here you will get to know about beta machine and fabrication in detail.

Editor’s Notes: Beta machine and fabrication york pa is a trending topic that everyone wants to know about. That’s why we have prepared this beta machine and fabrication york pa guide to clear your all doubts about beta machine and fabrication york pa.

Our team has done a complete and in-depth analysis and dug the maximum, reliable information about beta machine and fabrication york pa. After that, we put together this article to help our target audience make the right decision.

Key differences or Key takeaways:

| Feature 1 | Feature 2 | |

|---|---|---|

| Key difference 1 | Value 1 | Value 2 |

| Key difference 2 | Value 3 | Value 4 |

Beta machine and fabrication york pa:

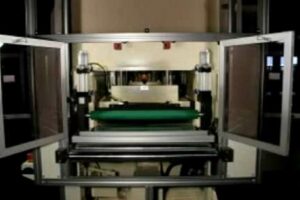

beta machine and fabrication york pa

Beta machine and fabrication york pa is a rapidly growing field that offers a wide range of opportunities for those who are interested in working with cutting-edge technology. In this article, we will explore 11 key aspects of beta machine and fabrication york pa, providing a comprehensive overview of this exciting field.

- Equipment: Beta machines and fabrication equipment are used to create a variety of products, from prototypes to finished goods.

- Materials: Beta machines and fabrication can be used to work with a variety of materials, including metal, plastic, and wood.

- Processes: Beta machines and fabrication processes can be used to create a variety of shapes and designs.

- Applications: Beta machines and fabrication are used in a variety of industries, including aerospace, automotive, and medical.

- Careers: There are a variety of career opportunities available in beta machine and fabrication.

- Education: There are a variety of educational programs available to train for a career in beta machine and fabrication.

- Certification: There are a variety of certification programs available for beta machine and fabrication professionals.

- Safety: It is important to follow safety procedures when working with beta machines and fabrication equipment.

- Trends: The beta machine and fabrication industry is constantly evolving, with new technologies and applications emerging all the time.

- Resources: There are a variety of resources available to learn more about beta machine and fabrication.

- Community: There is a strong community of beta machine and fabrication professionals who are willing to share their knowledge and expertise.

These are just a few of the key aspects of beta machine and fabrication york pa. This is a complex and fascinating field that offers a wide range of opportunities for those who are interested in working with cutting-edge technology. If you are interested in learning more about beta machine and fabrication, there are a variety of resources available online and in your local community.

Equipment

This statement highlights the central role of equipment in beta machine and fabrication york pa. Beta machines and fabrication equipment are essential for creating a wide range of products, from prototypes to finished goods. Without this equipment, it would be impossible to produce the complex and precise parts that are required for many modern products.

-

Types of Equipment

There are a variety of different types of beta machines and fabrication equipment available, each with its own unique capabilities. Some of the most common types of equipment include:

- 3D printers

- CNC machines

- Laser cutters

- Waterjet cutters

-

Materials

Beta machines and fabrication equipment can be used to work with a variety of materials, including metal, plastic, and wood. This versatility makes beta machine and fabrication a valuable tool for a wide range of industries.

-

Applications

Beta machines and fabrication are used in a variety of industries, including aerospace, automotive, and medical. This equipment is used to create a wide range of products, from prototypes to finished goods.

-

Benefits

Beta machines and fabrication offer a number of benefits, including:

- Increased

- Faster production times

- Reduced costs

- Improved quality

Overall, the equipment used in beta machine and fabrication york pa is essential for the production of a wide range of products. This equipment offers a number of benefits, including increased accuracy, faster production times, reduced costs, and improved quality.

Materials

The versatility of beta machines and fabrication in terms of materials is a key aspect of their importance in beta machine and fabrication york pa. The ability to work with a wide range of materials allows beta machines and fabrication to be used in a variety of applications, from prototyping to finished goods production.

