Colleges offering welding and fabrication are in high demand as the need for skilled welders and fabricators continues to grow. These programs provide students with the knowledge and skills necessary to succeed in this in-demand field.

Editor’s Note: Colleges offering welding and fabrication are an important resource for students who want to pursue a career in this field. These programs provide students with the skills and knowledge they need to be successful in this growing industry.

To help you find the best college for your needs, we’ve put together this guide to colleges offering welding and fabrication. We’ve analyzed dozens of programs and compared them based on factors such as cost, location, and curriculum. We’ve also included information on the job outlook for welders and fabricators, so you can make an informed decision about your future.

Key differences or Key takeways, provide in informative table format

Transition to main article topics

Colleges Offering Welding and Fabrication

Colleges offering welding and fabrication programs provide students with the skills and knowledge they need to succeed in this in-demand field. These programs cover a wide range of topics, including:

- Welding theory and practice

- Fabrication techniques

- Blueprint reading

- Safety procedures

- Quality control

- Project management

- Business skills

- Computer-aided design (CAD)

These key aspects of colleges offering welding and fabrication programs are essential for students who want to pursue a career in this field. By providing students with a strong foundation in these areas, these programs can help them to be successful in the workforce.

Welding Theory and Practice

Welding theory and practice are essential components of colleges offering welding and fabrication. Welding theory provides students with the knowledge they need to understand the welding process, while welding practice gives them the skills they need to perform welding tasks safely and efficiently.

Welding theory covers a wide range of topics, including the different types of welding processes, the properties of different metals, and the safety procedures that must be followed when welding. Welding practice provides students with the opportunity to apply the theory they have learned in the classroom to real-world welding projects.

Colleges offering welding and fabrication programs typically offer a variety of welding theory and practice courses. These courses may include:

- Introduction to Welding

- Welding Processes

- Welding Metallurgy

- Welding Safety

- Welding Practice

- Advanced Welding Techniques

The specific courses that are offered will vary depending on the college or university. However, all of these courses are essential for students who want to pursue a career in welding and fabrication.

Welding theory and practice are essential for students who want to pursue a career in welding and fabrication. By providing students with a strong foundation in these areas, colleges offering welding and fabrication programs can help them to be successful in the workforce.

| Welding Theory | Welding Practice |

|---|---|

| Provides students with the knowledge they need to understand the welding process. | Gives students the skills they need to perform welding tasks safely and efficiently. |

| Covers a wide range of topics, including the different types of welding processes, the properties of different metals, and the safety procedures that must be followed when welding. | Provides students with the opportunity to apply the theory they have learned in the classroom to real-world welding projects. |

| Is essential for students who want to pursue a career in welding and fabrication. | Is essential for students who want to pursue a career in welding and fabrication. |

Fabrication techniques

Fabrication techniques are an essential part of colleges offering welding and fabrication. These techniques allow students to create metal structures and products by cutting, bending, and assembling metal components. Fabrication techniques are used in a wide variety of industries, including construction, manufacturing, and transportation.

-

Cutting

Cutting is a fabrication technique that involves removing material from a metal workpiece. Cutting can be done using a variety of methods, including sawing, shearing, and waterjet cutting. -

Bending

Bending is a fabrication technique that involves shaping a metal workpiece by applying force. Bending can be done using a variety of methods, including press brakes, hand brakes, and roll benders. -

Assembling

Assembling is a fabrication technique that involves joining two or more metal components together. Assembling can be done using a variety of methods, including welding, riveting, and bolting. -

Finishing

Finishing is a fabrication technique that involves improving the appearance or durability of a metal workpiece. Finishing can be done using a variety of methods, including painting, plating, and polishing.

Fabrication techniques are essential for students who want to pursue a career in welding and fabrication. By providing students with a strong foundation in these techniques, colleges offering welding and fabrication programs can help them to be successful in the workforce.

Blueprint Reading

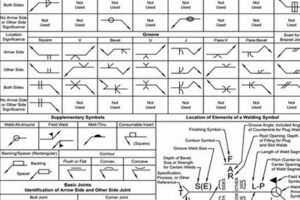

Blueprint reading is an essential skill for students in colleges offering welding and fabrication. Blueprints are technical drawings that provide detailed instructions for the construction of a product. They include information on the dimensions of the product, the materials to be used, and the assembly process.

