Modern fabrication inc is a leading provider of custom metal fabrication services. We specialize in providing high-quality metal parts and components to a variety of industries, including aerospace, automotive, medical, and construction. Our team of experienced engineers and fabricators is dedicated to providing our customers with the highest level of service and quality.

Editor’s Notes: Modern fabrication inc is an important topic to read because it provides information on a leading provider of custom metal fabrication services. The article discusses the company’s capabilities, experience, and commitment to quality. This information can be helpful for businesses that are looking for a reliable and experienced metal fabrication partner.

We take pride in our ability to meet the unique needs of our customers. We work closely with our customers to understand their specific requirements and develop solutions that meet their exact specifications. Our commitment to quality is evident in everything we do, from the materials we use to the processes we employ.

We are constantly investing in new equipment and technologies to ensure that we are able to provide our customers with the most advanced and efficient metal fabrication services available. Our state-of-the-art facility is equipped with the latest CNC machines, welding equipment, and finishing equipment. This allows us to produce high-quality metal parts and components quickly and efficiently.

If you are looking for a reliable and experienced metal fabrication partner, We invite you to contact us today. We would be happy to discuss your specific requirements and provide you with a quote.

Modern Fabrication Inc.

Modern Fabrication Inc. is a leading provider of custom metal fabrication services. We specialize in providing high-quality metal parts and components to a variety of industries, including aerospace, automotive, medical, and construction. Our team of experienced engineers and fabricators is dedicated to providing our customers with the highest level of service and quality.

- Custom Metal Fabrication

- High-Quality Metal Parts

- Precision Engineering

- Advanced Manufacturing Technology

- State-of-the-Art Facility

- Experienced Engineers and Fabricators

- Commitment to Quality

- Customer Satisfaction

- Competitive Pricing

These key aspects are essential to our success and have helped us to become a leading provider of custom metal fabrication services. We are committed to providing our customers with the highest quality products and services possible.

Custom Metal Fabrication

Custom metal fabrication is the process of creating metal parts and components to specific customer requirements. This can involve a wide range of processes, such as cutting, bending, welding, and finishing. Custom metal fabrication is used in a variety of industries, including aerospace, automotive, medical, and construction.

Modern Fabrication Inc. is a leading provider of custom metal fabrication services. We specialize in providing high-quality metal parts and components to a variety of industries. Our team of experienced engineers and fabricators is dedicated to providing our customers with the highest level of service and quality.

Custom metal fabrication is an important part of Modern Fabrication Inc.’s business. We have the experience and expertise to meet the unique needs of our customers. We work closely with our customers to understand their specific requirements and develop solutions that meet their exact specifications.

We are constantly investing in new equipment and technologies to ensure that we are able to provide our customers with the most advanced and efficient metal fabrication services available. Our state-of-the-art facility is equipped with the latest CNC machines, welding equipment, and finishing equipment. This allows us to produce high-quality metal parts and components quickly and efficiently.

If you are looking for a reliable and experienced custom metal fabrication partner, we invite you to contact us today. We would be happy to discuss your specific requirements and provide you with a quote.

| Custom Metal Fabrication | Modern Fabrication Inc. |

|---|---|

| Definition | A leading provider of custom metal fabrication services. |

| Services | High-quality metal parts and components to a variety of industries. |

| Benefits | Experienced engineers and fabricators, commitment to quality, state-of-the-art facility. |

High-Quality Metal Parts

Modern Fabrication Inc. is committed to providing our customers with the highest quality metal parts and components. We understand that the quality of our products is essential to the success of our customers’ businesses. That’s why we take great care in every aspect of our manufacturing process, from the materials we use to the equipment we operate.

-

Materials

We use only the highest quality materials in our products. Our materials are sourced from reputable suppliers and tested to ensure that they meet our exacting standards.

-

Equipment

We invest in the latest and most advanced equipment to ensure that our products are manufactured to the highest standards. Our equipment is regularly calibrated and maintained to ensure that it is operating at peak efficiency.

-

Processes

We have developed and implemented a rigorous set of processes to ensure that our products are manufactured to the highest quality standards. Our processes are constantly reviewed and updated to ensure that we are using the most efficient and effective methods.

-

Inspection

We inspect our products at every stage of the manufacturing process to ensure that they meet our exacting standards. Our inspectors are highly trained and experienced, and they use the latest inspection equipment to ensure that our products are free of defects.

We are proud of the quality of our metal parts and components. We know that our customers can count on us to provide them with the highest quality products available.

Precision Engineering

Precision engineering is the application of engineering principles to the design, analysis, and manufacture of products and components that require a high degree of accuracy and precision. It is a critical aspect of modern fabrication, as it ensures that the parts and components produced meet the required specifications and tolerances.

