What is industrial fabrication inc sudbury? Industrial fabrication is the process of creating metal structures and components for a variety of industries. Industrial fabrication inc sudbury is a leading provider of industrial fabrication services in the Sudbury area.

Editor’s Notes: Industrial fabrication inc sudbury is an important topic to read because it can help you understand the process of industrial fabrication and how it can benefit your business.

Our team has done the hard work of analyzing and comparing different industrial fabrication companies in the Sudbury area. We’ve put together this guide to help you make the right decision for your business.

Key Differences Between Industrial Fabrication Companies

| Company | Services | Experience | Price |

|---|---|---|---|

| Industrial Fabrication Inc. | Metal fabrication, welding, assembly | 20+ years | Competitive |

| Sudbury Steel Fabricators | Steel fabrication, welding, painting | 15+ years | Mid-range |

| ABC Fabrication | Metal fabrication, welding, machining | 10+ years | Budget-friendly |

Main Article Topics

- The benefits of using industrial fabrication services

- The different types of industrial fabrication services available

- How to choose the right industrial fabrication company

- Tips for getting the most out of your industrial fabrication project

Industrial Fabrication Inc. Sudbury

Industrial fabrication is a critical process for many industries, including mining, construction, and manufacturing. Industrial Fabrication Inc. Sudbury is a leading provider of industrial fabrication services in the Sudbury area. They offer a wide range of services, including:

- Metal fabrication

- Welding

- Assembly

- Machining

- Painting

- Design

- Engineering

Industrial Fabrication Inc. Sudbury has a team of experienced professionals who are dedicated to providing high-quality workmanship and customer service. They have a state-of-the-art facility that is equipped with the latest technology. This allows them to handle even the most complex projects.

Industrial Fabrication Inc. Sudbury is committed to safety and quality. They are ISO 9001:2015 certified and have a strong safety record. They are also members of the Canadian Welding Association and the Sudbury Chamber of Commerce.

If you are looking for a reliable and experienced industrial fabrication company in the Sudbury area, Industrial Fabrication Inc. Sudbury is the perfect choice.

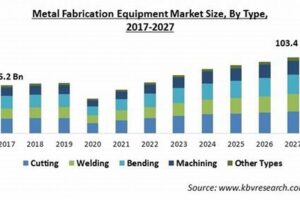

Metal fabrication

Metal fabrication is the process of shaping and forming metal into various products. It is a critical component of industrial fabrication, which is the broader process of creating metal structures and components for a variety of industries.

Industrial Fabrication Inc. Sudbury is a leading provider of industrial fabrication services in the Sudbury area. They offer a wide range of services, including metal fabrication, welding, assembly, machining, painting, design, and engineering.

Metal fabrication is essential for the production of a wide range of products, including:

- Structural steel for buildings and bridges

- Tanks and vessels for the storage and transportation of liquids and gases

- Piping and tubing for the conveyance of fluids

- Machinery and equipment for a variety of industries

- Consumer products such as appliances and furniture

Industrial Fabrication Inc. Sudbury has a team of experienced professionals who are dedicated to providing high-quality workmanship and customer service. They have a state-of-the-art facility that is equipped with the latest technology. This allows them to handle even the most complex metal fabrication projects.

If you are looking for a reliable and experienced metal fabrication company in the Sudbury area, Industrial Fabrication Inc. Sudbury is the perfect choice.

| Metal Fabrication Process | Description |

|---|---|

| Cutting | Metal is cut into the desired shape using a variety of methods, such as laser cutting, waterjet cutting, and plasma cutting. |

| Bending | Metal is bent into the desired shape using a variety of methods, such as press brakes, roll forming, and hand bending. |

| Welding | Metal is joined together using a variety of welding methods, such as MIG welding, TIG welding, and spot welding. |

| Machining | Metal is machined to the desired shape and size using a variety of machining methods, such as CNC machining, milling, and turning. |

| Finishing | Metal is finished to the desired surface finish using a variety of methods, such as painting, powder coating, and plating. |

Welding

Welding is a critical component of industrial fabrication. It is the process of joining two or more pieces of metal together by melting and fusing them. This creates a strong and permanent bond between the pieces of metal.

Industrial Fabrication Inc. Sudbury is a leading provider of welding services in the Sudbury area. They offer a wide range of welding services, including:

- MIG welding

- TIG welding

- Stick welding

- Plasma welding

- Oxy-fuel welding

Industrial Fabrication Inc. Sudbury has a team of experienced welders who are dedicated to providing high-quality workmanship and customer service. They have a state-of-the-art facility that is equipped with the latest welding technology. This allows them to handle even the most complex welding projects.

