What is Blackwater Welding and Fabrication? It is a metalworking process that joins pieces of metal by melting and fusing them together. It is used to create a wide range of products, from small parts to large structures.

Blackwater welding and fabrication is a critical process in many industries, including construction, manufacturing, and transportation. It is used to create a wide range of products, from simple brackets to complex machinery.

Editor’s Notes: Blackwater welding and fabrication is a topic of interest for many people. The process can be complex and requires specialized skills, so we wanted to put together this guide to help you understand the basics of blackwater welding and fabrication.

Our team of experts has conducted extensive research and analysis to provide you with the most up-to-date information on blackwater welding and fabrication. We will cover everything from the different types of welding processes to the safety precautions that need to be taken.

Key Differences or Key Takeaways:

| Blackwater Welding | Fabrication | |

|---|---|---|

| Definition | A metalworking process that joins pieces of metal by melting and fusing them together. | The process of shaping and assembling metal components into a finished product. |

| Purpose | To create a strong and durable joint between two pieces of metal. | To create a variety of metal products, from simple brackets to complex machinery. |

| Equipment | Welding machine, welding torch, welding rod, safety gear | Cutting torch, welder, grinder, drill press, metalworking tools |

| Applications | Construction, manufacturing, transportation, shipbuilding, etc. | Construction, manufacturing, automotive, aerospace, etc. |

Main Article Topics:

- Types of Welding Processes

- Safety Precautions for Blackwater Welding and Fabrication

- Applications of Blackwater Welding and Fabrication

Blackwater Welding and Fabrication

Blackwater welding and fabrication is a critical process in many industries, including construction, manufacturing, and transportation. It is used to create a wide range of products, from simple brackets to complex machinery. There are many key aspects to consider when it comes to blackwater welding and fabrication, including:

- Equipment: The type of equipment used for blackwater welding and fabrication will vary depending on the specific application. However, some common equipment includes welding machines, welding torches, welding rods, and safety gear.

- Materials: The type of metal used for blackwater welding and fabrication will also vary depending on the specific application. However, some common metals include steel, aluminum, and stainless steel.

- Processes: There are a variety of different welding processes that can be used for blackwater welding and fabrication. Some common processes include arc welding, MIG welding, and TIG welding.

- Safety: Blackwater welding and fabrication can be a dangerous process, so it is important to take proper safety precautions. Some common safety precautions include wearing protective clothing, using proper ventilation, and following all safety regulations.

- Applications: Blackwater welding and fabrication is used in a wide range of applications, including construction, manufacturing, and transportation. Some common applications include welding bridges, buildings, and ships.

- Skills: Blackwater welding and fabrication requires specialized skills and training. Some common skills include welding, cutting, and fitting.

- Education: There are a variety of educational programs available for blackwater welding and fabrication. Some common programs include vocational schools, community colleges, and universities.

- Careers: There are a variety of career opportunities available for blackwater welders and fabricators. Some common careers include welder, fabricator, and welding inspector.

- Industry: The blackwater welding and fabrication industry is a growing industry with a strong outlook for the future. Some common industries that use blackwater welding and fabrication include construction, manufacturing, and transportation.

These are just a few of the key aspects to consider when it comes to blackwater welding and fabrication. By understanding these aspects, you can make informed decisions about the use of blackwater welding and fabrication in your own projects.

Equipment

The type of equipment used for blackwater welding and fabrication will vary depending on the specific application. However, some common equipment includes welding machines, welding torches, welding rods, and safety gear. This equipment is essential for performing blackwater welding and fabrication safely and efficiently.

Welding machines are used to create an electric arc between the welding electrode and the workpiece. This arc melts the metal at the joint, allowing it to be fused together. Welding torches are used to direct the welding arc and to add filler metal to the joint. Welding rods are used as filler metal, and they are available in a variety of materials to match the metal being welded.