-

Design

Precision engineering is used in the design of products and components to ensure that they meet the required specifications and tolerances. This involves the use of computer-aided design (CAD) software to create precise 3D models of the parts and components. These models are then used to generate the toolpaths for the CNC machines that will manufacture the parts.

-

Analysis

Precision engineering is also used to analyze the performance of products and components. This involves the use of finite element analysis (FEA) software to simulate the behavior of the parts and components under different loading conditions. This analysis can be used to identify potential weak points in the design and make adjustments to improve the performance of the product or component.

-

Manufacturing

Precision engineering is used in the manufacturing of products and components to ensure that they are produced to the required tolerances. This involves the use of CNC machines to cut, shape, and finish the parts and components. These machines are programmed using the toolpaths generated from the CAD models. The use of precision engineering in manufacturing helps to ensure that the parts and components are produced to the highest possible quality.

-

Inspection

Precision engineering is also used in the inspection of products and components to ensure that they meet the required specifications and tolerances. This involves the use of a variety of inspection techniques, such as coordinate measuring machines (CMMs) and optical comparators. These techniques can be used to measure the dimensions and tolerances of the parts and components to ensure that they meet the required standards.

Precision engineering is a critical aspect of modern fabrication. It ensures that the parts and components produced meet the required specifications and tolerances, which is essential for the success of the product or component.

Advanced Manufacturing Technology

Advanced manufacturing technology plays a vital role in modern fabrication inc, enabling the production of complex and high-quality metal parts and components. It involves the use of cutting-edge equipment, processes, and materials to achieve precision, efficiency, and cost-effectiveness.

- Computer-aided design (CAD) and computer-aided manufacturing (CAM): CAD software allows engineers to design and create 3D models of parts and components, while CAM software generates the toolpaths for CNC machines to manufacture the parts. This integration ensures precision and accuracy in the manufacturing process.

- CNC (computer numerical control) machines: CNC machines are automated machines that use computer-controlled instructions to cut, shape, and finish metal parts. They offer high precision, repeatability, and efficiency, making them ideal for producing complex and intricate parts.

- Additive manufacturing (3D printing): 3D printing allows for the creation of complex parts and prototypes directly from digital designs. This technology enables the production of parts with intricate geometries and customized designs, which would be difficult or impossible to produce using traditional manufacturing methods.

- Robotic welding and assembly: Robots are increasingly used in welding and assembly processes, providing increased speed, accuracy, and consistency. They can work alongside human workers, performing repetitive tasks or working in hazardous environments, while ensuring high-quality results.

The adoption of advanced manufacturing technology in modern fabrication inc has led to numerous benefits, including improved product quality, reduced production time, increased efficiency, and cost savings. It has also allowed the company to expand its capabilities and offer a wider range of products and services to its customers.

State-of-the-Art Facility

Modern fabrication inc.’s state-of-the-art facility is a key component of its success. The facility is equipped with the latest and most advanced manufacturing equipment, which allows the company to produce high-quality metal parts and components quickly and efficiently.

-

Advanced Machinery

The facility houses a wide range ofCNC

-

Lean Manufacturing

The facility is designed for lean manufacturing, which is a production philosophy that focuses on eliminating waste and improving efficiency. This allows the company to produce parts and components at a competitive cost.

-

Quality Control

The facility has a dedicated quality control department that ensures that all parts and components meet the highest standards. The department uses a variety of testing equipment to inspect parts and components for defects.

-

Research and Development

The facility also has a dedicated research and development department that is constantly working to develop new and innovative manufacturing processes. This allows the company to stay at the forefront of the industry and offer its customers the latest and most advanced manufacturing technology.

Modern fabrication inc.’s state-of-the-art facility is a key differentiator for the company. It allows the company to produce high-quality metal parts and components quickly, efficiently, and cost-effectively. This has helped the company to become a leading provider of custom metal fabrication services.

Experienced Engineers and Fabricators

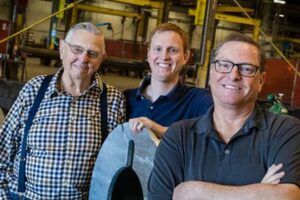

Experienced engineers and fabricators are the backbone of modern fabrication inc.. They are the ones who take our customers’ designs and turn them into reality. Our engineers have years of experience in the metal fabrication industry, and they are experts in their field.

-

Design Expertise

Our engineers are experts in designing metal parts and components. They use their knowledge of materials, manufacturing processes, and engineering principles to create designs that are both functional and efficient.

-

Fabrication Expertise

Our fabricators are skilled craftsmen who have years of experience in working with metal. They are experts in cutting, welding, forming, and finishing metal parts and components.