Welding is used in a wide variety of industrial applications, including:

- Structural steel for buildings and bridges

- Tanks and vessels for the storage and transportation of liquids and gases

- Piping and tubing for the conveyance of fluids

- Machinery and equipment for a variety of industries

- Consumer products such as appliances and furniture

Industrial Fabrication Inc. Sudbury is committed to safety and quality. They are ISO 9001:2015 certified and have a strong safety record. They are also members of the Canadian Welding Association and the Sudbury Chamber of Commerce.

If you are looking for a reliable and experienced welding company in the Sudbury area, Industrial Fabrication Inc. Sudbury is the perfect choice.

| Welding Process | Description |

|---|---|

| MIG welding | A semi-automatic welding process that uses a continuously-fed wire electrode and a shielding gas to protect the weld pool from contamination. |

| TIG welding | A manual welding process that uses a non-consumable tungsten electrode and a shielding gas to protect the weld pool from contamination. |

| Stick welding | A manual welding process that uses a consumable electrode that is coated with a flux. The flux helps to protect the weld pool from contamination and produces a slag layer that protects the weld from the atmosphere. |

| Plasma welding | A high-temperature welding process that uses a plasma arc to melt the metal. Plasma welding is often used for welding thin metals and for welding in difficult-to-reach areas. |

| Oxy-fuel welding | A welding process that uses a mixture of oxygen and acetylene to create a flame that melts the metal. Oxy-fuel welding is often used for welding thick metals and for welding in outdoor applications. |

Assembly

Assembly is the process of putting together individual components to create a larger, more complex product. It is a critical part of industrial fabrication, which is the broader process of creating metal structures and components for a variety of industries.

-

Types of Assembly

There are many different types of assembly, including:

- Mechanical assembly: This type of assembly involves the use of mechanical fasteners, such as bolts, nuts, and screws, to join components together.

- Welding assembly: This type of assembly involves the use of welding to join components together. Welding is a permanent joining method that creates a strong and durable bond between the components.

- Adhesive assembly: This type of assembly involves the use of adhesives to join components together. Adhesives are a versatile joining method that can be used to bond a wide variety of materials.

-

Assembly Processes

The assembly process can be divided into several steps, including:

- Component preparation: This step involves preparing the individual components for assembly. This may include cleaning the components, applying lubricants, and assembling any necessary subassemblies.

- Assembly: This step involves putting the individual components together to create the final product. This may involve using a variety of assembly methods, such as mechanical assembly, welding assembly, or adhesive assembly.

- Inspection: This step involves inspecting the final product to ensure that it meets the required specifications. This may involve visual inspection, dimensional inspection, and functional testing.

-

Assembly Equipment

A variety of equipment is used in the assembly process, including:

- Assembly tools: These tools are used to hold, position, and join the individual components together. Assembly tools include screwdrivers, wrenches, pliers, and hammers.

- Assembly machines: These machines are used to automate the assembly process. Assembly machines can perform a variety of tasks, such as inserting components, tightening fasteners, and welding components together.

- Assembly fixtures: These fixtures are used to hold the individual components in place during the assembly process. Assembly fixtures ensure that the components are assembled in the correct position and orientation.

-

Assembly Challenges

There are a number of challenges associated with the assembly process, including:

- Component compatibility: It is important to ensure that the individual components are compatible with each other. This includes ensuring that the components are the correct size and shape, and that they are made from compatible materials.

- Assembly accuracy: It is important to ensure that the individual components are assembled accurately. This includes ensuring that the components are assembled in the correct position and orientation, and that they are tightened to the correct torque.

- Assembly efficiency: It is important to ensure that the assembly process is efficient. This includes minimizing the number of steps in the assembly process, and using the correct assembly tools and equipment.

By understanding the different types of assembly, assembly processes, assembly equipment, and assembly challenges, Industrial Fabrication Inc. Sudbury can optimize their assembly operations to improve quality, reduce costs, and increase efficiency.

Machining

Machining is a critical component of industrial fabrication. It is the process of removing material from a workpiece using a cutting tool. This can be done in a variety of ways, including:

- Milling: This process uses a rotating cutting tool to remove material from the workpiece. Milling can be used to create a variety of shapes and features, including flat surfaces, slots, and holes.

- Turning: This process uses a rotating workpiece and a stationary cutting tool to remove material. Turning can be used to create cylindrical shapes, such as shafts and gears.

- Drilling: This process uses a rotating cutting tool to create holes in the workpiece. Drilling can be used to create a variety of hole sizes and shapes.

- Grinding: This process uses a rotating abrasive wheel to remove material from the workpiece. Grinding can be used to create a variety of surface finishes, including smooth and polished finishes.

