Seeking a solution for your metal fabrication needs in Atlanta? Look no further than custom metal fabrication, the answer to your manufacturing challenges.

Editor’s Notes: Custom metal fabrication in Atlanta plays a vital role in various industries, offering numerous benefits that can enhance your operations. This guide delves into the key aspects to help you make informed decisions about custom metal fabrication.

Through extensive analysis and research, we have compiled this comprehensive guide to assist you in navigating the world of custom metal fabrication in Atlanta.

Key Differences:

| Custom Metal Fabrication | |

|---|---|

| Definition | Creating metal products tailored to specific requirements and designs |

| Benefits | Precision, durability, cost-effectiveness, design flexibility |

| Applications | Automotive, construction, aerospace, electronics, and more |

Main Article Topics:

- Types of Custom Metal Fabrication

- Materials Used in Custom Metal Fabrication

- Advantages of Custom Metal Fabrication

- Applications of Custom Metal Fabrication in Atlanta

- Choosing a Custom Metal Fabrication Company in Atlanta

Custom Metal Fabrication Atlanta

Custom metal fabrication in Atlanta encompasses various essential aspects that contribute to its significance in manufacturing and diverse industries:

- Precision and accuracy: Custom metal fabrication ensures high-precision manufacturing, meeting exact specifications and tolerances.

- Durability and longevity: Fabricated metal products are known for their exceptional durability and long-lasting performance.

- Design flexibility: Custom fabrication allows for limitless design possibilities, enabling the creation of unique and complex metal structures.

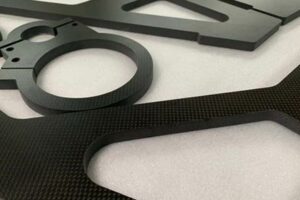

- Material versatility: A wide range of metals can be utilized, from aluminum and stainless steel to exotic alloys, catering to specific application requirements.

- Cost-effectiveness: Custom fabrication offers cost-effective solutions compared to mass-produced products, optimizing production costs.

- Reduced lead times: Local fabrication reduces lead times and ensures faster delivery of products.

- Skilled workforce: Atlanta boasts a skilled workforce experienced in metal fabrication, guaranteeing quality craftsmanship.

- Industry expertise: Custom metal fabricators in Atlanta possess in-depth knowledge of industry standards and best practices.

These key aspects highlight the advantages of custom metal fabrication in Atlanta, showcasing its ability to meet the unique demands of various industries, from automotive and construction to aerospace and electronics. By leveraging these aspects, businesses can enhance their operations, improve product quality, and gain a competitive edge in the market.

Precision and accuracy

The precision and accuracy of custom metal fabrication in Atlanta are crucial for a variety of reasons. First, high-precision manufacturing ensures that products meet exact specifications and tolerances, which is essential for applications where even the smallest deviation can have a significant impact on performance. For example, in the aerospace industry, custom metal components must be fabricated with extreme precision to ensure the safety and reliability of aircraft. Similarly, in the medical industry, custom metal implants and devices must be manufactured with high accuracy to ensure proper fit and function.

In addition to meeting specific requirements, precision and accuracy in custom metal fabrication also contribute to overall product quality and durability. High-precision manufacturing techniques minimize defects and imperfections, resulting in products that are more likely to perform as intended and last longer. This is especially important for products that are used in demanding environments or applications where failure could have serious consequences.

The skilled workforce and industry expertise available in Atlanta contribute to the high level of precision and accuracy in custom metal fabrication. Fabricators in the region have the experience and knowledge necessary to work with a wide range of metals and utilize advanced fabrication techniques to achieve the desired results. They also have access to state-of-the-art equipment and technology, which further enhances their ability to produce high-quality products.

Overall, the precision and accuracy of custom metal fabrication in Atlanta are essential for meeting the demands of various industries and applications. By leveraging the skilled workforce and industry expertise available in the region, fabricators can produce high-quality products that meet exact specifications and tolerances, contributing to overall product performance and durability.

Key Insights:

- Precision and accuracy in custom metal fabrication are essential for meeting the demands of various industries and applications.

- High-precision manufacturing ensures that products meet exact specifications and tolerances, which is critical for performance and safety in demanding applications.

- Precision and accuracy also contribute to overall product quality and durability, reducing defects and imperfections.

- Atlanta’s skilled workforce and industry expertise, combined with advanced equipment and technology, enable fabricators to achieve high levels of precision and accuracy.

