What is a fabrication services company? A fabrication services company is a business that provides a range of services related to the fabrication of metal, plastic, and other materials. These services can include cutting, bending, welding, and assembling. Fabrication services companies often work with other businesses to help them design and manufacture products.

Editor’s Notes: Fabrication services companies play an important role in the manufacturing industry. They provide the skills and equipment necessary to turn raw materials into finished products. Without fabrication services companies, many businesses would not be able to operate.

After doing some analysis and digging through the available information, we have put together this fabrication services company guide to help you make the right decision.

Key differences or Key takeaways

| Fabrication Services Company | |

|---|---|

| Definition | A business that provides a range of services related to the fabrication of metal, plastic, and other materials. |

| Services | Can include cutting, bending, welding, and assembling. |

| Importance | Plays an important role in the manufacturing industry by providing the skills and equipment necessary to turn raw materials into finished products. |

Main article topics

- What is a fabrication services company?

- What services do fabrication services companies provide?

- Why are fabrication services companies important?

- How to choose the right fabrication services company

Fabrication Services Company

Fabrication services companies play a vital role in the manufacturing industry. They provide the skills and equipment necessary to turn raw materials into finished products. There are many different aspects to consider when choosing a fabrication services company. Here are 12 key aspects to keep in mind:

- Capabilities: What types of fabrication services does the company offer? Do they have the equipment and expertise to meet your needs?

- Quality: What is the quality of the company’s work? Do they have a good reputation for producing high-quality products?

- Price: What are the company’s prices? Are they competitive with other fabrication services companies?

- Location: Where is the company located? Is it convenient for you to do business with them?

- Experience: How long has the company been in business? Do they have a lot of experience in the fabrication industry?

- Customer service: What is the company’s customer service like? Are they responsive to your needs and questions?

- Flexibility: Is the company flexible enough to meet your changing needs?

- Technology: What kind of technology does the company use? Do they have the latest and greatest equipment?

- Safety: What is the company’s safety record? Do they have a good safety program in place?

- Sustainability: Is the company committed to sustainability? Do they use environmentally friendly practices?

- Certifications: Does the company have any certifications? This can be an indication of their quality and commitment to excellence.

- References: Can the company provide you with references from past customers?

These are just a few of the key aspects to consider when choosing a fabrication services company. By taking the time to research and compare different companies, you can find the best one for your needs.

Capabilities

The capabilities of a fabrication services company are one of the most important factors to consider when choosing a partner. You need to make sure that the company has the equipment and expertise to meet your specific needs. Some of the key capabilities to look for include:

- Cutting: The company should have the ability to cut metal, plastic, and other materials to your specifications. This may include laser cutting, waterjet cutting, or plasma cutting.

- Bending: The company should be able to bend metal and other materials to create complex shapes. This may include press brake bending, roll bending, or tube bending.

- Welding: The company should be able to weld metal and other materials to create strong and durable joints. This may include MIG welding, TIG welding, or spot welding.

- Assembly: The company should be able to assemble components into finished products. This may include mechanical assembly, electrical assembly, or welding assembly.

In addition to these core capabilities, you may also want to consider the company’s experience, quality control procedures, and customer service. By taking the time to research and compare different companies, you can find a fabrication services company that has the capabilities and expertise to meet your needs.

Quality

The quality of a fabrication services company’s work is paramount. You need to be sure that the company can produce high-quality products that meet your specifications. Here are a few things to consider when assessing the quality of a fabrication services company:

- Materials: The company should use high-quality materials in its products. This includes the type of metal, plastic, or other materials used, as well as the quality of the finishes.

- Workmanship: The company’s workmanship should be of a high standard. This means that the products should be well-made and free of defects.

- Quality control: The company should have a good quality control process in place to ensure that its products meet the required standards.

- Reputation: The company should have a good reputation for producing high-quality products. You can check online reviews or ask for references from past customers to get an idea of the company’s quality.

By considering these factors, you can assess the quality of a fabrication services company and make an informed decision about whether or not to do business with them.

Price

When choosing a fabrication services company, it is important to consider their prices. You want to make sure that you are getting a fair price for the services you need. Here are a few things to keep in mind when evaluating the prices of fabrication services companies:

- Cost of materials: The cost of materials is a major factor in the price of fabrication services. The type of material you choose, as well as the quantity you need, will affect the overall cost of your project.

- Complexity of the project: The complexity of your project will also affect the price. A simple project will cost less to fabricate than a complex project.

- Labor costs: Labor costs are another major factor in the price of fabrication services. The hourly rate of the fabricators will vary depending on their experience and location.

