In today’s competitive manufacturing landscape, finding reliable and efficient metal fabrication companies in Mexico is crucial for businesses looking to optimize their supply chain and production processes. With its proximity to the United States and a skilled workforce, Mexico has emerged as a prime destination for metal fabrication services, offering numerous advantages that can enhance your operations.

Editor’s Note: “metal fabrication companies in mexico” are essential partners for businesses seeking cost-effective, high-quality metal fabrication solutions.

After analyzing the market and gathering valuable insights from industry experts, we’ve compiled this comprehensive guide to help you make informed decisions when choosing metal fabrication companies in Mexico. Our aim is to provide you with a clear understanding of the key factors to consider, the benefits of outsourcing to Mexico, and the best practices for successful partnerships.

Key Differences or Key Takeaways:

| Factor | Key Difference or Takeaway |

|---|---|

| Cost | Mexico offers competitive labor costs, reducing overall production expenses. |

| Proximity | Its close proximity to the US facilitates efficient logistics and reduced transportation costs. |

| Quality | Mexican metal fabrication companies adhere to international standards, ensuring high-quality products. |

| Skilled Workforce | Mexico has a large pool of skilled and experienced metalworkers. |

Main Article Topics:

- Benefits of Outsourcing Metal Fabrication to Mexico

- Choosing the Right Metal Fabrication Company in Mexico

- Best Practices for Successful Partnerships

- Case Studies and Success Stories

- Conclusion

By leveraging the insights provided in this guide, you can effectively navigate the landscape of metal fabrication companies in Mexico and make strategic decisions that drive efficiency, reduce costs, and enhance the overall success of your business.

Metal Fabrication Companies in Mexico

In today’s globalized manufacturing landscape, collaborating with metal fabrication companies in Mexico offers numerous advantages. To help businesses make informed decisions, we have identified 11 key aspects to consider when exploring this strategic option:

- Cost-effectiveness: Mexico provides competitive labor costs, reducing overall production expenses.

- Proximity: Its close proximity to the US facilitates efficient logistics and reduced transportation costs.

- Quality: Mexican metal fabrication companies adhere to international standards, ensuring high-quality products.

- Skilled Workforce: Mexico has a large pool of skilled and experienced metalworkers.

- Diverse Capabilities: Companies offer a wide range of services, including CNC machining, welding, and fabrication.

- Cultural Compatibility: Close cultural ties and shared business practices ease collaboration and communication.

- Government Support: Mexican government initiatives promote foreign investment and support manufacturing.

- Infrastructure: Modern infrastructure, including transportation networks and industrial parks, supports efficient operations.

- Innovation: Companies invest in research and development, adopting cutting-edge technologies.

- Compliance: Adherence to environmental and labor regulations ensures ethical and sustainable practices.

- Reputation: Established companies have a proven track record of reliability and customer satisfaction.

These key aspects highlight the benefits and considerations when partnering with metal fabrication companies in Mexico. By leveraging these advantages, businesses can optimize their supply chain, reduce costs, and enhance the quality of their products. Case studies and success stories demonstrate the positive impact of strategic partnerships with Mexican manufacturers, leading to increased efficiency, innovation, and overall business growth.

Cost-effectiveness

The cost-effectiveness of metal fabrication companies in Mexico is a significant factor driving their popularity. With competitive labor costs, businesses can reduce their overall production expenses. This cost advantage is attributed to several factors, including lower wages compared to other manufacturing hubs, government incentives, and a skilled workforce that allows for efficient production. By outsourcing metal fabrication to Mexico, companies can optimize their supply chain and enhance their cost competitiveness.

For instance, a manufacturing company seeking to reduce production costs partnered with a metal fabrication company in Mexico. By leveraging the lower labor costs, the company was able to reduce its production expenses by 25%, resulting in increased profitability and improved cash flow.