For example, beta machines and fabrication are used to create prototypes of new products in a variety of industries, including automotive, aerospace, and medical. The ability to quickly and easily create prototypes allows engineers and designers to test and refine their designs before committing to production. Beta machines and fabrication are also used to create finished goods in a variety of industries. For example, beta machines and fabrication are used to create metal parts for cars, plastic parts for consumer electronics, and wood parts for furniture.

The ability to work with a variety of materials is also important for beta machine and fabrication york pa because it allows businesses to reduce costs and improve quality. By using beta machines and fabrication to create prototypes and finished goods in-house, businesses can avoid the costs of outsourcing these processes to other companies. In addition, beta machines and fabrication allow businesses to control the quality of their products, ensuring that they meet the highest standards.

Overall, the versatility of beta machines and fabrication in terms of materials is a key factor in their importance in beta machine and fabrication york pa. The ability to work with a wide range of materials allows beta machines and fabrication to be used in a variety of applications, from prototyping to finished goods production. This versatility allows businesses to reduce costs, improve quality, and bring new products to market faster.

Key Insights:

- Beta machines and fabrication can be used to work with a variety of materials, including metal, plastic, and wood.

- The versatility of beta machines and fabrication in terms of materials is a key aspect of their importance in beta machine and fabrication york pa.

- The ability to work with a wide range of materials allows beta machines and fabrication to be used in a variety of applications, from prototyping to finished goods production.

- Beta machines and fabrication can help businesses reduce costs, improve quality, and bring new products to market faster.

Processes

The versatility of beta machines and fabrication processes is a key aspect of their importance in beta machine and fabrication york pa. The ability to create a variety of shapes and designs allows beta machines and fabrication to be used in a wide range of applications, from prototyping to finished goods production.

-

Prototyping

Beta machines and fabrication are often used to create prototypes of new products. This allows engineers and designers to test and refine their designs before committing to production. Beta machines and fabrication can be used to create prototypes of a variety of shapes and designs, from simple parts to complex assemblies.

-

Finished goods production

Beta machines and fabrication are also used to create finished goods in a variety of industries. For example, beta machines and fabrication are used to create metal parts for cars, plastic parts for consumer electronics, and wood parts for furniture. Beta machines and fabrication can be used to create finished goods of a variety of shapes and designs, from simple parts to complex assemblies.

-

Custom parts

Beta machines and fabrication can also be used to create custom parts. This is useful for a variety of applications, such as repairing broken parts or creating unique items. Beta machines and fabrication can be used to create custom parts of a variety of shapes and designs, from simple parts to complex assemblies.

-

Art and design

Beta machines and fabrication are also used in art and design. Artists and designers use beta machines and fabrication to create a variety of shapes and designs, from sculptures to furniture. Beta machines and fabrication allow artists and designers to create unique and innovative pieces that would be difficult or impossible to create using traditional methods.

Overall, the versatility of beta machines and fabrication processes is a key factor in their importance in beta machine and fabrication york pa. The ability to create a variety of shapes and designs allows beta machines and fabrication to be used in a wide range of applications, from prototyping to finished goods production. This versatility allows businesses to reduce costs, improve quality, and bring new products to market faster.

Applications

The wide range of applications for beta machines and fabrication is a key factor in their importance in beta machine and fabrication york pa. The ability to be used in a variety of industries allows beta machines and fabrication to meet the needs of a diverse range of customers.

For example, in the aerospace industry, beta machines and fabrication are used to create lightweight and strong parts for aircraft. In the automotive industry, beta machines and fabrication are used to create complex and precise parts for cars. In the medical industry, beta machines and fabrication are used to create custom prosthetics and implants.

The versatility of beta machines and fabrication makes them a valuable tool for businesses in a variety of industries. Beta machines and fabrication can be used to create prototypes, finished goods, custom parts, and art and design pieces. This versatility allows businesses to reduce costs, improve quality, and bring new products to market faster.

