What is metal design and fabrication? It is the process of creating metal structures and products by cutting, bending, and welding metal. It is used in a wide variety of industries, from construction to automotive to aerospace.

Editor’s Notes: Metal design and fabrication is an important topic to understand because it is used in so many different industries. By understanding the basics of metal design and fabrication, you can make informed decisions about the products you buy and the projects you undertake.

We’ve done the research and analyzed the information, and put together this metal design and fabrication guide to help you make the right decision.

Key differences or Key takeaways:

| Metal Design | Metal Fabrication |

|---|---|

| The process of creating metal structures and products by cutting, bending, and welding metal. | The process of creating metal structures and products by cutting, bending, and welding metal. |

| Used in a wide variety of industries, from construction to automotive to aerospace. | Used in a wide variety of industries, from construction to automotive to aerospace. |

Main article topics:

- The benefits of metal design and fabrication

- The different types of metal design and fabrication

- How to choose the right metal design and fabrication company

Metal Design and Fabrication

Metal design and fabrication is a critical process in a wide range of industries, from construction to manufacturing to automotive. It involves the creation of metal structures and products by cutting, bending, and welding metal. Here are 11 key aspects of metal design and fabrication:

- Materials: The type of metal used in a project will depend on the specific application and requirements.

- Processes: There are a variety of metal fabrication processes, including cutting, bending, welding, and finishing.

- Equipment: The equipment used in metal fabrication ranges from simple hand tools to complex automated systems.

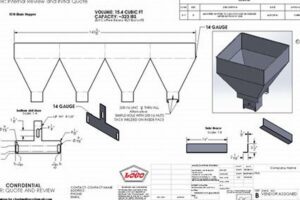

- Design: Metal design is the process of creating a blueprint or plan for a metal structure or product.

- Engineering: Metal engineering is the application of engineering principles to the design and fabrication of metal structures and products.

- Safety: Metal fabrication can be a hazardous process, so it is important to follow all safety protocols.

- Quality: The quality of a metal fabrication project will depend on the skill of the fabricator and the quality of the materials and equipment used.

- Cost: The cost of a metal fabrication project will vary depending on the complexity of the project and the materials and equipment used.

- Time: The time it takes to complete a metal fabrication project will vary depending on the complexity of the project and the resources available.

- Industry: Metal design and fabrication is used in a wide variety of industries, including construction, manufacturing, and automotive.

- Applications: Metal design and fabrication is used in a wide variety of applications, from bridges to buildings to cars.

These are just a few of the key aspects of metal design and fabrication. By understanding these aspects, you can make informed decisions about the products you buy and the projects you undertake.

Materials

The type of metal used in a metal design and fabrication project will depend on a number of factors, including the intended use of the product, the environment in which it will be used, and the budget. Some of the most common types of metal used in metal design and fabrication include:

- Steel: Steel is a strong and durable metal that is relatively inexpensive. It is often used in construction, automotive, and manufacturing applications.

- Aluminum: Aluminum is a lightweight and corrosion-resistant metal that is often used in aerospace, marine, and food processing applications.

- Stainless steel: Stainless steel is a corrosion-resistant metal that is often used in food processing, medical, and chemical processing applications.

- Copper: Copper is a conductive metal that is often used in electrical applications.

- Brass: Brass is a corrosion-resistant metal that is often used in plumbing, musical instruments, and jewelry.

The choice of metal for a particular project will depend on the specific requirements of the application. For example, a product that will be used in a corrosive environment will need to be made from a corrosion-resistant metal such as stainless steel or aluminum. A product that will be used in a high-strength application will need to be made from a strong metal such as steel.

By understanding the different types of metal and their properties, metal designers and fabricators can select the right material for each project. This will ensure that the product meets the specific requirements of the application and performs as expected.

Table: Metal Types and Applications

| Metal | Properties | Applications |

|---|---|---|

| Steel | Strong, durable, inexpensive | Construction, automotive, manufacturing |

| Aluminum | Lightweight, corrosion-resistant | Aerospace, marine, food processing |

| Stainless steel | Corrosion-resistant | Food processing, medical, chemical processing |

| Copper | Conductive | Electrical applications |

| Brass | Corrosion-resistant | Plumbing, musical instruments, jewelry |

Processes

The processes used in metal design and fabrication are essential to creating the desired product. These processes include cutting, bending, welding, and finishing. Each process plays a vital role in the overall design and fabrication of the product.

