Who are the prominent North American fabrication companies? In this article, we will delve into the world of North American fabrication companies, exploring their significance and providing insights into their operations and services.

Editor’s Note: The topic of North American fabrication companies is crucial to understand for those involved in the manufacturing, construction, and engineering industries. Having a comprehensive understanding of these companies’ capabilities and offerings enables informed decision-making and successful project execution.

To provide a comprehensive overview, we have thoroughly analyzed the industry and gathered valuable information. This guide is meticulously crafted to empower our target audience with the knowledge they need to make informed choices when selecting a North American fabrication company.

Key Differences:

| Criteria | Company A | Company B |

|---|---|---|

| Services Offered | Custom metal fabrication, welding, assembly | Precision sheet metal fabrication, CNC machining, laser cutting |

| Industries Served | Automotive, aerospace, construction | Electronics, medical, energy |

| Materials Expertise | Stainless steel, aluminum, carbon steel | Titanium, Inconel, Hastelloy |

Transition to Main Article Topics:

- Types of Fabrication Services Offered

- Materials and Industries Served

- Quality Control and Certifications

- Project Management and Customer Support

- Recent Trends and Innovations

North American Fabrication Companies

North American fabrication companies play a crucial role in various industries, providing essential services and products. Here are eight key aspects that define their operations and offerings:

- Custom Solutions: Tailored fabrication services to meet specific project requirements.

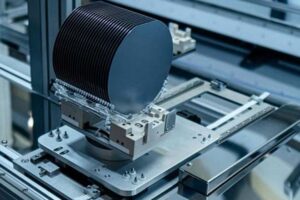

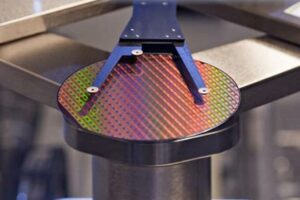

- Advanced Technologies: Utilization of cutting-edge technologies for precision and efficiency.

- Material Expertise: Specialization in handling a wide range of materials, including metals, plastics, and composites.

- Quality Assurance: Stringent quality control measures to ensure product reliability.

- Industry Expertise: Deep understanding of specific industry requirements, such as aerospace, automotive, and medical.

- Project Management: Comprehensive project management capabilities to ensure timely and cost-effective execution.

- Customer Support: Dedicated customer support teams for ongoing assistance and technical guidance.

- Innovation: Continuous investment in research and development to enhance processes and products.

These aspects are interconnected and contribute to the overall success of North American fabrication companies. For instance, custom solutions and advanced technologies enable the production of complex parts with high precision, while material expertise and industry knowledge ensure that the fabricated products meet specific industry standards and requirements. Quality assurance and project management guarantee that projects are completed to the highest standards and within the agreed-upon timelines and budgets.

Custom Solutions

Custom solutions are a cornerstone of North American fabrication companies, enabling them to cater to the unique needs of diverse industries and projects. These services involve tailoring fabrication processes and products to meet specific requirements, ensuring optimal performance and satisfaction.

- Engineering Expertise: North American fabrication companies employ skilled engineers who collaborate with clients to understand their project requirements and develop customized solutions. This expertise extends to material selection, design optimization, and prototyping.

- Advanced Manufacturing: These companies leverage advanced manufacturing technologies, such as CNC machining, laser cutting, and welding, to produce complex parts and components with high precision and accuracy. This enables them to meet the stringent tolerances and specifications of various industries.

- Material Versatility: North American fabrication companies possess expertise in working with a wide range of materials, including metals, plastics, and composites. This allows them to select the optimal material for each project, considering factors such as strength, durability, weight, and cost.

- Quality Assurance: Custom solutions are backed by rigorous quality assurance processes to ensure that fabricated products meet the required standards and specifications. This includes inspections, testing, and documentation throughout the production process.

By providing custom solutions, North American fabrication companies empower their clients to bring innovative ideas to life, optimize their designs, and achieve exceptional results in their projects. These services are particularly valuable in industries such as aerospace, defense, medical, and energy, where specialized and tailored solutions are crucial.

