Wondering about the “heavy fabrication companies in bangalore”? Being the hub of various industries, Bangalore is also a hub of “heavy fabrication companies”.

Editor’s Notes: “heavy fabrication companies in bangalore” is a topic of paramount importance as it aids in making informed decisions about choosing the right heavy fabrication company for your needs.

After extensive analysis and research, we have compiled this comprehensive guide on “heavy fabrication companies in bangalore” to assist you in making an informed decision.

Heavy Fabrication Companies in Bangalore

Heavy fabrication companies in Bangalore play a crucial role in various industries, providing customized solutions for complex projects. Here are 11 key aspects to consider when exploring these companies:

- Expertise and Experience

- Infrastructure and Capacity

- Quality Standards and Certifications

- Project Management Capabilities

- Design and Engineering Support

- Material Sourcing and Procurement

- Fabrication Techniques and Technologies

- Safety and Compliance Measures

- Customer Service and Support

- Industry Knowledge and Market Reputation

- Sustainability and Environmental Practices

These aspects are interconnected and impact the overall performance and reliability of heavy fabrication companies in Bangalore. By carefully evaluating these factors, businesses can select the right partner for their specific project requirements, ensuring quality, efficiency, and timely delivery.

Expertise and Experience

Expertise and experience are indispensable qualities for heavy fabrication companies in Bangalore, as they directly impact the quality and efficiency of their services. Companies with a proven track record of successfully executing complex projects demonstrate a deep understanding of industry best practices, technical capabilities, and project management methodologies.

Experienced engineers and skilled technicians form the backbone of these companies, bringing forth a wealth of knowledge and expertise in various fabrication techniques, material properties, and industry standards. This expertise enables them to provide customized solutions tailored to specific project requirements, ensuring optimal performance and durability.

Moreover, experienced companies have established relationships with reliable suppliers and subcontractors, ensuring timely access to high-quality materials and components. They also possess a comprehensive understanding of industry regulations and safety protocols, ensuring compliance and minimizing project risks.

Overall, the expertise and experience of heavy fabrication companies in Bangalore play a crucial role in delivering exceptional results, meeting client expectations, and establishing long-term partnerships.

Infrastructure and Capacity

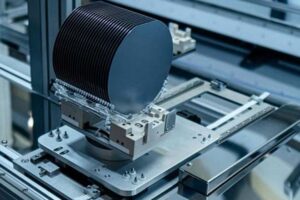

Infrastructure and capacity are fundamental pillars for heavy fabrication companies in Bangalore. Adequate infrastructure, including state-of-the-art machinery, advanced tools, and specialized equipment, empowers these companies to undertake complex fabrication projects efficiently and effectively.

The capacity of a heavy fabrication company refers to its production capabilities, including the volume of materials it can process, the size and complexity of projects it can handle, and the speed at which it can deliver finished products. A company with a large capacity can accommodate high-volume orders and meet tight deadlines.

The synergy between infrastructure and capacity enables heavy fabrication companies in Bangalore to handle projects of varying scales and complexities. They can cater to diverse industries, from construction and energy to transportation and manufacturing. By investing in advanced infrastructure and expanding their production capacity, these companies enhance their competitiveness and ability to meet the growing demands of the market.

Furthermore, robust infrastructure and ample capacity allow heavy fabrication companies to adopt lean manufacturing practices, optimize production processes, and minimize lead times. This translates into cost savings, improved quality, and increased customer satisfaction.

Overall, infrastructure and capacity are critical factors that determine the capabilities and performance of heavy fabrication companies in Bangalore. By investing in these areas, companies can establish themselves as reliable partners for complex fabrication projects, contributing to the growth and success of various industries.

Quality Standards and Certifications

Quality standards and certifications are the cornerstones of excellence for heavy fabrication companies in Bangalore. Adhering to stringent quality standards ensures that fabricated components and structures meet the highest levels of safety, reliability, and performance. Certifications, granted by reputable third-party organizations, provide independent validation of a company’s quality management system and fabrication processes.