- Cutting: Cutting is the process of removing material from a metal workpiece. This can be done using a variety of methods, including sawing, shearing, and laser cutting. The type of cutting method used will depend on the thickness and type of metal being cut.

- Bending: Bending is the process of shaping metal by applying force to it. This can be done using a variety of methods, including hand bending, press brake bending, and roll bending. The type of bending method used will depend on the thickness and type of metal being bent.

- Welding: Welding is the process of joining two pieces of metal together by melting them together. This can be done using a variety of methods, including arc welding, MIG welding, and TIG welding. The type of welding method used will depend on the thickness and type of metal being welded.

- Finishing: Finishing is the process of giving the metal product a desired surface finish. This can be done using a variety of methods, including grinding, polishing, and painting. The type of finishing method used will depend on the desired appearance and performance of the product.

These are just a few of the processes used in metal design and fabrication. By understanding these processes, you can gain a better understanding of how metal products are made and how to choose the right metal fabrication company for your project.

Equipment

The equipment used in metal design and fabrication is an essential part of the process. It can determine the accuracy, efficiency, and quality of the finished product. The type of equipment used will depend on the specific project requirements, but some of the most common types of equipment include:

- Hand tools: Hand tools are used for a variety of tasks in metal design and fabrication, such as cutting, bending, and welding. Examples of hand tools include hammers, wrenches, pliers, and screwdrivers.

- Power tools: Power tools are used to automate tasks that would otherwise be done by hand. Examples of power tools include drills, saws, and grinders.

- Machine tools: Machine tools are used to perform complex tasks that would be difficult or impossible to do by hand. Examples of machine tools include lathes, mills, and CNC machines.

The choice of equipment for a particular project will depend on the specific requirements of the project. For example, a project that requires high precision will need to use more sophisticated equipment than a project that does not require as much precision.

By understanding the different types of equipment used in metal design and fabrication, you can gain a better understanding of the process and how to choose the right equipment for your project.

Table: Equipment Types and Uses

| Equipment Type | Uses |

|---|---|

| Hand tools | Cutting, bending, welding |

| Power tools | Drilling, sawing, grinding |

| Machine tools | Lathing, milling, CNC machining |

Design

Metal design is a critical component of metal design and fabrication. It is the process of creating a blueprint or plan for a metal structure or product. This plan includes all of the necessary details for the fabrication process, such as the dimensions, materials, and finishes. Without a proper design, it would be impossible to fabricate a metal product that meets the desired specifications.

There are a number of different software programs that can be used for metal design. These programs allow designers to create 3D models of their designs, which can then be used to generate the necessary fabrication drawings. Once the design is complete, it is then sent to the fabrication shop, where it is used to create the actual metal product.

Metal design is a complex and challenging process, but it is also an essential one. By understanding the importance of metal design, you can gain a better understanding of the metal design and fabrication process as a whole.

Table: The Importance of Metal Design

| Importance | Description |

|---|---|

| Ensures that the fabricated product meets the desired specifications | A well-designed metal product will be more likely to meet the desired specifications, such as strength, durability, and appearance. |

| Reduces the risk of errors | A well-designed metal product will be less likely to have errors, which can save time and money in the long run. |

| Facilitates communication between designers and fabricators | A well-designed metal product will make it easier for designers and fabricators to communicate with each other, which can help to ensure that the product is fabricated correctly. |

Engineering

Metal engineering plays a crucial role in the field of metal design and fabrication. It involves the application of engineering principles to ensure the structural integrity, safety, and functionality of metal products and structures.

-

Structural Analysis

Metal engineers analyze the forces and stresses acting on metal structures and components. They use this information to design structures that can withstand these forces and stresses without failing. -

Material Selection

Metal engineers select the appropriate type of metal for each component based on its strength, durability, and corrosion resistance. They also consider the cost and availability of different metals. -

Design Optimization

Metal engineers use computer-aided design (CAD) software to optimize the design of metal structures and components. This software helps them to create designs that are both efficient and cost-effective. -

Fabrication Supervision

Metal engineers supervise the fabrication of metal structures and components to ensure that they are fabricated according to the design specifications. They also inspect the finished products to ensure that they meet the required quality standards.

By applying engineering principles to the design and fabrication of metal products and structures, metal engineers help to ensure that these products and structures are safe, reliable, and efficient.