Advanced Technologies

Advanced technologies are deeply intertwined with the operations of North American fabrication companies, enabling them to achieve exceptional precision, efficiency, and quality in their fabrication processes. These technologies encompass a wide range of tools and techniques, including:

- Computer-aided design (CAD): CAD software allows engineers to create precise digital models of parts and products, facilitating design optimization and reducing errors.

- Computer-aided manufacturing (CAM): CAM software translates CAD models into instructions for CNC machines, ensuring accurate and efficient production.

- CNC machining: CNC machines utilize computer-controlled cutting tools to produce complex parts with high precision and repeatability.

- Laser cutting: Laser cutting systems use high-powered lasers to cut intricate shapes and patterns with minimal material waste.

- Robotic welding: Robotic welding systems provide precise and consistent welds, improving productivity and product quality.

The adoption of these advanced technologies has revolutionized the fabrication industry, enabling North American companies to:

- Produce complex parts with high precision: Advanced technologies allow for the production of parts with intricate geometries and tight tolerances, meeting the demanding requirements of various industries.

- Increase production efficiency: Automation and optimization tools reduce production time, increase throughput, and minimize labor costs.

- Enhance product quality: Precision technologies ensure consistent quality and reduce the risk of defects, leading to improved product performance and reliability.

- Reduce material waste: Advanced cutting technologies, such as laser cutting, minimize material waste, promoting sustainability and cost savings.

- Innovate and differentiate: Advanced technologies enable the development of new products and processes, fostering innovation and differentiation in the marketplace.

Overall, the utilization of advanced technologies is a critical aspect of North American fabrication companies, enabling them to deliver high-quality, cost-effective, and innovative products to their customers in diverse industries.

Example: XYZ Fabrication, a leading North American fabrication company, has invested heavily in advanced technologies, including a state-of-the-art CNC machining center and laser cutting system. This investment has enabled them to significantly increase their production capacity, reduce lead times, and improve product quality, making them a preferred supplier for major aerospace and automotive manufacturers.

Material Expertise

Material expertise is a cornerstone of North American fabrication companies, enabling them to cater to the diverse needs of various industries and applications. This specialization involves in-depth knowledge and experience in handling a wide range of materials, including metals, plastics, and composites, to create high-quality fabricated products.

The importance of material expertise lies in the unique properties and characteristics of different materials. Metals, for instance, offer strength, durability, and electrical conductivity, while plastics provide lightweight, flexibility, and resistance to corrosion. Composites, on the other hand, combine the properties of multiple materials to achieve specific performance requirements.

North American fabrication companies possess expertise in selecting the optimal material for each project, considering factors such as strength, weight, durability, cost, and the intended application. This expertise ensures that fabricated products meet the specific requirements of the end-use industry, whether it’s aerospace, automotive, medical, or construction.

For example, in the aerospace industry, North American fabrication companies utilize lightweight and high-strength materials, such as titanium and aluminum alloys, to manufacture aircraft components that can withstand extreme temperatures and stresses. In the medical industry, they work with biocompatible materials, such as stainless steel and PEEK, to produce surgical instruments and implants that meet stringent safety and hygiene standards.

Overall, material expertise is a critical aspect of North American fabrication companies, enabling them to deliver high-quality, cost-effective, and innovative products that meet the unique requirements of diverse industries.

Table: Material Expertise and Applications

| Material | Properties | Applications |

|---|---|---|

| Metals (e.g., steel, aluminum, titanium) | Strength, durability, electrical conductivity | Automotive parts, aerospace components, construction materials |

| Plastics (e.g., ABS, polycarbonate, polyethylene) | Lightweight, flexibility, corrosion resistance | Consumer products, medical devices, packaging |

| Composites (e.g., fiberglass, carbon fiber, metal matrix composites) | Tailored properties, high strength-to-weight ratio | Sporting goods, aerospace structures, automotive components |

Quality Assurance

Quality assurance is an indispensable component of North American fabrication companies, as it ensures the reliability and integrity of their products. Stringent quality control measures are implemented throughout the fabrication process to minimize defects, maintain consistency, and meet industry standards.