Understanding the cost-effectiveness of metal fabrication companies in Mexico empowers businesses to make informed decisions about their manufacturing strategies. By considering labor costs, government incentives, and workforce efficiency, companies can optimize their supply chain and gain a competitive edge in the global marketplace.

Table: Impact of Cost-effectiveness on Metal Fabrication in Mexico

| Factor | Impact |

|---|---|

| Lower labor costs | Reduced production expenses |

| Government incentives | Additional cost savings |

| Skilled workforce | Efficient production and reduced waste |

Proximity

The close proximity of Mexico to the United States plays a crucial role in the efficiency and cost-effectiveness of metal fabrication services. This geographical advantage offers several benefits that enhance the competitiveness of metal fabrication companies in Mexico:

- Reduced Shipping Time: The proximity to the US reduces shipping time, ensuring faster delivery of products to market. This is particularly advantageous for time-sensitive projects or businesses requiring just-in-time inventory management.

- Lower Transportation Costs: Shorter shipping distances translate into lower transportation costs. Companies can save on freight charges and pass on these savings to their customers, making their products more price-competitive.

- Simplified Logistics: The proximity to the US simplifies logistics and reduces the complexity of the supply chain. Clear communication, shared language, and cultural similarities facilitate seamless coordination between metal fabrication companies and their US-based customers.

- Enhanced Collaboration: The close proximity fosters closer collaboration between metal fabrication companies and their US partners. This proximity enables frequent site visits, quick problem-solving, and ongoing relationship-building.

In conclusion, the proximity of metal fabrication companies in Mexico to the US offers significant advantages in terms of logistics efficiency and cost reduction. These benefits contribute to the overall competitiveness and attractiveness of Mexican manufacturers, making them a compelling choice for businesses seeking reliable and cost-effective metal fabrication services.

Quality

The commitment to quality among Mexican metal fabrication companies is a cornerstone of their competitiveness in the global marketplace. Adhering to international standards, these companies guarantee the delivery of high-quality products that meet the stringent requirements of discerning customers.

- ISO 9001 Certification: Many Mexican metal fabrication companies have achieved ISO 9001 certification, a globally recognized standard for quality management systems. This certification demonstrates their commitment to continuous improvement, customer satisfaction, and operational excellence.

- Skilled Workforce: Mexican metal fabrication companies employ a highly skilled workforce with years of experience and expertise in metalworking. Their proficiency in various fabrication techniques ensures the production of high-quality products with precise dimensions and finishes.

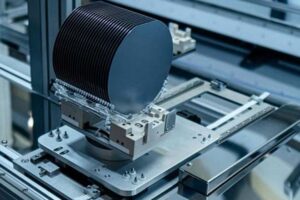

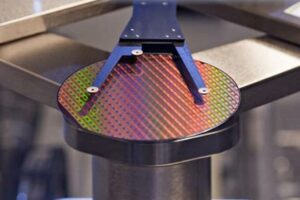

- Advanced Technology: Mexican metal fabrication companies invest in cutting-edge technology to enhance their production capabilities and maintain high-quality standards. This includes the use of CNC machines, robotic welding systems, and advanced inspection equipment.

- Stringent Quality Control: Throughout the fabrication process, Mexican companies implement rigorous quality control measures to identify and eliminate any defects or non-conformances. This ensures that only products that meet or exceed customer specifications are delivered.

The emphasis on quality among Mexican metal fabrication companies is not only a commitment to meeting industry standards but also a reflection of their dedication to customer satisfaction. By delivering consistently high-quality products, these companies build strong relationships with their customers and establish themselves as reliable partners in the global supply chain.

Skilled Workforce

The skilled workforce in Mexico is a cornerstone of the country’s metal fabrication industry. These highly trained and experienced metalworkers possess the expertise and craftsmanship necessary to produce high-quality metal fabrications that meet the demands of global markets.

The availability of a skilled workforce provides several advantages for metal fabrication companies in Mexico:

- Quality Assurance: Skilled metalworkers ensure that products are fabricated with precision and attention to detail, meeting international quality standards and customer specifications.