Safety

Metal fabrication is a process that involves cutting, bending, and welding metal. These processes can generate sparks, fumes, and other hazards that can cause injury or illness if proper safety protocols are not followed. Some of the most common safety hazards in metal fabrication include:

- Cuts and lacerations: These can occur when working with sharp metal objects or machinery.

- Burns: These can occur when working with hot metal or welding equipment.

- Eye injuries: These can occur when working with metal that is being cut, welded, or ground.

- Respiratory problems: These can occur when inhaling fumes from welding or other metal fabrication processes.

To prevent these and other hazards, it is important to follow all safety protocols when working in a metal fabrication shop. These protocols may include:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a welding helmet.

- Using machinery and equipment properly and in accordance with the manufacturer’s instructions.

- Keeping the work area clean and free of debris.

- Being aware of the hazards of the materials being used.

- Following proper lockout/tagout procedures when working on machinery or equipment.

By following these safety protocols, metal fabricators can help to prevent injuries and illnesses and ensure a safe work environment.

Table: Safety Protocols for Metal Fabrication

| Hazard | Safety Protocol |

|---|---|

| Cuts and lacerations | Wear cut-resistant gloves and keep work area clean. |

| Burns | Wear heat-resistant clothing and gloves, use welding blankets, and keep a fire extinguisher nearby. |

| Eye injuries | Wear safety glasses or a welding helmet at all times. |

| Respiratory problems | Use a respirator or work in a well-ventilated area. |

Quality

Quality is of paramount importance in metal design and fabrication. It encompasses various aspects that directly impact the durability, functionality, and overall performance of the final product. Several factors contribute to the quality of a metal fabrication project, including the skill of the fabricator, the quality of the materials used, and the quality of the equipment utilized.

- Craftsmanship: The skill and experience of the fabricator play a pivotal role in determining the quality of the finished product. Skilled fabricators possess a deep understanding of metalworking techniques, enabling them to execute precise cuts, bends, and welds, resulting in a high-quality product.

- Material Selection: The choice of materials significantly influences the quality and properties of the fabricated product. High-quality materials, such as durable metals and alloys, contribute to the strength, longevity, and resistance to corrosion and wear. Fabricators must carefully select materials based on the specific requirements of the project.

- Equipment and Technology: Advanced equipment and technology enhance the precision and efficiency of the fabrication process. Modern machinery, such as CNC machines and laser cutters, allow for intricate designs and precise cutting, contributing to overall quality and reducing the risk of errors.

- Quality Control: Implementing a robust quality control process is crucial to ensure the consistency and reliability of fabricated products. This involves regular inspections, testing, and adherence to industry standards, guaranteeing that the final product meets the desired specifications and quality requirements.

By considering these factors and emphasizing quality at every stage of the metal design and fabrication process, manufacturers can deliver exceptional products that meet the demands of various industries and applications, ensuring durability, functionality, and customer satisfaction.

Cost

Cost is a crucial aspect of metal design and fabrication, influencing project planning, resource allocation, and decision-making. The complexity of a project significantly impacts its cost. Intricate designs, tight tolerances, and challenging material requirements demand specialized expertise, advanced equipment, and extended production time, leading to higher costs.

Material selection plays a pivotal role in cost determination. Exotic alloys, high-strength steels, and corrosion-resistant metals are more expensive than standard materials. The quantity of materials required also affects the overall cost. Thicker materials and larger quantities result in increased material expenses.

Equipment and technology employed in metal fabrication directly impact project costs. Advanced machinery, such as CNC machines and laser cutters, enhances efficiency and precision but comes with a higher price tag. Labor costs also vary based on the skill level and experience of the fabricators involved.

Understanding the cost factors associated with metal design and fabrication is essential for effective project management. By carefully considering the complexity of the project, material selection, and equipment requirements, manufacturers can optimize costs while ensuring quality and meeting project objectives.

Table: Cost Factors in Metal Fabrication

| Factor | Impact on Cost |

|---|---|

| Complexity | Higher complexity leads to increased costs due to specialized expertise, advanced equipment, and extended production time. |

| Materials | Exotic alloys, high-strength steels, and corrosion-resistant metals are more expensive than standard materials. |

| Equipment and Technology | Advanced machinery, such as CNC machines and laser cutters, enhances efficiency but increases costs. |

Time

Time is a crucial factor in metal design and fabrication, impacting project planning, resource allocation, and overall efficiency. The complexity of a project directly influences the time required for its completion. Intricate designs, tight tolerances, and challenging material requirements demand specialized expertise, advanced equipment, and extended production time.