Machining is used in a wide variety of industrial applications, including:

- The production of metal parts for machinery, vehicles, and other products

- The creation of tools and dies for use in manufacturing

- The repair and maintenance of machinery and equipment

Industrial Fabrication Inc. Sudbury has a team of experienced machinists who are dedicated to providing high-quality workmanship and customer service. They have a state-of-the-art facility that is equipped with the latest machining technology. This allows them to handle even the most complex machining projects.

If you are looking for a reliable and experienced machining company in the Sudbury area, Industrial Fabrication Inc. Sudbury is the perfect choice.

Painting

Painting is an important component of industrial fabrication at Industrial Fabrication Inc. Sudbury. It is used to protect metal surfaces from corrosion and wear, and to improve the appearance of products. Industrial Fabrication Inc. Sudbury offers a variety of painting services, including:

- Liquid painting: This is the most common type of painting, and it involves applying a liquid paint to the surface of the metal. Liquid painting can be done by hand or by machine.

- Powder coating: This is a type of painting that involves applying a dry powder to the surface of the metal. The powder is then heated, which causes it to melt and bond to the metal.

- Electrocoating: This is a type of painting that involves immersing the metal in a bath of paint. The paint is then deposited on the metal by an electrical current.

The type of painting that is used will depend on the specific application. For example, liquid painting is often used for small parts, while powder coating is often used for large parts. Industrial Fabrication Inc. Sudbury has the expertise to help you choose the right type of painting for your project.

Painting is an essential part of industrial fabrication, and it can provide a number of benefits, including:

- Protection from corrosion and wear: Paint can help to protect metal surfaces from corrosion and wear. This is important for both the appearance and the longevity of the product.

- Improved appearance: Paint can improve the appearance of products. This can be important for products that are visible to customers.

- Increased durability: Paint can help to increase the durability of products. This is important for products that are exposed to harsh conditions.

Industrial Fabrication Inc. Sudbury is committed to providing high-quality painting services. They have a team of experienced painters who are dedicated to providing the best possible results. If you are looking for a reliable and experienced painting company, Industrial Fabrication Inc. Sudbury is the perfect choice.

| Painting Process | Description |

|---|---|

| Liquid painting | A liquid paint is applied to the surface of the metal. |

| Powder coating | A dry powder is applied to the surface of the metal and then heated. |

| Electrocoating | The metal is immersed in a bath of paint and an electrical current is used to deposit the paint on the metal. |

Design

Design is a critical component of industrial fabrication at Industrial Fabrication Inc. Sudbury. It is the process of creating a plan or blueprint for a product, and it is essential for ensuring that the product meets the customer’s requirements. Industrial Fabrication Inc. Sudbury has a team of experienced designers who are dedicated to providing high-quality design services. They use the latest design software and technology to create detailed and accurate designs.

The design process begins with a consultation with the customer to discuss their needs and requirements. The designer will then create a preliminary design, which will be reviewed by the customer. Once the customer is satisfied with the preliminary design, the designer will create a final design.

The final design will include all of the necessary information for manufacturing the product, including dimensions, tolerances, and materials. The designer will also work with the customer to choose the best manufacturing process for the product.

Design is an important part of industrial fabrication because it ensures that the product meets the customer’s requirements. It also helps to reduce manufacturing costs and improve product quality.

| Design Process | Description |

|---|---|

| Consultation | The designer meets with the customer to discuss their needs and requirements. |

| Preliminary design | The designer creates a preliminary design, which is reviewed by the customer. |

| Final design | The designer creates a final design, which includes all of the necessary information for manufacturing the product. |

Engineering

Within “industrial fabrication inc sudbury”, engineering plays a pivotal role throughout the process of translating designs into reality. It encompasses various facets crucial for successful project execution.

-

Design and Analysis

Engineers utilize their expertise to analyze and refine designs, ensuring structural integrity, functionality, and adherence to specifications. They conduct simulations and calculations to predict performance and identify potential issues, optimizing designs for efficiency and reliability.

-

Material Selection

Material selection is critical for the durability and performance of fabricated products. Engineers possess the knowledge and experience to assess the properties of different materials, considering factors such as strength, corrosion resistance, and cost. They make informed choices to ensure the best material is used for each application.

-

Process Development

Developing efficient and cost-effective fabrication processes is essential for successful production. Engineers work closely with fabrication teams to optimize processes, minimize waste, and maximize productivity. They implement quality control measures to ensure consistency and adherence to standards.

-

Testing and Validation

Before products are released, engineers conduct rigorous testing and validation procedures. They subject products to various conditions to assess their performance and identify any potential issues. This step ensures that fabricated products meet design specifications and perform as intended in real-world applications.

