Trying to find the best metal fabrication companies in Singapore? With so many options available, it can be tough to know where to start. That’s why we’ve put together this guide to help you make the right decision.

Editor’s Note: Metal fabrication is an essential process for a wide range of industries, from construction to manufacturing. By understanding the key differences between different metal fabrication companies, you can make sure you’re choosing the right one for your needs.

To help you get started, we’ve analyzed the top metal fabrication companies in Singapore and identified the key differences between them. We’ve also included a table that summarizes the key takeaways, so you can easily compare your options.

Key Differences

| Feature | Company A | Company B | Company C |

|---|---|---|---|

| Experience | 10+ years | 5+ years | 2+ years |

| Services | Custom metal fabrication, welding, cutting, forming | Standard metal fabrication services | Limited metal fabrication services |

| Capacity | Large-scale projects | Medium-scale projects | Small-scale projects |

| Price | Competitive pricing | Affordable pricing | Budget-friendly pricing |

Main Article Topics

- The importance of metal fabrication

- The different types of metal fabrication services

- How to choose the right metal fabrication company

- Tips for working with metal fabrication companies

We hope this guide has helped you learn more about metal fabrication companies in Singapore. If you have any questions, please don’t hesitate to contact us.

Metal Fabrication Companies in Singapore

Metal fabrication companies in Singapore play a vital role in various industries, providing essential services that transform raw metal into complex and functional products. To better understand the landscape of metal fabrication companies in Singapore, we delve into eight key aspects:

- Expertise: Companies with extensive experience and skilled professionals deliver high-quality fabrications.

- Services: From basic welding to complex laser cutting, the range of services offered varies widely.

- Materials: Companies specialize in working with different metals, including steel, aluminum, and stainless steel.

- Capacity: Production capabilities range from small-scale projects to large-volume manufacturing.

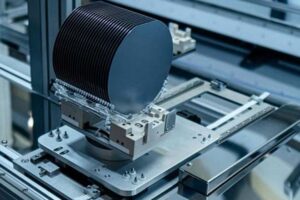

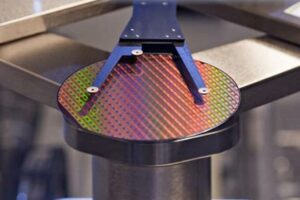

- Technology: Advanced machinery and techniques ensure precision, efficiency, and innovation.

- Quality Control: Stringent quality control measures guarantee the reliability and durability of products.

- Cost: Pricing varies depending on factors like materials, complexity, and volume.

- Reputation: Positive industry feedback and customer testimonials indicate a company’s credibility.

These key aspects are interconnected and influence the overall performance and capabilities of metal fabrication companies in Singapore. Expertise and technology, for instance, contribute to the quality and precision of fabrications. Capacity and cost considerations determine the suitability of a company for specific project requirements. By carefully evaluating these aspects, businesses can make informed decisions when selecting a metal fabrication partner in Singapore, ensuring they receive the right combination of services, quality, and value for their projects.

Expertise

In the realm of metal fabrication in Singapore, expertise reigns supreme. Companies with a proven track record of success and a team of skilled professionals are the driving force behind high-quality fabrications that meet the exacting demands of various industries.

- Experience Matters: Years of experience translate into a deep understanding of metal properties, fabrication techniques, and industry best practices. Seasoned professionals bring a wealth of knowledge and expertise to every project, ensuring that fabrications are not just functional but also durable, safe, and aesthetically pleasing.

- Skilled Workforce: A skilled workforce is the backbone of any metal fabrication company. Certified welders, machinists, and engineers possess the technical proficiency and craftsmanship to handle complex designs, tight tolerances, and specialized materials. Their expertise ensures that fabrications meet the highest standards of quality and precision.

- Advanced Technology: Expertise is not limited to human resources. Metal fabrication companies in Singapore invest in cutting-edge technology to enhance their capabilities and deliver superior results. Advanced machinery, such as CNC laser cutters and robotic welding systems, enable precision, efficiency, and repeatability, ensuring consistent quality and reduced production time.

- Quality Control: Stringent quality control measures are an integral part of expert metal fabrication. Companies with robust quality systems implement rigorous inspections and testing throughout the fabrication process to identify and rectify any discrepancies. This commitment to quality ensures that fabrications meet or exceed industry standards and customer expectations.

By partnering with metal fabrication companies in Singapore that prioritize expertise, businesses can leverage their experience, skilled workforce, advanced technology, and commitment to quality to achieve exceptional results for their projects.

