Design fabrication jobs encompass a wide range of roles that combine creativity and technical expertise. These professionals are responsible for turning design concepts into tangible products, using a variety of tools and technologies.

Editor’s Note: Design fabrication is a rapidly growing field, driven by the increasing demand for customized and innovative products. As a result, design fabrication jobs are in high demand, offering competitive salaries and excellent career prospects.

To help you learn more about design fabrication jobs, we’ve put together this comprehensive guide. We’ll cover everything from the different types of design fabrication jobs to the skills and training you need to succeed in this field.

Key Differences in Design Fabrication Jobs

There are many different types of design fabrication jobs, each with its own unique set of skills and responsibilities. Some of the most common types of design fabrication jobs include:

| Job Title | Description |

|---|---|

| CAD/CAM Technician | Creates and modifies computer-aided design (CAD) drawings and models, which are used to create prototypes and finished products. |

| CNC Machinist | Operates computer-controlled machinery to create precision parts and components. |

| 3D Printer Operator | Uses 3D printers to create prototypes, models, and finished products. |

| Mold Maker | Creates molds and patterns used to cast or form metal, plastic, or other materials. |

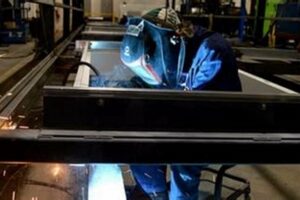

| Welder | Joins metal components using welding techniques. |

Benefits of Design Fabrication Jobs

There are many benefits to working in design fabrication, including:

- High demand: Design fabrication jobs are in high demand, due to the increasing demand for customized and innovative products.

- Competitive salaries: Design fabrication professionals earn competitive salaries, commensurate with their skills and experience.

- Excellent career prospects: There are excellent career prospects for design fabrication professionals, with opportunities for advancement in management and leadership roles.

- Creative and rewarding work: Design fabrication jobs offer the opportunity to work on creative and rewarding projects, that can make a real difference in the world.

If you’re interested in a career in design fabrication, there are a number of things you can do to prepare yourself, including:

Earning a degree or certificate in design fabrication, engineering, or a related field.Developing strong skills in CAD, CAM, and other design fabrication software.Gaining experience working with different materials and processes.Networking with other professionals in the field.

With the right skills and training, you can succeed in a design fabrication job and enjoy a rewarding career.

Design Fabrication Jobs

Design fabrication jobs encompass a wide range of roles that combine creativity and technical expertise. These professionals are responsible for turning design concepts into tangible products, using a variety of tools and technologies.

- Creativity: Design fabrication jobs require creativity and innovation to develop new products and solutions.

- Technical expertise: Design fabrication professionals must have a strong understanding of engineering principles and manufacturing processes.

- Collaboration: Design fabrication jobs often involve working with a team of engineers, designers, and other professionals.

- Problem-solving: Design fabrication professionals must be able to solve problems and develop innovative solutions.

- Attention to detail: Design fabrication jobs require a high level of attention to detail to ensure that products are manufactured to precise specifications.

- Communication skills: Design fabrication professionals must be able to communicate effectively with colleagues, clients, and other stakeholders.

- Computer-aided design (CAD) skills: Design fabrication professionals must be proficient in CAD software to create and modify designs.

- Manufacturing skills: Design fabrication professionals must have a strong understanding of manufacturing processes, such as machining, welding, and molding.

- Project management skills: Design fabrication professionals must be able to manage projects from concept to completion.

- Business acumen: Design fabrication professionals must have a basic understanding of business principles to be able to contribute to the success of their organization.

These key aspects are essential for success in design fabrication jobs. By developing these skills and knowledge, you can increase your chances of success in this exciting and rewarding field.

Creativity

Creativity is essential for design fabrication jobs, as it allows professionals to develop new and innovative products and solutions. This creativity can be expressed in a variety of ways, such as:

- Ideation: Generating new ideas and concepts for products and solutions.

- Problem-solving: Finding creative solutions to design challenges.

- Experimentation: Trying out new materials, processes, and technologies to create new products and solutions.

- Collaboration: Working with other creative professionals to develop new ideas and solutions.