Students in welding and fabrication programs need to be able to read blueprints in order to understand the specifications for the products they are making. They also need to be able to interpret blueprints in order to create accurate and efficient welds.

Colleges offering welding and fabrication programs typically offer courses in blueprint reading. These courses teach students the basics of blueprint reading, including how to interpret symbols, dimensions, and notes. Students also learn how to use measuring tools and scales to accurately measure and lay out parts.

Blueprint reading is a valuable skill for students in colleges offering welding and fabrication. By providing students with the ability to read and interpret blueprints, these programs can help them to be successful in the workforce.

| Importance of Blueprint Reading in Welding and Fabrication | Benefits of Blueprint Reading for Welders and Fabricators |

|---|---|

| Provides detailed instructions for the construction of a product. | Helps welders and fabricators to understand the specifications for the products they are making. |

| Includes information on the dimensions of the product, the materials to be used, and the assembly process. | Enables welders and fabricators to create accurate and efficient welds. |

| Essential for students in colleges offering welding and fabrication programs. | Provides students with the skills they need to be successful in the workforce. |

Safety procedures

Safety procedures are essential in colleges offering welding and fabrication. Welding and fabrication can be dangerous occupations, so it is important for students to learn how to work safely. Safety procedures cover a wide range of topics, including:

-

Personal protective equipment (PPE)

PPE is essential for protecting welders and fabricators from hazards such as sparks, fumes, and molten metal. PPE includes items such as welding helmets, gloves, and respirators.

-

Fire safety

Welding and fabrication can create sparks and flames, so it is important to be aware of fire safety procedures. These procedures include knowing how to use a fire extinguisher and how to evacuate a building in the event of a fire.

-

Electrical safety

Welding and fabrication equipment can be electrically charged, so it is important to be aware of electrical safety procedures. These procedures include knowing how to lock out and tag out equipment and how to avoid electrical shock.

-

Gas safety

Welding and fabrication can involve the use of gases such as oxygen and acetylene. It is important to be aware of gas safety procedures to avoid explosions and other accidents.

Safety procedures are essential for students in colleges offering welding and fabrication. By providing students with a strong foundation in safety procedures, these programs can help them to be successful in the workforce.

Quality control

Quality control is an essential component of colleges offering welding and fabrication. It ensures that the products and services produced by students meet the required standards of quality. Quality control processes include:

- Inspection: Checking products and services to identify defects.

- Testing: Evaluating products and services to ensure they meet performance requirements.

- Calibration: Adjusting equipment to ensure it is accurate and reliable.

- Documentation: Recording the results of inspections, tests, and calibrations.

Quality control is important in colleges offering welding and fabrication for several reasons. First, it helps to ensure that students are producing high-quality products and services. This is important for both the students and the college. Students need to be able to produce high-quality work in order to be successful in the workforce. The college needs to be able to produce high-quality products and services in order to maintain its reputation.

Second, quality control helps to prevent accidents and injuries. By ensuring that equipment is properly calibrated and that products are properly inspected, quality control helps to reduce the risk of accidents and injuries.

Third, quality control helps to improve efficiency. By identifying and correcting defects early in the production process, quality control helps to reduce waste and rework. This can lead to improved efficiency and productivity.

Colleges offering welding and fabrication can implement a variety of quality control measures to ensure the quality of their products and services. These measures may include:

- Establishing quality standards: Defining the standards that products and services must meet.

- Developing quality control procedures: Outlining the steps that must be taken to ensure that products and services meet quality standards.

- Training staff on quality control procedures: Ensuring that staff is trained on the quality control procedures and understands the importance of quality.

- Conducting regular inspections and tests: Regularly checking products and services to identify defects and ensure that they meet quality standards.

- Documenting quality control results: Recording the results of inspections and tests to track quality trends and identify areas for improvement.