Safety gear is essential for protecting the welder from the hazards of welding, such as sparks, fumes, and radiation. Safety gear includes welding helmets, gloves, and clothing.

The following table provides a summary of the key equipment used for blackwater welding and fabrication:

| Equipment | Description |

|---|---|

| Welding machines | Used to create an electric arc between the welding electrode and the workpiece. |

| Welding torches | Used to direct the welding arc and to add filler metal to the joint. |

| Welding rods | Used as filler metal, and they are available in a variety of materials to match the metal being welded. |

| Safety gear | Used to protect the welder from the hazards of welding, such as sparks, fumes, and radiation. |

By understanding the importance of the equipment used for blackwater welding and fabrication, you can make informed decisions about the equipment you need for your own projects.

Materials

The type of metal used for blackwater welding and fabrication has a significant impact on the final product. Different metals have different properties, such as strength, ductility, and corrosion resistance. These properties must be carefully considered when selecting a metal for a particular application.

Steel is a common choice for blackwater welding and fabrication because it is strong and durable. It is also relatively inexpensive and easy to weld. However, steel is not as corrosion-resistant as other metals, such as aluminum and stainless steel.

Aluminum is another popular choice for blackwater welding and fabrication. It is lightweight and corrosion-resistant, making it ideal for applications where weight and durability are important. However, aluminum is more expensive than steel and can be more difficult to weld.

Stainless steel is a third option for blackwater welding and fabrication. It is strong, corrosion-resistant, and easy to weld. However, stainless steel is more expensive than steel and aluminum.

The following table provides a summary of the key properties of steel, aluminum, and stainless steel:

| Property | Steel | Aluminum | Stainless steel |

|---|---|---|---|

| Strength | High | Medium | High |

| Ductility | Low | High | Medium |

| Corrosion resistance | Low | High | High |

| Cost | Low | High | Medium |

| Weldability | Good | Fair | Good |

By understanding the properties of different metals, you can make informed decisions about the type of metal to use for your blackwater welding and fabrication projects.

Conclusion:

The type of metal used for blackwater welding and fabrication is a critical factor to consider. Different metals have different properties, and these properties must be carefully considered when selecting a metal for a particular application. By understanding the properties of different metals, you can make informed decisions about the type of metal to use for your blackwater welding and fabrication projects.

Processes

The choice of welding process for blackwater welding and fabrication depends on a number of factors, including the type of metal being welded, the thickness of the metal, and the desired strength of the weld. Arc welding is a common process for blackwater welding and fabrication because it is versatile and can be used to weld a wide range of metals. MIG welding is another popular choice for blackwater welding and fabrication because it is fast and efficient. TIG welding is a more specialized process that is often used for welding thin metals or for welding metals that are difficult to weld with other processes.

The following table provides a summary of the key advantages and disadvantages of arc welding, MIG welding, and TIG welding:

| Process | Advantages | Disadvantages |

|---|---|---|

| Arc welding | Versatile, can be used to weld a wide range of metals | Slower than MIG welding and TIG welding |

| MIG welding | Fast and efficient | Not as versatile as arc welding, can be more difficult to weld thin metals |

| TIG welding | Produces high-quality welds, can be used to weld thin metals and difficult-to-weld metals | Slower than arc welding and MIG welding |

By understanding the different welding processes available for blackwater welding and fabrication, you can make informed decisions about the best process to use for your specific application.

Practical Applications:

The different welding processes used for blackwater welding and fabrication have a wide range of practical applications. For example, arc welding is used to weld bridges, buildings, and ships. MIG welding is used to weld cars, trucks, and airplanes. TIG welding is used to weld medical devices, jewelry, and electronics.

Challenges:

There are a number of challenges associated with blackwater welding and fabrication. One challenge is the need for specialized skills and training. Another challenge is the need for proper safety precautions. Welding can produce fumes and sparks, so it is important to wear protective clothing and to use proper ventilation.

