What is the industrial machine and fabrication industry like? Industrial machine & fabrication inc is a broad term used to describe the design, fabrication, and installation of machinery and equipment used in a variety of industries.

Editor’s Note: Industrial machine & fabrication inc is an important topic to understand because it is a major part of the manufacturing industry.

We’ve done the legwork and put together this guide to help you understand the basics of industrial machine & fabrication inc. So whether you’re a business owner looking to invest in new equipment or a consumer who wants to learn more about how things are made, read on!

Key Differences

| Characteristic | Industrial Machine | Fabrication |

|---|---|---|

| Purpose | To perform specific tasks, such as cutting, shaping, or assembling materials | To create custom metal structures and components |

| Materials Used | Metals, plastics, wood | Primarily metals |

| Skills Required | Machinists, engineers, technicians | Welders, fabricators, metalworkers |

Transition to main article topics

- The different types of industrial machines and fabrication services

- The benefits of using industrial machines and fabrication services

- How to choose the right industrial machine or fabrication service for your needs

Industrial Machine & Fabrication Inc.

Industrial machine & fabrication inc. is a broad term used to describe the design, fabrication, and installation of machinery and equipment used in a variety of industries. It encompasses a wide range of activities, from the design of new machines to the repair and maintenance of existing ones.

- Design: Industrial machines and fabrication services can be used to design and create new machines and equipment, or to modify existing ones.

- Fabrication: Industrial machines and fabrication services can be used to fabricate metal, plastic, and other materials into custom components and structures.

- Installation: Industrial machines and fabrication services can be used to install and commission new machines and equipment, as well as to relocate or repair existing ones.

- Maintenance: Industrial machines and fabrication services can be used to maintain and repair existing machines and equipment, ensuring that they operate safely and efficiently.

- Safety: Industrial machines and fabrication services can be used to improve the safety of industrial workplaces, by designing and installing safety guards and other protective devices.

- Efficiency: Industrial machines and fabrication services can be used to improve the efficiency of industrial processes, by designing and installing automated systems and other productivity-enhancing equipment.

- Quality: Industrial machines and fabrication services can be used to improve the quality of industrial products, by designing and installing precision machinery and other quality control equipment.

- Cost: Industrial machines and fabrication services can be used to reduce the cost of industrial operations, by designing and installing energy-efficient equipment and other cost-saving measures.

These are just a few of the key aspects of industrial machine & fabrication inc. By understanding these aspects, you can better understand the importance of this industry and how it can benefit your business.

Design

The design of industrial machines and fabrication services is a critical component of industrial machine & fabrication inc. It is the process of creating new machines and equipment, or modifying existing ones, to meet the specific needs of a particular industry or application. This can involve a wide range of activities, from conceptual design to detailed engineering drawings.

There are many benefits to using industrial machines and fabrication services for design. First, it allows businesses to create custom machines and equipment that are tailored to their specific needs. This can give them a competitive advantage by allowing them to produce products or services that are unique to the market.

Second, industrial machines and fabrication services can help businesses to improve the efficiency of their operations. By designing and installing automated systems and other productivity-enhancing equipment, businesses can reduce labor costs and improve throughput.

Third, industrial machines and fabrication services can help businesses to improve the quality of their products. By designing and installing precision machinery and other quality control equipment, businesses can reduce defects and improve customer satisfaction.

Overall, the design of industrial machines and fabrication services is a critical component of industrial machine & fabrication inc. It allows businesses to create custom machines and equipment, improve the efficiency of their operations, and improve the quality of their products.

| Challenge | Solution |

|---|---|

| Need to create custom machines and equipment | Industrial machines and fabrication services can design and create custom machines and equipment to meet specific needs. |

| Need to improve the efficiency of operations | Industrial machines and fabrication services can design and install automated systems and other productivity-enhancing equipment. |

| Need to improve the quality of products | Industrial machines and fabrication services can design and install precision machinery and other quality control equipment. |

Fabrication

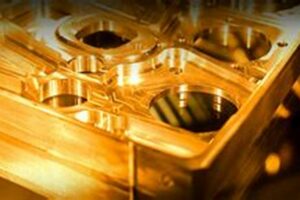

Fabrication is a critical part of industrial machine & fabrication inc. It is the process of creating custom metal, plastic, and other materials into components and structures. This can involve a wide range of activities, from cutting and welding to forming and assembling.

