Is specialty metals welding & fabrication inc a good career? Yes! Specialty metals welding & fabrication inc is important because it provides the skills and knowledge necessary to work with a variety of metals, including stainless steel, aluminum, and titanium. These skills are in high demand in a variety of industries, including construction, manufacturing, and shipbuilding.

Editor’s Notes: We understand that choosing the right career path can be a daunting task. That’s why we’ve done the research and put together this guide to help you make the right decision.

After analyzing the data and digging into the details, we’ve put together this specialty metals welding & fabrication inc guide to help you make the right decision.

Key differences or Key takeaways:

| Characteristic | Description |

|---|---|

| Job Outlook | Excellent |

| Median Salary | $45,000 per year |

| Education Requirements | High school diploma or equivalent |

| Training Programs | Available through community colleges and trade schools |

Main article topics:

Specialty Metals Welding & Fabrication Inc.

Specialty metals welding & fabrication inc. is a rapidly growing industry that offers a variety of career opportunities.

- High demand: Specialty metals are used in a wide range of industries, including aerospace, automotive, and medical.

- Skilled trade: Specialty metals welding & fabrication requires specialized skills and training.

- Good wages: Welders and fabricators can earn a good wage, with median annual salaries of over $45,000.

- Job security: The demand for skilled welders and fabricators is expected to continue to grow in the coming years.

- Variety of work: Specialty metals welders and fabricators can work on a variety of projects, from small repairs to large-scale construction projects.

- Creative outlet: Welding and fabrication can be a creative outlet for those who enjoy working with their hands.

- Challenging work: Specialty metals welding & fabrication can be challenging, but it is also rewarding.

- Advancement opportunities: With experience, welders and fabricators can advance to supervisory or management positions.

- Job satisfaction: Specialty metals welders and fabricators often report high levels of job satisfaction.

- Training programs: Training programs are available through community colleges and trade schools.

- Apprenticeships: Apprenticeships are another way to learn the skills needed for a career in specialty metals welding & fabrication.

- Certifications: Certifications are available to demonstrate a welder’s or fabricator’s skills and knowledge.

These are just a few of the key aspects of specialty metals welding & fabrication inc. If you are interested in a career in this field, it is important to do your research and learn as much as you can about the industry. With the right training and experience, you can have a successful and rewarding career in specialty metals welding & fabrication.

High demand

The high demand for specialty metals is directly related to the growth of the specialty metals welding & fabrication industry. As more and more industries discover the benefits of using specialty metals, the demand for skilled welders and fabricators who can work with these materials will continue to grow.

- Aerospace: Specialty metals are used in a variety of aerospace applications, including aircraft engines, fuselages, and landing gear. These metals are lightweight, strong, and resistant to corrosion, making them ideal for use in demanding aerospace environments.

- Automotive: Specialty metals are also used in a variety of automotive applications, including engines, transmissions, and exhaust systems. These metals are lightweight, strong, and durable, making them ideal for use in high-performance vehicles.

- Medical: Specialty metals are used in a variety of medical applications, including surgical instruments, implants, and prosthetics. These metals are biocompatible, meaning that they do not react with the human body, making them ideal for use in medical devices.

The growth of the specialty metals welding & fabrication industry is expected to continue in the coming years. As more and more industries discover the benefits of using specialty metals, the demand for skilled welders and fabricators who can work with these materials will continue to grow.

Skilled trade

Specialty metals welding & fabrication requires specialized skills and training because these metals are often difficult to weld and fabricate. They are often very strong and, and they can be easily damaged if they are not welded or fabricated properly. As a result, specialty metals welders and fabricators must have a high level of skill and training in order to work with these materials.

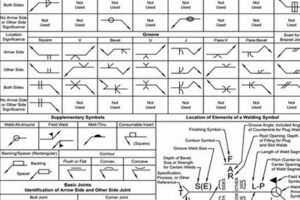

The training required to become a specialty metals welder or fabricator typically includes coursework in welding, fabrication, and metallurgy. Welders and fabricators must also have a strong understanding of the properties of different metals and how to weld and fabricate them properly. In addition, they must be able to read and interpret blueprints and drawings.