Durability and longevity

Custom metal fabrication in Atlanta plays a significant role in the durability and longevity of fabricated metal products. Here are key facets to explore:

- Material Selection: Custom metal fabricators in Atlanta have access to a wide range of metals, including aluminum, stainless steel, and exotic alloys. These metals are known for their inherent strength, corrosion resistance, and ability to withstand harsh environments. By selecting the appropriate metal for the specific application, fabricators can ensure the durability and longevity of the final product.

- Fabrication Techniques: The fabrication techniques employed by Atlanta’s skilled workforce contribute to the longevity of metal products. Experienced fabricators utilize welding, cutting, forming, and finishing techniques to create robust and durable structures. By adhering to industry standards and best practices, they ensure the integrity and longevity of the fabricated products.

- Quality Control: Custom metal fabricators in Atlanta implement rigorous quality control measures throughout the fabrication process. This involves inspections at various stages to identify and address any potential defects or imperfections. By maintaining high quality standards, fabricators ensure that the products meet the required specifications and are built to last.

- Environmental Factors: Atlanta’s climate and environmental conditions can impact the durability of metal products. Custom metal fabricators in the region are knowledgeable about the effects of humidity, temperature fluctuations, and other environmental factors on different metals. They take necessary precautions, such as applying protective coatings or finishes, to enhance the longevity of the products in Atlanta’s specific environment.

These facets highlight how custom metal fabrication in Atlanta contributes to the durability and longevity of fabricated metal products. By leveraging the region’s skilled workforce, advanced fabrication techniques, and commitment to quality, custom metal fabricators can create products that withstand the test of time and meet the demands of various industries and applications.

Design flexibility

Design flexibility is a key aspect of custom metal fabrication in Atlanta, empowering businesses to bring their unique visions to life. This flexibility stems from the ability of skilled fabricators to work with a wide range of metals and utilize advanced fabrication techniques to achieve intricate designs.

The limitless design possibilities offered by custom metal fabrication open up a world of opportunities for architects, engineers, and designers. They can create structures and products that are not only visually appealing but also highly functional and durable. For instance, custom metal fabricators in Atlanta have played a pivotal role in the construction of iconic buildings and landmarks in the city, such as the Mercedes-Benz Stadium and the Atlanta BeltLine.

The practical significance of design flexibility in custom metal fabrication extends beyond aesthetics. It enables businesses to create products and structures that are tailored to their specific needs and requirements. For example, custom metal fabricators can create bespoke equipment for manufacturing facilities, specialized components for automotive or aerospace applications, and unique architectural elements for commercial and residential buildings.

In summary, design flexibility is a cornerstone of custom metal fabrication in Atlanta, allowing for the creation of unique and complex metal structures that meet the specific demands of various industries and applications. This flexibility empowers businesses to bring their innovative ideas to life and create products and structures that are both visually appealing and highly functional.

Key Insights:

- Design flexibility in custom metal fabrication allows for the creation of unique and complex metal structures.

- Skilled fabricators in Atlanta utilize advanced techniques to work with a wide range of metals, enabling limitless design possibilities.

- Custom metal fabrication offers practical benefits, allowing businesses to create products and structures tailored to their specific needs.

- Design flexibility contributes to the creation of visually appealing, highly functional, and durable metal structures.

Material versatility

The material versatility of custom metal fabrication in Atlanta is a significant aspect that contributes to its prominence within the manufacturing sector. The ability to utilize a diverse range of metals empowers fabricators to meet the unique requirements of various industries and applications.

- Matching Material Properties to Application Needs: The wide selection of metals available allows fabricators to choose the most suitable material for each project. For instance, aluminum is lightweight and corrosion-resistant, making it ideal for aerospace and marine applications. Stainless steel, known for its strength and durability, is commonly used in construction and food processing equipment.

- Exotic Alloys for Specialized Applications: Custom metal fabricators in Atlanta have access to exotic alloys that possess unique properties not found in common metals. These alloys, such as titanium and Inconel, are employed in demanding applications like high-performance engines, medical implants, and chemical processing equipment.

- Meeting Industry Standards and Regulations: The material versatility of custom metal fabrication enables fabricators to adhere to industry standards and regulations. Different industries have specific requirements for the types of metals used in their products. By utilizing the appropriate metals, fabricators ensure compliance with these standards, ensuring product safety and reliability.

- Cost Optimization and Value Engineering: The ability to choose from a range of metals allows fabricators to optimize costs while maintaining product quality. By selecting the most cost-effective metal that meets the necessary performance requirements, fabricators can provide value-engineered solutions for their clients.