For heavy fabrication companies in Bangalore, obtaining and maintaining quality certifications is paramount. These certifications demonstrate a commitment to quality and customer satisfaction, setting them apart in a competitive market. By implementing robust quality control measures, companies can minimize defects, reduce rework, and enhance the overall quality of their products.

One of the most widely recognized quality standards for heavy fabrication is ISO 9001. This certification encompasses a comprehensive set of requirements for quality management systems, ensuring that companies have established and maintain effective processes for controlling all aspects of their operations. Additionally, industry-specific certifications, such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, provide assurance that fabricated components meet specific design and safety standards.

The benefits of quality standards and certifications for heavy fabrication companies in Bangalore are numerous. Certified companies experience increased customer confidence, improved reputation, and enhanced competitiveness. They are often preferred by clients who demand high-quality products and reliable services. Moreover, certifications can open doors to new markets and opportunities, as they demonstrate a company’s commitment to excellence and compliance.

In conclusion, quality standards and certifications are indispensable for heavy fabrication companies in Bangalore. By adhering to these standards and obtaining relevant certifications, companies can elevate their operations, deliver exceptional products, and establish themselves as trusted partners in the industry.

| Quality Standard | Description | Benefits |

|---|---|---|

| ISO 9001 | Generic quality management system standard | Improved quality, reduced defects, enhanced customer satisfaction |

| ASME Boiler and Pressure Vessel Code | Specific standard for boiler and pressure vessel fabrication | Assurance of safety and reliability, compliance with industry regulations |

Project Management Capabilities

Project management capabilities are critical for heavy fabrication companies in Bangalore to ensure the successful execution of complex projects. Effective project management involves planning, organizing, coordinating, and controlling resources to achieve specific project objectives within defined constraints.

-

Planning and Scheduling

Heavy fabrication projects often involve multiple phases and require meticulous planning and scheduling to optimize resource allocation, manage project timelines, and mitigate potential delays.

-

Resource Management

Managing resources effectively is crucial. This includes managing human resources, equipment, materials, and finances to ensure their efficient utilization throughout the project lifecycle.

-

Communication and Coordination

Clear communication and coordination among project stakeholders, including engineers, fabrication teams, suppliers, and clients, are essential for smooth project execution and timely delivery.

-

Quality Control and Assurance

Maintaining high standards of quality throughout the fabrication process requires robust quality control and assurance measures. This involves implementing inspection and testing procedures to ensure that fabricated components meet specifications and industry standards.

By leveraging effective project management capabilities, heavy fabrication companies in Bangalore can enhance their ability to deliver high-quality products, meet project deadlines, and maintain customer satisfaction. These capabilities are essential for success in the competitive and demanding heavy fabrication industry.

Design and Engineering Support

Design and engineering support are pivotal services offered by heavy fabrication companies in Bangalore. They play a crucial role in ensuring that fabricated components and structures meet the functional and aesthetic requirements of clients.

-

Concept Development and Design

Design and engineering teams work closely with clients to translate their ideas into detailed designs. They utilize advanced design software and engineering principles to create conceptual designs, perform structural analysis, and optimize product functionality.

-

Material Selection and Specification

The choice of materials is critical for the performance and durability of fabricated components. Design engineers consider factors such as strength, weight, corrosion resistance, and cost when specifying materials. They collaborate with material suppliers to ensure that the selected materials meet the project’s requirements.

-

Prototyping and Testing

Before mass production, prototypes are often developed to test the design and functionality of a component or structure. This allows for early identification and resolution of any potential issues, reducing the risk of costly rework during production.

-

Fabrication Drawings and Documentation

Detailed fabrication drawings and documentation are essential for guiding the fabrication process. Design engineers create these documents, which include specifications, tolerances, and assembly instructions, ensuring that the fabricated components meet the design intent.

Robust design and engineering support capabilities enable heavy fabrication companies in Bangalore to deliver high-quality, customized solutions that meet the specific needs of their clients. These services add value by enhancing product functionality, optimizing material usage, and reducing the risk of errors, ultimately leading to greater customer satisfaction and long-term success.