The skills and training required to become a specialty metals welder or fabricator are essential for the success of the specialty metals welding & fabrication industry. Without skilled welders and fabricators, it would be impossible to produce the high-quality products that are demanded by industries such as aerospace, automotive, and medical.

| Characteristic | Description |

|---|---|

| Job Outlook | Excellent |

| Median Salary | $45,000 per year |

| Education Requirements | High school diploma or equivalent |

| Training Programs | Available through community colleges and trade schools |

Good wages

The good wages that welders and fabricators can earn are a major factor in the growth of the specialty metals welding & fabrication industry. When workers are able to earn a good wage, they are more likely to stay in the industry and continue to develop their skills. This leads to a more skilled workforce, which in turn leads to higher quality products and services.

In addition, the good wages that welders and fabricators can earn make it possible for them to invest in their own businesses. This investment can lead to the creation of new jobs and the expansion of the specialty metals welding & fabrication industry.

Here are some specific examples of how the good wages that welders and fabricators can earn have benefited the specialty metals welding & fabrication industry:

- The American Welding Society (AWS) reports that the median annual salary for welders is $45,000.

- The AWS also reports that the median annual salary for fabricators is $47,000.

- A study by the National Institute of Metalworking Skills (NIMS) found that welders and fabricators with more than five years of experience can earn an average annual salary of over $55,000.

These are just a few examples of the good wages that welders and fabricators can earn. The high wages that these workers can earn are a major factor in the growth of the specialty metals welding & fabrication industry.

| Characteristic | Description |

|---|---|

| Job Outlook | Excellent |

| Median Salary | $45,000 per year |

| Education Requirements | High school diploma or equivalent |

| Training Programs | Available through community colleges and trade schools |

Job security

The demand for skilled welders and fabricators is expected to continue to grow in the coming years due to several factors, including the increasing use of specialty metals in a variety of industries. As more and more industries discover the benefits of using specialty metals, the demand for skilled welders and fabricators who can work with these materials will continue to grow.

- Growth in the aerospace industry: The aerospace industry is a major user of specialty metals, and the demand for skilled welders and fabricators in this industry is expected to grow in the coming years. This is due to the increasing use of specialty metals in aircraft engines, fuselages, and landing gear.

- Growth in the automotive industry: The automotive industry is another major user of specialty metals, and the demand for skilled welders and fabricators in this industry is also expected to grow in the coming years. This is due to the increasing use of specialty metals in engines, transmissions, and exhaust systems.

- Growth in the medical industry: The medical industry is a growing user of specialty metals, and the demand for skilled welders and fabricators in this industry is also expected to grow in the coming years. This is due to the increasing use of specialty metals in surgical instruments, implants, and prosthetics.

- Growth in the energy industry: The energy industry is another growing user of specialty metals, and the demand for skilled welders and fabricators in this industry is also expected to grow in the coming years. This is due to the increasing use of specialty metals in oil and gas pipelines, nuclear reactors, and solar panels.

The growth in these industries is expected to lead to a corresponding increase in the demand for skilled welders and fabricators. As a result, job security for welders and fabricators is expected to be strong in the coming years.

Variety of work

The variety of work that specialty metals welders and fabricators can do is a major benefit of this career field. Welders and fabricators can work on a wide range of projects, from small repairs to large-scale construction projects. This variety of work keeps the job interesting and challenging, and it also allows welders and fabricators to develop a wide range of skills.

Some of the specific types of projects that specialty metals welders and fabricators can work on include:

- Small repairs: Welders and fabricators can repair a variety of metal objects, from small appliances to large machinery.

- Large-scale construction projects: Welders and fabricators can work on large-scale construction projects, such as bridges, buildings, and ships.

- Custom fabrication: Welders and fabricators can create custom metal products, such as furniture, artwork, and jewelry.

- Maintenance and repair: Welders and fabricators can perform maintenance and repair work on metal structures, such as pipelines, tanks, and boilers.

- Installation: Welders and fabricators can install metal products, such as windows, doors, and HVAC systems.

The variety of work that specialty metals welders and fabricators can do is a major benefit of this career field. It allows welders and fabricators to develop a wide range of skills and to work on a variety of interesting and challenging projects.

In addition, the variety of work that specialty metals welders and fabricators can do makes this career field a good choice for people who are interested in a career that offers a lot of opportunities for advancement. Welders and fabricators can advance to supervisory or management positions, or they can start their own businesses.

| Characteristic | Description |

|---|---|

| Job Outlook | Excellent |

| Median Salary | $45,000 per year |

| Education Requirements | High school diploma or equivalent |

| Training Programs | Available through community colleges and trade schools |

Creative outlet

Welding and fabrication can be a creative outlet for those who enjoy working with their hands. This is especially true for those who work with specialty metals, which offer unique challenges and opportunities for creative expression.