There are many benefits to using industrial machines and fabrication services for fabrication. First, it allows businesses to create custom components and structures that are tailored to their specific needs. This can give them a competitive advantage by allowing them to produce products or services that are unique to the market.

Second, industrial machines and fabrication services can help businesses to improve the efficiency of their operations. By using automated systems and other productivity-enhancing equipment, businesses can reduce labor costs and improve throughput.

Third, industrial machines and fabrication services can help businesses to improve the quality of their products. By using precision machinery and other quality control equipment, businesses can reduce defects and improve customer satisfaction.

Overall, fabrication is a critical part of industrial machine & fabrication inc. It allows businesses to create custom components and structures, improve the efficiency of their operations, and improve the quality of their products.

-

Components

Industrial machines and fabrication services can be used to create a wide range of components, including gears, shafts, housings, and frames. These components can be made from a variety of materials, including metal, plastic, and wood. -

Examples

Industrial machines and fabrication services are used in a wide range of industries, including automotive, aerospace, and construction. Some examples of products that are made using industrial machines and fabrication services include cars, airplanes, and bridges. -

Implications

The use of industrial machines and fabrication services has a number of implications for businesses. First, it allows businesses to create custom products and services that are tailored to their specific needs. Second, it can help businesses to improve the efficiency of their operations and reduce costs. Third, it can help businesses to improve the quality of their products and increase customer satisfaction.

Installation

Installation is a critical part of industrial machine & fabrication inc. It is the process of installing and commissioning new machines and equipment, as well as relocating or repairing existing ones. This can be a complex and challenging process, but it is essential to ensure that machines and equipment are installed and operated safely and efficiently.

There are many benefits to using industrial machines and fabrication services for installation. First, it can help to ensure that machines and equipment are installed correctly and to the manufacturer’s specifications. This can help to prevent accidents and injuries, and it can also help to extend the life of the equipment.

Second, industrial machines and fabrication services can help to improve the efficiency of installation. By using specialized tools and equipment, and by having experienced technicians perform the installation, businesses can reduce the amount of time it takes to install machines and equipment. This can help to reduce downtime and get businesses up and running faster.

Third, industrial machines and fabrication services can help to improve the safety of installation. By following proper safety procedures and using the right tools and equipment, businesses can help to reduce the risk of accidents and injuries during installation.

Overall, installation is a critical part of industrial machine & fabrication inc. It is essential to ensure that machines and equipment are installed correctly and safely. By using industrial machines and fabrication services for installation, businesses can help to reduce downtime, improve efficiency, and enhance safety.

| Challenge | Solution |

|---|---|

| Need to install new machines and equipment | Industrial machines and fabrication services can install and commission new machines and equipment. |

| Need to relocate existing machines and equipment | Industrial machines and fabrication services can relocate existing machines and equipment. |

| Need to repair existing machines and equipment | Industrial machines and fabrication services can repair existing machines and equipment. |

Maintenance

Maintenance is a critical component of industrial machine & fabrication inc. It is the process of maintaining and repairing existing machines and equipment to ensure that they operate safely and efficiently. This can involve a wide range of activities, from regular inspections and adjustments to major overhauls.

There are many benefits to using industrial machines and fabrication services for maintenance. First, it can help to prevent breakdowns and accidents. By regularly inspecting and maintaining machines and equipment, businesses can identify and fix potential problems before they become major issues. This can help to reduce downtime and improve safety.

Second, industrial machines and fabrication services can help to improve the efficiency of operations. By keeping machines and equipment in good working order, businesses can reduce the amount of time and resources that are required to produce products and services. This can help to improve productivity and reduce costs.