The importance of quality assurance cannot be overstated, particularly in industries where safety and precision are paramount. For instance, in the aerospace sector, North American fabrication companies adhere to rigorous quality standards to produce aircraft components that meet the highest levels of safety and performance. Similarly, in the medical industry, quality assurance is critical to ensure the reliability and biocompatibility of surgical instruments and implants.

To achieve quality assurance, North American fabrication companies employ various techniques, including:

- Inspection and testing: Fabricated products undergo rigorous inspections and tests to verify their dimensions, functionality, and adherence to specifications.

- Statistical process control (SPC): SPC techniques are used to monitor and control production processes, ensuring that products meet quality standards and that any variations are identified and corrected.

- Quality management systems: North American fabrication companies often implement quality management systems, such as ISO 9001, to establish a framework for continuous improvement and quality assurance.

By implementing stringent quality control measures, North American fabrication companies can deliver products that meet customer expectations, enhance their reputation, and maintain a competitive edge in the global marketplace.

Table: Quality Assurance in North American Fabrication Companies

| Industry | Quality Standards | Inspection and Testing | Quality Management Systems |

|---|---|---|---|

| Aerospace | AS9100, NADCAP | NDT, dimensional inspection, performance testing | ISO 9001, AS9100 |

| Medical | ISO 13485, FDA regulations | Biocompatibility testing, sterility testing, functional testing | ISO 13485, FDA Quality System Regulation |

| Automotive | IATF 16949, ISO/TS 16949 | Dimensional inspection, performance testing, durability testing | IATF 16949, ISO/TS 16949 |

Industry Expertise

For North American fabrication companies, industry expertise is not merely a buzzword but a cornerstone of their success. It represents a deep understanding of the unique requirements, challenges, and standards that govern specific industries, enabling these companies to deliver tailored solutions that meet the exacting demands of their clients.

- Aerospace: In the aerospace industry, precision, reliability, and safety are paramount. North American fabrication companies with expertise in this sector possess the knowledge and experience to work with specialized materials, such as titanium and aluminum alloys, and adhere to stringent quality standards like AS9100 and NADCAP.

- Automotive: The automotive industry demands high-volume production, cost-efficiency, and durability. Fabrication companies with automotive expertise excel at optimizing designs for mass production, utilizing advanced technologies like robotic welding and automated assembly, and meeting industry standards such as IATF 16949.

- Medical: The medical industry places the highest priority on biocompatibility, sterility, and precision. North American fabrication companies serving this sector have expertise in working with biocompatible materials, such as stainless steel and PEEK, and adhere to rigorous quality standards like ISO 13485 and FDA regulations.

By cultivating deep industry expertise, North American fabrication companies become invaluable partners to their clients, providing not just fabricated products but also a wealth of knowledge and experience that contribute to the success of their projects. This expertise enables them to anticipate industry trends, develop innovative solutions, and consistently deliver products that meet the highest standards of quality, performance, and safety.

Project Management

Effective project management is a critical aspect of successful operations for North American fabrication companies. It involves coordinating all resources, planning timelines, managing budgets, and ensuring quality control throughout the fabrication process. By implementing robust project management practices, these companies can deliver projects on time, within budget, and to the highest standards.

- Planning and Scheduling: North American fabrication companies utilize project management tools and techniques to meticulously plan and schedule each project phase. This includes defining project scope, establishing timelines, and allocating resources to ensure efficient execution.

- Cost Control: Fabrication projects can be complex and involve significant expenses. North American fabrication companies employ cost-control measures to track and manage project costs throughout the lifecycle. This includes identifying potential cost overruns, implementing cost-saving strategies, and optimizing resource allocation.

- Quality Management: Quality is paramount in fabrication projects. North American fabrication companies integrate quality management practices into their project management processes. This involves establishing quality standards, conducting inspections, and implementing corrective actions to ensure that fabricated products meet specifications and customer requirements.