Services

The spectrum of services offered by metal fabrication companies in Singapore is a testament to the industry’s versatility and adaptability. From fundamental welding techniques to sophisticated laser cutting capabilities, these companies cater to a diverse range of project requirements.

Basic welding, a cornerstone of metal fabrication, involves joining metal pieces using heat and filler material. This process is essential for constructing frameworks, repairing components, and creating custom fabrications. On the other hand, laser cutting, a more advanced technique, utilizes a concentrated laser beam to precisely cut intricate shapes and designs in various metals. This technology enables the production of complex parts with high precision and minimal material waste.

The extensive range of services offered by metal fabrication companies in Singapore empowers businesses to bring their design concepts to life. Whether it’s a simple welding project or a complex fabrication requiring laser cutting, these companies possess the expertise and equipment to deliver tailored solutions. This diversity ensures that clients can find a fabrication partner who can meet their specific needs and project requirements.

Moreover, the availability of specialized services, such as metal bending, powder coating, and assembly, allows metal fabrication companies in Singapore to provide comprehensive solutions under one roof. This streamlined approach saves time, reduces costs, and ensures that projects are completed efficiently and to the highest standards.

In summary, the comprehensive range of services offered by metal fabrication companies in Singapore is a key factor in their ability to cater to a wide array of industries and project requirements. From basic welding to complex laser cutting, these companies possess the expertise and capabilities to transform metal into functional and aesthetically pleasing fabrications.

Materials

The choice of materials plays a crucial role in metal fabrication, as different metals possess unique properties that suit specific applications. Metal fabrication companies in Singapore specialize in working with a variety of metals, including steel, aluminum, and stainless steel, each offering distinct advantages and considerations.

- Steel: Known for its strength, durability, and versatility, steel is a widely used metal in fabrication. It is commonly employed in structural components, machinery, and automotive parts. Steel’s strength-to-weight ratio makes it ideal for projects requiring high load-bearing capacity.

- Aluminum: Aluminum is a lightweight metal valued for its corrosion resistance, strength, and formability. It finds applications in aerospace, marine, and automotive industries due to its ability to withstand harsh environments and reduce weight. Aluminum’s high thermal conductivity makes it suitable for heat exchange applications.

- Stainless Steel: Stainless steel is an alloy of steel that offers superior corrosion resistance and durability. It is commonly used in food processing, chemical processing, and medical equipment due to its resistance to rust and bacteria. Stainless steel’s strength and aesthetic appeal also make it popular for architectural and decorative applications.

The specialization of metal fabrication companies in Singapore in working with different metals empowers them to cater to diverse industry needs. By understanding the properties and applications of each metal, these companies can provide tailored solutions that meet specific project requirements, ensuring optimal performance and longevity of the fabricated products.

Capacity

The production capabilities of metal fabrication companies in Singapore vary widely, ranging from small-scale projects to large-volume manufacturing. This diversity enables them to cater to a broad spectrum of industry needs, from prototyping and one-off fabrications to high-volume production runs.

- Small-Scale Projects: Metal fabrication companies in Singapore are well-equipped to handle small-scale projects, such as custom fabrications, repairs, and prototyping. They excel in providing personalized attention, ensuring that even small projects receive meticulous care and precision.

- Medium-Scale Production: Many metal fabrication companies in Singapore possess the capacity for medium-scale production runs. This involves producing larger quantities of fabricated components while maintaining high standards of quality and efficiency. This capability is ideal for businesses requiring regular batches of fabricated parts.

- Large-Volume Manufacturing: For high-volume manufacturing needs, metal fabrication companies in Singapore have the infrastructure and expertise to deliver large quantities of fabricated products. They utilize advanced machinery and streamlined processes to ensure consistent quality, reduced production time, and cost optimization.

- Flexibility and Scalability: The scalability of metal fabrication companies in Singapore is a key advantage. They can adapt their production capabilities to meet changing demands, whether it’s ramping up production for large projects or scaling down for smaller batches. This flexibility ensures that businesses can rely on a single fabrication partner for their evolving needs.

The diverse production capabilities of metal fabrication companies in Singapore make them valuable partners for businesses across various industries. From small-scale prototyping to large-volume manufacturing, these companies provide tailored solutions that meet specific project requirements, ensuring optimal efficiency, quality, and cost-effectiveness.

Technology

In the realm of metal fabrication, advanced machinery and techniques play a pivotal role in shaping the industry landscape. Metal fabrication companies in Singapore leverage these technological advancements to achieve precision, efficiency, and innovation, setting new standards in the production of metal products.