By implementing these quality control measures, colleges offering welding and fabrication can ensure that their products and services meet the highest standards of quality.

| Benefits of Quality Control in Colleges Offering Welding and Fabrication | Examples of Quality Control Measures |

|---|---|

| Ensures that students are producing high-quality products and services. | Establishing quality standards, developing quality control procedures, training staff on quality control procedures, conducting regular inspections and tests, documenting quality control results. |

| Prevents accidents and injuries. | Ensuring that equipment is properly calibrated and that products are properly inspected. |

| Improves efficiency. | Identifying and correcting defects early in the production process, reducing waste and rework. |

Project management

Project management is an essential part of colleges offering welding and fabrication. It involves planning, organizing, and managing resources to complete a project successfully. In the context of colleges offering welding and fabrication, project management may involve tasks such as:

- Planning and scheduling classes

- Ordering and managing materials

- Supervising students

- Ensuring that projects are completed on time and within budget

Effective project management is essential for the success of colleges offering welding and fabrication. By planning and organizing resources effectively, colleges can ensure that students have the resources they need to succeed and that projects are completed on time and within budget.

| Benefits of Effective Project Management in Colleges Offering Welding and Fabrication | Examples of Effective Project Management |

|---|---|

| Ensures that students have the resources they need to succeed | Planning and scheduling classes to ensure that students have access to the equipment and materials they need |

| Helps to complete projects on time and within budget | Ordering and managing materials to ensure that projects are completed on time and within budget |

| Improves the overall efficiency of the college | Supervising students and ensuring that projects are completed on time and within budget can help to improve the overall efficiency of the college |

Business skills

Business skills are essential for success in any industry, including welding and fabrication. Colleges offering welding and fabrication programs can help students develop the business skills they need to be successful in the workforce. These skills include:

-

Communication skills

Communication skills are essential for welding and fabrication professionals to be able to communicate effectively with clients, colleagues, and supervisors. This includes being able to write clear and concise proposals, reports, and emails, as well as being able to give presentations and participate in meetings.

-

Customer service skills

Customer service skills are important for welding and fabrication professionals to be able to build and maintain relationships with clients. This includes being able to understand client needs, resolve complaints, and provide excellent service.

-

Financial management skills

Financial management skills are essential for welding and fabrication professionals to be able to manage their finances effectively. This includes being able to track income and expenses, create budgets, and make sound financial decisions.

-

Marketing skills

Marketing skills are important for welding and fabrication professionals to be able to promote their businesses and attract new clients. This includes being able to develop marketing materials, create websites, and use social media.

Colleges offering welding and fabrication programs can help students develop the business skills they need to be successful in the workforce by offering courses in these areas. These courses can help students to improve their communication skills, customer service skills, financial management skills, and marketing skills.

Computer-aided Design (CAD)

Computer-aided design (CAD) is a key component of colleges offering welding and fabrication. CAD software allows students to create detailed drawings of their projects, which can then be used to create precise cuts and welds. This technology is essential for students to learn in order to be successful in the welding and fabrication industry.

There are many different CAD software programs available, each with its own strengths and weaknesses. Some of the most popular CAD programs for welding and fabrication include AutoCAD, SolidWorks, and Inventor. These programs allow students to create 2D and 3D drawings of their projects, and they can also be used to generate toolpaths for CNC machines.

CAD software is an essential tool for welding and fabrication students because it allows them to create accurate and detailed drawings of their projects. This technology helps students to visualize their projects and to identify any potential problems before they start welding or fabricating. CAD software also helps students to create precise cuts and welds, which can save time and money in the long run.

Benefits of CAD in Welding and Fabrication

- Allows students to create accurate and detailed drawings of their projects.

- Helps students to visualize their projects and to identify any potential problems before they start welding or fabricating.

- Helps students to create precise cuts and welds, which can save time and money in the long run.

Examples of CAD in Welding and Fabrication

- Students can use CAD to create drawings of welding joints, such as butt joints, T-joints, and corner joints.

- Students can use CAD to create drawings of welding fixtures, such as welding tables and welding clamps.

- Students can use CAD to create drawings of welding projects, such as sculptures, furniture, and tools.

Conclusion

CAD is an essential tool for welding and fabrication students. It allows them to create accurate and detailed drawings of their projects, which can then be used to create precise cuts and welds. This technology can save students time and money in the long run, and it can also help them to produce higher-quality work.