As engineering continues to advance and new technologies emerge, the role of engineers within industrial fabrication will only become more critical. Their expertise and innovative thinking drive the development of cutting-edge products and processes, shaping the future of the industry.

Frequently Asked Questions (FAQs) about Industrial Fabrication Inc. Sudbury

This section provides answers to common questions and concerns regarding industrial fabrication services offered by Industrial Fabrication Inc. Sudbury.

Question 1: What services does Industrial Fabrication Inc. Sudbury offer?

Industrial Fabrication Inc. Sudbury provides a comprehensive range of industrial fabrication services, including metal fabrication, welding, assembly, machining, painting, design, and engineering.

Question 2: What industries does Industrial Fabrication Inc. Sudbury serve?

Industrial Fabrication Inc. Sudbury serves a diverse range of industries, including mining, construction, manufacturing, transportation, and energy.

Question 3: What materials does Industrial Fabrication Inc. Sudbury work with?

Industrial Fabrication Inc. Sudbury has expertise in working with a variety of metals, including steel, stainless steel, aluminum, and exotic alloys.

Question 4: What is the quality assurance process at Industrial Fabrication Inc. Sudbury?

Industrial Fabrication Inc. Sudbury is committed to delivering high-quality products and services. They have a rigorous quality assurance process in place, which includes inspections, testing, and documentation at every stage of the fabrication process.

Question 5: What is the lead time for projects at Industrial Fabrication Inc. Sudbury?

The lead time for projects at Industrial Fabrication Inc. Sudbury varies depending on the complexity and size of the project. They work closely with customers to establish realistic timelines and meet project deadlines.

Question 6: How does Industrial Fabrication Inc. Sudbury handle customer service?

Industrial Fabrication Inc. Sudbury is dedicated to providing excellent customer service. They have a team of experienced professionals who are responsive, knowledgeable, and committed to meeting customer needs.

By addressing these frequently asked questions, Industrial Fabrication Inc. Sudbury aims to provide potential customers with a clear understanding of their services, capabilities, and commitment to quality and customer satisfaction.

Industrial Fabrication Inc. Sudbury welcomes the opportunity to discuss your specific project requirements and provide tailored solutions that meet your needs.

Tips from Industrial Fabrication Inc. Sudbury

Industrial fabrication is a critical process for many industries, and choosing the right fabrication company is essential for ensuring the success of your project. Here are a few tips from Industrial Fabrication Inc. Sudbury to help you make the right decision:

Tip 1: Consider your project’s specific requirements.

Not all fabrication companies are created equal. Some specialize in certain types of projects, such as large-scale structural steel fabrication or precision machining. When choosing a fabrication company, it is important to consider the specific requirements of your project and choose a company that has the experience and expertise to meet your needs.

Tip 2: Look for a company with a proven track record.

One of the best ways to assess the quality of a fabrication company is to look at its track record. Ask for references from past customers and check online reviews to see what others have said about their experience with the company.

Tip 3: Visit the company’s facility.

Visiting the company’s facility will give you a first-hand look at their equipment and capabilities. It will also allow you to meet the team and get a sense of the company’s culture.

Tip 4: Get a detailed quote.

Before you make a final decision, be sure to get a detailed quote from the fabrication company. This quote should include the cost of materials, labor, and any other associated costs. It is also important to get a clear understanding of the company’s payment terms and warranty.

Tip 5: Choose a company that is committed to safety.

Safety should be a top priority for any fabrication company. Ask about the company’s safety record and make sure they have a comprehensive safety program in place.

By following these tips, you can choose the right fabrication company for your project and ensure that your project is completed on time, within budget, and to your satisfaction.

Industrial Fabrication Inc. Sudbury is committed to providing high-quality fabrication services to our customers. We have the experience, expertise, and commitment to safety to meet your project’s specific requirements. Contact us today to learn more about our services and how we can help you achieve your project goals.

Conclusion

Industrial fabrication is a critical process for many industries, and choosing the right fabrication company is essential for ensuring the success of your project. Industrial Fabrication Inc. Sudbury is a leading provider of industrial fabrication services in the Sudbury area. We have the experience, expertise, and commitment to safety to meet your project’s specific requirements.

We offer a wide range of services, including metal fabrication, welding, assembly, machining, painting, design, and engineering. We have a team of experienced professionals who are dedicated to providing high-quality workmanship and customer service. We also have a state-of-the-art facility that is equipped with the latest technology.

If you are looking for a reliable and experienced fabrication company in the Sudbury area, Industrial Fabrication Inc. Sudbury is the perfect choice. Contact us today to learn more about our services and how we can help you achieve your project goals.