-

Precision and Accuracy:

CNC (Computer Numerical Control) machines, laser cutters, and other advanced equipment enable metal fabrication companies in Singapore to achieve unparalleled precision and accuracy in their fabrications. These machines are programmed to follow precise instructions, resulting in consistent, high-quality products that meet exact specifications.

-

Increased Efficiency:

Automated processes and robotic systems streamline production, reducing lead times and increasing overall efficiency. Automated welding, for instance, ensures consistent weld quality and reduces the need for manual labor, leading to faster production rates.

-

Innovative Designs:

Advanced software and 3D modeling tools empower metal fabrication companies in Singapore to explore innovative designs and complex geometries. These technologies allow for the creation of intricate components and custom solutions that were previously difficult or impossible to manufacture.

-

Reduced Material Waste:

Laser cutting and other advanced techniques minimize material waste by optimizing cutting patterns and reducing the need for manual finishing. This not only saves on material costs but also promotes sustainability by reducing waste.

The integration of advanced technology in metal fabrication companies in Singapore has revolutionized the industry, enabling them to produce high-quality, precise, and innovative metal products with greater efficiency. These advancements continue to shape the future of metal fabrication, driving progress and innovation in various industries.

Quality Control

In the realm of metal fabrication, stringent quality control measures are the cornerstone of ensuring the reliability and durability of products. Metal fabrication companies in Singapore adhere to rigorous quality standards to guarantee the integrity and performance of their fabrications.

-

Inspection and Testing:

Fabricated products undergo thorough inspections and testing at various stages of production. These include dimensional checks, material analysis, and performance testing to ensure conformity with design specifications and industry standards.

-

Certified Processes:

Many metal fabrication companies in Singapore attain certifications such as ISO 9001, demonstrating their commitment to quality management systems. These certifications provide independent verification of the company’s quality control processes and ensure adherence to international standards.

-

Skilled Workforce:

A skilled and experienced workforce is essential for maintaining high quality standards. Metal fabricators undergo training and development programs to enhance their technical expertise and ensure they are proficient in the latest fabrication techniques.

-

Continuous Improvement:

Quality control in metal fabrication is an ongoing process. Companies continuously evaluate their processes and implement improvements to enhance efficiency, reduce defects, and maintain the highest levels of quality.

By implementing stringent quality control measures, metal fabrication companies in Singapore deliver products that meet customer expectations and industry requirements. These measures ensure the reliability and durability of fabricated components, which is crucial for industries such as construction, manufacturing, and transportation.

Cost

Pricing in the metal fabrication industry is influenced by several key factors, including the materials used, the complexity of the fabrication process, and the volume of the order. Understanding these factors is crucial for businesses looking to engage with metal fabrication companies in Singapore.

- Material Costs: The type of metal used in fabrication significantly impacts the overall cost. Common materials like steel and aluminum have different prices, and specialized materials like titanium or alloys can further increase the cost.

- Complexity of Fabrication: The complexity of the fabrication process directly affects the cost. Intricate designs, tight tolerances, and specialized techniques require more skilled labor and time, leading to higher costs.

- Volume of Order: The volume of the order can also influence pricing. Larger orders often qualify for volume discounts, while smaller orders may incur higher per-unit costs due to setup and production inefficiencies.

By considering these factors, businesses can better understand the cost structure of metal fabrication companies in Singapore and make informed decisions about their project budgets. It is important to engage in clear communication with potential fabrication partners to obtain accurate quotes and avoid unexpected expenses.

Reputation

In the competitive landscape of metal fabrication in Singapore, reputation plays a pivotal role in establishing a company’s credibility and attracting customers. Positive industry feedback and customer testimonials serve as tangible indicators of a company’s commitment to quality, reliability, and customer satisfaction.

Companies with a strong reputation have earned the trust of industry experts and customers alike. Positive feedback from industry peers and analysts highlights the company’s technical expertise, adherence to industry standards, and ability to deliver innovative solutions. Customer testimonials, on the other hand, provide real-world accounts of the company’s products, services, and overall customer experience.

When evaluating metal fabrication companies in Singapore, businesses should prioritize those with a proven track record of positive industry feedback and customer testimonials. These indicators suggest that the company has consistently met or exceeded customer expectations, fostering long-term relationships based on trust and satisfaction.