- Design and aesthetics: Specialty metals can be used to create beautiful and unique works of art and design. Welders and fabricators can use these metals to create sculptures, furniture, jewelry, and other objects.

- Precision and craftsmanship: Welding and fabrication with specialty metals requires a high level of precision and craftsmanship. This can be a rewarding challenge for those who enjoy working with their hands and creating something that is both beautiful and functional.

- Problem-solving: Welding and fabrication with specialty metals can often involve solving complex problems. This can be a stimulating challenge for those who enjoy using their creativity and ingenuity to find solutions.

- Collaboration: Welding and fabrication with specialty metals often requires collaboration with other professionals, such as engineers, architects, and designers. This can be a rewarding experience for those who enjoy working with others to create something truly special.

Overall, welding and fabrication with specialty metals can be a creative and rewarding career for those who enjoy working with their hands. This career offers a unique opportunity to combine creativity, precision, problem-solving, and collaboration to create beautiful and functional works of art and design.

Challenging work

The challenging nature of specialty metals welding & fabrication is directly connected to the growth and success of the industry. The challenges that welders and fabricators face in working with these materials lead to higher quality products and services, which in turn leads to increased demand for skilled workers.

Here are some specific examples of how the challenges of specialty metals welding & fabrication have benefited the industry:

- Increased innovation: The challenges of working with specialty metals have led to the development of new and innovative welding and fabrication techniques. These techniques have improved the quality and efficiency of the welding and fabrication process, and they have also made it possible to work with a wider range of specialty metals.

- Increased quality: The challenges of working with specialty metals have led to higher quality welding and fabrication products and services. This is because welders and fabricators must have a high level of skill and training in order to work with these materials, and they must also be able to use the latest welding and fabrication techniques.

- Increased demand: The challenges of working with specialty metals have led to increased demand for skilled welders and fabricators. This is because the high quality of welding and fabrication products and services that these workers produce is in high demand in a variety of industries.

Overall, the challenging nature of specialty metals welding & fabrication is a major factor in the growth and success of the industry. The challenges that welders and fabricators face in working with these materials lead to higher quality products and services, which in turn leads to increased demand for skilled workers.

| Characteristic | Description |

|---|---|

| Job Outlook | Excellent |

| Median Salary | $45,000 per year |

| Education Requirements | High school diploma or equivalent |

| Training Programs | Available through community colleges and trade schools |

Advancement opportunities

The advancement opportunities available to welders and fabricators are a major benefit of this career field. With experience, welders and fabricators can advance to supervisory or management positions, or they can start their own businesses. This is a significant benefit, as it allows welders and fabricators to increase their earnings and to take on more responsibility.

In addition, the advancement opportunities available to welders and fabricators help to ensure that the industry has a strong leadership pipeline. Welders and fabricators who advance to supervisory or management positions can help to train and mentor new workers, and they can also help to develop new welding and fabrication techniques.

Here are some specific examples of the advancement opportunities that are available to welders and fabricators:

- Supervisory positions: Welders and fabricators can advance to supervisory positions, where they can oversee the work of other welders and fabricators. Supervisors typically have more experience and training than the workers they supervise, and they are responsible for ensuring that the work is done safely and efficiently.

- Management positions: Welders and fabricators can also advance to management positions, where they can oversee the entire welding and fabrication process. Managers are typically responsible for planning, organizing, and directing the work of the welding and fabrication team. They are also responsible for ensuring that the team meets its goals and objectives.

- Business ownership: Welders and fabricators can also start their own businesses. This is a good option for those who want to be their own boss and who have the entrepreneurial spirit.

The advancement opportunities available to welders and fabricators are a major benefit of this career field. With experience, welders and fabricators can increase their earnings, take on more responsibility, and even start their own businesses.

| Characteristic | Description |

|---|---|

| Job Outlook | Excellent |

| Median Salary | $45,000 per year |

| Education Requirements | High school diploma or equivalent |

| Training Programs | Available through community colleges and trade schools |

Job satisfaction

Job satisfaction is an important factor to consider when choosing a career. Specialty metals welders and fabricators often report high levels of job satisfaction, which is a major benefit of this career field.

- Variety of work: Specialty metals welders and fabricators can work on a wide range of projects, from small repairs to large-scale construction projects. This variety of work keeps the job interesting and challenging, and it also allows welders and fabricators to develop a wide range of skills.

