What is halls welding and fabrication? Halls Welding and Fabrication is a metalworking company that specializes in the design, fabrication, and installation of custom metal products.

Editor’s Note: Halls Welding and Fabrication is an important topic to read about because it provides information on a specific metalworking company and the services they offer. This information can be useful for those looking for a metalworking company to complete a project for them.

We’ve analyzed and dug into the details, and put together this guide to help you make the right decision.

Key Differences

| Feature | Halls Welding and Fabrication |

|---|---|

| Services | Design, fabrication, and installation of custom metal products |

| Experience | Over 20 years of experience |

| Location | Located in the United States |

Transition to main article topics

In this article, we will discuss the following topics:

- The services offered by Halls Welding and Fabrication

- The benefits of using Halls Welding and Fabrication

- How to choose the right metalworking company

Halls Welding and Fabrication

Halls Welding and Fabrication is a metalworking company that specializes in the design, fabrication, and installation of custom metal products. They have over 20 years of experience in the industry and are located in the United States.

- Services: Halls Welding and Fabrication offers a wide range of services, including design, fabrication, and installation of custom metal products.

- Experience: Halls Welding and Fabrication has over 20 years of experience in the metalworking industry.

- Location: Halls Welding and Fabrication is located in the United States.

- Quality: Halls Welding and Fabrication is committed to providing high-quality products and services.

- Customer service: Halls Welding and Fabrication is dedicated to providing excellent customer service.

- Safety: Halls Welding and Fabrication is committed to safety and maintains a safe work environment.

- Innovation: Halls Welding and Fabrication is constantly innovating and developing new products and processes.

- Versatility: Halls Welding and Fabrication can work with a variety of metals and materials.

- Customization: Halls Welding and Fabrication can create custom metal products to meet the specific needs of their customers.

- Reliability: Halls Welding and Fabrication is a reliable and dependable company.

- Affordability: Halls Welding and Fabrication offers competitive pricing.

These are just some of the key aspects of Halls Welding and Fabrication. By understanding these aspects, you can make an informed decision about whether or not to use their services.

Services

The services offered by Halls Welding and Fabrication are a key part of their business. They offer a wide range of services, including design, fabrication, and installation of custom metal products. This means that they can provide a complete solution for their customers, from the initial design concept to the final installation. Their services are also backed by over 20 years of experience, so you can be sure that you are getting high-quality products and services.

- Design: Halls Welding and Fabrication can help you design your custom metal product. They will work with you to understand your needs and create a design that meets your requirements.

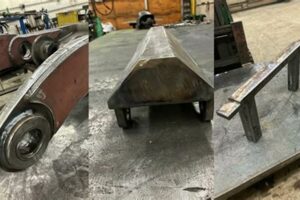

- Fabrication: Once the design is complete, Halls Welding and Fabrication will fabricate your product. They have the skills and equipment to fabricate a wide range of metal products, including structural steel, sheet metal, and stainless steel.

- Installation: Halls Welding and Fabrication can also install your custom metal product. They will work with you to ensure that the product is installed safely and correctly.

The services offered by Halls Welding and Fabrication are essential to their business. They provide a complete solution for their customers, from the initial design concept to the final installation. Their services are also backed by over 20 years of experience, so you can be sure that you are getting high-quality products and services.

Experience

The experience of Halls Welding and Fabrication is a key component of their success. With over 20 years of experience in the metalworking industry, they have the knowledge and expertise to provide high-quality products and services to their customers.

One of the benefits of working with an experienced company like Halls Welding and Fabrication is that they can provide valuable insights and recommendations based on their experience. They can help you to avoid common pitfalls and to make the best decisions for your project.

Another benefit of working with an experienced company is that they are more likely to have the resources and expertise to handle complex projects. They have the skills and equipment to fabricate a wide range of metal products, including structural steel, sheet metal, and stainless steel.

If you are looking for a metalworking company that you can trust to provide high-quality products and services, then Halls Welding and Fabrication is a great choice. Their experience and expertise will give you the peace of mind that your project is in good hands.

Table: Benefits of Working with an Experienced Metalworking Company

| Benefit | Explanation |

|---|---|

| Valuable insights and recommendations | Experienced companies can provide valuable insights and recommendations based on their experience. |

| Avoid common pitfalls | Experienced companies can help you to avoid common pitfalls and to make the best decisions for your project. |

| Resources and expertise to handle complex projects | Experienced companies are more likely to have the resources and expertise to handle complex projects. |

Location

The location of Halls Welding and Fabrication in the United States is a key component of their success. Being located in the United States gives them access to a large and skilled workforce, as well as a well-developed infrastructure. This allows them to provide high-quality products and services to their customers at competitive prices.