- Design Complexity: Complex designs with numerous components, intricate shapes, and precise dimensions require more time for planning, prototyping, and fabrication. The level of detail and the need for custom solutions contribute to the overall time frame.

- Material Selection: The properties of the materials used in metal fabrication significantly impact the time required. Exotic alloys, high-strength steels, and corrosion-resistant metals often require specialized equipment and techniques, leading to extended production times.

- Equipment and Resources: The availability and capabilities of equipment and resources play a vital role in determining the time frame of a metal fabrication project. Advanced machinery, such as CNC machines and laser cutters, can enhance efficiency and reduce production time. However, the availability of skilled operators and adequate resources is crucial for timely project completion.

- Project Scope and Scale: The scope and scale of a metal fabrication project directly influence the time required. Large-scale projects with multiple components, assemblies, and finishing processes demand more time for production and quality control.

Understanding the factors that impact the time frame of a metal fabrication project is essential for effective project management. By carefully considering the complexity of the design, material selection, equipment availability, and project scope, manufacturers can plan and allocate resources accordingly to meet project deadlines and customer expectations.

Industry

Metal design and fabrication is an essential component of a wide range of industries, including construction, manufacturing, and automotive. It is used to create a variety of products, from buildings and bridges to cars and airplanes. The versatility of metal design and fabrication makes it a valuable tool for businesses in a variety of sectors.

In the construction industry, metal design and fabrication is used to create structural components, such as beams, columns, and trusses. These components are used to build a variety of structures, including commercial buildings, bridges, and warehouses. Metal design and fabrication is also used to create architectural features, such as railings, staircases, and canopies.

In the manufacturing industry, metal design and fabrication is used to create a variety of products, including machinery, tools, and consumer goods. Metal design and fabrication is also used to create parts for other products, such as cars and airplanes. The ability of metal to be formed into complex shapes makes it an ideal material for a variety of manufacturing applications.

In the automotive industry, metal design and fabrication is used to create structural components, such as frames and bodies. Metal design and fabrication is also used to create a variety of other components, such as engines, transmissions, and suspension systems. The strength and durability of metal make it an ideal material for automotive applications.

The use of metal design and fabrication in a wide variety of industries is a testament to its versatility and importance. Metal design and fabrication is a valuable tool for businesses in a variety of sectors, and it is essential for the production of a wide range of products.

Table: Applications of Metal Design and Fabrication

| Industry | Applications |

|---|---|

| Construction | Structural components, architectural features |

| Manufacturing | Machinery, tools, consumer goods, parts for other products |

| Automotive | Structural components, engines, transmissions, suspension systems |

Applications

Metal design and fabrication is a versatile field with a wide range of applications in various industries. Its adaptability and durability make it a valuable material for constructing structures, manufacturing products, and creating functional components.

- Construction: Metal design and fabrication play a crucial role in the construction industry, enabling the creation of robust and durable structural components such as beams, columns, and trusses. These components form the backbone of buildings, bridges, warehouses, and other structures, providing strength and stability.

- Manufacturing: In the manufacturing sector, metal design and fabrication are essential for producing machinery, tools, and consumer goods. From intricate machine parts to everyday appliances, metal is shaped and formed into functional components that drive various industries.

- Automotive: The automotive industry relies heavily on metal design and fabrication for creating structural components such as frames and bodies. Metal’s strength and durability make it ideal for withstanding the rigors of the road, ensuring the safety and performance of vehicles.

- Infrastructure: Metal design and fabrication extend beyond buildings and vehicles. They are used in the construction of bridges, transportation systems, and other infrastructure projects. Metal’s ability to withstand various environmental conditions makes it a reliable material for long-lasting infrastructure.

The applications of metal design and fabrication are vast and continue to grow as technology advances. Its versatility, durability, and adaptability make it an essential material for shaping our world, from the buildings we inhabit to the vehicles we drive and the infrastructure that connects us.

Frequently Asked Questions about Metal Design and Fabrication

This section addresses common inquiries and misconceptions regarding metal design and fabrication to provide a clear understanding of the subject.

Question 1: What is the difference between metal design and metal fabrication?

Metal design involves the conceptualization and creation of blueprints or plans for metal structures and products. It focuses on the aesthetic and functional aspects of the design. In contrast, metal fabrication is the physical process of transforming these designs into tangible products by cutting, shaping, and assembling metal components.

Question 2: What are some common materials used in metal design and fabrication?