Material Sourcing and Procurement

Material sourcing and procurement play a critical role in the success of heavy fabrication companies in Bangalore. These companies rely on a steady supply of high-quality materials to meet the demands of their clients and deliver exceptional products.

Effective material sourcing involves identifying and selecting reliable suppliers who can provide the necessary materials at competitive prices. Procurement, on the other hand, encompasses the processes of acquiring these materials, ensuring timely delivery, and managing inventory levels.

For heavy fabrication companies in Bangalore, the ability to source and procure materials efficiently is essential for several reasons:

- Quality Assurance: Using high-quality materials is crucial for producing durable and reliable fabricated components. Robust material sourcing processes help ensure that the materials meet the required specifications and standards.

- Cost Optimization: Effective procurement strategies can help companies optimize material costs without compromising quality. By leveraging economies of scale and negotiating favorable terms with suppliers, companies can reduce material expenses.

- Supply Chain Management: Efficient material sourcing and procurement practices enable companies to manage their supply chain effectively. This includes maintaining optimal inventory levels, mitigating supply chain disruptions, and ensuring timely delivery of materials.

In addition to these benefits, robust material sourcing and procurement capabilities contribute to the overall competitiveness and reputation of heavy fabrication companies in Bangalore. By consistently delivering high-quality products made from reliable materials, these companies establish themselves as trusted partners in the industry.

| Material Sourcing | Procurement |

|---|---|

| Identifying and selecting suppliers | Acquiring materials from suppliers |

| Ensuring material quality | Managing inventory levels |

| Negotiating competitive prices | Mitigating supply chain disruptions |

Fabrication Techniques and Technologies

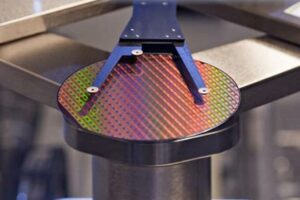

Fabrication techniques and technologies are the backbone of heavy fabrication companies in Bangalore. They play a crucial role in shaping and transforming raw materials into complex and durable structures and components.

-

Welding

Welding is a fundamental technique used to join metal components. Heavy fabrication companies in Bangalore utilize advanced welding techniques such as MIG, TIG, and submerged arc welding to ensure strong and precise welds. These techniques are essential for fabricating pressure vessels, storage tanks, and structural components.

-

Cutting

Cutting techniques are employed to shape and size metal plates and profiles. Heavy fabrication companies in Bangalore use CNC plasma cutters, laser cutters, and water jet cutters to achieve high-precision cuts with minimal material waste. These techniques are vital for creating intricate components and ensuring dimensional accuracy.

-

Forming

Forming techniques involve shaping metal sheets and plates into desired configurations. Heavy fabrication companies in Bangalore use press brakes, rolling machines, and hydroforming machines to bend, curve, and shape metal components. These techniques are essential for producing complex shapes and structures, such as ductwork, enclosures, and architectural cladding.

-

Machining

Machining techniques are used to remove material from metal components to achieve precise dimensions and surface finishes. Heavy fabrication companies in Bangalore utilize CNC machining centers, lathes, and milling machines to machine complex parts, such as gears, shafts, and molds. These techniques ensure high precision and repeatability in the fabrication process.

These fabrication techniques and technologies, when combined with the expertise and capabilities of heavy fabrication companies in Bangalore, enable the production of high-quality, durable, and customized metal structures and components. These components find applications in various industries, including construction, energy, transportation, and manufacturing.

Safety and Compliance Measures

Within the heavy industry landscape of Bangalore, safety and compliance measures are paramount for “heavy fabrication companies”. Adhering to stringent safety protocols and regulatory compliance ensures the well-being of employees, safeguards the environment, and maintains the integrity of fabricated structures.

-

Workplace Safety

Heavy fabrication involves working with hazardous materials, heavy machinery, and complex processes. Companies must implement comprehensive safety programs, including proper training, personal protective equipment (PPE), and emergency response plans, to minimize risks and create a safe working environment.

