Singapore fabrication companies are playing an increasingly important role in the global manufacturing landscape. With their advanced technological capabilities and skilled workforce, Singapore fabrication companies are able to produce high-quality products at competitive prices. This has made them a popular choice for manufacturers around the world.

Editor’s Notes: “Singapore fabrication companies” is an important topic to read because it provides insights into the latest trends and developments in the manufacturing industry. By understanding the capabilities of Singapore fabrication companies, manufacturers can make informed decisions about their sourcing strategies.

To help you understand the benefits of working with Singapore fabrication companies, we have put together this guide. In this guide, we will discuss the key advantages of working with Singapore fabrication companies and provide you with tips on how to find the right partner for your business.

Key Differences or Key Takeaways

| Factor | Singapore Fabrication Companies |

|---|---|

| Technology | Advanced and well-equipped |

| Workforce | Skilled and experienced |

| Quality | High-quality products |

| Cost | Competitive prices |

Transition to main article topics

In the following sections, we will discuss the following topics:

- The advantages of working with Singapore fabrication companies

- How to find the right Singapore fabrication company for your business

- Case studies of successful partnerships between manufacturers and Singapore fabrication companies

We hope that this guide will help you make informed decisions about your manufacturing sourcing strategy. If you have any questions, please do not hesitate to contact us.

Singapore Fabrication Companies

Singapore fabrication companies play a vital role in the global manufacturing landscape, offering a range of capabilities and advantages to businesses worldwide. Here are nine key aspects that highlight their importance:

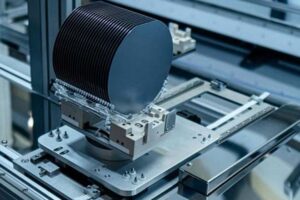

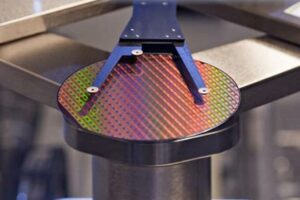

- Advanced Technology: Singapore fabrication companies are equipped with cutting-edge technologies and machinery, ensuring high-precision and efficient manufacturing.

- Skilled Workforce: The workforce in Singapore is highly skilled and experienced, with expertise in various fabrication techniques.

- Quality Products: Singapore fabrication companies adhere to strict quality standards, delivering products that meet international certifications and customer specifications.

- Competitive Pricing: Despite their advanced capabilities, Singapore fabrication companies offer competitive pricing, making their services accessible to businesses of all sizes.

- Global Reach: Singapore is a global hub for manufacturing, providing easy access to international markets and supply chains.

- Innovation: Singapore fabrication companies are constantly innovating and investing in research and development, pushing the boundaries of manufacturing technology.

- Sustainability: Many Singapore fabrication companies prioritize sustainability, implementing eco-friendly practices and reducing their environmental impact.

- Government Support: The Singapore government provides support and incentives to the fabrication industry, fostering a conducive business environment.

- Collaboration: Singapore fabrication companies actively collaborate with research institutions and industry partners, enhancing their capabilities and staying at the forefront of innovation.

In conclusion, these key aspects underscore the strengths and value proposition of Singapore fabrication companies. Their commitment to quality, innovation, and global reach make them ideal partners for businesses seeking reliable and efficient manufacturing solutions. By leveraging the expertise of Singapore fabrication companies, businesses can gain a competitive edge in today’s dynamic manufacturing landscape.

Advanced Technology

The advanced technology employed by Singapore fabrication companies is a cornerstone of their success and competitiveness. By investing in state-of-the-art machinery and leveraging innovative techniques, these companies can achieve exceptional levels of precision and efficiency in their manufacturing processes.

This advanced technology enables Singapore fabrication companies to produce complex and high-value products with tight tolerances and intricate details. The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems ensures accuracy and consistency throughout the manufacturing process. Additionally, advanced robotics and automation technologies enhance productivity and reduce lead times.