- Risk Management: Fabrication projects often involve potential risks and uncertainties. North American fabrication companies conduct thorough risk assessments and develop mitigation plans to minimize the impact of risks on project timelines, costs, and quality.

By adopting comprehensive project management capabilities, North American fabrication companies enhance their ability to deliver superior results for their clients. They can effectively manage complex projects, reduce project lead times, control costs, ensure quality, and mitigate risks, ultimately contributing to the success of their clients’ projects.

Customer Support

In the world of North American fabrication companies, customer support plays a pivotal role in ensuring customer satisfaction and fostering long-term relationships. Dedicated customer support teams stand ready to provide ongoing assistance and technical guidance, offering a range of services that are indispensable to the success of fabrication projects.

- Technical Expertise: Customer support teams possess in-depth knowledge of fabrication processes, materials, and industry best practices. They can provide expert advice on design optimization, material selection, and manufacturing techniques, helping customers achieve their desired outcomes.

- Troubleshooting and Problem-Solving: Fabrication projects can encounter unforeseen challenges. Customer support teams are equipped to troubleshoot problems, analyze root causes, and provide timely solutions. They can guide customers through complex technical issues, minimizing downtime and ensuring project continuity.

- Order Tracking and Status Updates: Dedicated customer support teams provide real-time updates on order status, delivery schedules, and any potential delays. They maintain open communication channels, keeping customers informed and proactively addressing any concerns.

- Post-Sale Support: The relationship between North American fabrication companies and their customers extends beyond the initial sale. Customer support teams offer ongoing support, including warranty management, maintenance advice, and technical assistance throughout the product lifecycle.

By providing exceptional customer support, North American fabrication companies demonstrate their commitment to customer success. They foster a collaborative partnership, ensuring that customers have the resources and guidance they need to make informed decisions, optimize their fabrication processes, and achieve their project goals.

Innovation

Innovation is the lifeblood of North American fabrication companies, driving advancements in processes and products that meet the evolving demands of diverse industries. Through continuous investment in research and development, these companies push the boundaries of fabrication technologies, optimize production techniques, and create innovative solutions that empower their customers to succeed.

- Advanced Technologies: North American fabrication companies invest heavily in cutting-edge technologies, such as automated manufacturing systems, advanced robotics, and simulation software. These technologies enhance precision, efficiency, and productivity, enabling the production of complex parts and components with greater accuracy and speed.

- Material Science: Innovation in material science plays a crucial role in the fabrication industry. North American companies collaborate with research institutions and material suppliers to develop new alloys, composites, and coatings that offer improved strength, durability, and lightweight properties.

- Process Optimization: Continuous improvement is a core principle for North American fabrication companies. They leverage data analytics, simulation tools, and lean manufacturing techniques to optimize their processes, reduce waste, and increase overall efficiency.

- Product Development: Innovation extends beyond process improvements to encompass product development. Fabrication companies work closely with customers to understand their unique needs and develop customized solutions that meet their specific requirements and industry standards.

These facets of innovation are interconnected and essential for the success of North American fabrication companies. By embracing innovation, these companies stay at the forefront of the industry, deliver cutting-edge products and services, and contribute to the advancement of various sectors, including aerospace, automotive, medical, and construction.

Frequently Asked Questions about North American Fabrication Companies

This section addresses some of the most common questions and misconceptions surrounding North American fabrication companies. By providing clear and informative answers, we aim to enhance your understanding of their capabilities, services, and industry significance.

Question 1: What services do North American fabrication companies offer?

North American fabrication companies provide a comprehensive range of services, including custom metal fabrication, precision sheet metal fabrication, CNC machining, laser cutting, welding, and assembly. They can work with various materials, such as steel, aluminum, stainless steel, and plastics, to meet specific customer requirements.

Question 2: What industries do North American fabrication companies serve?