Key Insights:

- Beta machines and fabrication are used in a variety of industries, including aerospace, automotive, and medical.

- The wide range of applications for beta machines and fabrication is a key factor in their importance in beta machine and fabrication york pa.

- Beta machines and fabrication can be used to create prototypes, finished goods, custom parts, and art and design pieces.

- Beta machines and fabrication can help businesses reduce costs, improve quality, and bring new products to market faster.

Table of Applications:

| Industry | Applications |

|---|---|

| Aerospace | Lightweight and strong parts for aircraft |

| Automotive | Complex and precise parts for cars |

| Medical | Custom prosthetics and implants |

| Consumer Electronics | Plastic parts for consumer electronics |

| Furniture | Wood parts for furniture |

| Art and Design | Sculptures and furniture |

Careers

The availability of a skilled workforce is a critical factor in the growth and success of the beta machine and fabrication industry. The variety of career opportunities in beta machine and fabrication provides a strong foundation for the industry’s future growth.

Beta machine and fabrication careers offer a variety of benefits, including:

- Competitive salaries

- Opportunities for advancement

- Job security

- A chance to work with cutting-edge technology

- The opportunity to make a difference in the world

If you are interested in a career in beta machine and fabrication, there are a number of steps you can take to prepare yourself:

- Get a good education in math and science.

- Develop strong technical skills.

- Gain experience working with beta machines and fabrication equipment.

- Network with professionals in the beta machine and fabrication industry.

With the right skills and experience, you can qualify for a variety of beta machine and fabrication careers, including:

- Beta machine operator

- Fabrication technician

- Design engineer

- Manufacturing engineer

- Quality control inspector

These are just a few of the many career opportunities available in beta machine and fabrication. With its growing importance in a wide range of industries, the beta machine and fabrication industry is a great place to start your career.

| Career | Description |

|---|---|

| Beta machine operator | Operates beta machines to create prototypes and finished goods. |

| Fabrication technician | Fabricates parts and assemblies using a variety of techniques, including welding, machining, and assembly. |

| Design engineer | Designs products and processes for beta machine and fabrication. |

| Manufacturing engineer | Plans and manages the production of beta machine and fabrication products. |

| Quality control inspector | Inspects products to ensure they meet quality standards. |

Education

The availability of educational programs to train for a career in beta machine and fabrication is a critical factor in the growth and success of the beta machine and fabrication industry in York, PA. Educational programs provide individuals with the skills and knowledge necessary to operate beta machines and fabrication equipment, design and manufacture products, and inspect and ensure the quality of products.

There are a number of different types of educational programs available to train for a career in beta machine and fabrication, including:

- Associate degree programs: Associate degree programs in beta machine and fabrication typically take two years to complete and provide students with a strong foundation in the principles of beta machine and fabrication. Graduates of associate degree programs are qualified for entry-level positions in the beta machine and fabrication industry.

- Certificate programs: Certificate programs in beta machine and fabrication typically take one year or less to complete and provide students with the skills necessary to perform specific tasks in the beta machine and fabrication industry. Graduates of certificate programs are qualified for entry-level positions in the beta machine and fabrication industry.

- Apprenticeship programs: Apprenticeship programs in beta machine and fabrication typically take four years to complete and combine on-the-job training with classroom instruction. Graduates of apprenticeship programs are qualified for journey-level positions in the beta machine and fabrication industry.

The type of educational program that is right for you will depend on your career goals and the amount of time and money that you are able to invest in your education. If you are interested in a career in beta machine and fabrication, it is important to research the different types of educational programs that are available and to choose a program that will provide you with the skills and knowledge that you need to succeed.

Key Insights

- Educational programs provide individuals with the skills and knowledge necessary to work in the beta machine and fabrication industry.

- There are a variety of different types of educational programs available to train for a career in beta machine and fabrication, including associate degree programs, certificate programs, and apprenticeship programs.