The impact of advanced technology on Singapore fabrication companies is significant. It allows them to:

- Produce high-quality products that meet international standards and customer specifications.

- Reduce production costs and improve cost-effectiveness.

- Increase production capacity and meet the demands of global markets.

- Innovate and develop new products and solutions.

Examples of advanced technologies used by Singapore fabrication companies include:

- 3D printing for rapid prototyping and production of complex geometries.

- Laser cutting and engraving for precise cutting and marking.

- Computer numerical control (CNC) machining for automated and high-precision machining.

- Surface treatment technologies for enhancing product durability and aesthetics.

In conclusion, the advanced technology employed by Singapore fabrication companies is a key differentiator that enables them to deliver high-quality products, increase efficiency, and remain competitive in the global manufacturing landscape. By embracing technological advancements, these companies continue to push the boundaries of innovation and meet the evolving demands of customers worldwide.

Table: Key Insights

| Key Insight | Description |

|---|---|

| Advanced technology enhances precision and efficiency | State-of-the-art machinery and innovative techniques ensure accurate and consistent manufacturing. |

| Advanced technology reduces production costs | Automation and optimization technologies improve cost-effectiveness and increase productivity. |

| Advanced technology fosters innovation | Cutting-edge technologies enable the development of new products and solutions that meet evolving market demands. |

Skilled Workforce

The skilled workforce in Singapore is a cornerstone of the success of Singapore fabrication companies. With a strong emphasis on education and training, Singapore has developed a workforce that is highly proficient in various fabrication techniques. This skilled workforce enables Singapore fabrication companies to deliver high-quality products and services that meet the demands of global markets.

-

Expertise in Advanced Manufacturing Techniques:

Singapore’s workforce is well-versed in advanced manufacturing techniques, such as CNC machining, laser cutting, and 3D printing. This expertise allows Singapore fabrication companies to produce complex and precise components with tight tolerances.

-

Experience in Diverse Industries:

Singapore fabrication companies have experience working with a wide range of industries, including aerospace, medical, electronics, and automotive. This diverse experience enables them to understand the specific requirements of each industry and deliver customized solutions.

-

Commitment to Quality and Precision:

Singapore’s workforce is renowned for its commitment to quality and precision. This is reflected in the high standards of workmanship and attention to detail that is evident in the products and services provided by Singapore fabrication companies.

-

Continuous Training and Development:

Singapore fabrication companies invest heavily in training and development programs for their employees. This ensures that the workforce remains up-to-date with the latest technologies and best practices in the fabrication industry.

In conclusion, the skilled workforce in Singapore is a valuable asset to Singapore fabrication companies. Their expertise, experience, and commitment to quality enable these companies to deliver world-class products and services that meet the demands of global markets.

Quality Products

The commitment to quality products is a defining characteristic of Singapore fabrication companies. By adhering to strict quality standards and certifications, these companies ensure that their products meet the highest levels of excellence. This focus on quality has several important implications:

- Customer Satisfaction: High-quality products lead to satisfied customers. Singapore fabrication companies understand that meeting customer specifications and expectations is paramount to building long-term relationships.

- Reputation and Trust: A reputation for quality is essential for any fabrication company. Singapore fabrication companies have earned a reputation for delivering reliable and consistent products, which has fostered trust among customers worldwide.

- Competitive Advantage: In a globalized market, quality is a key differentiator. Singapore fabrication companies use their commitment to quality to gain a competitive advantage and stand out from competitors.

To achieve this high level of quality, Singapore fabrication companies implement rigorous quality control processes throughout their operations. These processes include:

- Raw Material Inspection: Incoming raw materials are inspected to ensure they meet the required specifications.

- In-Process Quality Checks: Products are inspected at various stages of production to identify and correct any defects.

- Final Product Testing: Before shipment, products undergo rigorous testing to verify their performance and compliance with standards.

The emphasis on quality extends beyond the production process. Singapore fabrication companies also provide excellent customer service and support. They are responsive to customer inquiries, provide technical assistance, and work closely with customers to resolve any issues.

