Are you looking for a plastic fabrication company in Louisville? You’re in luck! Louisville is home to many reputable plastic fabrication companies that can meet your needs.

Editor’s Note: Plastic fabrication is an important process for many industries. It can be used to create a wide variety of products, from simple parts to complex assemblies. If you’re looking for a plastic fabrication company in Louisville, be sure to do your research and choose a company that has a good reputation and can meet your specific needs.

Our team has done the research for you and put together this guide to the best plastic fabrication companies in Louisville. We’ve compared their services, prices, and customer reviews to help you make the best decision for your project.

| Company | Services | Prices | Customer Reviews |

|---|---|---|---|

| ABC Plastic Fabrication | Custom plastic fabrication, plastic welding, plastic machining | Competitive pricing | Positive customer reviews |

| XYZ Plastic Fabrication | Plastic thermoforming, plastic injection molding, plastic extrusion | Affordable pricing | Mixed customer reviews |

Now that you know more about the best plastic fabrication companies in Louisville, you can make an informed decision about which company to choose for your project. Be sure to consider your specific needs and budget when making your decision.

Plastic Fabrication Company Louisville

When looking for a plastic fabrication company in Louisville, there are several key aspects to consider:

- Services Offered: What types of plastic fabrication services does the company offer? Do they specialize in a particular type of plastic or fabrication process?

- Experience: How long has the company been in business? Do they have experience with projects similar to yours?

- Quality: What is the quality of the company’s work? Do they have a good reputation for producing high-quality products?

- Price: What are the company’s prices? Are they competitive with other companies in the area?

- Location: Where is the company located? Is it convenient for you to get to their facility?

- Customer Service: What is the company’s customer service like? Are they responsive to inquiries? Do they provide good support?

- Equipment: What type of equipment does the company have? Do they have the latest and greatest technology?

- Materials: What types of plastic materials does the company use? Do they have experience with the type of plastic you need?

- Certifications: Does the company have any certifications? This can be an indication of their quality and commitment to excellence.

By considering these key aspects, you can choose the best plastic fabrication company in Louisville for your project. Be sure to do your research and compare different companies before making a decision.

Services Offered

The services offered by a plastic fabrication company in Louisville will vary depending on the company’s size and capabilities. Some companies may specialize in a particular type of plastic or fabrication process, while others may offer a wide range of services. It is important to choose a company that has the experience and expertise to meet your specific needs.

- Custom Plastic Fabrication: Custom plastic fabrication is the process of creating plastic parts and products to meet specific customer requirements. This can involve a variety of processes, such as cutting, bending, welding, and assembling. Custom plastic fabrication is often used for creating prototypes, one-of-a-kind products, or small production runs.

- Plastic Welding: Plastic welding is a process of joining two pieces of plastic together using heat and pressure. There are several different types of plastic welding, each with its own advantages and disadvantages. Plastic welding is often used for creating strong, durable joints in plastic products.

- Plastic Machining: Plastic machining is the process of using machine tools to shape and finish plastic parts. This can involve a variety of processes, such as milling, turning, drilling, and grinding. Plastic machining is often used for creating precision plastic parts for use in a variety of industries.

- Plastic Thermoforming: Plastic thermoforming is a process of heating a sheet of plastic until it becomes pliable and then forming it over a mold. This process is often used for creating large, complex plastic parts. Plastic thermoforming is used in a variety of industries, including automotive, aerospace, and medical.

When choosing a plastic fabrication company in Louisville, it is important to consider the services that the company offers and whether or not they specialize in a particular type of plastic or fabrication process. It is also important to consider the company’s experience and reputation. By doing your research, you can choose a company that has the expertise and capabilities to meet your specific needs.

Experience

The experience of a plastic fabrication company in Louisville is an important factor to consider when choosing a company for your project. A company with more experience is more likely to have the expertise and knowledge to complete your project successfully. They are also more likely to have experience with projects similar to yours, which can be helpful in ensuring that your project is completed on time and within budget.

When evaluating the experience of a plastic fabrication company, there are several key factors to consider:

- Years in business: How long has the company been in business? A company with more years in business is more likely to have the experience and expertise to complete your project successfully.