The choice of materials depends on the specific application and requirements. Commonly used metals include steel, aluminum, stainless steel, copper, and brass. Each metal offers unique properties such as strength, durability, corrosion resistance, and conductivity.

Question 3: What factors influence the cost of a metal fabrication project?

The cost of metal fabrication is determined by several factors, including the complexity of the design, the type and quantity of materials used, the equipment and technology employed, and the labor costs. More intricate designs, specialized materials, and advanced equipment typically result in higher costs.

Question 4: How can I ensure the quality of a metal fabrication project?

Quality assurance in metal fabrication involves adhering to industry standards, utilizing skilled professionals, implementing quality control measures throughout the process, and conducting thorough inspections to verify the accuracy and integrity of the finished product.

Question 5: What are the advantages of using metal in design and fabrication?

Metal offers numerous benefits, including strength, durability, versatility, recyclability, and cost-effectiveness. Its ability to withstand various environmental conditions and its adaptability to diverse applications make it a valuable material for construction, manufacturing, and engineering.

Question 6: What are some emerging trends in metal design and fabrication?

The industry is embracing digital fabrication, advanced technologies, and sustainable practices. Computer-aided design (CAD) and computer-aided manufacturing (CAM) tools enhance precision and efficiency. Additionally, the use of eco-friendly materials and processes promotes environmental responsibility.

In summary, metal design and fabrication encompass a wide range of processes and applications, offering numerous advantages for industries such as construction, manufacturing, and engineering. Understanding the key aspects and addressing common concerns can help individuals make informed decisions and leverage the benefits of metal design and fabrication effectively.

Transitioning to the next article section: This comprehensive guide to metal design and fabrication provides a solid foundation for further exploration and engagement with this dynamic field.

Tips for Metal Design and Fabrication

To achieve optimal results in metal design and fabrication, consider these practical tips:

Tip 1: Plan Thoroughly

Before starting fabrication, create detailed plans that include precise measurements, material specifications, and assembly instructions. This meticulous planning helps minimize errors and ensures a smooth fabrication process.

Tip 2: Choose the Right Materials

Select materials based on the specific requirements of your project. Consider factors such as strength, durability, corrosion resistance, and cost. Expert advice from material suppliers can guide you in making informed choices.

Tip 3: Utilize Proper Equipment and Techniques

Use appropriate tools and equipment for each fabrication task. Employ safe and efficient techniques to ensure accuracy and prevent accidents. Invest in training and certification programs to enhance your skills.

Tip 4: Pay Attention to Detail

Even the smallest details can impact the overall quality of your fabrication. Take the time to ensure precise cuts, clean welds, and proper assembly. Attention to detail leads to a professional and visually appealing finished product.

Tip 5: Implement Quality Control Measures

Establish a robust quality control process to identify and correct any defects throughout the fabrication process. Regular inspections, testing, and adherence to industry standards help maintain high-quality standards.

Tip 6: Consider Post-Fabrication Treatments

Depending on the application, consider post-fabrication treatments such as painting, powder coating, or galvanizing. These treatments enhance the durability, appearance, and corrosion resistance of the fabricated metal components.

Tip 7: Seek Professional Advice When Needed

For complex or specialized projects, do not hesitate to consult with experienced metal design and fabrication professionals. Their expertise can provide valuable insights and ensure the success of your project.

By following these tips, you can elevate the quality and efficiency of your metal design and fabrication projects, achieving exceptional results that meet your specific requirements.

Conclusion: Embracing these tips empowers you to harness the full potential of metal design and fabrication, enabling you to create durable, functional, and aesthetically pleasing metal products that stand the test of time.

Conclusion

Metal design and fabrication have emerged as indispensable processes in a wide array of industries, from construction to manufacturing and automotive. Through the manipulation and transformation of metal, we have witnessed the creation of countless structures, products, and innovations that have shaped our world.

This exploration of metal design and fabrication has illuminated the intricate processes, diverse applications, and remarkable benefits associated with this field. It is a testament to the ingenuity and skill of metalworkers, engineers, and designers.

As we look towards the future, metal design and fabrication will undoubtedly continue to evolve, driven by technological advancements and the ever-changing needs of society. Embracing new materials, innovative techniques, and sustainable practices will be crucial for shaping the future of this dynamic field.

By harnessing the power of metal design and fabrication, we can unlock endless possibilities, pushing the boundaries of creativity and innovation. Let us continue to explore, experiment, and create with this versatile and enduring material, shaping a better future for generations to come.