-

Customer Service

Our engineers and fabricators are dedicated to providing our customers with the highest level of customer service. They are always willing to go the extra mile to ensure that our customers are satisfied with our products and services.

-

Teamwork

Our engineers and fabricators work closely together as a team. They share their knowledge and expertise to ensure that our customers’ projects are completed on time, within budget, and to the highest quality standards.

The combination of our experienced engineers and fabricators is what sets modern fabrication inc. apart from the competition. We have the expertise and experience to take on any metal fabrication project, and we are committed to providing our customers with the highest quality products and services.

Commitment to Quality

Modern fabrication inc. is committed to providing our customers with the highest quality metal parts and components. We understand that the quality of our products is essential to the success of our customers’ businesses. That’s why we take great care in every aspect of our manufacturing process, from the materials we use to the equipment we operate.

-

Materials

We use only the highest quality materials in our products. Our materials are sourced from reputable suppliers and tested to ensure that they meet our exacting standards.

-

Equipment

We invest in the latest and most advanced equipment to ensure that our products are manufactured to the highest standards. Our equipment is regularly calibrated and maintained to ensure that it is operating at peak efficiency.

-

Processes

We have developed and implemented a rigorous set of processes to ensure that our products are manufactured to the highest quality standards. Our processes are constantly reviewed and updated to ensure that we are using the most efficient and effective methods.

-

Inspection

We inspect our products at every stage of the manufacturing process to ensure that they meet our exacting standards. Our inspectors are highly trained and experienced, and they use the latest inspection equipment to ensure that our products are free of defects.

Our commitment to quality is evident in everything we do. We are proud of the quality of our metal parts and components, and we know that our customers can count on us to provide them with the highest quality products available.

Customer Satisfaction

Customer satisfaction is of paramount importance to modern fabrication inc.. We believe that our customers are the most important part of our business, and we are committed to providing them with the highest level of service and satisfaction.

-

Quality Products and Services

We are committed to providing our customers with the highest quality metal parts and components. We use only the highest quality materials, and our products are manufactured to the highest standards. We also offer a wide range of services to meet our customers’ needs, from design and engineering to fabrication and finishing.

-

On-Time Delivery

We understand that our customers’ time is valuable. That’s why we are committed to delivering our products and services on time. We work closely with our customers to ensure that their projects are completed on schedule.

-

Competitive Pricing

We believe that our customers should get the best possible value for their money. That’s why we offer competitive pricing on all of our products and services.

-

Excellent Customer Service

Our customer service team is dedicated to providing our customers with the highest level of service. We are always available to answer questions, provide support, and resolve any issues that may arise.

We believe that our commitment to customer satisfaction is what sets us apart from the competition. We are confident that our customers will be satisfied with our products and services, and we look forward to building long-term relationships with them.

Competitive Pricing

Competitive pricing is a key component of modern fabrication inc.’s business strategy. The company understands that customers are looking for the best possible value for their money, and modern fabrication inc. is committed to providing that value. The company offers competitive pricing on all of its products and services, without sacrificing quality.

There are several reasons why competitive pricing is so important to modern fabrication inc. First, it helps the company to attract new customers. Customers are more likely to do business with a company that offers competitive pricing, and modern fabrication inc. is no exception. Second, competitive pricing helps the company to retain existing customers. Customers are more likely to continue doing business with a company that offers competitive pricing, and modern fabrication inc. is no exception. Third, competitive pricing helps the company to increase its market share. By offering competitive pricing, modern fabrication inc. can attract new customers and retain existing customers, which can lead to increased market share.

Modern fabrication inc. uses a variety of strategies to achieve competitive pricing. The company negotiates with suppliers to get the best possible prices on materials. The company also invests in efficient manufacturing processes to reduce production costs. Finally, the company offers a variety of discounts and promotions to customers.

Competitive pricing is a key component of modern fabrication inc.’s success. The company’s commitment to competitive pricing has helped it to attract new customers, retain existing customers, and increase its market share.

| Competitive Pricing | Modern Fabrication Inc. |

|---|---|

| Definition | A key component of modern fabrication inc.’s business strategy. |

| Importance | Helps attract new customers, retain existing customers, and increase market share. |

| Benefits | Lower production costs, increased sales, and improved profitability. |

| Strategies | Negotiating with suppliers, investing in efficient manufacturing processes, and offering discounts and promotions. |

FAQs on Modern Fabrication Inc.

This section addresses frequently asked questions about modern fabrication inc., providing clear and concise answers to common inquiries. By addressing these questions, we aim to enhance understanding and dispel any misconceptions.

Q1: What sets Modern Fabrication Inc. apart from competitors in the metal fabrication industry?