Third, industrial machines and fabrication services can help to extend the life of machines and equipment. By properly maintaining and repairing machines and equipment, businesses can help to extend their lifespan and reduce the need for replacements. This can save money and help businesses to get the most out of their investment.

Overall, maintenance is a critical component of industrial machine & fabrication inc. It can help to prevent breakdowns and accidents, improve the efficiency of operations, and extend the life of machines and equipment. By using industrial machines and fabrication services for maintenance, businesses can help to ensure that their machines and equipment are operating safely and efficiently.

| Challenge | Solution |

|---|---|

| Need to prevent breakdowns and accidents | Industrial machines and fabrication services can regularly inspect and maintain machines and equipment to identify and fix potential problems before they become major issues. |

| Need to improve the efficiency of operations | Industrial machines and fabrication services can keep machines and equipment in good working order to reduce the amount of time and resources that are required to produce products and services. |

| Need to extend the life of machines and equipment | Industrial machines and fabrication services can properly maintain and repair machines and equipment to extend their lifespan and reduce the need for replacements. |

Safety

Safety is a critical component of industrial machine & fabrication inc. Industrial machines and fabrication services can be used to improve the safety of industrial workplaces by designing and installing safety guards and other protective devices.

Safety guards and other protective devices can help to prevent accidents and injuries in industrial workplaces. For example, safety guards can be used to prevent workers from coming into contact with moving machinery, and protective devices can be used to protect workers from hazardous materials.

By using industrial machines and fabrication services to improve safety, businesses can help to create a safer working environment for their employees. This can lead to reduced absenteeism and turnover, as well as increased productivity and morale.

In addition, businesses that are committed to safety are often seen as more responsible and trustworthy by their customers and partners. This can lead to increased sales and profits.

| Challenge | Solution |

|---|---|

| Need to improve the safety of industrial workplaces | Industrial machines and fabrication services can be used to design and install safety guards and other protective devices. |

| Need to reduce accidents and injuries in industrial workplaces | Safety guards and other protective devices can help to prevent accidents and injuries in industrial workplaces. |

| Need to create a safer working environment for employees | By using industrial machines and fabrication services to improve safety, businesses can help to create a safer working environment for their employees. |

Efficiency

Industrial machines and fabrication services play a critical role in improving the efficiency of industrial processes. By designing and installing automated systems and other productivity-enhancing equipment, businesses can reduce labor costs, improve throughput, and reduce waste.

For example, a manufacturing company might use industrial machines and fabrication services to design and install an automated assembly line. This assembly line could be used to assemble products more quickly and efficiently than a manual assembly line, which could lead to significant cost savings.

Additionally, industrial machines and fabrication services can be used to improve the quality of products. By using precision machinery and other quality control equipment, businesses can reduce defects and improve customer satisfaction.

| Challenge | Solution |

|---|---|

| Need to improve the efficiency of industrial processes | Industrial machines and fabrication services can be used to design and install automated systems and other productivity-enhancing equipment. |

| Need to reduce labor costs | Automated systems can reduce the need for manual labor, which can lead to significant cost savings. |

| Need to improve throughput | Automated systems can operate more quickly and efficiently than manual processes, which can lead to increased throughput. |

| Need to reduce waste | Automated systems can be programmed to minimize waste, which can lead to cost savings and environmental benefits. |

Overall, industrial machines and fabrication services are essential for improving the efficiency of industrial processes. By using these services, businesses can reduce costs, improve quality, and increase productivity.

Quality

Quality is a critical component of industrial machine & fabrication inc. Industrial machines and fabrication services can be used to improve the quality of industrial products by designing and installing precision machinery and other quality control equipment.

Precision machinery is essential for producing high-quality industrial products. By using precision machinery, businesses can reduce defects and improve the overall quality of their products. Quality control equipment is also essential for ensuring that industrial products meet the required specifications. By using quality control equipment, businesses can identify and eliminate defects before products are shipped to customers.