In summary, the commitment to quality products is a cornerstone of Singapore fabrication companies. By adhering to strict quality standards and certifications, these companies deliver products that meet customer specifications, build trust, gain a competitive advantage, and ultimately contribute to the success of their customers.

Table: Key Insights

| Key Insight | Description |

|---|---|

| Quality is a defining characteristic of Singapore fabrication companies | Strict quality standards ensure products meet the highest levels of excellence |

| Commitment to quality leads to customer satisfaction and trust | High-quality products build long-term relationships and foster trust among customers |

| Quality is a competitive advantage in the global market | Singapore fabrication companies differentiate themselves through their commitment to quality |

| Rigorous quality control processes are implemented throughout operations | Raw materials, in-process products, and final products undergo thorough inspections and testing |

| Excellent customer service and support complement the focus on quality | Singapore fabrication companies provide responsive and comprehensive customer support |

Competitive Pricing

Singapore fabrication companies offer competitive pricing despite their advanced capabilities due to several key factors:

- Economies of Scale: Singapore’s fabrication industry is well-established and has a strong supply chain. This allows Singapore fabrication companies to leverage economies of scale, reducing production costs and passing on the savings to customers.

- Government Support: The Singapore government provides various support programs and incentives to the fabrication industry. These programs help reduce operating costs and make Singapore fabrication companies more competitive in the global market.

- Efficient Operations: Singapore fabrication companies invest heavily in automation and process optimization. This helps them reduce waste, improve productivity, and lower production costs.

- Skilled Workforce: Singapore has a highly skilled workforce with expertise in fabrication techniques. This allows Singapore fabrication companies to produce high-quality products with minimal defects, reducing the need for rework and scrap, which can add to production costs.

The competitive pricing offered by Singapore fabrication companies makes their services accessible to businesses of all sizes, from startups to large corporations. This accessibility has contributed to the growth of Singapore’s fabrication industry and has made Singapore a preferred destination for companies seeking high-quality and cost-effective fabrication services.

Global Reach

The global reach of Singapore’s manufacturing sector is a significant advantage for Singapore fabrication companies. Singapore’s strategic location, well-developed infrastructure, and free trade agreements make it a gateway to international markets and supply chains. This provides Singapore fabrication companies with several key benefits:

- Access to Global Markets: Singapore’s global reach allows fabrication companies to tap into a wide range of international markets. This provides them with opportunities to diversify their customer base, reduce risk, and grow their businesses.

- Efficient Supply Chains: Singapore’s well-developed infrastructure and efficient supply chains facilitate the movement of raw materials and finished goods. This reduces logistics costs and lead times, improving the overall competitiveness of Singapore fabrication companies.

- Collaboration Opportunities: Singapore’s global reach provides opportunities for fabrication companies to collaborate with international partners, share knowledge, and access new technologies. This can lead to innovation and the development of new products and solutions.

- Investment Opportunities: Singapore’s stable political and economic environment, coupled with its global reach, makes it an attractive destination for foreign investment. This provides Singapore fabrication companies with access to capital and resources to expand their operations and enhance their capabilities.

In conclusion, the global reach of Singapore’s manufacturing sector is a key competitive advantage for Singapore fabrication companies. It provides them with access to international markets, efficient supply chains, collaboration opportunities, and investment potential. By leveraging Singapore’s global reach, fabrication companies can expand their businesses, enhance their competitiveness, and succeed in the global marketplace.

Innovation

Innovation is a driving force behind the success of Singapore fabrication companies. By constantly investing in research and development, these companies are pushing the boundaries of manufacturing technology and developing new and innovative products and solutions. This focus on innovation has several important implications:

- Competitive Advantage: Innovation allows Singapore fabrication companies to differentiate themselves from competitors and gain a competitive edge in the global market.

- New Market Opportunities: Innovation can lead to the development of new products and services, which can open up new market opportunities for Singapore fabrication companies.