Frequently Asked Questions about Colleges Offering Welding and Fabrication

This section provides answers to frequently asked questions about colleges offering welding and fabrication programs. These questions are designed to address common concerns and misconceptions, and provide prospective students with the information they need to make informed decisions about their education.

Question 1: What are the benefits of attending a college that offers welding and fabrication programs?

Answer: There are several benefits to attending a college that offers welding and fabrication programs. These benefits include:

- Access to state-of-the-art equipment and facilities

- Instruction from experienced and qualified faculty

- Opportunities to gain hands-on experience through internships and apprenticeships

- Preparation for a successful career in the welding and fabrication industry

Question 2: What are the admission requirements for welding and fabrication programs?

Answer: Admission requirements for welding and fabrication programs vary from college to college. However, most programs require applicants to have a high school diploma or equivalent, and some may also require applicants to have previous experience in welding or fabrication.

Question 3: What is the job outlook for welders and fabricators?

Answer: The job outlook for welders and fabricators is expected to be good over the next few years. This is due to the increasing demand for skilled workers in the construction, manufacturing, and transportation industries.

Question 4: What are the salary expectations for welders and fabricators?

Answer: The salary expectations for welders and fabricators vary depending on their experience, skills, and location. However, according to the Bureau of Labor Statistics, the median annual salary for welders and fabricators was $47,130 in May 2021.

Question 5: What are the career opportunities for welders and fabricators?

Answer: Welders and fabricators have a wide range of career opportunities. They can work in a variety of industries, including construction, manufacturing, and transportation. They can also work as self-employed contractors.

Question 6: What are the challenges of working as a welder or fabricator?

Answer: Welders and fabricators face a number of challenges on the job. These challenges include working in hazardous conditions, exposure to fumes and gases, and the need to wear uncomfortable protective gear.

Summary

Welding and fabrication is a rewarding career that offers a variety of opportunities. However, it is important to be aware of the challenges of the job before making a decision about whether or not to pursue a career in this field.

Transition to the next article section

Tips for Colleges Offering Welding and Fabrication

Colleges offering welding and fabrication programs can take a number of steps to improve the quality of their programs and the success of their students. These tips can help colleges to attract and retain students, and to prepare them for successful careers in the welding and fabrication industry.

Tip 1: Develop a strong curriculum. The curriculum for a welding and fabrication program should be designed to provide students with the skills and knowledge they need to be successful in the industry. The curriculum should include both theoretical and practical components, and it should be taught by experienced and qualified instructors.

Tip 2: Provide access to state-of-the-art equipment and facilities. Students need access to state-of-the-art equipment and facilities in order to learn the skills they need to be successful in the welding and fabrication industry. This includes access to welding machines, cutting machines, and other specialized equipment.

Tip 3: Offer opportunities for hands-on experience. Students learn best by doing, so it is important to provide them with opportunities to gain hands-on experience in welding and fabrication. This can be done through internships, apprenticeships, or other types of practical training.

Tip 4: Build relationships with local employers. Colleges offering welding and fabrication programs should build relationships with local employers in order to place students in internships and apprenticeships. These relationships can also help colleges to stay up-to-date on the latest industry trends and needs.

Tip 5: Provide career counseling and support services. Students need access to career counseling and support services in order to make informed decisions about their future careers. These services can help students to identify their career goals, develop a plan to achieve those goals, and find a job after graduation.

Summary

By following these tips, colleges offering welding and fabrication programs can improve the quality of their programs and the success of their students. These tips can help colleges to attract and retain students, and to prepare them for successful careers in the welding and fabrication industry.

Transition to the article’s conclusion

Conclusion

Colleges offering welding and fabrication programs provide students with the skills and knowledge they need to succeed in this in-demand field. These programs cover a wide range of topics, including welding theory and practice, fabrication techniques, blueprint reading, safety procedures, quality control, project management, business skills, and computer-aided design (CAD). By providing students with a strong foundation in these areas, colleges offering welding and fabrication programs can help them to be successful in the workforce.

The welding and fabrication industry is expected to continue to grow in the coming years, so there is a strong demand for skilled workers in this field. Colleges offering welding and fabrication programs can help to meet this demand by providing students with the skills and knowledge they need to be successful. By following the tips outlined in this article, colleges can improve the quality of their programs and the success of their students.