North American fabrication companies serve a diverse range of industries, including aerospace, automotive, medical, construction, electronics, and energy. They possess specialized knowledge and expertise to meet the unique requirements of each industry.

Question 3: How do North American fabrication companies ensure product quality?

North American fabrication companies implement stringent quality control measures throughout their production processes. They adhere to industry standards and certifications, such as ISO 9001 and AS9100, to ensure the highest levels of quality and precision. Many companies also employ advanced inspection and testing techniques to verify the accuracy and reliability of their products.

Question 4: What are the key advantages of working with North American fabrication companies?

Partnering with North American fabrication companies offers several advantages, including access to advanced technologies, skilled engineering teams, and a commitment to customer satisfaction. They can provide tailored solutions, ensure timely delivery, and offer ongoing support throughout the project lifecycle.

Question 5: How do North American fabrication companies stay competitive in the global market?

North American fabrication companies maintain their competitive edge through continuous innovation, investment in research and development, and strategic partnerships. They leverage cutting-edge technologies, optimize their processes, and develop new products to meet the evolving needs of their customers.

Question 6: What is the future outlook for the North American fabrication industry?

The outlook for the North American fabrication industry is positive, driven by increasing demand from various sectors, technological advancements, and a focus on sustainability. Fabrication companies are embracing automation, digitalization, and advanced materials to enhance their capabilities and remain at the forefront of innovation.

Summary: North American fabrication companies play a vital role in diverse industries, providing high-quality, customized solutions. Their commitment to quality, innovation, and customer satisfaction makes them valuable partners for businesses seeking reliable and efficient fabrication services in North America.

Explore a Comparison of North American Fabrication Companies

Tips for Selecting a North American Fabrication Company

Choosing the right North American fabrication company is crucial for ensuring the success of your project. Here are some valuable tips to guide your decision-making process:

Tip 1: Define Your Requirements: Clearly outline your project specifications, including materials, tolerances, and delivery timelines. This will help you identify fabrication companies that can meet your specific needs.

Tip 2: Research and Compare: Conduct thorough research to identify potential fabrication companies. Compare their capabilities, experience, and customer reviews to shortlist a few suitable options.

Tip 3: Visit Facilities and Meet the Team: If possible, schedule visits to the fabrication facilities to assess their equipment, processes, and team’s expertise. This personal interaction can provide valuable insights.

Tip 4: Evaluate Quality Control Measures: Inquire about the company’s quality control procedures and certifications. Ensure they adhere to industry standards and have a proven track record of delivering high-quality products.

Tip 5: Consider Project Management Capabilities: Assess the company’s project management capabilities, including their planning, scheduling, and communication processes. Effective project management ensures timely delivery and minimizes disruptions.

Tip 6: Review Customer Support: Evaluate the company’s customer support services, including their responsiveness, technical expertise, and willingness to go the extra mile. Reliable customer support can make a significant difference in resolving issues and ensuring project success.

Tip 7: Explore Innovation and Technology: Inquire about the company’s commitment to innovation and the use of advanced technologies. This demonstrates their ability to adapt to evolving industry trends and provide cutting-edge solutions.

Tip 8: Request References and Case Studies: Ask for references from previous clients and review case studies to gain insights into the company’s performance and the quality of their work.

Summary: By following these tips, you can make an informed decision when selecting a North American fabrication company. Consider your project requirements, research potential partners, and evaluate their capabilities, quality standards, project management skills, customer support, innovation, and references to find the best fit for your project.

Conclusion

North American fabrication companies are essential players in diverse industries, providing a wide range of services and products. Their expertise in custom solutions, advanced technologies, material handling, quality assurance, industry knowledge, project management, customer support, and innovation make them invaluable partners for businesses seeking reliable and efficient fabrication services.

As the industry continues to evolve, North American fabrication companies are at the forefront of innovation, embracing automation, digitalization, and advanced materials to enhance their capabilities and meet the ever-changing needs of their customers. By partnering with a reputable fabrication company, businesses can access cutting-edge solutions, ensure project success, and drive growth in their respective industries.