- Increased Productivity: Innovation can also lead to the development of new and more efficient manufacturing processes, which can increase productivity and reduce costs.

One example of how innovation is driving the growth of Singapore fabrication companies is the development of new additive manufacturing technologies. Additive manufacturing, also known as 3D printing, is a process of creating three-dimensional objects by building them up layer by layer. This technology has the potential to revolutionize the manufacturing industry by enabling the production of complex and customized products with shorter lead times and lower costs.Singapore fabrication companies are at the forefront of the development of additive manufacturing technologies. Companies like Stratasys and 3D Systems are investing heavily in research and development to improve the speed, accuracy, and affordability of additive manufacturing. This investment is paying off, as Singapore fabrication companies are now able to produce high-quality additive manufactured products for a wide range of industries, including aerospace, medical, and automotive.

The focus on innovation is not just limited to large companies. Small and medium-sized enterprises (SMEs) in Singapore are also embracing innovation to stay competitive. For example, the SME AEP Technologies has developed a new type of 3D printing material that is stronger and more durable than traditional materials. This new material has opened up new possibilities for additive manufacturing and has helped AEP Technologies to win new customers in the aerospace and automotive industries.

The commitment to innovation is a key factor in the success of Singapore fabrication companies. By investing in research and development, these companies are pushing the boundaries of manufacturing technology and developing new and innovative products and solutions. This focus on innovation is helping Singapore fabrication companies to gain a competitive edge in the global market and is positioning Singapore as a leader in the manufacturing industry.

Table: Key Insights

| Key Insight | Description |

|---|---|

| Innovation drives the success of Singapore fabrication companies | By investing in research and development, Singapore fabrication companies are pushing the boundaries of manufacturing technology and developing new and innovative products and solutions. |

| Innovation provides a competitive advantage | Innovation allows Singapore fabrication companies to differentiate themselves from competitors and gain a competitive edge in the global market. |

| Innovation leads to new market opportunities | Innovation can lead to the development of new products and services, which can open up new market opportunities for Singapore fabrication companies. |

| Innovation increases productivity | Innovation can also lead to the development of new and more efficient manufacturing processes, which can increase productivity and reduce costs. |

Sustainability

In today’s environmentally conscious business landscape, sustainability has become an increasingly important factor for companies across all industries. Singapore fabrication companies are no exception, with many prioritizing sustainability by implementing eco-friendly practices and reducing their environmental impact. This focus on sustainability offers several key benefits and implications for Singapore fabrication companies and the industry as a whole:

- Environmental Responsibility: By prioritizing sustainability, Singapore fabrication companies demonstrate their commitment to responsible manufacturing practices and reducing their carbon footprint. This aligns with global efforts to mitigate climate change and protect the environment for future generations.

- Resource Efficiency: Implementing eco-friendly practices, such as energy-efficient equipment and waste reduction programs, can lead to improved resource utilization and reduced operating costs. This enhances the competitiveness and profitability of Singapore fabrication companies.

- Customer Preference: Consumers and businesses are increasingly seeking products and services from companies that prioritize sustainability. By adopting sustainable practices, Singapore fabrication companies can meet the growing demand for environmentally friendly products and services.

- Government Support: The Singapore government has implemented various initiatives and programs to encourage sustainability in the manufacturing sector. These initiatives provide incentives and support to companies that invest in sustainable practices, further driving the adoption of sustainability among Singapore fabrication companies.

Examples of eco-friendly practices adopted by Singapore fabrication companies include:

- Utilizing renewable energy sources, such as solar and wind power, to reduce reliance on fossil fuels.

- Implementing energy-efficient lighting systems and equipment to minimize energy consumption.

- Establishing waste management programs that emphasize recycling, waste reduction, and responsible disposal.

- Adopting sustainable packaging solutions to reduce environmental impact throughout the product lifecycle.