In conclusion, the material versatility of custom metal fabrication in Atlanta provides numerous benefits, enabling fabricators to cater to the diverse needs of various industries. By utilizing a wide range of metals, from common alloys to exotic materials, fabricators can create products and structures that meet specific application requirements, adhere to industry standards, optimize costs, and deliver exceptional value to their customers.

Cost-effectiveness

Cost-effectiveness is a crucial aspect of custom metal fabrication in Atlanta. Custom fabrication provides cost-effective solutions compared to mass-produced products, enabling businesses to optimize production costs and maximize value.

One key factor driving the cost-effectiveness of custom metal fabrication is the ability to tailor products to specific requirements. By eliminating the need for costly tooling and setup associated with mass production, custom fabrication allows for efficient production of small batches or one-off pieces. This flexibility reduces overhead costs and minimizes material waste, resulting in cost savings for businesses.

Furthermore, custom metal fabricators in Atlanta leverage their expertise and experience to optimize production processes. They employ efficient fabrication techniques, such as lean manufacturing and value engineering, to streamline operations and reduce manufacturing costs. By utilizing advanced technology and skilled labor, fabricators can achieve high levels of precision and accuracy, minimizing the need for rework and scrap, further contributing to cost savings.

In addition to direct cost savings, custom metal fabrication offers long-term value for businesses. Custom-fabricated products are designed to meet specific performance requirements, ensuring durability and longevity. This reduces the need for frequent replacements or repairs, resulting in lower maintenance costs and increased productivity over the product’s lifespan.

The cost-effectiveness of custom metal fabrication in Atlanta has significant implications for businesses operating in the region. It enables them to reduce production costs, improve product quality, and enhance overall profitability. By leveraging the expertise of custom metal fabricators, businesses can gain a competitive advantage and succeed in the dynamic manufacturing landscape.

Key Insights:

- Custom metal fabrication provides cost-effective solutions compared to mass production, eliminating tooling costs and minimizing material waste.

- Custom fabricators optimize production processes through efficient techniques and skilled labor, reducing manufacturing costs.

- Custom-fabricated products are designed for durability, reducing maintenance costs and increasing productivity over the product’s lifespan.

- The cost-effectiveness of custom metal fabrication in Atlanta contributes to business profitability and competitiveness.

Example:

A manufacturing company in Atlanta required a specialized metal component for their production line. Mass-produced options were not suitable due to specific design requirements. By partnering with a local custom metal fabricator, the company was able to produce the component at a lower cost than mass-produced alternatives, while meeting their exact specifications and ensuring durability.

Reduced lead times

In the context of custom metal fabrication in Atlanta, reduced lead times are a significant advantage offered by local fabrication. Lead time refers to the time between placing an order and receiving the finished product. Local fabrication eliminates the need for long-distance transportation and reduces logistical delays, resulting in faster delivery of products.

Faster delivery times benefit businesses in several ways. Firstly, it allows for quicker product turnaround, enabling businesses to respond to market demands more efficiently. Secondly, reduced lead times minimize the risk of production delays and disruptions, ensuring a smooth supply chain. Thirdly, faster delivery enhances customer satisfaction by meeting project deadlines and reducing waiting periods.

For instance, a construction company in Atlanta working on a time-sensitive project required custom metal components. By partnering with a local fabricator, the company was able to receive the components within a shorter lead time compared to sourcing from distant suppliers. This timely delivery ensured the project’s completion on schedule, avoiding costly delays and potential penalties.

Overall, reduced lead times associated with local custom metal fabrication in Atlanta provide numerous benefits to businesses, including faster product turnaround, minimized production disruptions, and enhanced customer satisfaction. By leveraging the proximity of local fabricators, businesses can optimize their supply chain and achieve greater efficiency in their operations.

Key Insights:

- Local custom metal fabrication reduces lead times by eliminating long-distance transportation and logistical delays.

- Faster delivery times enable businesses to respond to market demands more efficiently and minimize production disruptions.

- Reduced lead times enhance customer satisfaction by meeting project deadlines and reducing waiting periods.

- Local fabrication supports faster product turnaround, supply chain optimization, and overall operational efficiency.

Skilled workforce

The skilled workforce in Atlanta is a cornerstone of the city’s thriving custom metal fabrication industry. Experienced metal fabricators in the region possess a deep understanding of metalworking techniques and a commitment to quality craftsmanship, ensuring that custom metal products meet the highest standards.

This skilled workforce is a result of Atlanta’s long history as a manufacturing hub. Over the years, the city has attracted a diverse pool of talented metalworkers, engineers, and designers. These professionals have honed their skills through years of experience, apprenticeships, and training programs, developing a mastery of various metal fabrication techniques.