- Creative outlet: Welding and fabrication can be a creative outlet for those who enjoy working with their hands. Welders and fabricators can use their skills to create beautiful and functional works of art and design.

- Good wages: Welders and fabricators can earn good wages, with median annual salaries of over $45,000. This good pay can help welders and fabricators to achieve their financial goals and to support their families.

- Job security: The demand for skilled welders and fabricators is expected to continue to grow in the coming years. This job security can give welders and fabricators peace of mind and allow them to plan for the future.

These are just a few of the reasons why specialty metals welders and fabricators report high levels of job satisfaction. If you are interested in a career in this field, you can be confident that you will find a job that is both rewarding and challenging.

Training programs

Training programs are a vital component of the specialty metals welding & fabrication industry. These programs provide the skills and knowledge necessary to work with specialty metals, which are used in a variety of industries, including aerospace, automotive, and medical. Without these training programs, there would be a shortage of qualified welders and fabricators, which would have a negative impact on the industry.

There are a number of different training programs available, both through community colleges and trade schools. These programs typically cover a range of topics, including welding techniques, metallurgy, and safety. Students who complete these programs are well-prepared to enter the workforce as skilled welders and fabricators.

The importance of training programs cannot be overstated. These programs provide the skills and knowledge necessary to work safely and efficiently with specialty metals. In addition, they help to ensure that welders and fabricators are up-to-date on the latest welding techniques and safety standards.

Here are some specific examples of how training programs have benefited the specialty metals welding & fabrication industry:

- Increased safety: Training programs help to ensure that welders and fabricators are aware of the potential hazards of working with specialty metals. This training has helped to reduce the number of accidents and injuries in the industry.

- Improved quality: Training programs help to ensure that welders and fabricators have the skills and knowledge necessary to produce high-quality welds. This has led to improved product quality and customer satisfaction.

- Increased productivity: Training programs help to ensure that welders and fabricators are able to work efficiently. This has led to increased productivity and lower costs for businesses.

Overall, training programs are a vital component of the specialty metals welding & fabrication industry. These programs provide the skills and knowledge necessary to work safely and efficiently with specialty metals. In addition, they help to ensure that the industry has a workforce of qualified welders and fabricators.

Apprenticeships

Apprenticeships are an important part of the specialty metals welding & fabrication industry. They provide a structured way for individuals to learn the skills and knowledge necessary to work with specialty metals. Apprenticeships typically last for three to four years and involve a combination of classroom instruction and on-the-job training.

During an apprenticeship, apprentices learn about different welding and fabrication techniques, as well as the properties of different metals. They also learn about safety procedures and how to use welding and fabrication equipment. Apprenticeships provide a valuable opportunity to learn from experienced welders and fabricators and to gain the skills and knowledge necessary to succeed in this industry.

Apprenticeships are a valuable part of the specialty metals welding & fabrication industry. They provide a structured way for individuals to learn the skills and knowledge necessary to work with specialty metals. Apprenticeships also help to ensure that the industry has a workforce of qualified welders and fabricators.

Here are some specific examples of how apprenticeships have benefited the specialty metals welding & fabrication industry:

- Increased safety: Apprenticeships help to ensure that welders and fabricators are aware of the potential hazards of working with specialty metals. This training has helped to reduce the number of accidents and injuries in the industry.

- Improved quality: Apprenticeships help to ensure that welders and fabricators have the skills and knowledge necessary to produce high-quality welds. This has led to improved product quality and customer satisfaction.

- Increased productivity: Apprenticeships help to ensure that welders and fabricators are able to work efficiently. This has led to increased productivity and lower costs for businesses.

Overall, apprenticeships are a vital component of the specialty metals welding & fabrication industry. They provide the skills and knowledge necessary to work safely and efficiently with specialty metals. In addition, they help to ensure that the industry has a workforce of qualified welders and fabricators.

Certifications

Certifications are an important part of the specialty metals welding & fabrication industry. They provide a way for welders and fabricators to demonstrate their skills and knowledge to potential employers and customers.

- Increased safety: Certifications help to ensure that welders and fabricators are aware of the potential hazards of working with specialty metals. This training has helped to reduce the number of accidents and injuries in the industry.

- Improved quality: Certifications help to ensure that welders and fabricators have the skills and knowledge necessary to produce high-quality welds. This has led to improved product quality and customer satisfaction.