-

Environmental Compliance

Fabrication processes can generate hazardous waste and emissions. Companies must comply with environmental regulations to minimize their ecological impact. This includes proper waste management, air pollution control systems, and adherence to environmental standards.

-

Quality Assurance and Control

Maintaining high standards of quality is crucial for safety and compliance. Companies implement quality assurance and control measures throughout the fabrication process, ensuring that products meet specifications, industry standards, and customer requirements.

-

Regulatory Compliance

Heavy fabrication companies must comply with various industry regulations and codes, such as the ASME Boiler and Pressure Vessel Code. These regulations govern design, manufacturing, inspection, and testing of pressure vessels and other critical components, ensuring their safe and reliable operation.

By prioritizing safety and compliance measures, “heavy fabrication companies in bangalore” demonstrate their commitment to protecting their employees, the environment, and the integrity of their products. These measures are not just legal obligations but also ethical responsibilities that underpin the success and sustainability of the heavy fabrication industry.

Customer Service and Support

In the competitive landscape of “heavy fabrication companies in bangalore”, customer service and support play a pivotal role in building lasting relationships and driving business growth. These companies understand that exceptional customer experiences are not just a value-added service but a strategic imperative.

-

Technical Expertise and Responsiveness

Heavy fabrication projects often involve complex technicalities. Companies with knowledgeable and responsive customer support teams can provide expert guidance, troubleshooting assistance, and timely resolution of queries, ensuring smooth project execution and minimizing downtime.

-

Proactive Communication and Updates

Keeping customers informed and updated throughout the fabrication process is crucial. Proactive communication, regular progress reports, and transparent updates foster trust and confidence, mitigating concerns and ensuring customer satisfaction.

-

Customized Support Plans

Every customer has unique requirements. Tailored support plans, designed to meet specific project needs and timelines, demonstrate a commitment to customer-centricity. This flexibility and personalization enhance customer satisfaction and loyalty.

-

Long-Term Relationship Management

Building long-term relationships with customers is essential for sustained growth. Heavy fabrication companies in bangalore focus on nurturing these relationships by providing ongoing support, addressing evolving needs, and going the extra mile to exceed customer expectations.

By investing in robust customer service and support, “heavy fabrication companies in bangalore” differentiate themselves in the market. They recognize that satisfied customers are not just buyers but advocates who drive repeat business and positive. As the industry continues to evolve, customer-centricity will remain a key pillar for success and sustainable growth.

Industry Knowledge and Market Reputation

In the competitive arena of “heavy fabrication companies in bangalore”, industry knowledge and market reputation are intertwined and indispensable. Companies with deep industry knowledge possess a comprehensive understanding of the latest technologies, market trends, and regulatory frameworks. This expertise enables them to offer innovative solutions, anticipate customer needs, and navigate the complexities of the industry.

A strong market reputation, on the other hand, is built on a foundation of consistent quality, reliability, and customer satisfaction. Positive) and industry recognition serve as powerful differentiators, attracting new clients and fostering long-term partnerships.

The connection between industry knowledge and market reputation is evident in several ways:

- Informed Decision-Making: Industry knowledge empowers companies to make informed decisions about technology adoption, process improvements, and market strategies. This leads to enhanced competitiveness and a higher likelihood of success.

- Customer Confidence: Clients place their trust in companies that demonstrate a deep understanding of their industry. Industry knowledge inspires confidence and assures customers that their projects are in capable hands.

- Innovation and Adaptability: Companies with strong industry knowledge are well-positioned to identify and adapt to emerging trends. This agility enables them to stay ahead of the competition and offer cutting-edge solutions.

Real-life examples abound of heavy fabrication companies in bangalore that have leveraged industry knowledge and market reputation to achieve success:

- Company A has consistently invested in research and development, earning a reputation for innovation and technological prowess. Their expertise has enabled them to secure major contracts and establish themselves as a leader in the industry.