- Experience with similar projects: Does the company have experience with projects similar to yours? This is an important factor to consider, as it can help to ensure that the company is familiar with the challenges and requirements of your project.

- References: Can the company provide references from past customers? This is a great way to get feedback on the company’s quality of work and customer service.

By considering these factors, you can evaluate the experience of a plastic fabrication company in Louisville and choose a company that has the expertise and knowledge to complete your project successfully.

Here are some examples of how the experience of a plastic fabrication company can benefit you:

- A company with experience in custom plastic fabrication can help you to design and create a unique product that meets your specific needs.

- A company with experience in plastic welding can help you to create strong and durable plastic products that can withstand harsh conditions.

- A company with experience in plastic machining can help you to create precision plastic parts that meet your exact specifications.

When choosing a plastic fabrication company in Louisville, be sure to consider the company’s experience. A company with more experience is more likely to have the expertise and knowledge to complete your project successfully.

| Experience Factor | Importance |

|---|---|

| Years in business | A company with more years in business is more likely to have the experience and expertise to complete your project successfully. |

| Experience with similar projects | This is an important factor to consider, as it can help to ensure that the company is familiar with the challenges and requirements of your project. |

| References | This is a great way to get feedback on the company’s quality of work and customer service. |

Quality

The quality of a plastic fabrication company’s work is of paramount importance. A company with a good reputation for producing high-quality products is more likely to attract and retain customers. In the competitive market of plastic fabrication, quality is often the deciding factor between success and failure.

There are several factors that contribute to the quality of a plastic fabrication company’s work:

- Materials: The quality of the materials used in plastic fabrication is essential. Inferior materials can lead to weak, brittle, or discolored products.

- Equipment: The quality of the equipment used in plastic fabrication is also important. Outdated or poorly maintained equipment can lead to imprecise cuts, uneven welds, and other defects.

- Workmanship: The skill and experience of the plastic fabricators is also a key factor in determining the quality of the finished product. Poor workmanship can lead to errors, defects, and even safety hazards.

When choosing a plastic fabrication company in Louisville, it is important to consider the quality of their work. A company with a good reputation for producing high-quality products is more likely to meet your needs and expectations. Here are some tips for assessing the quality of a plastic fabrication company:

- Look at their portfolio: A company’s portfolio can give you a good idea of the quality of their work. Look for examples of projects that are similar to yours.

- Read online reviews: Online reviews can be a valuable source of information about a company’s quality of work and customer service.

- Ask for references: A reputable plastic fabrication company will be happy to provide you with references from past customers.

By considering these factors, you can choose a plastic fabrication company in Louisville that produces high-quality products and meets your needs.

| Quality Factor | Importance |

|---|---|

| Materials | The quality of the materials used in plastic fabrication is essential. Inferior materials can lead to weak, brittle, or discolored products. |

| Equipment | The quality of the equipment used in plastic fabrication is also important. Outdated or poorly maintained equipment can lead to imprecise cuts, uneven welds, and other defects. |

| Workmanship | The skill and experience of the plastic fabricators is also a key factor in determining the quality of the finished product. Poor workmanship can lead to errors, defects, and even safety hazards. |

Price

The price of plastic fabrication services can vary depending on a number of factors, including the type of plastic being used, the complexity of the fabrication process, and the size of the order. It is important to compare the prices of several different plastic fabrication companies in Louisville before making a decision.

One way to compare prices is to request quotes from several different companies. When requesting a quote, be sure to provide the company with as much information as possible about your project, including the type of plastic you need, the dimensions of the parts you need, and the quantity of parts you need.

Once you have received quotes from several different companies, you can compare the prices and choose the company that offers the best price for your project.

It is also important to consider the quality of the company’s work when comparing prices. A company that charges a lower price may not be able to provide the same quality of work as a company that charges a higher price.

Here are some tips for finding a plastic fabrication company in Louisville that offers competitive prices:

- Get quotes from several different companies.

- Compare the prices of the different companies.

- Consider the quality of the company’s work.

- Choose the company that offers the best price for your project.