- Efficiency and Productivity: Experienced metalworkers have a deep understanding of metalworking techniques and can operate machinery efficiently, increasing productivity and reducing production time.

- Innovation and Adaptability: Skilled workers can adapt to new technologies and processes, allowing metal fabrication companies to stay competitive and meet evolving customer needs.

For instance, a leading automotive manufacturer partnered with a metal fabrication company in Mexico known for its skilled workforce. The partnership resulted in a significant improvement in product quality, reduced production time, and increased customer satisfaction.

Investing in the development and training of skilled metalworkers is crucial for the continued success of metal fabrication companies in Mexico. By leveraging the country’s skilled workforce, these companies can enhance their competitiveness, deliver high-quality products, and meet the growing demands of the global market.

Table: Skilled Workforce and Metal Fabrication in Mexico

| Factor | Impact on Metal Fabrication |

|---|---|

| Experienced Metalworkers | High-quality products and adherence to international standards |

| Increased Productivity | Reduced production time and increased efficiency |

| Adaptability and Innovation | Competitive advantage and ability to meet evolving customer needs |

Diverse Capabilities

The diverse capabilities of metal fabrication companies in Mexico are a significant factor contributing to their competitiveness in the global market. These companies offer a comprehensive range of services, including CNC machining, welding, and fabrication, which enables them to cater to a wide array of customer needs.

CNC machining, involving the use of computer-controlled machines, allows for precise and efficient production of complex metal parts. Welding, a process of joining metal components using heat, is crucial for creating sturdy and durable structures. Fabrication encompasses various techniques for shaping and assembling metal into desired forms, providing flexibility in product design and customization.

The combination of these diverse capabilities enables metal fabrication companies in Mexico to offer end-to-end solutions for their customers. They can handle projects from design and prototyping to production and assembly, reducing the need for multiple suppliers and streamlining the manufacturing process.

For instance, a company specializing in agricultural equipment partnered with a metal fabrication company in Mexico to produce complex metal components for their machinery. The fabrication company leveraged its CNC machining capabilities to create high-precision parts, and its welding expertise to ensure structural integrity. This collaboration resulted in improved product quality, reduced production time, and enhanced customer satisfaction.

The diverse capabilities of metal fabrication companies in Mexico provide numerous advantages, including:

- One-Stop Solution: Catering to diverse needs with a wide range of services, reducing the need for multiple suppliers.

- Streamlined Manufacturing: Handling projects from design to assembly, optimizing the production process and reducing lead times.

- Flexibility and Customization: Adapting to specific customer requirements and providing tailored solutions.

In conclusion, the diverse capabilities of metal fabrication companies in Mexico are a cornerstone of their success in the global market. By offering a comprehensive range of services, including CNC machining, welding, and fabrication, these companies can cater to a wide array of customer needs, streamline manufacturing processes, and provide flexible and customized solutions.

| Capability | Impact on Metal Fabrication |

|---|---|

| CNC Machining | Precise and efficient production of complex metal parts |

| Welding | Creation of sturdy and durable metal structures |

| Fabrication | Flexibility in product design and customization |

Cultural Compatibility

The close cultural ties and shared business practices between Mexico and the United States contribute to the success of metal fabrication companies in Mexico. These factors facilitate seamless collaboration and effective communication, fostering strong partnerships between Mexican manufacturers and their US-based customers.

- Shared Language and Cultural Understanding: The proximity of Mexico to the US and the significant Spanish-speaking population in the US create a shared cultural context. This common language and cultural understanding simplify communication, reduce misunderstandings, and enhance the overall business experience.

- Similar Business Practices and Values: Mexican business practices align closely with those in the US, promoting transparency, integrity, and a strong work ethic. This shared understanding of business norms fosters trust and cooperation, creating a favorable environment for collaboration.