In addition, being located in the United States gives Halls Welding and Fabrication access to a wide range of resources. This includes access to raw materials, suppliers, and equipment. This allows them to quickly and easily obtain the materials and resources they need to complete projects for their customers.

The location of Halls Welding and Fabrication in the United States also gives them a competitive advantage in the global marketplace. The United States has a strong reputation for producing high-quality metal products. This reputation gives Halls Welding and Fabrication an advantage over companies that are located in other countries.

Overall, the location of Halls Welding and Fabrication in the United States is a key component of their success. It gives them access to a large and skilled workforce, a well-developed infrastructure, a wide range of resources, and a competitive advantage in the global marketplace.

Table: Benefits of Halls Welding and Fabrication’s Location in the United States

| Benefit | Explanation |

|---|---|

| Access to a large and skilled workforce | The United States has a large and skilled workforce that is experienced in metalworking. |

| Access to a well-developed infrastructure | The United States has a well-developed infrastructure that supports the metalworking industry. |

| Access to a wide range of resources | The United States has a wide range of resources that are essential to the metalworking industry. |

| Competitive advantage in the global marketplace | The United States has a strong reputation for producing high-quality metal products. |

Quality

The commitment to quality at Halls Welding and Fabrication is a cornerstone of their business. It is evident in every aspect of their operations, from the materials they use to the processes they employ. Their dedication to quality ensures that their customers receive products and services that meet the highest standards.

- Materials: Halls Welding and Fabrication uses only the highest quality materials in their products. This includes high-strength steel, stainless steel, and aluminum. These materials are carefully selected for their durability, corrosion resistance, and strength.

- Processes: Halls Welding and Fabrication employs state-of-the-art processes to ensure the quality of their products. This includes using precision welding techniques, CNC machining, and automated quality control systems. These processes help to ensure that their products are accurate, consistent, and reliable.

- Inspection: Halls Welding and Fabrication has a rigorous inspection process in place to ensure that their products meet the highest standards. This process includes visual inspections, dimensional inspections, and non-destructive testing. This helps to ensure that their products are free of defects and meet all customer specifications.

- Customer service: Halls Welding and Fabrication is committed to providing excellent customer service. This includes providing timely and accurate quotes, responding quickly to inquiries, and resolving any issues promptly and efficiently.

The commitment to quality at Halls Welding and Fabrication is evident in everything they do. Their products are built to last and their services are designed to meet the needs of their customers. If you are looking for a metalworking company that you can trust to provide high-quality products and services, then Halls Welding and Fabrication is a great choice.

Customer service

Excellent customer service is a cornerstone of Halls Welding and Fabrication’s business. They understand that their customers are their most important asset, and they are committed to providing them with the best possible experience. This commitment to customer service is evident in every aspect of their business, from the way they answer the phone to the way they follow up after a job is complete.

- Timely and accurate quotes: Halls Welding and Fabrication provides timely and accurate quotes to their customers. They understand that their customers need to be able to budget for their projects, and they want to make sure that they have all the information they need to make an informed decision.

- Responsive to inquiries: Halls Welding and Fabrication is responsive to inquiries from their customers. They know that their customers need to be able to get in touch with them quickly and easily, and they make sure that they are available to answer any questions or concerns that their customers may have.

- Resolve issues promptly and efficiently: Halls Welding and Fabrication resolves issues promptly and efficiently. They understand that their customers need to be able to get their projects completed on time and within budget, and they work hard to make sure that any issues that arise are resolved quickly and efficiently.

Halls Welding and Fabrication’s commitment to customer service is one of the things that sets them apart from other metalworking companies. They understand that their customers are their most important asset, and they are dedicated to providing them with the best possible experience. If you are looking for a metalworking company that you can trust to provide excellent customer service, then Halls Welding and Fabrication is a great choice.

Safety

Safety is a top priority for Halls Welding and Fabrication. They are committed to providing a safe work environment for their employees and customers. They have a comprehensive safety program in place that includes regular safety training, inspections, and audits. They also have a dedicated safety team that is responsible for developing and implementing safety procedures and for investigating accidents and incidents.

- Employee training: Halls Welding and Fabrication provides regular safety training to all of their employees. This training covers a variety of topics, including general safety procedures, specific hazards associated with metalworking, and emergency procedures.

- Regular inspections: Halls Welding and Fabrication conducts regular safety inspections of their facilities and equipment. These inspections help to identify and eliminate potential hazards.