The expertise of Atlanta’s metal fabricators extends to all aspects of custom metal fabrication, from design and engineering to production and finishing. They are proficient in working with a wide range of metals, including steel, aluminum, stainless steel, and exotic alloys. This versatility enables them to create custom metal products for a diverse array of industries, including construction, automotive, aerospace, and healthcare.

The skilled workforce in Atlanta is not only essential for producing high-quality custom metal products but also for driving innovation in the industry. Their knowledge and expertise allow them to develop new and improved fabrication techniques, optimize production processes, and create innovative solutions for complex design challenges.

Overall, the skilled workforce in Atlanta is a critical component of the city’s custom metal fabrication industry. Their experience, expertise, and commitment to quality craftsmanship ensure that custom metal products manufactured in Atlanta meet the highest standards of precision, durability, and aesthetic appeal.

Key Insights

- Atlanta’s skilled workforce has a deep understanding of metalworking techniques and a commitment to quality craftsmanship.

- The city’s long history as a manufacturing hub has attracted a diverse pool of talented metalworkers, engineers, and designers.

- Atlanta’s metal fabricators are proficient in working with a wide range of metals and fabrication techniques.

- The skilled workforce is essential for producing high-quality custom metal products and driving innovation in the industry.

Example

A leading construction company in Atlanta partnered with a local custom metal fabricator to create a unique architectural feature for a new skyscraper. The fabricator’s skilled workforce utilized advanced metalworking techniques to craft intricate metal panels that formed a stunning exterior facade. The project showcased the exceptional craftsmanship and expertise of Atlanta’s metal fabricators.

Industry expertise

Industry expertise is a cornerstone of custom metal fabrication in Atlanta, empowering fabricators to deliver exceptional products and services that meet the unique demands of various industries. Their in-depth knowledge of industry standards and best practices ensures that custom metal products are not only tailored to specific requirements but also adhere to the highest quality and safety standards.

- Compliance with Industry Regulations: Custom metal fabricators in Atlanta are well-versed in the regulatory landscape governing their industry. They stay up-to-date with the latest codes and standards, ensuring that their products comply with all applicable safety and performance requirements. This compliance minimizes risks, enhances product reliability, and demonstrates a commitment to ethical and responsible manufacturing practices.

- Optimization of Fabrication Techniques: Industry expertise enables fabricators to leverage the latest fabrication techniques and technologies. They are constantly exploring and implementing innovative methods to improve efficiency, precision, and quality. By staying abreast of industry advancements, fabricators can optimize their production processes, reduce costs, and deliver superior products to their customers.

- Value Engineering and Design Optimization: Custom metal fabricators in Atlanta are not merely manufacturers; they are also trusted advisors to their clients. Their industry expertise allows them to provide valuable insights into design optimization and value engineering. By understanding the specific needs and challenges of each industry, fabricators can suggest design modifications, material substitutions, and process improvements that enhance product performance and cost-effectiveness.

- Collaboration and Knowledge Sharing: Atlanta’s custom metal fabrication industry fosters a spirit of collaboration and knowledge sharing. Fabricators actively participate in industry events, conferences, and training programs. This engagement enables them to exchange ideas, learn from peers, and stay informed about emerging trends and best practices. Ultimately, this collaborative environment contributes to the continuous improvement of the industry as a whole.

In conclusion, the industry expertise possessed by custom metal fabricators in Atlanta is a key differentiator that sets them apart. Their in-depth knowledge of industry standards, best practices, and innovative techniques ensures that they can deliver exceptional products and services that meet the unique demands of their clients. By leveraging their industry expertise, fabricators contribute to the overall success and competitiveness of Atlanta’s manufacturing sector.

Frequently Asked Questions about Custom Metal Fabrication in Atlanta

This section addresses common questions and concerns regarding custom metal fabrication in Atlanta, providing informative answers to help you make informed decisions.

Question 1: What are the advantages of choosing custom metal fabrication in Atlanta?

Custom metal fabrication in Atlanta offers numerous advantages, including precision and accuracy, durability and longevity, design flexibility, material versatility, cost-effectiveness, reduced lead times, a skilled workforce, and industry expertise. These advantages enable businesses to meet their unique requirements, optimize production costs, and enhance product quality.

Question 2: What industries benefit from custom metal fabrication in Atlanta?

Custom metal fabrication in Atlanta serves a wide range of industries, including construction, automotive, aerospace, healthcare, and electronics. Fabricators in the region possess the expertise to create custom metal products tailored to the specific needs and demands of each industry.