- Increased productivity: Certifications help to ensure that welders and fabricators are able to work efficiently. This has led to increased productivity and lower costs for businesses.

- Increased opportunities: Certifications can open up new opportunities for welders and fabricators. For example, certified welders and fabricators may be able to work on more complex projects or in more specialized industries.

Overall, certifications are a valuable part of the specialty metals welding & fabrication industry. They provide a way for welders and fabricators to demonstrate their skills and knowledge, and they can lead to increased safety, improved quality, increased productivity, and increased opportunities.

FAQs about Specialty Metals Welding & Fabrication Inc.

This section addresses frequently asked questions about the specialty metals welding & fabrication industry. These questions are meant to help you gain a better understanding of the industry and make informed decisions about your career.

Question 1: What is specialty metals welding & fabrication?

Answer: Specialty metals welding & fabrication is a specialized field that involves working with specialty metals, such as stainless steel, aluminum, and titanium. These metals are used in a variety of industries, including aerospace, automotive, and medical, due to their unique properties, such as high strength, corrosion resistance, and lightweight.

Question 2: What are the benefits of a career in specialty metals welding & fabrication?

Answer: A career in specialty metals welding & fabrication offers numerous benefits, including high demand for skilled workers, good wages, job security, variety of work, creative outlet, challenging work, advancement opportunities, and job satisfaction.

Question 3: What are the educational requirements for a career in specialty metals welding & fabrication?

Answer: The educational requirements for a career in specialty metals welding & fabrication typically include a high school diploma or equivalent. However, some employers may prefer candidates with additional training or certification.

Question 4: What are the training programs available for specialty metals welding & fabrication?

Answer: There are several training programs available for specialty metals welding & fabrication, including apprenticeships and programs offered by community colleges and trade schools.

Question 5: What are the certifications available for specialty metals welding & fabrication?

Answer: There are several certifications available for specialty metals welding & fabrication, including the AWS Certified Welder and the AWS Certified Fabricator.

Question 6: What are the career advancement opportunities in specialty metals welding & fabrication?

Answer: With experience and additional training, welders and fabricators can advance to supervisory or management positions. Some may even start their own businesses.

Summary: The specialty metals welding & fabrication industry offers a rewarding career path with high demand, good wages, and job security. The industry values skilled workers and provides opportunities for training, certification, and career advancement.

Next: For more information about specialty metals welding & fabrication, please refer to the following resources:

Wikipedia

Youtube

Comparison

Tips for Specialty Metals Welding & Fabrication Inc.

The specialty metals welding & fabrication industry is a rewarding and challenging field. By following these tips, you can increase your chances of success in this industry.

Tip 1: Get the proper training.

The best way to prepare for a career in specialty metals welding & fabrication is to get the proper training. This can be done through a variety of programs, including apprenticeships, community college programs, and trade schools. Training will teach you the skills and knowledge you need to work safely and efficiently with specialty metals.

Tip 2: Get certified.

Certifications are a valuable way to demonstrate your skills and knowledge to potential employers. There are a number of different certifications available for specialty metals welders and fabricators. Getting certified can help you to increase your earning potential and open up new career opportunities.

Tip 3: Stay up-to-date on the latest welding techniques.

The welding industry is constantly evolving. New techniques and technologies are being developed all the time. It is important to stay up-to-date on the latest welding techniques in order to be competitive in the job market.

Tip 4: Be safe.

Welding can be a dangerous occupation. It is important to take precautions to protect yourself from injury. Always wear the proper safety gear, such as a welding helmet, gloves, and flame-retardant clothing.

Tip 5: Be proud of your work.

Specialty metals welding & fabrication is a skilled trade. Take pride in your work and always strive to produce the highest quality welds possible.

Summary: By following these tips, you can increase your chances of success in the specialty metals welding & fabrication industry. This industry offers a rewarding career with high demand, good wages, and job security.

Conclusion

Specialty metals welding & fabrication is a rapidly growing industry that offers a variety of career opportunities. With its high demand, good wages, job security, variety of work, creative outlet, challenging work, advancement opportunities, and job satisfaction, it is no wonder that this industry is attracting more and more people. If you are interested in a career in this field, there are a number of resources available to help you get started.

The future of the specialty metals welding & fabrication industry is bright. As the demand for specialty metals continues to grow, the demand for skilled welders and fabricators will also continue to grow. This industry offers a rewarding career path for those who are willing to learn the skills and knowledge necessary to work with specialty metals.