- Safety audits: Halls Welding and Fabrication also conducts regular safety audits. These audits are more comprehensive than inspections and they cover all aspects of their safety program.

- Dedicated safety team: Halls Welding and Fabrication has a dedicated safety team that is responsible for developing and implementing safety procedures. This team also investigates accidents and incidents and makes recommendations for corrective actions.

Halls Welding and Fabrication’s commitment to safety is evident in their safety record. They have a low rate of accidents and injuries. This is a testament to their commitment to providing a safe work environment for their employees and customers.

Innovation

Innovation is a key component of Halls Welding and Fabrication’s success. They are constantly innovating and developing new products and processes to meet the needs of their customers. This commitment to innovation has allowed them to become a leader in the metalworking industry.

- New products: Halls Welding and Fabrication is constantly developing new products to meet the needs of their customers. This includes new types of metal products, as well as new features and improvements to existing products.

- New processes: Halls Welding and Fabrication is also constantly developing new processes to improve the efficiency and quality of their products. This includes new welding techniques, new fabrication techniques, and new quality control processes.

- Research and development: Halls Welding and Fabrication has a dedicated research and development team that is constantly exploring new technologies and developing new products and processes. This team works closely with customers to identify new needs and develop solutions that meet those needs.

- Partnerships: Halls Welding and Fabrication also partners with other companies to develop new products and processes. This allows them to access new technologies and expertise, and to bring new products and processes to market more quickly.

Halls Welding and Fabrication’s commitment to innovation has allowed them to become a leader in the metalworking industry. They are constantly developing new products and processes to meet the needs of their customers. This commitment to innovation will continue to drive their success in the years to come.

Versatility

Halls Welding and Fabrication’s versatility is a key component of their success. They can work with a variety of metals and materials, which allows them to meet the needs of a wide range of customers. This versatility is evident in the diversity of projects that they have completed, from small custom projects to large-scale commercial projects.

- Metals: Halls Welding and Fabrication can work with a variety of metals, including steel, stainless steel, aluminum, and copper. This allows them to meet the specific needs of their customers, depending on the application and environment. For example, they can use stainless steel for projects that require corrosion resistance, or aluminum for projects that require lightweight strength.

- Materials: In addition to metals, Halls Welding and Fabrication can also work with a variety of other materials, such as plastic, wood, and glass. This allows them to create custom projects that incorporate a variety of materials, and to meet the specific needs of their customers. For example, they can use plastic for projects that require electrical insulation, or wood for projects that require a natural aesthetic.

- Custom projects: Halls Welding and Fabrication is able to create custom projects to meet the specific needs of their customers. This versatility is evident in the diversity of projects that they have completed, from small custom projects to large-scale commercial projects. For example, they have created custom metal sculptures, furniture, and architectural elements.

- Commercial projects: Halls Welding and Fabrication also has the experience and expertise to complete large-scale commercial projects. They have worked on a variety of commercial projects, including retail stores, restaurants, and office buildings. For example, they have fabricated and installed metal framing, railings, and signage.

Halls Welding and Fabrication’s versatility is a key component of their success. It allows them to meet the needs of a wide range of customers, from small custom projects to large-scale commercial projects. If you are looking for a metalworking company that can meet your specific needs, then Halls Welding and Fabrication is a great choice.

Customization

Customization is a key component of Halls Welding and Fabrication’s business. They understand that their customers have unique needs, and they are committed to providing them with custom metal products that meet those needs. This commitment to customization is evident in every aspect of their business, from the design process to the fabrication process.

In the design process, Halls Welding and Fabrication works closely with their customers to understand their specific needs. They take the time to listen to their customers’ ideas and to develop a design that meets their requirements. They also provide their customers with a variety of options to choose from, so that they can create a product that is truly unique.

In the fabrication process, Halls Welding and Fabrication uses state-of-the-art equipment and techniques to create custom metal products that are of the highest quality. They take pride in their workmanship, and they are committed to providing their customers with products that are built to last.