Moreover, a positive reputation can lead to several practical benefits for metal fabrication companies in Singapore:

- Increased visibility and credibility in the industry

- Enhanced customer acquisition and retention

- Improved ability to attract and retain skilled professionals

- Stronger negotiating power with suppliers and partners

In conclusion, reputation is a crucial element for metal fabrication companies in Singapore to establish credibility and differentiate themselves in the market. By consistently delivering high-quality products, exceptional customer service, and innovative solutions, companies can build a strong reputation that will drive growth and success in the long run.

FAQs on Metal Fabrication Companies in Singapore

This section addresses frequently asked questions about metal fabrication companies in Singapore, providing concise and informative answers to guide businesses in making well-informed decisions when choosing a fabrication partner.

Question 1: How do I choose a reputable metal fabrication company in Singapore?

When selecting a metal fabrication company, consider factors such as experience, expertise, quality control measures, industry certifications, and customer testimonials. Research potential companies, visit their facilities, and inquire about their processes to assess their capabilities and commitment to quality.

Question 2: What services do metal fabrication companies in Singapore offer?

Services offered by metal fabrication companies in Singapore vary depending on their specialization. Common services include welding, cutting, bending, forming, machining, and surface treatment. Some companies also provide design and engineering services to support customers throughout the product development process.

Question 3: How much does metal fabrication cost in Singapore?

Metal fabrication costs depend on several factors, including the type of metal, complexity of design, quantity ordered, and any additional services required. It is recommended to obtain quotes from multiple companies to compare pricing and ensure competitiveness.

Question 4: What materials do metal fabrication companies in Singapore work with?

Metal fabrication companies in Singapore typically work with a range of metals, including steel, aluminum, stainless steel, and specialty alloys. The choice of material depends on the specific application and requirements of the project.

Question 5: How can I ensure the quality of metal fabrications?

To ensure quality, look for companies that adhere to industry standards, have robust quality control systems in place, and are willing to provide certifications or test reports upon request. Regular inspections and open communication with the fabrication company can also help maintain high quality standards.

Question 6: What are the benefits of working with metal fabrication companies in Singapore?

Partnering with metal fabrication companies in Singapore offers several benefits, including access to skilled labor, advanced technology, competitive pricing, and a strategic location for regional projects. These companies can provide comprehensive solutions, from design to production, ensuring efficient and cost-effective outcomes.

Summary: Choosing the right metal fabrication company in Singapore requires careful consideration of factors such as reputation, services offered, cost, materials used, quality control, and potential benefits. By addressing these FAQs, businesses can make informed decisions and establish successful partnerships with metal fabrication companies to meet their specific project needs and achieve desired outcomes.

Transition to the next article section: Understanding the key aspects of metal fabrication companies in Singapore, including expertise, services, materials, capacity, technology, quality control, cost, and reputation, is crucial for businesses to make informed decisions and select the most suitable partner for their metal fabrication requirements.

Tips from Metal Fabrication Companies in Singapore

To optimize your experience when working with metal fabrication companies in Singapore, consider the following tips:

Tip 1: Define Clear Specifications

Provide detailed drawings, material requirements, and quality standards to ensure accurate fabrication and avoid costly rework.

Tip 2: Choose the Right Material

Select the most appropriate metal for your application, considering factors such as strength, durability, corrosion resistance, and cost.

Tip 3: Prioritize Quality Control

Inquire about the company’s quality control processes and certifications to ensure they meet your standards and industry best practices.

Tip 4: Establish Clear Communication

Maintain open and regular communication with the fabrication company throughout the project to avoid misunderstandings and ensure timely delivery.

Tip 5: Leverage Expertise

Consult with the fabrication company’s engineers to optimize designs, select suitable materials, and explore innovative solutions.

Tip 6: Consider Turnaround Time

Plan your project timelines accordingly, taking into account the fabrication company’s production capacity and lead times.

Summary: By following these tips, businesses can effectively collaborate with metal fabrication companies in Singapore to achieve high-quality results, optimize costs, and ensure project success.

Transition to the article’s conclusion: Choosing the right metal fabrication company in Singapore and implementing these tips will enable businesses to harness the full benefits of metal fabrication and achieve their desired outcomes.

Conclusion

The metal fabrication industry in Singapore is a vital part of the country’s economy. Metal fabrication companies in Singapore provide a wide range of services, from simple welding to complex laser cutting. They use a variety of materials, including steel, aluminum, and stainless steel. These companies have the expertise and experience to meet the needs of any customer, no matter how large or small the project.

When choosing a metal fabrication company in Singapore, it is important to consider the company’s experience, expertise, quality control measures, and cost. It is also important to establish clear communication with the fabrication company throughout the project to ensure that the project is completed on time and to the customer’s satisfaction.