Conclusion:

The choice of welding process for blackwater welding and fabrication is a critical factor to consider. Different welding processes have different advantages and disadvantages, and the best process for a particular application will depend on a number of factors. By understanding the different welding processes available, you can make informed decisions about the best process to use for your specific application.

Safety

Blackwater welding and fabrication can be a dangerous process, so it is important to take proper safety precautions. Some common safety precautions include wearing protective clothing, using proper ventilation, and following all safety regulations. These precautions are essential for protecting the welder from the hazards of welding, such as sparks, fumes, and radiation.

- Protective Clothing: Welders should wear protective clothing to protect their skin from sparks, fumes, and radiation. This clothing should include a welding helmet, gloves, and apron.

- Proper Ventilation: Welding produces fumes that can be harmful to the welder’s health. It is important to use proper ventilation to remove these fumes from the work area.

- Following Safety Regulations: Welders should follow all safety regulations to protect themselves from injury. These regulations may include wearing proper safety gear, using proper ventilation, and following proper welding procedures.

By taking proper safety precautions, welders can reduce the risk of injury and illness. These precautions are essential for protecting the welder’s health and safety.

Applications

Blackwater welding and fabrication is a critical process in many industries, including construction, manufacturing, and transportation. It is used to create a wide range of products, from simple brackets to complex machinery. The applications of blackwater welding and fabrication are vast and varied, and the process plays a vital role in the construction of many of the structures and products we rely on every day.

One of the most common applications of blackwater welding and fabrication is in the construction industry. Welders are responsible for joining the steel beams and other structural components of bridges, buildings, and other structures. Blackwater welding and fabrication is also used to create a variety of architectural features, such as railings, staircases, and fences.

In the manufacturing industry, blackwater welding and fabrication is used to create a wide range of products, including cars, trucks, airplanes, and machinery. Welders are responsible for joining the metal components of these products, ensuring that they are strong and durable. Blackwater welding and fabrication is also used to create a variety of industrial equipment, such as boilers, pressure vessels, and pipelines.

Blackwater welding and fabrication is also used in the transportation industry. Welders are responsible for joining the metal components of ships, trains, and airplanes. Blackwater welding and fabrication is also used to create a variety of transportation infrastructure, such as bridges, railroads, and airports.

The applications of blackwater welding and fabrication are vast and varied. The process plays a vital role in the construction of many of the structures and products we rely on every day. From bridges and buildings to cars and airplanes, blackwater welding and fabrication is essential for our modern world.

| Industry | Applications |

|---|---|

| Construction | Bridges, buildings, architectural features |

| Manufacturing | Cars, trucks, airplanes, machinery, industrial equipment |

| Transportation | Ships, trains, airplanes, transportation infrastructure |

Skills

Blackwater welding and fabrication is a specialized trade that requires a unique set of skills and training. These skills include welding, cutting, and fitting. Welders must be able to read blueprints, understand welding symbols, and operate a variety of welding equipment. They must also be able to work safely and efficiently in a variety of environments.

- Welding: Welding is the process of joining two pieces of metal together by melting them and fusing them together. Welders must be able to control the welding torch and filler metal to create a strong and durable weld.

- Cutting: Cutting is the process of separating two pieces of metal. Welders must be able to use a variety of cutting tools, including plasma cutters, oxy-fuel torches, and grinders, to cut metal safely and accurately.

- Fitting: Fitting is the process of preparing two pieces of metal for welding. Welders must be able to measure, mark, and cut metal to ensure that the pieces fit together properly.

These are just a few of the skills that blackwater welders and fabricators must have. These skills are essential for performing blackwater welding and fabrication safely and efficiently. Without these skills, it would be impossible to create the strong and durable welds that are required for a variety of applications.

Education

Acquiring the necessary knowledge and skills for blackwater welding and fabrication requires formal education and training. Educational programs provide individuals with the theoretical foundation and practical experience essential for success in this field.