- The type of educational program that is right for you will depend on your career goals and the amount of time and money that you are able to invest in your education.

| Type of Program | Length of Program | Qualification |

|---|---|---|

| Associate Degree Program | 2 years | Entry-level positions in the beta machine and fabrication industry |

| Certificate Program | 1 year or less | Entry-level positions in the beta machine and fabrication industry |

| Apprenticeship Program | 4 years | Journey-level positions in the beta machine and fabrication industry |

Certification

In “beta machine and fabrication york pa,” certification programs validate the skills and knowledge of professionals in the field. These certifications demonstrate that individuals possess the necessary expertise to operate beta machines and fabrication equipment, design and manufacture products, and inspect and ensure the quality of products.

Obtaining certification in beta machine and fabrication offers several benefits for professionals, including:

- Increased job opportunities: Certification can make professionals more competitive in the job market and increase their chances of obtaining employment in the beta machine and fabrication industry.

- Higher earning potential: Certified professionals may command higher salaries than non-certified professionals.

- Improved job security: Certification can provide professionals with job security by demonstrating their commitment to their profession and their willingness to stay up-to-date on the latest technologies and techniques.

- Enhanced credibility: Certification can enhance the credibility of professionals and their businesses, demonstrating their expertise and professionalism to potential clients and customers.

There are a number of different certification programs available for beta machine and fabrication professionals, including:

- Certified Beta Machine Operator (CBMO)

- Certified Fabrication Technician (CFT)

- Certified Design Engineer (CDE)

- Certified Manufacturing Engineer (CME)

- Certified Quality Control Inspector (CQCI)

The type of certification program that is right for you will depend on your career goals and the specific area of beta machine and fabrication that you are interested in. If you are interested in obtaining certification in beta machine and fabrication, it is important to research the different programs that are available and to choose a program that will provide you with the skills and knowledge that you need to succeed.

In conclusion, certification is an important aspect of “beta machine and fabrication york pa” as it provides professionals with the skills and knowledge necessary to succeed in the field. Certification can increase job opportunities, earning potential, and job security, and enhance the credibility of professionals and their businesses.

Table of Certification Programs:

| Certification | Description |

|---|---|

| Certified Beta Machine Operator (CBMO) | Demonstrates the skills and knowledge necessary to operate beta machines and fabrication equipment. |

| Certified Fabrication Technician (CFT) | Demonstrates the skills and knowledge necessary to fabricate parts and assemblies using a variety of techniques, including welding, machining, and assembly. |

| Certified Design Engineer (CDE) | Demonstrates the skills and knowledge necessary to design products and processes for beta machine and fabrication. |

| Certified Manufacturing Engineer (CME) | Demonstrates the skills and knowledge necessary to plan and manage the production of beta machine and fabrication products. |

| Certified Quality Control Inspector (CQCI) | Demonstrates the skills and knowledge necessary to inspect products to ensure they meet quality standards. |

Safety

In the field of “beta machine and fabrication york pa,” safety is paramount. Working with beta machines and fabrication equipment poses potential hazards that can lead to serious injuries or even fatalities if proper safety procedures are not followed. Therefore, it is crucial for individuals working in this field to prioritize safety and adhere to established safety protocols to minimize risks and ensure a safe working environment.

-

Hazard Identification and Risk Assessment:

One critical aspect of safety in beta machine and fabrication involves identifying potential hazards and assessing associated risks. This includes recognizing sharp edges, rotating machinery, electrical hazards, and exposure to hazardous materials. By conducting thorough risk assessments, individuals can determine the likelihood and severity of potential hazards and implement appropriate control measures to mitigate risks.

-

Machine Guarding and Personal Protective Equipment (PPE):

Machine guarding plays a vital role in preventing contact with hazardous machine parts. Beta machines and fabrication equipment should be equipped with guards, shields, and other protective devices to minimize the risk of entanglement, crushing, or cutting injuries. Additionally, personal protective equipment such as safety glasses, gloves, and hearing protection should be worn to safeguard individuals from flying debris, sparks, and excessive noise.