- Overhead costs: Fabrication services companies also have overhead costs, such as rent, utilities, and insurance. These costs are factored into the price of their services.

It is important to compare the prices of several fabrication services companies before making a decision. You should also get a written quote from each company so that you can compare the prices apples-to-apples. By taking the time to do your research, you can find a fabrication services company that offers competitive prices and high-quality services.

Location

The location of a fabrication services company is an important factor to consider when choosing a partner. There are a few key reasons why location matters:

- Shipping costs: If the fabrication services company is located far away from your business, you will have to pay higher shipping costs. This can be a significant expense, especially if you are shipping large or heavy items.

- Lead times: The location of the fabrication services company can also affect lead times. If the company is located overseas, it may take longer to receive your products. This can be a problem if you need your products quickly.

- Communication: It is important to be able to communicate easily with your fabrication services company. If the company is located in a different time zone or speaks a different language, it can be difficult to get the information you need.

In addition to these factors, you may also want to consider the company’s proximity to your other suppliers and customers. By choosing a fabrication services company that is conveniently located, you can save time and money.

Here are some tips for choosing a fabrication services company that is conveniently located:

- Consider your location: Where is your business located? What are the major transportation routes in your area? By understanding your own location, you can start to narrow down your search for a fabrication services company.

- Research different companies: Once you have a list of potential fabrication services companies, research each company to learn more about their location. You can also contact the companies directly to ask about their shipping policies and lead times.

- Choose a company that is easy to communicate with: Make sure that the fabrication services company is easy to reach by phone, email, or video chat. You should also be able to understand the company’s communication style.

By following these tips, you can choose a fabrication services company that is conveniently located and meets your other needs.

Experience

When choosing a fabrication services company, it is important to consider their experience. A company with a lot of experience is more likely to have the skills and knowledge to produce high-quality products and services. Here are a few things to keep in mind when evaluating the experience of a fabrication services company:

- Years in business: How long has the company been in business? A company that has been in business for a long time has had more time to develop its skills and knowledge.

- Experience in the fabrication industry: Does the company have experience in the specific type of fabrication you need? For example, if you need metal fabrication services, you should choose a company that has experience in metal fabrication.

- Customer testimonials: What do past customers say about the company’s experience? Positive customer testimonials are a good indication that the company is experienced and reliable.

By considering these factors, you can assess the experience of a fabrication services company and make an informed decision about whether or not to do business with them.

Customer service

Customer service is an important aspect of any business, but it is especially important for fabrication services companies. These companies often work with customers on complex projects, and it is important to have a good relationship with the customer in order to ensure that the project is completed successfully.

There are a number of factors to consider when evaluating the customer service of a fabrication services company. These factors include:

- Responsiveness: How quickly does the company respond to inquiries? Are they available to answer questions and provide support when you need it?

- Knowledge: Do the company’s representatives have a good understanding of the fabrication process and the products that they sell? Can they answer your questions and provide helpful advice?

- Friendliness: Are the company’s representatives friendly and helpful? Do they make you feel like you are valued as a customer?

It is also important to consider the company’s customer service policies. For example, does the company offer a warranty on its products? What is the company’s return policy? It is important to choose a company that has customer service policies that meet your needs.

Good customer service can make a big difference in the success of a fabrication project. By choosing a company with good customer service, you can ensure that you have a positive experience and that your project is completed successfully.

Here are some real-life examples of the importance of customer service in the fabrication industry:

- A customer is working on a complex fabrication project and needs help with a specific design. The customer service representative is able to provide the customer with the necessary information and support, which helps the customer to complete the project successfully.

- A customer is having trouble with a product that they purchased from a fabrication services company. The customer service representative is able to quickly resolve the issue and provide the customer with a replacement product.

- A customer is looking for a specific type of fabrication service, but they are not sure which company to choose. The customer service representative is able to provide the customer with information about the different fabrication services companies in the area and help the customer to choose the right company for their needs.

These are just a few examples of how good customer service can make a big difference in the fabrication industry. By choosing a company with good customer service, you can ensure that you have a positive experience and that your project is completed successfully.

Table: Key insights on the connection between customer service and fabrication services companies

| Customer Service | Fabrication Services Company |

|---|---|

| Responsiveness | Ensures that projects are completed on time and within budget. |

| Knowledge | Helps customers to make informed decisions about their fabrication projects. |

| Friendliness | Creates a positive experience for customers and builds long-term relationships. |

Flexibility

In today’s rapidly changing business environment, flexibility is more important than ever before. Fabrication services companies that are able to adapt to changing customer needs and market conditions are more likely to be successful than those that are not.