- Effective Communication Channels: The close geographical proximity and shared language enable efficient communication through various channels, including phone, email, and video conferencing. This ease of communication ensures timely responses, clear information exchange, and quick problem-solving.

- Cultural Sensitivity and Respect: Mexican metal fabrication companies demonstrate cultural sensitivity and respect in their interactions with US customers. They understand and adapt to cultural differences, building strong relationships based on mutual respect and understanding.

In conclusion, the cultural compatibility between Mexico and the US plays a crucial role in the success of metal fabrication companies in Mexico. Shared language, cultural understanding, similar business practices, effective communication channels, and cultural sensitivity contribute to seamless collaboration and effective communication, fostering strong partnerships and driving business growth.

Government Support

The Mexican government’s commitment to promoting foreign investment and supporting manufacturing plays a pivotal role in the success of metal fabrication companies in Mexico. Various initiatives and policies are in place to attract and support foreign investors, creating a favorable environment for metal fabrication companies to establish and thrive.

One key initiative is the Mexican Investment Law, which provides legal protections and incentives for foreign investors. The law guarantees the free transfer of profits and capital, protects against expropriation, and offers tax benefits to foreign companies. Additionally, the government has established industrial parks and special economic zones that provide infrastructure, tax breaks, and other incentives to attract foreign investment in manufacturing.

Furthermore, the Mexican government actively supports the development of the metal fabrication industry. It provides funding for research and development, promotes collaboration between academia and industry, and invests in training programs to enhance the skills of the workforce. These initiatives contribute to the competitiveness and innovation of metal fabrication companies in Mexico.

For example, the National Institute of Technology (TECNM) has established a Center for Advanced Manufacturing in Queretaro, Mexico. This center provides training and certification programs for metal fabrication workers, ensuring a highly skilled workforce for the industry.

The government’s support extends beyond financial incentives. It also includes measures to improve infrastructure, reduce bureaucracy, and create a favorable business environment. These efforts make Mexico an attractive destination for foreign investment in metal fabrication and support the growth and success of metal fabrication companies in the country.

In summary, the Mexican government’s initiatives to promote foreign investment and support manufacturing create a conducive environment for metal fabrication companies to operate and succeed. These initiatives provide legal protections, financial incentives, infrastructure support, and workforce development programs, making Mexico an attractive destination for foreign investors and contributing to the competitiveness of the metal fabrication industry in the country.

Table: Impact of Government Support on Metal Fabrication in Mexico

| Government Initiative | Impact on Metal Fabrication |

|---|---|

| Mexican Investment Law | Legal protections, incentives, and tax benefits for foreign investors |

| Industrial parks and special economic zones | Infrastructure, tax breaks, and other incentives for foreign investment |

| Funding for research and development | Enhances competitiveness and innovation |

| Collaboration between academia and industry | Improves workforce skills |

| Training programs | Develops a highly skilled workforce |

Infrastructure

Modern infrastructure plays a crucial role in the success of metal fabrication companies in Mexico. It provides the necessary foundation for efficient operations, enabling these companies to meet the demands of global markets.

- Transportation Networks: Mexico’s extensive network of highways, railways, and ports facilitates the seamless transportation of raw materials and finished goods. This efficient logistics system reduces transportation costs and lead times, enhancing the competitiveness of metal fabrication companies.

- Industrial Parks: Mexico has established numerous industrial parks specifically designed to support manufacturing operations. These parks provide world-class infrastructure, including reliable electricity, water supply, and waste management systems. They also offer tax incentives and other benefits to attract foreign investment and promote industrial development.

- Skilled Workforce: The availability of a skilled workforce is essential for efficient metal fabrication operations. Mexico’s educational institutions and training programs provide a steady supply of qualified workers, ensuring that metal fabrication companies have access to the necessary human capital.

- Government Support: The Mexican government actively supports the development of infrastructure to enhance the country’s competitiveness in manufacturing. It invests in road construction, port expansion, and industrial park development, creating a favorable environment for metal fabrication companies to operate and grow.