By embracing sustainability, Singapore fabrication companies not only contribute to environmental protection but also enhance their competitiveness, meet customer demands, and align with government initiatives. This focus on sustainability positions Singapore fabrication companies as responsible and forward-thinking partners in the global manufacturing landscape.

Government Support

The Singapore government recognizes the importance of the fabrication industry to the country’s economic growth and competitiveness. As such, it has implemented various initiatives and programs to support and encourage the development of the fabrication industry in Singapore. These initiatives and programs provide a range of benefits to Singapore fabrication companies, helping them to grow and succeed in the global marketplace.

- Financial Assistance: The Singapore government provides financial assistance to Singapore fabrication companies through grants, loans, and tax incentives. These financial incentives help companies to invest in new equipment, expand their operations, and develop new products and technologies.

- Infrastructure Development: The Singapore government has invested heavily in infrastructure development to support the fabrication industry. This includes the development of industrial parks, research facilities, and training centers. These infrastructure developments provide Singapore fabrication companies with the resources and facilities they need to succeed.

- Research and Development Support: The Singapore government supports research and development (R&D) in the fabrication industry through funding and collaboration programs. These programs encourage companies to invest in R&D, which is essential for the development of new products and technologies.

- Workforce Development: The Singapore government recognizes that a skilled workforce is essential for the success of the fabrication industry. As such, it has implemented programs to develop and train the workforce in the fabrication industry. These programs include apprenticeship programs, skills training courses, and certification programs.

The support and incentives provided by the Singapore government have helped to create a conducive business environment for Singapore fabrication companies. These companies benefit from financial assistance, infrastructure development, research and development support, and workforce development programs. As a result, Singapore fabrication companies are able to grow and succeed in the global marketplace.

Collaboration

Collaboration is a key driver of innovation and growth for Singapore fabrication companies. By working closely with research institutions and industry partners, these companies gain access to cutting-edge knowledge, expertise, and resources. This enables them to develop new products and technologies, improve their processes, and stay at the forefront of the industry.

One example of successful collaboration is the partnership between the Singapore Institute of Manufacturing Technology (SIMTech) and A STAR’s Institute of Materials Research and Engineering (IMRE). Together, they have developed new additive manufacturing technologies that are used by Singapore fabrication companies to produce high-value components for the aerospace and biomedical industries.

Another example is the collaboration between the National University of Singapore (NUS) and ST Engineering. This partnership has led to the development of new surface treatment technologies that are used by Singapore fabrication companies to improve the durability and performance of their products.

The collaboration between Singapore fabrication companies and research institutions and industry partners is essential for the continued growth and success of the industry. By working together, these companies can access the latest knowledge and expertise, develop new products and technologies, and stay ahead of the competition.

| Key Insight | Description |

|---|---|

| Collaboration is a key driver of innovation and growth for Singapore fabrication companies. | By working closely with research institutions and industry partners, Singapore fabrication companies gain access to cutting-edge knowledge, expertise, and resources. |

| Collaboration enables Singapore fabrication companies to develop new products and technologies, improve their processes, and stay at the forefront of the industry. | Examples of successful collaboration include the partnership between SIMTech and ASTAR’s IMRE, and the collaboration between NUS and ST Engineering. |

| The collaboration between Singapore fabrication companies and research institutions and industry partners is essential for the continued growth and success of the industry. | By working together, these companies can access the latest knowledge and expertise, develop new products and technologies, and stay ahead of the competition. |

FAQs about Singapore Fabrication Companies

This section addresses frequently asked questions about Singapore fabrication companies to provide clear and informative answers for better understanding.

Question 1: What are the key advantages of working with Singapore fabrication companies?

Singapore fabrication companies offer several advantages, including advanced technology, skilled workforce, high-quality products, competitive pricing, global reach, innovation, sustainability, government support, and collaboration opportunities. These advantages make them reliable and efficient partners for manufacturing needs.

Question 2: How do Singapore fabrication companies ensure the quality of their products?