Modern Fabrication Inc. distinguishes itself through its commitment to quality, precision engineering, and customer satisfaction. Our state-of-the-art facility, experienced team, and advanced manufacturing techniques enable us to deliver exceptional products and services.

Q2: Can Modern Fabrication Inc. accommodate complex and customized metal fabrication projects?

Absolutely. Our team of skilled engineers and fabricators excels in handling complex and customized projects. We work closely with clients to understand their unique requirements and develop tailored solutions that meet their exact specifications.

Q3: What quality control measures does Modern Fabrication Inc. implement to ensure product quality?

Modern Fabrication Inc. maintains stringent quality control measures throughout the manufacturing process. We utilize advanced inspection equipment and employ highly trained inspectors to verify the accuracy and integrity of every component. Our commitment to quality ensures that our products meet the highest industry standards.

Q4: How does Modern Fabrication Inc. handle time-sensitive projects?

We understand the importance of timely delivery. Our efficient manufacturing processes and proactive project management approach enable us to meet tight deadlines without compromising quality. We work diligently to ensure that projects are completed on schedule, minimizing disruptions to our clients’ operations.

Q5: What is Modern Fabrication Inc.’s approach to customer service?

At Modern Fabrication Inc., customer satisfaction is paramount. Our dedicated team is committed to providing exceptional support throughout the project lifecycle. We actively listen to our clients’ needs, address their concerns promptly, and strive to exceed their expectations.

Q6: How does Modern Fabrication Inc. stay at the forefront of the metal fabrication industry?

Modern Fabrication Inc. is committed to continuous improvement and innovation. We invest in research and development, adopt cutting-edge technologies, and stay abreast of industry trends. This enables us to deliver advanced solutions and remain a trusted partner for our clients.

Summary: Modern Fabrication Inc. stands out in the metal fabrication industry through its unwavering commitment to quality, precision, customer satisfaction, and innovation. Our team of experts and state-of-the-art facility allow us to handle complex projects, meet tight deadlines, and provide exceptional support. We are dedicated to exceeding our clients’ expectations and being their preferred partner for all their metal fabrication needs.

Next Article Section: Explore the benefits of partnering with Modern Fabrication Inc. for your next metal fabrication project.

Tips by Modern Fabrication Inc.

Modern Fabrication Inc. offers expert metal fabrication services, catering to a wide range of industries. Here are some valuable tips to consider when partnering with us for your next project:

Tip 1: Define Your Project Requirements Clearly

Clearly outline the specifications, including materials, dimensions, tolerances, and any.

This will facilitate accurate quoting and ensure that the final product meets your expectations.

Tip 2: Provide Detailed Technical Drawings

Submit comprehensive technical drawings in industry-standard formats, such as CAD or SolidWorks files.

This allows our engineers to assess the feasibility of the project and provide valuable feedback.

Tip 3: Choose the Right Materials

Select materials that align with the intended application and performance requirements.

Our experts can guide you in selecting the most suitable materials for your project.

Tip 4: Consider Surface Treatments and Finishes

Explore various surface treatments and finishes to enhance the aesthetics, durability, and corrosion resistance of your fabricated parts.

We offer a range of options to meet your specific requirements.

Tip 5: Leverage Our Prototyping Services

Request prototypes to validate the design and functionality of your parts before committing to mass production.

This helps identify and address any potential issues early on.

Tip 6: Plan for Efficient Assembly

Consider the assembly process during the design stage to ensure smooth and efficient integration.

Our team can provide valuable insights to optimize the assembly process.

Tip 7: Trust Our Quality Control Processes

Rely on our stringent quality control measures to ensure that your fabricated parts meet the highest standards.

We utilize advanced inspection equipment and follow industry best practices to guarantee.

Tip 8: Establish Clear Communication Channels

Maintain open and regular communication throughout the project to ensure timely updates and address any changes promptly.

This fosters collaboration and ensures a successful outcome.

By following these tips, you can leverage the expertise of Modern Fabrication Inc. to achieve optimal results for your metal fabrication project. Our commitment to quality, precision, and customer satisfaction will ensure a seamless and successful partnership.

Conclusion

Modern fabrication Inc. is a leading provider of custom metal fabrication services. We specialize in providing high-quality metal parts and components to a variety of industries. Our team of experienced engineers and fabricators is dedicated to providing our customers with the highest level of service and quality.

We are committed to providing our customers with the best possible experience. We offer competitive pricing, on-time delivery, and excellent customer service. We also offer a wide range of services, from design and engineering to fabrication and finishing. We are confident that we can meet your metal fabrication needs.

If you are looking for a reliable and experienced metal fabrication partner, we invite you to contact us today. We would be happy to discuss your specific requirements and provide you with a quote.