There are a number of ways that fabrication services companies can demonstrate flexibility. One way is by being willing to work with customers on custom projects. Another way is by being able to quickly change production schedules to meet customer demand. Fabrication services companies that are flexible are also more likely to be able to offer competitive pricing and meet customer deadlines.

Here are some real-life examples of how flexibility can benefit fabrication services companies:

- A fabrication services company is able to quickly adapt its production schedule to meet a customer’s urgent need for a large order of metal components.

- A fabrication services company is able to work with a customer to develop a custom solution for a complex fabrication project.

- A fabrication services company is able to offer a competitive price on a large order of fabricated parts by being flexible with its pricing.

These are just a few examples of how flexibility can benefit fabrication services companies. By being flexible, fabrication services companies can increase their sales, improve customer satisfaction, and gain a competitive advantage.

Table: Key insights on the connection between flexibility and fabrication services companies

| Flexibility | Fabrication Services Company |

|---|---|

| Allows companies to adapt to changing customer needs | Increased sales and improved customer satisfaction |

| Enables companies to quickly change production schedules | Competitive pricing and ability to meet customer deadlines |

| Helps companies to offer custom solutions | Gain a competitive advantage |

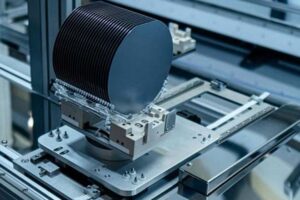

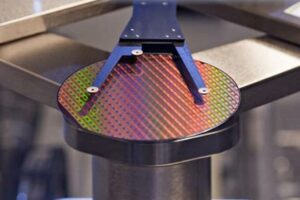

Technology

In today’s competitive manufacturing environment, fabrication services companies that use the latest technology have a significant advantage over those that do not. The latest technology can help fabrication services companies to improve their efficiency, accuracy, and quality.

One of the most important aspects of technology for fabrication services companies is the use of computer-aided design (CAD) software. CAD software allows engineers and designers to create detailed 3D models of products. These models can then be used to create tool paths for CNC machines, which can automate the fabrication process. CAD software can also be used to simulate the fabrication process, which can help to identify and eliminate potential problems.

Another important aspect of technology for fabrication services companies is the use of CNC machines. CNC machines are computer-controlled machines that can be used to cut, bend, and weld metal. CNC machines are much more precise and efficient than manual machines, and they can be used to produce complex parts that would be difficult or impossible to produce by hand.

In addition to CAD software and CNC machines, fabrication services companies can also use a variety of other technologies to improve their operations. These technologies include laser cutters, waterjet cutters, and 3D printers.

Fabrication services companies that use the latest technology are able to produce high-quality products quickly and efficiently. This can give them a significant advantage over their competitors.

Here are some real-life examples of how technology has helped fabrication services companies to succeed:

- A fabrication services company used CAD software to create a 3D model of a complex part. The model was then used to create a tool path for a CNC machine, which automated the fabrication process. This allowed the company to produce the part quickly and accurately.

- A fabrication services company used a laser cutter to cut a intricate design into a sheet of metal. The laser cutter was able to cut the design with precision and accuracy, which would have been difficult or impossible to do by hand.

- A fabrication services company used a 3D printer to create a prototype of a new product. The 3D printer was able to create a high-quality prototype quickly and inexpensively, which allowed the company to test the design before committing to production.

These are just a few examples of how technology can benefit fabrication services companies. By using the latest technology, fabrication services companies can improve their efficiency, accuracy, and quality. This can give them a significant advantage over their competitors.

Table: Key insights on the connection between technology and fabrication services companies

| Technology | Fabrication Services Company |

|---|---|

| Improves efficiency | Increased production output and reduced labor costs |

| Enhances accuracy | Reduced scrap and rework, improved product quality |

| Increases quality | Improved product performance and customer satisfaction |

Safety

In the fabrication industry, safety is of paramount importance. Fabrication processes involve the use of heavy machinery and hazardous materials, which can pose significant risks to workers. Therefore, it is essential for fabrication services companies to have a strong safety program in place to protect their employees and maintain a safe working environment.

- Compliance with safety regulations: Fabrication services companies must comply with all applicable safety regulations, including those set by OSHA and other regulatory agencies. This includes adhering to standards for machine guarding, hazardous materials handling, and personal protective equipment.