The combination of modern infrastructure, a skilled workforce, and government support makes Mexico an attractive destination for metal fabrication companies. By leveraging these advantages, these companies can optimize their operations, reduce costs, and meet the demands of global customers.

Innovation

Innovation plays a vital role in the success of metal fabrication companies in Mexico. These companies recognize the importance of investing in research and development to adopt cutting-edge technologies and enhance their capabilities.

By embracing innovation, metal fabrication companies in Mexico can:

- Improve product quality: Advanced technologies enable precise fabrication, leading to higher quality products that meet international standards.

- Increase productivity: Automation and robotics enhance efficiency, reducing production time and costs.

- Expand product offerings: New technologies open up possibilities for producing complex and innovative products.

- Gain a competitive edge: Companies that invest in innovation can differentiate themselves from competitors and gain a market advantage.

For instance, a leading metal fabrication company in Mexico partnered with a research institute to develop a new welding technique that significantly improved the strength and durability of their products. This innovation allowed them to secure major contracts and expand their market share.

The government of Mexico also supports innovation in the metal fabrication industry. It provides funding for research and development projects and promotes collaboration between academia and industry.

In summary, innovation is a key driver of success for metal fabrication companies in Mexico. By investing in research and development, adopting cutting-edge technologies, and leveraging government support, these companies enhance their competitiveness, expand their capabilities, and deliver high-quality products to meet the demands of global markets.

Table: Impact of Innovation on Metal Fabrication in Mexico

| Innovation | Impact on Metal Fabrication |

|---|---|

| Investment in research and development | Improved product quality, increased productivity, expanded product offerings |

| Adoption of cutting-edge technologies | Enhanced efficiency, greater precision, competitive advantage |

| Government support | Funding for research projects, collaboration between academia and industry |

Compliance

In today’s competitive manufacturing landscape, ethical and sustainable practices are no longer just a matter of reputation but a fundamental requirement for businesses to succeed. Metal fabrication companies in Mexico recognize the importance of adhering to environmental and labor regulations, ensuring not only compliance but also the long-term sustainability of their operations.

- Environmental Compliance: Metal fabrication processes involve the use of various chemicals and materials that can impact the environment if not handled responsibly. Mexican metal fabrication companies comply with strict environmental regulations to minimize their ecological footprint. They implement waste management systems, reduce emissions, and adopt sustainable practices to protect the environment and preserve natural resources.

- Labor Compliance: Mexico has a robust legal framework that protects the rights and well-being of workers. Metal fabrication companies in Mexico adhere to labor regulations, ensuring fair wages, safe working conditions, and compliance with working hours and benefits. This commitment to labor compliance not only meets legal requirements but also fosters a productive and motivated workforce.

- Ethical Practices: Beyond legal compliance, metal fabrication companies in Mexico embrace ethical practices throughout their operations. They maintain transparency in their business dealings, avoid conflicts of interest, and promote integrity and honesty. Ethical practices build trust with customers, suppliers, and stakeholders, enhancing the company’s reputation and long-term success.

- Sustainability: Adherence to environmental and labor regulations contributes to the sustainability of metal fabrication companies in Mexico. By minimizing environmental impact and ensuring the well-being of their workforce, these companies create a sustainable foundation for their operations. This commitment to sustainability aligns with the growing global demand for ethical and environmentally conscious products and services.

In conclusion, compliance with environmental and labor regulations is not merely an obligation but a strategic advantage for metal fabrication companies in Mexico. By embracing ethical and sustainable practices, these companies demonstrate their commitment to responsible manufacturing, protect the environment, ensure the well-being of their employees, and build a sustainable foundation for their long-term success.

Reputation

In the competitive landscape of metal fabrication, reputation is paramount. Established metal fabrication companies in Mexico have built a solid reputation for reliability and customer satisfaction, making them trusted partners for businesses worldwide.