Creativity is a key skill for design fabrication professionals, as it allows them to develop innovative and unique products and solutions that meet the needs of customers. Without creativity, design fabrication professionals would be limited to producing the same old products and solutions, which would not be able to meet the ever-changing needs of the market.

Technical expertise

Technical expertise is essential for design fabrication professionals, as it allows them to understand the engineering principles and manufacturing processes that are used to create products. This expertise enables them to design and fabricate products that are both functional and efficient.

- Engineering principles: Design fabrication professionals must have a strong understanding of engineering principles, such as mechanics, materials science, and thermodynamics. This knowledge allows them to design products that are structurally sound and able to withstand the forces that they will be subjected to.

- Manufacturing processes: Design fabrication professionals must also have a strong understanding of manufacturing processes, such as machining, welding, and molding. This knowledge allows them to design products that can be manufactured efficiently and cost-effectively.

- Materials science: Design fabrication professionals must have a strong understanding of materials science, such as the properties of different materials and how they can be used to create products. This knowledge allows them to select the right materials for each product, based on its intended use and performance requirements.

- Computer-aided design (CAD): Design fabrication professionals must be proficient in CAD software, which is used to create and modify designs. This software allows them to create detailed models of products, which can then be used to generate instructions for manufacturing.

Technical expertise is a key differentiator for design fabrication professionals. By developing this expertise, you can increase your chances of success in this exciting and rewarding field.

Collaboration

Collaboration is essential for design fabrication jobs, as it allows professionals to pool their knowledge and expertise to create innovative and successful products. This collaboration can take place at various stages of the design and fabrication process, from brainstorming new ideas to troubleshooting manufacturing issues.

- Ideation: Collaboration is essential during the ideation stage, as it allows professionals from different disciplines to share their ideas and perspectives. This can lead to the development of more innovative and creative solutions.

- Problem-solving: Collaboration is also important during the problem-solving stage, as it allows professionals to share their knowledge and expertise to find solutions to design and manufacturing challenges.

- Manufacturing: Collaboration is also important during the manufacturing stage, as it allows professionals from different disciplines to work together to ensure that products are manufactured efficiently and to the highest quality standards.

- Project management: Collaboration is also important for project management, as it allows professionals from different disciplines to work together to ensure that projects are completed on time and within budget.

By collaborating with other professionals, design fabrication professionals can create products that are both innovative and successful. Collaboration is a key skill for design fabrication professionals, and it is one of the things that makes this field so exciting and rewarding.

Problem-solving

Problem-solving is a critical skill for design fabrication professionals, as it allows them to overcome challenges and develop innovative solutions. This ability is essential for success in this field, as design fabrication professionals are often faced with complex problems that require creative solutions.

There are many different types of problems that design fabrication professionals may encounter, such as:

- Design challenges: These challenges may include developing new products or processes, or finding ways to improve existing products or processes.

- Manufacturing challenges: These challenges may include finding ways to manufacture products efficiently and cost-effectively, or overcoming challenges related to materials or equipment.

- Customer challenges: These challenges may include meeting customer needs or resolving customer complaints.

Design fabrication professionals must be able to approach these challenges with a problem-solving mindset. This means being able to identify the root cause of a problem, develop creative solutions, and implement those solutions effectively.

There are a number of different problem-solving techniques that design fabrication professionals can use, such as:

- Brainstorming: This technique involves generating a large number of ideas, no matter how outlandish, and then evaluating them to find the best solution.

- Root cause analysis: This technique involves identifying the underlying cause of a problem, rather than just treating the symptoms.

- Lateral thinking: This technique involves thinking outside the box and coming up with creative solutions that may not be immediately obvious.

By developing their problem-solving skills, design fabrication professionals can increase their chances of success in this exciting and rewarding field.

| Problem-solving skills | Benefits for design fabrication professionals |

|---|---|

| Identify the root cause of a problem | Develop more effective solutions |

| Develop creative solutions | Come up with new and innovative ideas |

| Implement solutions effectively | Ensure that solutions are successful |

Attention to detail

Attention to detail is essential for design fabrication jobs, as it ensures that products are manufactured to precise specifications. This is important for a number of reasons. First, it ensures that products are safe and functional. Second, it ensures that products meet customer requirements. Third, it helps to reduce waste and rework, which can save time and money.