-

Vocational Schools:

Vocational schools offer specialized training programs in blackwater welding and fabrication. These programs typically focus on developing practical skills through hands-on training in welding techniques, metalworking, and fabrication processes.

-

Community Colleges:

Community colleges provide associate degree programs in welding technology or related fields. These programs combine classroom instruction with hands-on lab experience, covering topics such as welding theory, metallurgy, and welding codes and standards.

-

Universities:

Universities offer bachelor’s and master’s degree programs in welding engineering or materials science. These programs provide a comprehensive understanding of the scientific principles underlying welding processes, materials behavior, and design considerations.

-

Certifications and Licenses:

In addition to formal education, many blackwater welders and fabricators pursue industry certifications or licenses to demonstrate their skills and knowledge. These credentials enhance job prospects and earning potential.

Education and training play a crucial role in the blackwater welding and fabrication industry by equipping individuals with the expertise and proficiency required to produce high-quality welded structures and components.

Careers

The field of blackwater welding and fabrication offers diverse career opportunities for skilled individuals. These professions play vital roles in industries that rely on the fabrication and assembly of metal structures and components.

-

Welder:

Welders are responsible for joining metal parts together using various welding techniques. They ensure that welded joints meet the required standards for strength, durability, and safety.

-

Fabricator:

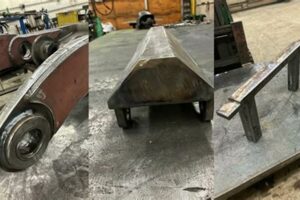

Fabricators construct and assemble metal structures and components based on blueprints and specifications. They use specialized tools and equipment to cut, shape, and weld metal.

-

Welding Inspector:

Welding inspectors ensure the quality and safety of welded joints by examining them for defects and adherence to codes and standards. They play a critical role in maintaining the integrity of structures and preventing failures.

These careers offer competitive salaries, job stability, and the opportunity to work on challenging and rewarding projects. With the increasing demand for skilled blackwater welders and fabricators, individuals with the necessary training and experience will find ample career opportunities in this growing industry.

Industry

The blackwater welding and fabrication industry is closely intertwined with a wide range of sectors that rely on metal structures and components. This connection stems from the essential role that blackwater welding and fabrication plays in creating durable and reliable products and infrastructure.

-

Construction:

Blackwater welding and fabrication are indispensable in the construction industry. Welders and fabricators are responsible for joining steel beams, erecting bridges, and constructing buildings. Their expertise ensures the structural integrity and stability of these structures, which are critical for public safety and economic growth.

-

Manufacturing:

Blackwater welding and fabrication are vital in the manufacturing sector. Welders and fabricators create and assemble metal components for a variety of products, including cars, airplanes, and machinery. Their skills are essential for producing durable and high-performing products that meet industry standards and consumer expectations.

-

Transportation:

Blackwater welding and fabrication are crucial in the transportation industry. Welders and fabricators construct and repair ships, trains, and airplanes. Their work ensures the safety and reliability of these transportation systems, which are essential for global commerce and mobility.

The growing demand for infrastructure development, the expansion of manufacturing industries, and the advancement of transportation technologies are all contributing to the positive outlook for the blackwater welding and fabrication industry. As these sectors continue to grow, the need for skilled welders and fabricators will remain strong, providing ample opportunities for career growth and job stability in this dynamic field.

FAQs on Blackwater Welding and Fabrication

This section addresses frequently asked questions (FAQs) related to blackwater welding and fabrication, providing concise and informative answers to common concerns or misconceptions.

Question 1: What is the difference between blackwater welding and other types of welding?

Answer: Blackwater welding is a specialized welding process that involves welding underwater or in other extreme conditions, such as in oil and gas pipelines or offshore structures. It requires specialized equipment and techniques to ensure the safety and integrity of the weld.

Question 2: What are the key safety considerations for blackwater welding?