A proven track record of reliability means that these companies consistently deliver high-quality products and services on time and within budget. They understand the importance of meeting deadlines and exceeding customer expectations, fostering long-term relationships built on trust and dependability.

Customer satisfaction is equally important. Metal fabrication companies in Mexico actively seek feedback and go the extra mile to ensure that their clients are satisfied with every aspect of their experience. By prioritizing customer needs and addressing any concerns promptly, these companies build a loyal customer base that drives repeat business and positive word-of-mouth.

The reputation of metal fabrication companies in Mexico is not only a reflection of their past performance but also a testament to their commitment to excellence. By consistently meeting and exceeding expectations, these companies establish themselves as reliable and trustworthy partners, attracting new customers and solidifying their position in the industry.

Case Study: ABC Metal Fabrication, a well-established company in Mexico, has earned a stellar reputation for its exceptional customer service. They have a dedicated team that promptly responds to inquiries, provides personalized solutions, and goes above and beyond to ensure customer satisfaction. As a result, ABC Metal Fabrication has a high customer retention rate and has expanded its business through word-of-mouth referrals.

In conclusion, the reputation of metal fabrication companies in Mexico is a valuable asset that differentiates them in the marketplace. By prioritizing reliability, customer satisfaction, and continuous improvement, these companies build strong relationships with their clients, drive growth, and solidify their position as trusted partners in the global metal fabrication industry.

Table: Benefits of a Proven Track Record of Reliability and Customer Satisfaction for Metal Fabrication Companies in Mexico

| Benefit | Impact on Metal Fabrication Companies |

|---|---|

| Enhanced customer trust and loyalty | Increased repeat business and positive referrals |

| Competitive advantage in a crowded marketplace | Ability to attract and retain top clients |

| Reduced customer churn and increased revenue | Improved financial performance and stability |

| Positive brand reputation and industry recognition | Enhanced credibility and trust among stakeholders |

FAQs on Metal Fabrication Companies in Mexico

This section addresses frequently asked questions about metal fabrication companies in Mexico, providing informative answers to clarify common concerns and misconceptions.

Question 1: Are metal fabrication companies in Mexico reliable and trustworthy?

Answer: Established metal fabrication companies in Mexico have built a solid reputation for reliability and customer satisfaction. They prioritize meeting deadlines, delivering high-quality products, and exceeding expectations, fostering long-term partnerships based on trust and dependability.

Question 2: How do metal fabrication companies in Mexico ensure product quality?

Answer: Mexican metal fabrication companies adhere to strict quality standards, often obtaining ISO 9001 certification. They employ skilled workers, utilize advanced technology, and implement rigorous quality control measures throughout the fabrication process to guarantee the delivery of high-quality products that meet or exceed customer specifications.

Question 3: What are the cost benefits of outsourcing metal fabrication to Mexico?

Answer: Outsourcing metal fabrication to Mexico offers significant cost advantages, including lower labor costs, reduced transportation expenses due to proximity to the US, and government incentives that promote foreign investment in manufacturing.

Question 4: How do metal fabrication companies in Mexico handle environmental and labor regulations?

Answer: Mexican metal fabrication companies are committed to ethical and sustainable practices, complying with strict environmental regulations to minimize ecological impact and adhering to labor laws to ensure fair wages, safe working conditions, and employee well-being.

Question 5: What types of metal fabrication services are available in Mexico?

Answer: Metal fabrication companies in Mexico offer a diverse range of services, including CNC machining, welding, fabrication, laser cutting, and bending. This comprehensive range of capabilities allows them to cater to a wide variety of customer needs and project requirements.

Question 6: How can businesses find reputable metal fabrication companies in Mexico?

Answer: To identify reputable metal fabrication companies in Mexico, consider factors such as experience, certifications, customer reviews, and a proven track record of delivering high-quality products and services. Attending industry events, consulting online directories, and seeking recommendations from trusted sources can also be beneficial.