There are a number of ways to improve attention to detail in design fabrication jobs. One way is to use checklists to ensure that all steps in the manufacturing process are followed correctly. Another way is to use quality control measures to inspect products at various stages of the manufacturing process. Finally, it is important to provide training to employees on the importance of attention to detail.

By following these tips, design fabrication professionals can improve their attention to detail and ensure that products are manufactured to precise specifications.

| Importance of attention to detail in design fabrication jobs | Benefits of attention to detail in design fabrication jobs |

|---|---|

| Ensures that products are safe and functional | Reduces waste and rework |

| Ensures that products meet customer requirements | Saves time and money |

Communication skills

Communication skills are essential for design fabrication professionals, as they allow them to convey their ideas clearly and effectively to a variety of audiences. These audiences may include colleagues, clients, suppliers, and other stakeholders. Effective communication is essential for the success of any design fabrication project, as it ensures that everyone involved is on the same page and working towards the same goals.

- Clear and concise communication: Design fabrication professionals must be able to communicate their ideas clearly and concisely. This means being able to articulate their thoughts in a way that is easy for others to understand. They must also be able to write and speak effectively, as they will often need to communicate with clients, suppliers, and other stakeholders.

- Active listening: Design fabrication professionals must be able to listen actively to others. This means paying attention to what others are saying, both verbally and nonverbally, and asking clarifying questions to ensure that they understand. Active listening is essential for building rapport with clients and colleagues, and for understanding their needs and requirements.

- Cultural sensitivity: Design fabrication professionals must be culturally sensitive. This means being aware of the cultural differences that may exist between themselves and their clients, colleagues, and other stakeholders. Cultural sensitivity is important for building rapport and trust, and for ensuring that communication is effective.

- Conflict resolution: Design fabrication professionals must be able to resolve conflict effectively. This means being able to identify the root cause of a conflict, and to develop and implement a solution that is acceptable to all parties involved. Conflict resolution is essential for maintaining a positive and productive work environment.

By developing their communication skills, design fabrication professionals can increase their chances of success in this exciting and rewarding field.

Computer-aided design (CAD) skills

Computer-aided design (CAD) skills are essential for design fabrication jobs, as they allow professionals to create and modify designs digitally. This is important for a number of reasons. First, CAD software allows professionals to create precise and detailed designs that can be easily shared with others. Second, CAD software can be used to simulate the manufacturing process, which can help to identify and resolve potential problems before they occur. Third, CAD software can be used to generate instructions for CNC machines, which can automate the manufacturing process and improve efficiency.

There are many different CAD software programs available, each with its own strengths and weaknesses. Some of the most popular CAD software programs include AutoCAD, SolidWorks, and Creo Parametric. Design fabrication professionals should choose a CAD software program that is best suited to their specific needs and requirements.

In addition to CAD software, design fabrication professionals should also be proficient in other software programs, such as CAM software and FEA software. CAM software is used to generate instructions for CNC machines, while FEA software is used to analyze the strength and durability of designs.

By developing their CAD skills, design fabrication professionals can increase their chances of success in this exciting and rewarding field.

| Importance of CAD skills in design fabrication jobs | Benefits of CAD skills in design fabrication jobs |

|---|---|

| Create precise and detailed designs | Improve communication and collaboration |

| Simulate the manufacturing process | Identify and resolve potential problems before they occur |

| Generate instructions for CNC machines | Automate the manufacturing process and improve efficiency |

Manufacturing skills

Manufacturing skills are essential for design fabrication jobs, as they allow professionals to understand the processes used to create products. This understanding is important for a number of reasons. First, it allows professionals to design products that can be manufactured efficiently and cost-effectively. Second, it allows professionals to identify and resolve potential manufacturing problems before they occur. Third, it allows professionals to communicate effectively with manufacturing engineers and technicians.

There are a variety of manufacturing processes that design fabrication professionals should be familiar with, including:

- Machining: Machining is a process of removing material from a workpiece using a cutting tool. Machining can be used to create a variety of shapes and features, such as holes, slots, and threads.