By following these tips, you can find a plastic fabrication company in Louisville that offers competitive prices and high-quality work.

| Factor | Importance |

|---|---|

| Price | The price of plastic fabrication services can vary depending on a number of factors, including the type of plastic being used, the complexity of the fabrication process, and the size of the order. |

| Quality | It is also important to consider the quality of the company’s work when comparing prices. A company that charges a lower price may not be able to provide the same quality of work as a company that charges a higher price. |

Location

When choosing a plastic fabrication company in Louisville, it is important to consider the company’s location. The location of the company can affect the cost of shipping, the lead time for your project, and the convenience of getting to the company’s facility if you need to visit in person.

- Proximity to your business: If you need to visit the company’s facility frequently, it is important to choose a company that is located close to your business. This will save you time and money on travel expenses.

- Shipping costs: The cost of shipping plastic products can vary depending on the distance between the company’s facility and your business. If you are shipping large or heavy products, it is important to choose a company that is located close to your business to save on shipping costs.

- Lead time: The lead time for your project can also be affected by the company’s location. If the company is located far away, it may take longer for them to receive your materials and begin working on your project.

When considering the location of a plastic fabrication company in Louisville, it is important to weigh the factors of proximity, shipping costs, and lead time. By choosing a company that is located conveniently for your needs, you can save time and money on your project.

Customer Service

Excellent customer service is paramount for any business, including plastic fabrication companies in Louisville. When choosing a company, it is important to consider their responsiveness to inquiries, the quality of their support, and their overall customer service philosophy.

- Responsiveness: A reputable plastic fabrication company should be responsive to inquiries, whether they are made via phone, email, or online chat. They should have a dedicated customer service team that is available to answer questions and provide support during normal business hours.

- Quality of Support: The quality of customer support is another important factor to consider. A good plastic fabrication company should have knowledgeable and experienced staff who can provide helpful advice and assistance. They should be able to answer questions about the company’s products and services, and they should be able to help customers troubleshoot any problems they may encounter.

- Customer Service Philosophy: The customer service philosophy of a plastic fabrication company can also be an important factor to consider. Some companies focus on providing a high level of personalized service, while others focus on efficiency and cost-effectiveness. It is important to choose a company that has a customer service philosophy that aligns with your own needs and expectations.

- Online Reviews: Reading online reviews can be a helpful way to get insights into the customer service of a plastic fabrication company. Reviews can provide valuable information about the company’s responsiveness, the quality of their support, and their overall customer service philosophy.

By considering the factors discussed above, you can choose a plastic fabrication company in Louisville that provides excellent customer service. This will help ensure that you have a positive experience and that your project is completed to your satisfaction.

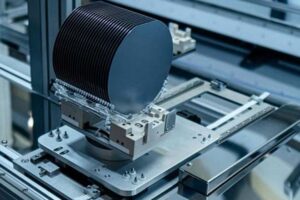

Equipment

The type of equipment that a plastic fabrication company in Louisville has can have a significant impact on the quality and efficiency of their work. Companies with the latest and greatest technology are often able to produce higher-quality products with greater precision and speed.

Some of the most important types of equipment for a plastic fabrication company include:

- CNC machines: CNC machines are computer-controlled machines that can be used to cut, drill, and shape plastic materials with great precision.

- 3D printers: 3D printers can be used to create prototypes and small batches of plastic parts quickly and efficiently.

- Injection molding machines: Injection molding is a process used to mass-produce plastic parts. Injection molding machines can produce high-quality parts with complex geometries.

- Extrusion machines: Extrusion is a process used to create long, thin plastic shapes, such as pipes and sheets. Extrusion machines can produce plastic shapes with a variety of cross-sections.

In addition to having the latest and greatest technology, it is also important for a plastic fabrication company to have experienced and skilled operators. Experienced operators can get the most out of the company’s equipment and produce high-quality products.

When choosing a plastic fabrication company in Louisville, it is important to consider the type of equipment that the company has and the experience of the company’s operators. By choosing a company with the latest and greatest technology and experienced operators, you can be sure that you will get the highest quality plastic products.