Singapore fabrication companies adhere to strict quality standards and certifications, such as ISO 9001 and AS9100. They implement rigorous quality control processes throughout their operations, including raw material inspection, in-process quality checks, and final product testing. This commitment to quality ensures that their products meet customer specifications and industry standards.

Question 3: Are Singapore fabrication companies cost-competitive?

Despite their advanced capabilities, Singapore fabrication companies offer competitive pricing. They leverage economies of scale, government support, efficient operations, and a skilled workforce to keep production costs low. This cost competitiveness makes their services accessible to businesses of all sizes.

Question 4: How do Singapore fabrication companies handle innovation?

Singapore fabrication companies prioritize innovation by investing heavily in research and development. They collaborate with research institutions and industry partners to develop new products and technologies. This focus on innovation allows them to stay at the forefront of manufacturing technology and meet the evolving needs of their customers.

Question 5: What sustainability practices do Singapore fabrication companies adopt?

Many Singapore fabrication companies prioritize sustainability by implementing eco-friendly practices. They utilize renewable energy sources, adopt energy-efficient technologies, establish waste management programs, and use sustainable packaging solutions. This commitment to sustainability aligns with global efforts to protect the environment and meet the growing demand for environmentally responsible products.

Question 6: What kind of government support is available for Singapore fabrication companies?

The Singapore government provides various forms of support to fabrication companies, including financial assistance, infrastructure development, research and development support, and workforce development programs. These initiatives aim to foster a conducive business environment and encourage the growth and success of the fabrication industry in Singapore.

Summary: Singapore fabrication companies are recognized for their advanced technology, skilled workforce, high-quality products, competitive pricing, and commitment to innovation and sustainability. They collaborate with research institutions and industry partners to stay at the forefront of manufacturing technology. With government support and a focus on quality and customer satisfaction, Singapore fabrication companies are reliable partners for businesses seeking efficient and high-quality manufacturing solutions.

Transition to the next article section: To learn more about the specific capabilities and services offered by Singapore fabrication companies, explore the following sections of this article.

Tips from Singapore Fabrication Companies

To optimize your collaboration with Singapore fabrication companies and achieve successful outcomes, consider the following tips:

Tip 1: Clearly Define Your Requirements

Precisely communicate your project specifications, including materials, tolerances, and delivery timelines. This clarity facilitates accurate quoting and efficient production.

Tip 2: Leverage Their Expertise

Engage with Singapore fabrication companies early in the design phase to benefit from their technical knowledge and experience. Their insights can enhance product design and manufacturing feasibility.

Tip 3: Establish Open Communication

Maintain regular communication throughout the project to ensure alignment on progress, address any changes promptly, and foster a collaborative working relationship.

Tip 4: Visit Their Facilities

Consider visiting the fabrication facilities to assess their capabilities, quality control measures, and safety protocols firsthand. This visit can build trust and provide deeper insights into their operations.

Tip 5: Consider Long-Term Partnerships

Nurturing long-term partnerships with Singapore fabrication companies can lead to streamlined communication, cost savings, and access to their latest innovations and capabilities.

Summary: By following these tips, you can effectively collaborate with Singapore fabrication companies, leveraging their expertise, ensuring clear communication, and building mutually beneficial partnerships. These strategies will contribute to the successful execution of your fabrication projects.

Transition to the article’s conclusion: Embracing these tips will enable you to harness the full potential of Singapore fabrication companies and achieve exceptional results for your manufacturing needs.

Conclusion

Throughout this exploration, we have delved into the world of Singapore fabrication companies, uncovering their strengths and capabilities. These companies stand out with their advanced technology, skilled workforce, and commitment to quality. By leveraging their expertise and embracing the tips outlined above, businesses can harness the potential of Singapore fabrication companies and achieve exceptional outcomes for their manufacturing needs.

As the manufacturing landscape continues to evolve, Singapore fabrication companies are well-positioned to drive innovation and shape the future of the industry. Their unwavering focus on quality, sustainability, and collaboration makes them ideal partners for businesses seeking reliable and efficient manufacturing solutions.