The following are some examples of custom metal products that Halls Welding and Fabrication has created for their customers:

- Custom metal sculptures

- Custom metal furniture

- Custom metal architectural elements

- Custom metal railings

- Custom metal signage

These are just a few examples of the many custom metal products that Halls Welding and Fabrication can create. If you have a need for a custom metal product, then Halls Welding and Fabrication is the company for you. They have the experience, the expertise, and the commitment to quality that you need to get the job done right.

| Feature | Benefit |

|---|---|

| Custom design | Halls Welding and Fabrication works closely with their customers to understand their specific needs and to develop a design that meets their requirements. |

| Variety of options | Halls Welding and Fabrication provides their customers with a variety of options to choose from, so that they can create a product that is truly unique. |

| State-of-the-art equipment and techniques | Halls Welding and Fabrication uses state-of-the-art equipment and techniques to create custom metal products that are of the highest quality. |

| Commitment to quality | Halls Welding and Fabrication takes pride in their workmanship, and they are committed to providing their customers with products that are built to last. |

Reliability

In the realm of metalworking, reliability is a virtue that sets exceptional companies apart. Halls Welding and Fabrication stands tall as a beacon of reliability, consistently delivering on its promises and earning the trust of its customers.

- Timely Delivery: Punctuality is a cornerstone of reliability. Halls Welding and Fabrication adheres to strict timelines, ensuring that projects are completed within the agreed-upon timeframe. This unwavering commitment to deadlines minimizes disruptions and fosters a seamless workflow for their clients.

- Quality Workmanship: Reliability extends beyond meeting deadlines. Halls Welding and Fabrication takes immense pride in the quality of its craftsmanship. Their skilled artisans meticulously execute each project, adhering to the highest industry standards. The result is a finished product that not only meets but surpasses expectations, ensuring long-term durability and satisfaction.

- Exceptional Customer Service: Reliability encompasses open communication and responsive support. Halls Welding and Fabrication maintains a dedicated customer service team that promptly addresses inquiries, provides regular project updates, and goes the extra mile to ensure customer satisfaction. Their commitment to transparency and accessibility fosters strong relationships and instills confidence in their clients.

- Financial Stability: Financial stability is a testament to a company’s reliability. Halls Welding and Fabrication operates on a sound financial footing, ensuring that it has the resources to fulfill its commitments. Their financial strength provides peace of mind to customers, who can rest assured that their projects will be executed without interruptions or delays due to financial constraints.

The unwavering reliability of Halls Welding and Fabrication permeates every aspect of their business. By consistently delivering high-quality work, meeting deadlines, providing exceptional customer service, and maintaining financial stability, they have earned a reputation as a trusted and dependable partner in the metalworking industry.

Affordability

In today’s competitive market, affordability is a crucial factor for businesses and consumers alike. Halls Welding and Fabrication recognizes this need and offers competitive pricing on all their products and services, making their exceptional craftsmanship accessible to a wider range of clients.

The affordability of Halls Welding and Fabrication’s services stems from several key factors. Firstly, they leverage economies of scale by streamlining their production processes and utilizing advanced equipment. This efficiency allows them to minimize production costs without compromising quality.

Secondly, Halls Welding and Fabrication maintains strong relationships with suppliers, securing favorable terms on raw materials and components. By reducing procurement costs, they can pass on the savings to their customers.

Furthermore, Halls Welding and Fabrication’s commitment to customer satisfaction extends to their pricing strategy. They understand that affordability is not merely about offering the lowest price but about providing value for money. Their competitive pricing ensures that customers receive a fair return on their investment, fostering long-term partnerships.

The affordability of Halls Welding and Fabrication’s services has significant implications. It enables small businesses and startups to access high-quality metalworking services without breaking the bank. It also allows individuals to pursue their creative projects and home improvement endeavors without exorbitant expenses.

By offering competitive pricing, Halls Welding and Fabrication empowers its customers to realize their metalworking visions without compromising quality or financial constraints.

| Feature | Benefit |

|---|---|

| Economies of scale | Streamlined production processes and advanced equipment minimize production costs. |

| Strong supplier relationships | Favorable terms on raw materials and components reduce procurement costs. |

| Commitment to customer satisfaction | Pricing strategy prioritizes value for money, ensuring fair returns on investment. |

| Empowerment of customers | Competitive pricing enables businesses and individuals to access high-quality metalworking services without financial constraints. |

Frequently Asked Questions

This section addresses common inquiries and misconceptions regarding Halls Welding and Fabrication.

Question 1: What sets Halls Welding and Fabrication apart from other metalworking companies?

Answer: Halls Welding and Fabrication distinguishes itself through its unwavering commitment to quality, innovation, and customer satisfaction. With over 20 years of experience and a team of highly skilled artisans, they consistently deliver exceptional craftsmanship and tailored solutions to meet specific project requirements.

Question 2: How does Halls Welding and Fabrication ensure the quality of its products?

Answer: Halls Welding and Fabrication adheres to rigorous quality control measures throughout the production process. They utilize state-of-the-art equipment, employ skilled artisans, and implement a comprehensive inspection system to guarantee that every product meets the highest standards of precision, durability, and aesthetic appeal.