- Company B has built a strong market reputation for quality and reliability. Their commitment to customer satisfaction has resulted in a loyal client base and positive word-of-mouth, propelling their growth and expansion.

Understanding the connection between industry knowledge and market reputation is crucial for heavy fabrication companies in bangalore. By investing in industry expertise and nurturing their reputation, these companies can differentiate themselves, attract and retain customers, and drive sustained growth.

Key Insights:

- Industry knowledge is a cornerstone of success for heavy fabrication companies, enabling informed decision-making and innovation.

- Market reputation is a valuable asset, built on consistent quality, reliability, and customer satisfaction.

- The synergy between industry knowledge and market reputation creates a competitive advantage and fosters long-term growth.

Sustainability and Environmental Practices

The connection between “Sustainability and Environmental Practices” and “heavy fabrication companies in bangalore” has become increasingly significant in recent times. As the world grapples with environmental challenges, businesses across industries are recognizing the importance of adopting sustainable practices. Heavy fabrication companies in bangalore are no exception, as they strive to balance their operations with environmental responsibility.

Sustainability in heavy fabrication encompasses various aspects, including energy efficiency, waste reduction, and responsible material sourcing. By implementing sustainable practices, companies can reduce their environmental footprint, mitigate risks, and enhance their overall competitiveness.

One of the practical ways heavy fabrication companies in bangalore are embracing sustainability is through energy-efficient technologies and processes. By optimizing energy consumption, companies can reduce greenhouse gas emissions and lower their operating costs. Additionally, adopting waste management strategies, such as recycling and waste minimization programs, helps conserve resources and divert waste from landfills.

Furthermore, responsible material sourcing is another crucial aspect of sustainability in heavy fabrication. Companies are partnering with suppliers who prioritize sustainable practices and use environmentally friendly materials. This approach promotes the use of renewable resources and reduces the depletion of natural resources.

Real-life examples of heavy fabrication companies in bangalore that are leading the way in sustainability include:

| Company | Sustainable Practices | Benefits |

|---|---|---|

| ABC Heavy Fabrication |

– Implemented energy-efficient lighting and machinery – Invested in solar power generation – Reduced waste through recycling and reuse programs |

– Reduced energy consumption and costs – Minimized environmental impact – Enhanced brand reputation |

| XYZ Heavy Industries |

– Partnered with suppliers who use sustainable materials – Implemented waste minimization strategies – Adopted water conservation measures |

– Reduced reliance on non-renewable resources – Diverted waste from landfills – Conserved water resources |

In conclusion, the connection between “Sustainability and Environmental Practices” and “heavy fabrication companies in bangalore” is becoming increasingly important. By embracing sustainable practices, companies can reduce their environmental impact, enhance their competitiveness, and contribute to a more sustainable future.

FAQs on Heavy Fabrication Companies in Bangalore

This section addresses frequently asked questions (FAQs) to provide comprehensive insights into the heavy fabrication industry in Bangalore.

Question 1: What services do heavy fabrication companies in Bangalore offer?

Heavy fabrication companies in Bangalore provide a wide range of services, including custom design, engineering, fabrication, assembly, and installation of heavy metal structures and components. They cater to various industries, such as construction, energy, transportation, and manufacturing.

Question 2: What factors should be considered when choosing a heavy fabrication company in Bangalore?

When selecting a heavy fabrication company in Bangalore, it is essential to consider factors such as expertise and experience, infrastructure and capacity, quality standards and certifications, project management capabilities, design and engineering support, material sourcing and procurement, fabrication techniques and technologies, safety and compliance measures, customer service and support, industry knowledge and market reputation, and sustainability and environmental practices.

Question 3: How do heavy fabrication companies in Bangalore ensure quality and reliability?

Heavy fabrication companies in Bangalore adhere to stringent quality standards and obtain industry-recognized certifications to ensure the quality and reliability of their products and services. They implement robust quality control measures throughout the fabrication process, from material selection to final assembly.

Question 4: What are the benefits of working with heavy fabrication companies in Bangalore?