There are many benefits to using industrial machines and fabrication services to improve quality. First, it can help businesses to reduce costs. By reducing defects, businesses can reduce the amount of money they spend on rework and scrap. Second, improving quality can help businesses to improve customer satisfaction. Customers are more likely to be satisfied with products that are well-made and free of defects. Third, improving quality can help businesses to increase sales. Customers are more likely to purchase products from businesses that have a reputation for producing high-quality products.

Overall, quality is a critical component of industrial machine & fabrication inc. By using industrial machines and fabrication services to improve quality, businesses can reduce costs, improve customer satisfaction, and increase sales.

Here are some examples of how industrial machines and fabrication services can be used to improve quality:

- A manufacturing company can use a precision CNC machine to produce high-quality metal parts. This can reduce defects and improve the overall quality of the company’s products.

- A food processing company can use a quality control system to inspect and sort food products. This can help to ensure that only high-quality products are shipped to customers.

- A pharmaceutical company can use a precision filling machine to fill vials with medication. This can help to ensure that the medication is accurately and consistently dosed.

| Challenge | Solution |

|---|---|

| Need to improve the quality of industrial products | Industrial machines and fabrication services can be used to design and install precision machinery and other quality control equipment. |

| Need to reduce defects | Precision machinery and quality control equipment can help to reduce defects and improve the overall quality of industrial products. |

| Need to improve customer satisfaction | Customers are more likely to be satisfied with products that are well-made and free of defects. |

| Need to increase sales | Customers are more likely to purchase products from businesses that have a reputation for producing high-quality products. |

Cost

Cost is a critical component of industrial machine & fabrication inc. Industrial machines and fabrication services can be used to reduce the cost of industrial operations by designing and installing energy-efficient equipment and other cost-saving measures.

Energy-efficient equipment can help businesses to reduce their energy consumption, which can lead to significant cost savings. For example, a manufacturing company might use industrial machines and fabrication services to design and install an energy-efficient lighting system. This lighting system could use less energy than a traditional lighting system, which could lead to significant savings on the company’s energy bill.

Other cost-saving measures include using automated systems to reduce labor costs and using recycled materials to reduce raw material costs. By using industrial machines and fabrication services to implement these cost-saving measures, businesses can reduce their operating costs and improve their bottom line.

| Challenge | Solution |

|---|---|

| Need to reduce the cost of industrial operations | Industrial machines and fabrication services can be used to design and install energy-efficient equipment and other cost-saving measures. |

| Need to reduce energy consumption | Energy-efficient equipment can help businesses to reduce their energy consumption, which can lead to significant cost savings. |

| Need to reduce labor costs | Automated systems can be used to reduce labor costs. |

| Need to reduce raw material costs | Recycled materials can be used to reduce raw material costs. |

Overall, cost is a critical component of industrial machine & fabrication inc. By using industrial machines and fabrication services to reduce costs, businesses can improve their bottom line and gain a competitive advantage.

FAQs about Industrial Machine & Fabrication Inc.

This section provides answers to frequently asked questions about industrial machine & fabrication inc., covering various aspects such as its importance, benefits, and applications.

Question 1: What is industrial machine & fabrication inc. and why is it important?

Answer: Industrial machine & fabrication inc. encompasses the design, fabrication, and installation of machinery and equipment used across various industries. It plays a critical role in manufacturing, infrastructure development, and other sectors, enabling the production of essential goods and services.

Question 2: What are the key benefits of using industrial machine & fabrication inc. services?

Answer: Industrial machine & fabrication inc. services offer numerous benefits, including the ability to customize machinery and equipment to meet specific requirements, enhance operational efficiency through automation, improve product quality with precision engineering, extend equipment lifespan through proper maintenance, and enhance workplace safety with safety features.

Question 3: What are the different types of industrial machines and fabrication services available?

Answer: Industrial machines and fabrication services encompass a wide range, including CNC machining, welding, fabrication, assembly, and installation. These services cater to diverse industries, from automotive and aerospace to construction and energy.