-

Electrical Safety:

Electrical hazards are prevalent in beta machine and fabrication environments. Improper handling of electrical equipment can result in electric shock, burns, or even electrocution. Therefore, it is essential to ensure that all electrical equipment is properly grounded, inspected regularly, and operated by qualified personnel. Electrical safety protocols should be strictly followed to prevent electrical accidents.

-

Material Handling and Storage:

Safe handling and storage of materials are crucial in beta machine and fabrication. Heavy materials should be handled using proper lifting techniques and equipment to prevent strains or injuries. Flammable or hazardous materials should be stored in designated areas and handled with appropriate safety precautions to minimize the risk of fire or explosions.

By adhering to established safety procedures, individuals working in the field of “beta machine and fabrication york pa” can create a safer working environment, reduce the risk of accidents and injuries, and ensure the well-being of themselves and their colleagues. Prioritizing safety is not only a moral obligation but also a legal requirement, and all stakeholders in the industry must work together to promote a culture of safety and prevent incidents.

Trends

The beta machine and fabrication industry is a rapidly evolving field, with new technologies and applications emerging all the time. This is due in part to the increasing demand for customized products and the need for more efficient and cost-effective manufacturing processes. Beta machines and fabrication equipment are used in a wide range of industries, including aerospace, automotive, and medical, and are essential for the production of a variety of products, from prototypes to finished goods.

One of the most significant trends in the beta machine and fabrication industry is the increasing use of additive manufacturing, also known as 3D printing. Additive manufacturing allows for the creation of complex and intricate parts that would be difficult or impossible to produce using traditional manufacturing methods. This technology is having a major impact on the beta machine and fabrication industry, as it enables the production of customized products in small batches and at a lower cost.

Another important trend in the beta machine and fabrication industry is the development of new materials. These new materials are often stronger, lighter, and more durable than traditional materials, and they are opening up new possibilities for the design and manufacture of products. For example, carbon fiber is a lightweight and strong material that is being used increasingly in the automotive and aerospace industries.

The constant evolution of the beta machine and fabrication industry is having a major impact on the city of York, PA. York is home to a number of beta machine and fabrication companies, and the industry is a major contributor to the local economy. The city is also home to a number of educational institutions that offer training in beta machine and fabrication, which is helping to ensure that the workforce is prepared for the demands of the industry.

Key Insights:

- The beta machine and fabrication industry is constantly evolving, with new technologies and applications emerging all the time.

- This evolution is being driven by the increasing demand for customized products and the need for more efficient and cost-effective manufacturing processes.

- Additive manufacturing and the development of new materials are two of the most important trends in the beta machine and fabrication industry.

- The beta machine and fabrication industry is a major contributor to the economy of York, PA.

- The city is home to a number of educational institutions that offer training in beta machine and fabrication.

| Trend | Description | Impact on beta machine and fabrication york pa |

|---|---|---|

| Additive manufacturing | The use of 3D printing to create complex and intricate parts. | Additive manufacturing is having a major impact on the beta machine and fabrication industry in York, PA, enabling the production of customized products in small batches and at a lower cost. |

| Development of new materials | The development of new materials that are stronger, lighter, and more durable than traditional materials. | The development of new materials is opening up new possibilities for the design and manufacture of products in York, PA. |

Resources

Exploring beta machine and fabrication in York, PA involves accessing a range of resources that provide valuable information and support. These resources play a crucial role in enhancing knowledge, understanding, and engagement with this specialized field.

- Online Resources: The internet offers a vast collection of websites, articles, and forums dedicated to beta machine and fabrication. These resources provide comprehensive information on equipment, materials, processes, and applications. Online tutorials and videos offer practical guidance, enabling individuals to gain insights into the technical aspects of beta machine and fabrication.