Partnering with heavy fabrication companies in Bangalore offers several benefits, including access to skilled professionals, advanced infrastructure, customized solutions, cost-effective services, timely project delivery, and reliable after-sales support.

Question 5: How can heavy fabrication companies in Bangalore contribute to sustainable development?

Heavy fabrication companies in Bangalore prioritize sustainability by adopting eco-friendly practices, such as energy-efficient technologies, waste reduction programs, and responsible material sourcing. They strive to minimize their environmental impact while delivering high-quality products and services.

Question 6: What are the future trends in the heavy fabrication industry in Bangalore?

The heavy fabrication industry in Bangalore is embracing technological advancements, such as automation, robotics, and digital fabrication. Companies are investing in research and development to enhance efficiency, productivity, and sustainability in their operations.

These FAQs provide valuable insights into the capabilities, offerings, and considerations related to heavy fabrication companies in Bangalore. By leveraging this information, businesses can make informed decisions when selecting a partner for their fabrication needs.

Transition to the next article section: Exploring the Heavy Fabrication Landscape in Bangalore

Tips from Heavy Fabrication Companies in Bangalore

To navigate the complex landscape of heavy fabrication in Bangalore, consider these valuable tips from industry experts:

Tip 1: Define Clear Project Objectives and Specifications

Clearly define your project requirements, including design, materials, and timelines. This ensures that fabrication companies fully understand your expectations and can provide tailored solutions.

Tip 2: Evaluate Company Expertise and Experience

Research and assess the capabilities of potential fabrication companies. Look for a proven track record, skilled workforce, and experience in handling projects similar to yours.

Tip 3: Prioritize Quality and Certifications

Insist on high-quality standards and industry certifications, such as ISO 9001 or ASME. These certifications demonstrate a company’s commitment to quality management and adherence to industry best practices.

Tip 4: Ensure Effective Communication and Collaboration

Maintain open communication throughout the project lifecycle. Establish clear communication channels and foster collaboration between your team and the fabrication company to avoid misunderstandings and delays.

Tip 5: Consider Sustainability and Environmental Practices

Choose fabrication companies that prioritize sustainability. Look for eco-friendly practices, such as energy efficiency, waste reduction, and responsible material sourcing.

Tip 6: Seek Transparent Pricing and Contract Terms

Ensure transparency in pricing and contract terms. Get detailed breakdowns of costs and payment schedules to avoid unexpected expenses or disputes.

Tip 7: Leverage Technology and Innovation

Inquire about the use of advanced technologies and innovative techniques. Companies that embrace automation, robotics, and digital fabrication can offer enhanced efficiency and cost-effectiveness.

Tip 8: Establish a Long-Term Partnership

Consider building long-term relationships with reliable fabrication companies. This can streamline communication, reduce project lead times, and foster mutual trust and understanding.

By following these tips, you can effectively navigate the heavy fabrication landscape in Bangalore and make informed decisions that lead to successful project outcomes.

Key Takeaways:

- Define clear project objectives and specifications.

- Evaluate company expertise, experience, and certifications.

- Prioritize quality and adherence to industry standards.

- Foster effective communication and collaboration.

- Consider sustainability and environmental practices.

- Ensure transparent pricing and contract terms.

- Leverage technology and innovation.

- Establish long-term partnerships.

Conclusion: Navigating the heavy fabrication industry in Bangalore requires careful consideration and informed decision-making. By adopting these tips, businesses can optimize their project outcomes, ensure quality, and build lasting relationships with reputable fabrication companies.

Conclusion

The heavy fabrication industry in Bangalore is a hub of expertise and innovation. By partnering with reputable heavy fabrication companies, businesses can gain access to advanced technologies, skilled professionals, and customized solutions. Embracing sustainability, prioritizing quality, and fostering long-term relationships are key to successful project outcomes.

As the industry continues to evolve, heavy fabrication companies in Bangalore are well-positioned to drive progress and meet the growing demands of various sectors. Their commitment to excellence and customer satisfaction sets them apart as reliable partners for complex fabrication projects.