Question 3: How can custom metal fabrication help businesses optimize costs?

Custom metal fabrication offers cost-effective solutions by eliminating tooling costs associated with mass production. Fabricators leverage efficient production techniques and skilled labor to minimize manufacturing costs and material waste, resulting in cost savings for businesses.

Question 4: What sets Atlanta apart as a hub for custom metal fabrication?

Atlanta’s skilled workforce and industry expertise are key differentiators. Fabricators in the region have a deep understanding of metalworking techniques and industry standards, ensuring high-quality craftsmanship and compliance with regulatory requirements.

Question 5: How can businesses find reputable custom metal fabricators in Atlanta?

To find reputable custom metal fabricators in Atlanta, consider industry certifications, online reviews, and portfolios showcasing their capabilities. Visit their facilities, inquire about their experience, and assess their commitment to quality and customer satisfaction.

Question 6: What factors should businesses consider when choosing a custom metal fabricator in Atlanta?

When choosing a custom metal fabricator in Atlanta, consider their capabilities, capacity, quality standards, lead times, and customer service. Evaluate their ability to meet your specific requirements, timelines, and budget constraints.

These FAQs provide insights into the benefits and considerations of custom metal fabrication in Atlanta. By choosing reputable fabricators and leveraging their expertise, businesses can harness the potential of custom metal fabrication to enhance their operations and achieve their manufacturing goals.

Transition to the Next Article Section:

To learn more about the intricacies of custom metal fabrication in Atlanta, explore our comprehensive guide that delves into the key aspects, applications, and industry trends shaping this dynamic field.

Tips for Custom Metal Fabrication in Atlanta

Custom metal fabrication in Atlanta offers a range of benefits for businesses seeking precision, durability, and cost-effective manufacturing solutions. Here are some essential tips to consider:

Tip 1: Define Your Requirements Clearly

Clearly define your project specifications, including the desired material, thickness, dimensions, and any necessary features or finishes. This will help fabricators provide accurate quotes and ensure that the final product meets your exact requirements.

Tip 2: Choose a Reputable Fabricator

Select a custom metal fabricator with a proven track record of quality and customer satisfaction. Look for fabricators who are certified, experienced in your industry, and have the capacity to meet your production needs.

Tip 3: Optimize Material Selection

Work with your fabricator to determine the most suitable metal for your project. Consider factors such as strength, durability, corrosion resistance, and cost. Selecting the right material will ensure the longevity and performance of your fabricated product.

Tip 4: Leverage Design Flexibility

Custom metal fabrication allows for limitless design possibilities. Collaborate with your fabricator to explore innovative designs that meet your functional and aesthetic requirements. Don’t be afraid to challenge conventional designs and explore new possibilities.

Tip 5: Control Costs Effectively

Establish a clear budget and work with your fabricator to identify cost-saving opportunities. Consider factors such as material selection, production techniques, and lead times. Effective cost control will help you optimize your investment without sacrificing quality.

Tip 6: Ensure Timely Delivery

Discuss lead times with your fabricator and establish realistic delivery schedules. Consider factors such as the complexity of your project, material availability, and the fabricator’s production capacity. Timely delivery is essential to avoid project delays and ensure a smooth workflow.

Tip 7: Establish Clear Communication

Maintain open and regular communication with your fabricator. Provide clear instructions, ask questions, and review progress updates. Effective communication will minimize misunderstandings and ensure that your project is completed according to your specifications.

Tip 8: Inspect the Final Product Thoroughly

Upon completion, thoroughly inspect the fabricated product to ensure that it meets your requirements. Check for accuracy, quality of workmanship, and compliance with specifications. A thorough inspection will help you identify any issues and ensure that you receive a product that meets your expectations.

By following these tips, businesses in Atlanta can harness the benefits of custom metal fabrication and create high-quality, cost-effective, and innovative metal products.

Conclusion

Custom metal fabrication in Atlanta has emerged as a vital resource for businesses seeking high-precision, durable, and cost-effective manufacturing solutions. Through the skilled workforce, industry expertise, and commitment to innovation, Atlanta’s fabricators deliver exceptional custom metal products tailored to diverse industry demands.

Harnessing the power of custom metal fabrication empowers businesses to optimize their operations, enhance product quality, and gain a competitive edge in their respective markets. By partnering with reputable fabricators and leveraging the advantages of this dynamic industry, businesses in Atlanta can unlock new possibilities and drive success through innovative metalworking solutions.