- Welding: Welding is a process of joining two pieces of metal together by melting the metal at the joint. Welding can be used to create a strong and durable joint.

- Molding: Molding is a process of creating a part by pouring molten material into a mold. Molding can be used to create a variety of parts, such as plastic parts, metal parts, and ceramic parts.

Design fabrication professionals should also have a basic understanding of other manufacturing processes, such as assembly, finishing, and testing. This understanding will allow them to design products that can be manufactured efficiently and to the highest quality standards.

The following are some real-life examples of how manufacturing skills are used in design fabrication jobs:

- A design fabrication professional may use machining to create a prototype of a new product. The prototype can be used to test the design and to identify any potential manufacturing problems.

- A design fabrication professional may use welding to join two pieces of metal together to create a structural component. The structural component must be strong and durable to ensure the safety of the product.

- A design fabrication professional may use molding to create a plastic part. The plastic part may be used to create a housing for a product or to create a component for a product.

Manufacturing skills are essential for design fabrication jobs. By developing these skills, design fabrication professionals can increase their chances of success in this exciting and rewarding field.

| Importance of manufacturing skills in design fabrication jobs | Benefits of manufacturing skills in design fabrication jobs |

|---|---|

| Design products that can be manufactured efficiently and cost-effectively | Identify and resolve potential manufacturing problems before they occur |

| Communicate effectively with manufacturing engineers and technicians | Increase chances of success in the design fabrication field |

Project management skills

Project management skills are essential for design fabrication jobs, as they allow professionals to plan, organize, and execute projects successfully. This involves a variety of tasks, such as:

- Planning: Design fabrication professionals must be able to plan projects carefully, including developing a project scope, timeline, and budget.

- Organizing: Design fabrication professionals must be able to organize projects efficiently, including allocating resources and assigning tasks to team members.

- Executing: Design fabrication professionals must be able to execute projects effectively, including monitoring progress, managing risks, and making decisions.

- Closing: Design fabrication professionals must be able to close projects successfully, including delivering the final product, evaluating the project, and documenting lessons learned.

By developing their project management skills, design fabrication professionals can increase their chances of success in this exciting and rewarding field.

Business acumen

Business acumen is essential for design fabrication professionals, as it allows them to understand the business side of their organization and make decisions that contribute to its success. This includes understanding basic financial principles, such as profitability, cash flow, and return on investment. It also includes understanding the different functional areas of a business, such as marketing, sales, and operations.

There are a number of ways that design fabrication professionals can develop their business acumen. One way is to take courses in business administration or management. Another way is to read books and articles on business topics. Finally, design fabrication professionals can learn about business by working with other professionals in their organization, such as accountants, marketers, and sales representatives.

The following are some real-life examples of how design fabrication professionals have used their business acumen to contribute to the success of their organization:

- A design fabrication professional was able to identify an opportunity to reduce the cost of a product by redesigning it. The redesign resulted in a 20% reduction in manufacturing costs, which saved the company a significant amount of money.

- A design fabrication professional was able to develop a new marketing campaign that increased sales of a product by 15%. The campaign targeted a new customer segment, which helped the company to grow its market share.

- A design fabrication professional was able to negotiate a better deal with a supplier, which resulted in a 10% reduction in the cost of raw materials. The savings were passed on to customers, which helped the company to win new business.

These are just a few examples of how design fabrication professionals can use their business acumen to contribute to the success of their organization. By developing their business acumen, design fabrication professionals can increase their value to their organization and their chances of success in this exciting and rewarding field.

Table: The Importance of Business Acumen for Design Fabrication Professionals

| Importance | Benefits |

|---|---|

| Understanding the business side of their organization | Allows design fabrication professionals to make decisions that contribute to the success of their organization. |

| Understanding basic financial principles | Helps design fabrication professionals to make sound financial decisions. |

| Understanding the different functional areas of a business | Allows design fabrication professionals to collaborate effectively with other professionals in their organization. |

FAQs about Design Fabrication Jobs

Design fabrication jobs encompass a wide range of roles that combine creativity and technical expertise. These professionals are responsible for turning design concepts into tangible products, using a variety of tools and technologies.