Answer: Blackwater welding involves significant safety hazards, including electrical shock, drowning, and decompression sickness. Proper training, specialized equipment, and strict adherence to safety protocols are essential to minimize risks.

Question 3: What materials are commonly used in blackwater welding?

Answer: Blackwater welding is typically performed on metals such as steel, stainless steel, and aluminum. The choice of material depends on the specific application and the desired properties of the weld joint.

Question 4: What are the career opportunities in blackwater welding?

Answer: Skilled blackwater welders are in high demand in various industries, including offshore construction, shipbuilding, and underwater repair. They can work as welders, fabricators, or welding inspectors, with opportunities for career advancement and specialization.

Question 5: How can I become a certified blackwater welder?

Answer: To become a certified blackwater welder, individuals typically undergo specialized training programs and pass certification exams conducted by recognized organizations. Certification demonstrates competence and adherence to industry standards.

Question 6: What are the latest advancements in blackwater welding technology?

Answer: Blackwater welding technology is continuously evolving, with advancements such as automated welding systems, improved underwater visibility, and non-destructive testing techniques. These advancements enhance safety, efficiency, and the quality of underwater welds.

Summary: Blackwater welding and fabrication is a specialized and critical process with unique safety considerations and career opportunities. Understanding the key aspects, materials, and applications of blackwater welding is essential for those involved in this demanding field.

Transition: This concludes our comprehensive guide on blackwater welding and fabrication. For further information or inquiries, please refer to the resources provided in the following sections.

Blackwater Welding and Fabrication Tips

Blackwater welding and fabrication require specialized skills and attention to detail. Here are some tips to help you achieve successful and high-quality results:

Tip 1: Ensure Proper Training and Certification

Obtain formal training and certification from recognized organizations. This demonstrates your competence and adherence to industry standards, enhancing your credibility and safety on the job.

Tip 2: Prioritize Safety

Blackwater welding involves significant hazards. Always wear appropriate protective gear, follow safety protocols, and maintain a clean and organized work environment to minimize risks.

Tip 3: Choose the Right Equipment

Invest in high-quality welding equipment and specialized tools designed for blackwater welding. This includes selecting the appropriate welding machine, electrodes, and underwater communication systems.

Tip 4: Master Underwater Welding Techniques

Develop proficiency in underwater welding techniques, including controlling the welding arc, maintaining visibility, and handling equipment in challenging conditions. Practice in controlled environments before attempting real-world applications.

Tip 5: Understand Material Properties

Familiarize yourself with the properties of different metals used in blackwater welding, such as steel, stainless steel, and aluminum. This knowledge helps you select the appropriate welding parameters and techniques for each material.

Tip 6: Pay Attention to Joint Preparation

Proper joint preparation is crucial for successful welding. Clean, bevel, and fit the joint surfaces meticulously to ensure good weld penetration and strength.

Tip 7: Monitor Weld Quality

Regularly inspect your welds for defects using non-destructive testing methods such as radiography or ultrasonic testing. This helps identify and rectify any issues promptly, ensuring the integrity of the welded structure.

Tip 8: Stay Updated with Industry Advancements

Blackwater welding technology is constantly evolving. Stay informed about the latest advancements, such as automated welding systems and improved underwater visibility techniques, to enhance your skills and efficiency.

Conclusion

Blackwater welding and fabrication is a specialized and demanding field that plays a vital role in various industries. It requires a high level of skill, a commitment to safety, and a deep understanding of welding techniques and materials. This comprehensive guide has explored the key aspects of blackwater welding and fabrication, providing insights into its applications, processes, safety considerations, and career opportunities.

As the demand for skilled blackwater welders and fabricators continues to grow, embracing new technologies, pursuing professional development, and adhering to industry best practices will be essential for success in this dynamic field. By embracing innovation and maintaining a commitment to excellence, blackwater welders and fabricators can contribute to the construction of safe, reliable, and durable structures that shape our world.