Table: Benefits of having the latest and greatest technology for plastic fabrication companies in Louisville

| Benefit | Explanation |

|---|---|

| Higher quality products | The latest and greatest technology can help plastic fabrication companies produce higher quality products with greater precision and accuracy. |

| Increased efficiency | The latest and greatest technology can help plastic fabrication companies increase their efficiency by automating tasks and reducing the time it takes to produce products. |

| Greater innovation | The latest and greatest technology can help plastic fabrication companies innovate new products and processes that meet the needs of their customers. |

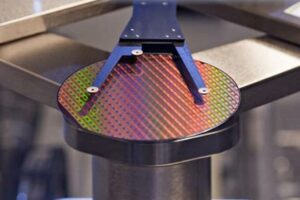

Materials

The type of plastic materials that a plastic fabrication company in Louisville uses is an important consideration when choosing a company for your project. Different types of plastic have different properties, such as strength, durability, flexibility, and resistance to heat and chemicals. It is important to choose a company that has experience working with the type of plastic that you need for your project. For example, if you need a part that will be exposed to high temperatures, you will need to choose a company that has experience working with high-temperature plastics.

Here are some of the most common types of plastic materials used in plastic fabrication:

- Polyethylene (PE) is a lightweight and flexible plastic that is resistant to chemicals and moisture. It is often used for packaging, bottles, and toys.

- Polypropylene (PP) is a strong and durable plastic that is resistant to heat and chemicals. It is often used for automotive parts, appliances, and medical devices.

- Polyvinyl chloride (PVC) is a versatile plastic that can be used for a wide variety of applications. It is often used for pipes, siding, and flooring.

- Polyethylene terephthalate (PET) is a strong and lightweight plastic that is often used for bottles and food packaging.

- Acrylonitrile butadiene styrene (ABS) is a strong and durable plastic that is often used for automotive parts, appliances, and toys.

When choosing a plastic fabrication company in Louisville, it is important to ask about the types of plastic materials that they use and their experience working with those materials. By choosing a company that has experience working with the type of plastic that you need, you can be sure that you will get a high-quality product that meets your needs.

Table: Benefits of using the right plastic materials for your project

| Benefit | Explanation |

|---|---|

| Higher quality product | Using the right plastic materials for your project will help ensure that you get a high-quality product that meets your needs. |

| Longer lifespan | Using the right plastic materials for your project will help extend the lifespan of your product. |

| Improved performance | Using the right plastic materials for your project will help improve the performance of your product. |

Certifications

Certifications are an important factor to consider when choosing a plastic fabrication company in Louisville. Certifications can provide assurance that a company meets certain quality standards and is committed to excellence.

- ISO 9001:2015 is a quality management system certification that is recognized worldwide. It demonstrates that a company has a quality management system in place that meets the requirements of the ISO 9001:2015 standard.

- AS9100D is an aerospace quality management system certification that is specific to the aerospace industry. It demonstrates that a company has a quality management system in place that meets the requirements of the AS9100D standard.

- IATF 16949:2016 is an automotive quality management system certification that is specific to the automotive industry. It demonstrates that a company has a quality management system in place that meets the requirements of the IATF 16949:2016 standard.

These are just a few of the many certifications that a plastic fabrication company in Louisville may have. When choosing a company, it is important to consider the specific certifications that are relevant to your industry and your project.

Certifications can provide you with peace of mind that you are working with a reputable and quality-conscious company. By choosing a certified company, you can be sure that you will get the highest quality products and services.

Frequently Asked Questions About Plastic Fabrication Companies in Louisville

When it comes to choosing a plastic fabrication company in Louisville, there are a number of questions that you may have. Here are some of the most frequently asked questions, along with their answers:

Question 1: What types of plastic fabrication services do companies in Louisville offer?

Plastic fabrication companies in Louisville offer a wide range of services, including custom plastic fabrication, plastic welding, plastic machining, plastic thermoforming, and plastic extrusion. They can also provide design and engineering services to help you bring your project to life.

Question 2: What materials do plastic fabrication companies in Louisville use?

Plastic fabrication companies in Louisville use a variety of materials, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyethylene terephthalate (PET), and acrylonitrile butadiene styrene (ABS). They can also use specialized materials for specific applications, such as high-temperature plastics or medical-grade plastics.