Question 3: Can Halls Welding and Fabrication handle complex or customized projects?

Answer: Yes, Halls Welding and Fabrication excels in tackling complex and customized projects. Their team of experienced engineers and designers collaborates closely with clients to understand their unique requirements and develop innovative solutions. They possess the expertise and capabilities to bring even the most challenging concepts to life.

Question 4: What materials does Halls Welding and Fabrication work with?

Answer: Halls Welding and Fabrication has extensive experience working with a wide range of metals, including steel, stainless steel, aluminum, and copper. They also possess the capability to incorporate other materials, such as plastic, wood, and glass, into their designs, providing clients with versatile and aesthetically pleasing solutions.

Question 5: How does Halls Welding and Fabrication ensure timely project delivery?

Answer: Halls Welding and Fabrication understands the importance of adhering to project deadlines. They employ efficient production processes, maintain open communication with clients, and allocate dedicated resources to each project. This commitment to timely delivery ensures that projects are completed within the agreed-upon timeframe, minimizing disruptions and maximizing client satisfaction.

Question 6: What are the pricing considerations for Halls Welding and Fabrication’s services?

Answer: Halls Welding and Fabrication offers competitive pricing while maintaining the highest standards of quality. They provide transparent cost breakdowns, work closely with clients to optimize project budgets, and explore cost-effective solutions without compromising the integrity of the final product.

In summary, Halls Welding and Fabrication stands out as a trusted and reliable partner for metalworking projects of all complexities. Their commitment to quality, innovation, and customer satisfaction, combined with their competitive pricing and ability to handle customized projects, makes them an ideal choice for businesses and individuals seeking exceptional craftsmanship and reliable service.

Transition to the next article section:

Explore the diverse range of services offered by Halls Welding and Fabrication, including design, fabrication, and installation, to meet your specific metalworking needs.

Tips from Halls Welding and Fabrication

Halls Welding and Fabrication, renowned for their expertise in metalworking, offers valuable tips to enhance your understanding and decision-making regarding metalworking projects.

Tip 1: Define Your Project Objectives Clearly

Before embarking on a metalworking project, clearly define your goals and requirements. Determine the intended purpose, desired aesthetics, and any specific functional specifications. This clarity will serve as a foundation for effective communication with the metalworking company and ensure that the final product aligns with your vision.

Tip 2: Choose the Right Metal for Your Project

The choice of metal is crucial for the success of your project. Consider factors such as strength, durability, corrosion resistance, and cost. Halls Welding and Fabrication offers a wide range of metals, including steel, stainless steel, aluminum, and copper, and can guide you in selecting the optimal material for your specific application.

Tip 3: Seek Professional Advice and Expertise

Partnering with an experienced metalworking company like Halls Welding and Fabrication provides access to their expertise and insights. They can advise on design, material selection, and fabrication techniques to ensure the best possible outcome for your project.

Tip 4: Consider Long-Term Maintenance and Durability

When selecting materials and designing your metalwork, think about long-term maintenance and durability. Factors such as exposure to elements, frequency of use, and potential wear and tear should be taken into account. Halls Welding and Fabrication can provide guidance on appropriate protective measures and maintenance practices to ensure the longevity of your metalwork.

Tip 5: Explore Innovative Design Solutions

Don’t limit yourself to traditional designs. Halls Welding and Fabrication encourages exploring innovative design solutions that combine functionality with aesthetics. Their team of experienced designers can collaborate with you to create unique and eye-catching metalwork that sets your project apart.

Key Takeaways:

- Clearly define project objectives for effective communication.

- Choose the right metal based on strength, durability, and cost.

- Seek professional advice to leverage expertise and insights.

- Consider long-term maintenance and durability for lasting value.

- Explore innovative design solutions to enhance functionality and aesthetics.

By following these tips from Halls Welding and Fabrication, you can make informed decisions, optimize your metalworking project, and achieve exceptional results that meet your specific requirements.

Conclusion

Halls Welding and Fabrication has emerged as a trusted provider of exceptional metalworking services, consistently exceeding customer expectations with their unwavering commitment to quality, innovation, and customer satisfaction. Their expertise spans a comprehensive range of services, from design and fabrication to installation, ensuring that clients receive end-to-end solutions tailored to their unique requirements.

As we look to the future, Halls Welding and Fabrication remains dedicated to pushing the boundaries of metalworking, embracing technological advancements and sustainable practices to deliver cutting-edge solutions that meet the evolving needs of their clients. Their unwavering commitment to excellence positions them as a valued partner for businesses and individuals seeking