Question 1: What are the different types of design fabrication jobs?

There are many different types of design fabrication jobs, including CAD/CAM technicians, CNC machinists, 3D printer operators, mold makers, and welders.

Question 2: What skills are required for design fabrication jobs?

Design fabrication jobs require a combination of creativity, technical expertise, and problem-solving skills. They also require proficiency in CAD software and manufacturing processes.

Question 3: What are the benefits of working in design fabrication?

Design fabrication jobs offer a number of benefits, including high demand, competitive salaries, excellent career prospects, and the opportunity to work on creative and rewarding projects.

Question 4: How can I prepare for a career in design fabrication?

You can prepare for a career in design fabrication by earning a degree or certificate in design fabrication, engineering, or a related field; developing strong skills in CAD, CAM, and other design fabrication software; gaining experience working with different materials and processes; and networking with other professionals in the field.

Question 5: What is the job outlook for design fabrication professionals?

The job outlook for design fabrication professionals is expected to be excellent over the next few years. This is due to the increasing demand for customized and innovative products.

Question 6: What are the career advancement opportunities for design fabrication professionals?

Design fabrication professionals can advance their careers by moving into management or leadership roles. They can also specialize in a particular area of design fabrication, such as product design or manufacturing engineering.

Summary of key takeaways:

- Design fabrication jobs offer a unique blend of creativity, technical expertise, and problem-solving skills.

- There are many different types of design fabrication jobs, each with its own unique set of skills and responsibilities.

- The benefits of working in design fabrication include high demand, competitive salaries, excellent career prospects, and the opportunity to work on creative and rewarding projects.

- You can prepare for a career in design fabrication by earning a degree or certificate in design fabrication, engineering, or a related field; developing strong skills in CAD, CAM, and other design fabrication software; gaining experience working with different materials and processes; and networking with other professionals in the field.

- The job outlook for design fabrication professionals is expected to be excellent over the next few years.

- Design fabrication professionals can advance their careers by moving into management or leadership roles. They can also specialize in a particular area of design fabrication, such as product design or manufacturing engineering.

Transition to the next article section:

If you are interested in a career in design fabrication, there are a number of resources available to help you get started. You can find more information about design fabrication programs and careers at the following websites:

- Wikipedia

- Youtube

- Comparison

Design Fabrication Jobs

Design fabrication jobs offer a unique blend of creativity, technical expertise, and problem-solving skills. If you’re interested in a career in this exciting field, here are a few tips to help you get started.

Tip 1: Develop strong technical skills.

Design fabrication professionals need to have a strong understanding of engineering principles and manufacturing processes. This includes proficiency in CAD software, CNC machining, and other design fabrication technologies.

Tip 2: Be creative and innovative.

Design fabrication jobs require creativity and innovation to develop new products and solutions. This means being able to think outside the box and come up with new and innovative ideas.

Tip 3: Be detail-oriented.

Design fabrication jobs require a high level of attention to detail. This is important for ensuring that products are manufactured to precise specifications.

Tip 4: Be a team player.

Design fabrication jobs often involve working with a team of engineers, designers, and other professionals. It’s important to be able to work effectively as part of a team.

Tip 5: Be passionate about your work.

Design fabrication jobs can be challenging, but they can also be very rewarding. If you’re passionate about your work, you’ll be more likely to succeed in this field.

Summary of key takeaways:

- Develop strong technical skills.

- Be creative and innovative.

- Be detail-oriented.

- Be a team player.

- Be passionate about your work.

Conclusion:

If you’re interested in a career in design fabrication, there are a number of resources available to help you get started. You can find more information about design fabrication programs and careers at the following websites:

- Wikipedia

- Youtube

- Comparison

Conclusion

Design fabrication jobs are in high demand due to the increasing need for customized and innovative products. These jobs offer a unique blend of creativity, technical expertise, and problem-solving skills. To be successful in this field, it is important to develop strong technical skills, be creative and innovative, be detail-oriented, be a team player, and be passionate about your work.

The future of design fabrication is bright. As technology continues to advance, new and innovative design fabrication techniques will be developed. This will lead to even more opportunities for design fabrication professionals.