Question 4: How can industrial machine & fabrication inc. help businesses improve their operations?

Answer: Industrial machine & fabrication inc. services can significantly enhance business operations by optimizing production processes, reducing costs through automation, minimizing downtime with efficient maintenance, and ensuring regulatory compliance with safety measures.

Question 5: What are the factors to consider when choosing an industrial machine & fabrication inc. provider?

Answer: When selecting an industrial machine & fabrication inc. provider, it’s crucial to evaluate their experience, technical expertise, quality standards, customer service, and industry reputation. These factors ensure that businesses can partner with reliable providers who can deliver high-quality solutions.

Question 6: What are some examples of industries that rely heavily on industrial machine & fabrication inc. services?

Answer: Industrial machine & fabrication inc. services find extensive applications across various sectors, including manufacturing, automotive, aerospace, construction, energy, healthcare, and transportation. These services are essential for producing machinery, equipment, and infrastructure that support these industries.

Summary: Industrial machine & fabrication inc. is a vital aspect of modern industries, enabling the design, fabrication, and installation of machinery and equipment that drive production, enhance efficiency, and ensure safety. By partnering with reputable providers, businesses can leverage these services to optimize their operations, improve product quality, and gain a competitive advantage.

Transition to the next article section: To delve deeper into the world of industrial machine & fabrication inc., let’s explore some of its key applications and how they impact various industries.

Tips from Industrial Machine & Fabrication Inc.

The realm of industrial machine & fabrication inc. presents a vast array of opportunities for businesses to enhance their operations. Here are some expert tips to help you navigate this landscape and harness its full potential:

Tip 1: Prioritize Collaboration and Communication

Foster open communication between design engineers, fabrication specialists, and end-users. This collaborative approach ensures that project requirements are clearly defined, potential challenges are identified early on, and solutions are developed efficiently.

Tip 2: Embrace Advanced Technologies

Incorporate cutting-edge technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), and 3D printing into your workflow. These technologies streamline design processes, enhance fabrication accuracy, and enable rapid prototyping.

Tip 3: Invest in Quality Materials and Equipment

Select high-grade materials and invest in durable fabrication equipment. This may involve conducting thorough research, consulting with industry experts, and partnering with reputable suppliers to ensure the longevity and reliability of your machinery.

Tip 4: Implement Regular Maintenance and Inspection

Establish a comprehensive maintenance schedule to keep your industrial machines and fabrication equipment operating at peak performance. Regular inspections can identify potential issues early on, preventing costly breakdowns and extending the lifespan of your assets.

Tip 5: Enhance Safety Measures

Prioritize workplace safety by implementing proper guarding, training employees on safe operating procedures, and conducting regular safety audits. These measures not only protect your workforce but also minimize the risk of accidents and ensure compliance with industry regulations.

Summary: By following these expert tips, businesses can optimize their industrial machine & fabrication processes, improve product quality, reduce downtime, and enhance overall operational efficiency. Embracing collaboration, leveraging technology, investing in quality, prioritizing maintenance, and ensuring safety are key strategies for maximizing the benefits of industrial machine & fabrication inc. services.

Transition to the article’s conclusion: With these tips in mind, businesses can confidently navigate the world of industrial machine & fabrication inc., unlocking its potential to drive innovation, productivity, and success.

Conclusion

In the vast landscape of modern industry, industrial machine & fabrication inc. stands as a cornerstone of progress and innovation. Throughout this article, we have explored its multifaceted nature, from design and fabrication to installation and maintenance. We have witnessed how these services empower businesses to customize machinery, enhance operational efficiency, improve product quality, and ensure workplace safety.

As we look towards the future, the role of industrial machine & fabrication inc. will only continue to grow. With the advent of new technologies, the demand for specialized machinery and equipment will surge across diverse industries. By embracing collaboration, leveraging advanced technologies, investing in quality, and prioritizing safety, businesses can harness the full potential of these services to drive innovation, productivity, and long-term success.