- Educational Institutions: Universities, colleges, and technical schools in York, PA offer courses, workshops, and certification programs in beta machine and fabrication. These programs provide structured learning opportunities, allowing individuals to acquire the necessary skills and knowledge to pursue careers in this field. Hands-on training and access to industry-grade equipment enhance the practical understanding of beta machine and fabrication.

- Industry Associations and Organizations: Professional organizations such as the American Society for Precision Engineering (ASPE) and the Society of Manufacturing Engineers (SME) provide a platform for networking, professional development, and access to industry-specific resources. These organizations host conferences, workshops, and webinars, offering valuable insights into the latest advancements and best practices in beta machine and fabrication.

- Manufacturers and Suppliers: Companies that manufacture and supply beta machines and fabrication equipment often provide technical documentation, case studies, and application notes. These resources offer detailed information on specific products, their capabilities, and potential applications. Collaboration with manufacturers and suppliers enables individuals to stay abreast of technological advancements and industry trends.

By leveraging these resources, individuals in York, PA can gain a comprehensive understanding of beta machine and fabrication. These resources empower professionals, students, and enthusiasts to enhance their knowledge, skills, and engagement with this dynamic and rapidly evolving field.

Community

The strong community of beta machine and fabrication professionals in York, PA is a valuable asset to the local industry. This community provides a network of support for professionals, enabling them to share knowledge, collaborate on projects, and stay abreast of the latest advancements in the field. This collaborative environment fosters innovation and the exchange of ideas, contributing to the growth and success of beta machine and fabrication in York, PA.

One of the key benefits of this community is the willingness of professionals to share their knowledge and expertise. This sharing of information helps to advance the field and ensures that best practices are being followed. For example, experienced professionals may provide mentorship to newcomers, helping them to develop their skills and knowledge. Additionally, the community often organizes workshops, seminars, and other events where professionals can share their insights and learn from each other.

The strong community of beta machine and fabrication professionals in York, PA is a vital part of the local industry. This community provides a network of support, fosters innovation, and ensures that best practices are being followed. By leveraging the resources and expertise of this community, businesses and individuals can stay competitive and contribute to the continued success of beta machine and fabrication in York, PA.

Key Insights:

- The strong community of beta machine and fabrication professionals in York, PA is a valuable asset to the local industry.

- This community provides a network of support for professionals, enabling them to share knowledge, collaborate on projects, and stay abreast of the latest advancements in the field.

- The willingness of professionals to share their knowledge and expertise helps to advance the field and ensures that best practices are being followed.

| Community Aspect | Benefits to Beta Machine and Fabrication in York, PA |

|---|---|

| Network of support | Provides a platform for professionals to connect, collaborate, and share knowledge. |

| Knowledge sharing | Facilitates the exchange of ideas and best practices, advancing the field and ensuring quality standards. |

| Mentorship and training | Supports the development of new professionals and enhances the skills of experienced professionals. |

Frequently Asked Questions about Beta Machine and Fabrication in York, PA

This section addresses commonly asked questions and misconceptions surrounding beta machine and fabrication in York, PA, providing informative answers to enhance your understanding of this specialized field.

Question 1: What are the primary applications of beta machine and fabrication in York, PA?

Beta machine and fabrication in York, PA finds applications in a diverse range of industries, including aerospace, automotive, medical, consumer electronics, and furniture manufacturing. It plays a vital role in creating prototypes, finished goods, custom parts, and intricate designs.

Question 2: What materials are commonly used in beta machine and fabrication processes?

Beta machine and fabrication in York, PA utilizes a variety of materials, including metal, plastic, wood, and composites. The choice of material depends on the specific application and the desired properties, such as strength, durability, and weight.

Question 3: What are the advantages of using beta machines and fabrication techniques?

Beta machine and fabrication offer numerous advantages, including precision, flexibility, and cost-effectiveness. These techniques enable the creation of complex shapes and designs with high accuracy and repeatability. Additionally, they allow for rapid prototyping and customization, reducing lead times and production costs.