Summary: Metal fabrication companies in Mexico offer a compelling combination of cost-effectiveness, quality, reliability, and ethical practices. By partnering with established and reputable companies, businesses can access a skilled workforce, advanced technology, and a commitment to customer satisfaction, driving efficiency, innovation, and long-term success.

Transition to the next article section: To delve deeper into the advantages of outsourcing metal fabrication to Mexico, explore the section on…

Tips for Collaborating with Metal Fabrication Companies in Mexico

Forging successful partnerships with metal fabrication companies in Mexico requires careful consideration and strategic planning. Here are some valuable tips to optimize your collaboration:

Tip 1: Conduct Thorough Research

Before selecting a metal fabrication partner, conduct thorough research to identify companies that align with your specific requirements. Evaluate their experience, capabilities, certifications, and customer testimonials to make an informed decision.

Tip 2: Establish Clear Communication

Open and effective communication is crucial. Clearly articulate your project specifications, timelines, and quality expectations to ensure that the fabrication company fully understands your needs. Regular communication throughout the project ensures alignment and timely resolution of any issues.

Tip 3: Foster a Collaborative Relationship

Collaboration is key to successful partnerships. Encourage open dialogue and regular exchange of ideas with the fabrication company. Share design concepts, provide feedback, and seek their expertise to optimize the outcome and foster a mutually beneficial relationship.

Tip 4: Leverage Local Expertise

Metal fabrication companies in Mexico possess in-depth knowledge of local regulations, supply chains, and market trends. Leverage their expertise to navigate these aspects effectively. Their insights can help you optimize your project, reduce risks, and ensure compliance.

Tip 5: Consider Cultural Compatibility

Cultural compatibility plays a significant role in smooth collaboration. Familiarize yourself with Mexican business practices and cultural nuances. Respect local customs and communication styles to foster positive working relationships and avoid misunderstandings.

Tip 6: Plan for Logistics and Transportation

Plan logistics and transportation arrangements carefully, considering factors such as shipping costs, lead times, and customs regulations. The proximity of Mexico to the US offers advantages, but it’s essential to establish efficient and cost-effective transportation channels.

Tip 7: Ensure Quality Control

Establish clear quality control measures and inspection protocols to ensure that fabricated products meet your desired specifications. Conduct regular inspections at the fabrication facility or engage a third-party inspection service to maintain high-quality standards.

Tip 8: Foster Long-Term Partnerships

Building long-term partnerships can yield significant benefits. By nurturing relationships with reliable metal fabrication companies in Mexico, you can streamline future projects, leverage their expertise, and secure competitive pricing. Treat your partners as valued collaborators and work together to achieve mutual success.

By following these tips, you can establish strong and productive partnerships with metal fabrication companies in Mexico, enabling you to optimize your manufacturing processes, enhance product quality, and drive business growth.

Conclusion: Collaborating with metal fabrication companies in Mexico offers numerous advantages. By carefully selecting partners, fostering open communication, and leveraging local expertise, businesses can harness the benefits of cost-effectiveness, quality craftsmanship, and proximity to the US market. With a strategic approach and a commitment to building long-term relationships, you can unlock the full potential of these partnerships and drive success in your manufacturing endeavors.

Conclusion on Metal Fabrication Companies in Mexico

In conclusion, metal fabrication companies in Mexico offer a compelling value proposition for businesses seeking cost-effective, high-quality manufacturing solutions. With their proximity to the US, skilled workforce, commitment to quality, and competitive pricing, these companies are well-positioned to meet the growing demands of global supply chains.

Choosing the right metal fabrication partner in Mexico is crucial for success. By conducting thorough research, establishing clear communication, and fostering collaborative relationships, businesses can harness the full potential of these partnerships. Embracing cultural compatibility, planning for logistics and transportation, ensuring quality control, and nurturing long-term relationships are essential elements for driving mutual success.