- Employee training and education: Employees must be properly trained on all safety procedures and hazards associated with their jobs. This includes training on the safe operation of machinery, the handling of hazardous materials, and emergency response procedures.

- Regular safety inspections: Fabrication services companies should conduct regular safety inspections of their facilities and equipment to identify and eliminate potential hazards. This includes inspections of machinery, electrical systems, and work areas.

- Accident investigation and reporting: In the event of an accident, fabrication services companies must investigate the incident thoroughly and report it to the appropriate authorities. This helps to identify the root cause of the accident and prevent similar incidents from happening in the future.

By implementing a comprehensive safety program, fabrication services companies can create a safe and healthy work environment for their employees. This not only protects workers from injury and illness, but it also helps to reduce absenteeism and turnover, which can improve productivity and profitability.

Sustainability

In today’s increasingly environmentally conscious world, sustainability is becoming a key factor for businesses of all types, including fabrication services companies. Customers are increasingly demanding products and services that are produced in a sustainable way, and fabrication services companies that are able to meet this demand are more likely to be successful.

There are a number of ways that fabrication services companies can demonstrate their commitment to sustainability. One way is by using environmentally friendly materials and processes. Another way is by reducing waste and emissions. Fabrication services companies that are committed to sustainability are also more likely to be involved in community outreach and education programs.

Here are some real-life examples of how sustainability can benefit fabrication services companies:

- A fabrication services company that uses recycled materials in its products is able to reduce its environmental impact and appeal to customers who are looking for sustainable products.

- A fabrication services company that invests in energy-efficient equipment is able to reduce its operating costs and improve its bottom line.

- A fabrication services company that partners with local schools to educate students about sustainability is able to build goodwill in the community and attract new customers.

These are just a few examples of how sustainability can benefit fabrication services companies. By adopting sustainable practices, fabrication services companies can improve their environmental performance, reduce their costs, and attract new customers.

Table: Key insights on the connection between sustainability and fabrication services companies

| Sustainability | Fabrication Services Company |

|---|---|

| Reduces environmental impact | Increased customer demand for sustainable products and services |

| Improves cost efficiency | Reduced operating costs through energy efficiency and waste reduction |

| Builds community goodwill | Positive reputation and increased customer loyalty |

Certifications

Certifications are an important consideration when choosing a fabrication services company. They provide assurance that the company has met certain standards of quality and competence. There are a number of different certifications that fabrication services companies can obtain, depending on their specific area of expertise.

- ISO 9001: ISO 9001 is a generic quality management system that can be applied to any organization, regardless of its size or industry. It sets out a framework for creating and maintaining a quality management system that ensures that products and services meet customer requirements and are consistently produced and delivered.

- AS9100: AS9100 is a quality management system specifically designed for the aerospace industry. It is based on ISO 9001 but includes additional requirements that are specific to the aerospace industry.

- Nadcap: Nadcap is a global accreditation program for the aerospace industry. It provides a standardized approach to quality assurance and supplier management.

- AWS: AWS is the American Welding Society. It offers a variety of certifications for welders and welding processes.

These are just a few of the many certifications that fabrication services companies can obtain. When choosing a fabrication services company, it is important to consider the specific certifications that are relevant to your industry and your project requirements.

References

References from past customers are an important factor to consider when choosing a fabrication services company. They can provide valuable insights into the company’s quality of work, customer service, and overall reliability. Here are a few reasons why references are important:

- Credibility: References from past customers can help to establish the credibility of a fabrication services company. They provide evidence that the company has successfully completed projects for other customers and that those customers were satisfied with the results.

- Quality of work: References can provide insights into the quality of a fabrication services company’s work. Past customers can provide feedback on the accuracy, precision, and overall quality of the company’s products and services.

- Customer service: References can also provide insights into a fabrication services company’s customer service. Past customers can share their experiences with the company’s responsiveness, communication, and willingness to resolve any issues.

- Reliability: References can provide information about a fabrication services company’s reliability. Past customers can attest to the company’s ability to meet deadlines, deliver on promises, and stand behind its work.

When requesting references, it is important to ask specific questions about the company’s performance. This may include questions about the quality of the work, the responsiveness of the customer service, and the company’s ability to meet deadlines. It is also helpful to ask for references from customers who have worked with the company on similar projects to your own.

References from past customers can be an invaluable resource when choosing a fabrication services company. By carefully considering the references, you can make an informed decision about which company is best suited to meet your needs.