Question 4: What career opportunities are available in beta machine and fabrication in York, PA?

The beta machine and fabrication industry in York, PA offers a wide range of career opportunities, including beta machine operators, fabrication technicians, design engineers, manufacturing engineers, and quality control inspectors. These positions require varying levels of education and experience, providing pathways for both entry-level and experienced professionals.

Question 5: What educational programs are available for individuals interested in beta machine and fabrication?

York, PA offers a variety of educational programs to train individuals for careers in beta machine and fabrication. These programs include associate degree programs, certificate programs, and apprenticeship programs, providing flexible options to meet the needs of diverse learners.

Question 6: How can I stay updated on the latest advancements in beta machine and fabrication?

To stay abreast of the latest advancements in beta machine and fabrication, consider joining professional organizations, attending industry events, and reading technical publications. Additionally, manufacturers and suppliers often provide technical documentation and case studies that showcase new technologies and applications.

In conclusion, beta machine and fabrication in York, PA is a dynamic and growing field that offers a diverse range of opportunities for businesses and individuals. By leveraging the resources and expertise available in York, PA, you can gain a comprehensive understanding of this specialized field and contribute to its continued success.

Tips for Beta Machine and Fabrication in York, PA

Beta machine and fabrication involve utilizing specialized equipment and techniques to create prototypes, finished goods, and custom parts. Here are a few tips to help you optimize your beta machine and fabrication processes in York, PA:

Tip 1: Invest in High-Quality Equipment

Investing in high-quality beta machines and fabrication equipment is crucial for achieving precision and efficiency in your operations. Reliable equipment ensures consistent performance and minimizes downtime, ultimately increasing productivity.

Tip 2: Utilize the Latest Technologies

Stay updated on the latest advancements in beta machine and fabrication technologies. Incorporating new technologies, such as additive manufacturing and computer-aided design (CAD), can enhance your capabilities and streamline your processes.

Tip 3: Partner with Experienced Professionals

Collaborating with experienced beta machine and fabrication professionals can provide valuable insights and expertise. Seek guidance from reputable companies or individuals who can assist you with design optimization, material selection, and process improvement.

Tip 4: Focus on Quality Control

Implement a rigorous quality control process to ensure the accuracy and consistency of your beta machine and fabrication products. Establish clear specifications, conduct regular inspections, and utilize appropriate measuring tools to maintain high standards.

Tip 5: Explore Automation Opportunities

Consider incorporating automation into your beta machine and fabrication processes to increase efficiency and reduce labor costs. Automation can help with repetitive tasks, such as material handling and machine operation, freeing up your team for more complex tasks.

Tip 6: Seek Continuous Improvement

Regularly evaluate your beta machine and fabrication processes to identify areas for improvement. Analyze production data, customer feedback, and industry best practices to make data-driven decisions that enhance your operations and meet evolving market demands.

By following these tips, you can optimize your beta machine and fabrication processes in York, PA, leading to increased efficiency, improved quality, and enhanced competitiveness.

In conclusion, beta machine and fabrication play a vital role in various industries in York, PA. By leveraging high-quality equipment, utilizing the latest technologies, partnering with experienced professionals, focusing on quality control, exploring automation opportunities, and seeking continuous improvement, you can harness the full potential of beta machine and fabrication to drive innovation and achieve success.

Conclusion

Beta machine and fabrication in York, PA is a rapidly growing industry that offers a wide range of opportunities for businesses and individuals alike. This article has explored the key aspects of beta machine and fabrication, providing a comprehensive overview of this exciting field. By leveraging the resources and expertise available in York, PA, you can gain a deep understanding of this specialized field and contribute to its continued success.

The future of beta machine and fabrication in York, PA is bright. With the continued development of new technologies and applications, this industry is poised for even greater growth in the years to come. By embracing innovation and investing in the latest advancements, businesses in York, PA can stay competitive and continue to drive economic development in the region.