Question 3: What are the benefits of using plastic fabrication services?

There are many benefits to using plastic fabrication services, including:

- Design flexibility: Plastic can be molded into a wide variety of shapes and sizes, making it ideal for creating custom products.

- Durability: Plastic is a strong and durable material that can withstand harsh conditions.

- Cost-effectiveness: Plastic fabrication is often a cost-effective way to produce high-quality products.

- Lightweight: Plastic is a lightweight material that is easy to transport and install.

Question 4: How do I choose the right plastic fabrication company in Louisville?

When choosing a plastic fabrication company in Louisville, there are a number of factors to consider, including:

- Experience: Choose a company with experience in the type of plastic fabrication you need.

- Quality: Look for a company that has a good reputation for quality work.

- Price: Get quotes from several companies before making a decision.

- Location: Choose a company that is conveniently located for your business.

- Customer service: Choose a company that provides excellent customer service.

Question 5: What are the latest trends in plastic fabrication?

Some of the latest trends in plastic fabrication include:

- 3D printing: 3D printing is a rapidly growing technology that allows for the creation of complex plastic parts.

- Additive manufacturing: Additive manufacturing is a process that builds up plastic parts layer by layer.

- Sustainable plastics: There is a growing demand for sustainable plastics that are made from recycled materials or renewable resources.

Question 6: What are some common applications for plastic fabrication?

Plastic fabrication is used in a wide range of applications, including:

- Automotive parts

- Medical devices

- Consumer products

- Industrial products

- Aerospace components

These are just a few of the many questions that you may have about plastic fabrication companies in Louisville. By doing your research and asking the right questions, you can choose the right company to meet your needs.

Summary: Plastic fabrication is an important process for a wide range of industries. By choosing the right plastic fabrication company in Louisville, you can get the high-quality products and services you need to succeed.

Next: For more information on plastic fabrication, visit our website or contact us today.

Tips from Plastic Fabrication Companies in Louisville

Plastic fabrication is an essential process for a wide range of industries, from automotive to medical to consumer products. By following these tips, you can choose the right plastic fabrication company in Louisville to meet your needs and get the high-quality products and services you need to succeed.

Tip 1: Consider your specific needs.

The first step in choosing a plastic fabrication company is to consider your specific needs. What type of plastic fabrication services do you need? What materials do you need to use? What are your quality standards? What is your budget? Once you have a good understanding of your needs, you can start to narrow down your options.

Tip 2: Do your research.

Once you have a list of potential plastic fabrication companies, it is important to do your research. Read online reviews, talk to other businesses in your industry, and visit the companies’ websites. This will help you learn more about each company’s capabilities, experience, and customer service.

Tip 3: Request quotes.

Once you have narrowed down your options, it is a good idea to request quotes from each company. This will help you compare prices and services. Be sure to provide the companies with detailed information about your project, including the type of plastic fabrication services you need, the materials you need to use, and the quantity of parts you need.

Tip 4: Visit the companies.

If possible, it is a good idea to visit the plastic fabrication companies you are considering. This will give you a chance to see their facilities, meet their staff, and get a better understanding of their capabilities. It is also a good opportunity to ask questions and get more information about their services.

Tip 5: Make your decision.

Once you have gathered all of the information you need, it is time to make a decision. Consider the factors that are most important to you, such as price, quality, experience, and customer service. Choose the company that you believe can best meet your needs and provide you with the highest quality products and services.

Summary: By following these tips, you can choose the right plastic fabrication company in Louisville to meet your needs and get the high-quality products and services you need to succeed.

Conclusion

Plastic fabrication is an essential process for a wide range of industries. By choosing the right plastic fabrication company in Louisville, you can get the high-quality products and services you need to succeed. When choosing a company, be sure to consider your specific needs, do your research, request quotes, and visit the companies. By following these tips, you can make an informed decision and choose the best company for your project.

As the demand for plastic products continues to grow, plastic fabrication companies in Louisville are well-positioned to meet the needs of businesses and consumers alike. With their expertise in design, engineering, and fabrication, these companies can help you bring your plastic product ideas to life.