Table: Key insights on the connection between references and fabrication services companies

| References | Fabrication Services Company |

|---|---|

| Credibility | Provides evidence of successful project completion and customer satisfaction |

| Quality of work | Insights into accuracy, precision, and overall quality |

| Customer service | Feedback on responsiveness, communication, and issue resolution |

| Reliability | Information about meeting deadlines, delivering on promises, and standing behind work |

Fabrication Services Company FAQs

This section addresses frequently asked questions (FAQs) about fabrication services companies to provide clear and concise information.

Question 1: What services do fabrication services companies offer?

Answer: Fabrication services companies offer a range of services related to the fabrication of metal, plastic, and other materials. These services may include cutting, bending, welding, assembling, and finishing. Some companies may also offer design and engineering services.

Question 2: How do I choose the right fabrication services company?

Answer: When choosing a fabrication services company, consider factors such as capabilities, quality, price, location, experience, customer service, flexibility, technology, safety, sustainability, certifications, and references.

Question 3: What is the importance of quality in fabrication services?

Answer: Quality is crucial in fabrication services as it ensures that products meet specifications, are well-made, and free of defects. A company’s quality control processes, certifications, and reputation can indicate their commitment to quality.

Question 4: How does technology impact fabrication services?

Answer: Technology, such as CAD software and CNC machines, enhances efficiency, accuracy, and quality in fabrication services. It enables precise cutting, bending, and welding, reduces errors, and streamlines production processes.

Question 5: What are the safety considerations when working with fabrication services companies?

Answer: Safety is paramount in fabrication services due to the use of heavy machinery and hazardous materials. Companies should have comprehensive safety programs that include compliance with regulations, employee training, regular inspections, and accident investigation procedures.

Question 6: How can I ensure sustainability in fabrication services?

Answer: Fabrication services companies can demonstrate sustainability by using environmentally friendly materials, reducing waste and emissions, and implementing energy-efficient practices. Certifications and community involvement can also indicate their commitment to sustainability.

Summary: Fabrication services companies play a vital role in various industries by providing customized solutions for metal, plastic, and other material fabrication needs. Choosing the right company requires careful consideration of their capabilities, quality, and other factors. Technology, safety, and sustainability are also important aspects to evaluate. Understanding these factors enables informed decision-making and successful partnerships with fabrication services companies.

Transition: For further insights into fabrication services and related topics, explore the following resources:

Fabrication Services Company Tips

Selecting the right fabrication services company is crucial for successful project outcomes. Here are some essential tips to guide your decision-making process:

Tip 1: Define Your Project Requirements Clearly

Before reaching out to fabrication services companies, clearly define your project specifications, including materials, dimensions, tolerances, and deadlines. This will help you identify companies that can meet your specific needs.

Tip 2: Research and Compare Capabilities

Thoroughly research potential fabrication services companies. Examine their capabilities, equipment, and experience in handling projects similar to yours. Compare their offerings to determine which company can best execute your project.

Tip 3: Prioritize Quality and Precision

Quality should be a top priority when evaluating fabrication services companies. Look for companies with a proven track record of delivering high-quality products. Consider their quality control processes, certifications, and customer testimonials.

Tip 4: Consider Location and Lead Times

The location of the fabrication services company can impact shipping costs, lead times, and communication. Choose a company that is conveniently located and can meet your project deadlines.

Tip 5: Evaluate Customer Service and Support

Excellent customer service is essential for a smooth project experience. Look for fabrication services companies that are responsive, communicate effectively, and are willing to go the extra mile to ensure customer satisfaction.

Tip 6: Request References and Case Studies

References from previous clients can provide valuable insights into the company’s performance, quality of work, and customer service. Request case studies to see examples of similar projects they have successfully completed.

Summary: By following these tips, you can make informed decisions when selecting a fabrication services company. Prioritizing clear project requirements, researching capabilities, emphasizing quality, considering location, evaluating customer service, and requesting references will help you find the right partner for your project.

Conclusion: Choosing the right fabrication services company is a critical step in ensuring the success of your project. By considering these factors and conducting thorough research, you can identify a company that aligns with your needs and delivers exceptional results.

Conclusion

Fabrication services companies play a pivotal role in various industries, providing customized solutions for metal, plastic, and other material fabrication needs. By understanding the key aspects to consider when choosing a fabrication services company, businesses and individuals can make informed decisions that align with their project requirements.

As technology continues to advance and sustainability becomes increasingly important, fabrication services companies that invest in innovation, embrace eco-friendly practices, and maintain high standards of quality and customer service will be well-positioned to meet the evolving demands of the market. The future of fabrication services holds exciting possibilities for collaboration, innovation, and the creation of groundbreaking products and solutions.