Have you ever wondered why steel fabrication is essential in various industries? Steel fabrication, the process of shaping and assembling steel components, plays a crucial role in construction, manufacturing, and infrastructure development.

Editor’s Notes: Steel fabrication is a critical aspect of modern construction and manufacturing processes. Understanding its significance can help you appreciate the value it brings to various industries.

Through extensive analysis and research, we have compiled this comprehensive guide to steel fabrication company profiles. Our goal is to empower you with the knowledge to make informed decisions regarding steel fabrication services.

Key Differences:

| Characteristic | Steel Fabrication |

|---|---|

| Definition | Process of shaping and assembling steel components |

| Applications | Construction, manufacturing, infrastructure |

| Materials | Various steel grades and alloys |

| Benefits | Strength, durability, versatility |

Transition to main article topics:

Steel Fabrication Company Profile

A steel fabrication company profile provides a comprehensive overview of a company’s capabilities, experience, and expertise in the field of steel fabrication. It serves as a valuable tool for potential customers to assess a company’s suitability for their specific project needs.

- Services Offered: Outlines the range of steel fabrication services provided, such as cutting, bending, welding, and assembly.

- Materials Expertise: Highlights the company’s knowledge and experience in working with various steel grades and alloys.

- Industry Experience: Demonstrates the company’s track record in specific industries, such as construction, manufacturing, or energy.

- Quality Standards: Emphasizes the company’s commitment to quality by adhering to industry standards and certifications.

- Equipment and Technology: Describes the company’s modern equipment and advanced technologies used in the fabrication process.

- Project Gallery: Showcases a portfolio of completed projects to demonstrate the company’s capabilities and craftsmanship.

- Customer Testimonials: Provides feedback from satisfied customers, highlighting their positive experiences with the company.

- Sustainability Practices: Outlines the company’s efforts in reducing environmental impact and promoting sustainability in its operations.

These key aspects provide a well-rounded view of a steel fabrication company’s profile. By considering these factors, potential customers can make informed decisions and select a company that aligns with their project requirements, industry knowledge, and values. For example, a company with extensive experience in a specific industry may have valuable insights and proven solutions for similar projects. Similarly, a company with a strong commitment to quality and sustainability can ensure that the fabricated steel components meet the highest standards and environmental considerations.

Services Offered

The services offered by a steel fabrication company are a fundamental aspect of its profile. These services encompass the core capabilities and expertise of the company in shaping and assembling steel components. A comprehensive overview of the services offered provides potential customers with a clear understanding of the company’s ability to meet their project requirements.

- Cutting: This service involves precise cutting of steel plates, beams, and other structural elements using advanced cutting technologies such as laser cutting, plasma cutting, and waterjet cutting.

- Bending: This process involves shaping steel components by applying controlled force to create curves, angles, and other complex geometries. Bending is crucial for creating structural supports, frames, and architectural elements.

- Welding: Welding is a vital service that joins steel components together using heat and pressure. Various welding techniques, such as MIG welding, TIG welding, and arc welding, are employed to create strong and durable joints.

- Assembly: This service involves assembling fabricated steel components into larger structures, such as bridges, buildings, and industrial equipment. Skilled technicians ensure precise alignment and secure connections to meet design specifications.

These services, when combined, enable steel fabrication companies to undertake complex projects that require precision, durability, and structural integrity. By carefully evaluating the services offered by different companies, potential customers can select a partner that aligns with their project’s specific needs and technical requirements.

Materials Expertise

Materials expertise is an essential component of a steel fabrication company profile. It demonstrates the company’s understanding of the unique properties and applications of different steel grades and alloys. This knowledge enables them to select the optimal materials for each project, ensuring structural integrity, durability, and cost-effectiveness.

Different steel grades and alloys possess varying characteristics, such as strength, hardness, corrosion resistance, and weldability. By understanding these properties, steel fabrication companies can tailor their material selection to meet specific project requirements. For instance, in the construction of bridges, high-strength steel alloys are used to withstand heavy loads and dynamic forces.

| Property | Suitable Steel Grade/Alloy | Application |

|---|---|---|

| Strength | High-strength steel alloys | Bridges, skyscrapers |

| Hardness | Tool steel | Cutting tools, dies |

| Corrosion resistance | Stainless steel | Food processing equipment, marine applications |

| Weldability | Low-carbon steel | General fabrication, automotive parts |

Steel fabrication companies with extensive materials expertise can provide valuable guidance to their customers. They can recommend the most appropriate steel grades and alloys based on factors such as the project’s intended use, environmental conditions, and budget constraints. This expertise ensures that the fabricated steel components meet the required performance and safety standards.

Industry Experience

Industry experience is a crucial component of a steel fabrication company profile as it showcases the company’s expertise and capabilities in specific industry sectors. This experience enables them to understand the unique challenges, requirements, and standards associated with each industry, ensuring that their products and services align with industry best practices and regulations.

For instance, in the construction industry, steel fabrication companies with extensive experience have a deep understanding of structural engineering principles, building codes, and safety standards. They can provide tailored solutions for various construction projects, such as bridges, skyscrapers, and industrial facilities, ensuring structural integrity and compliance with industry regulations.

Similarly, in the manufacturing industry, steel fabrication companies with industry experience can offer specialized services for the production of machinery, equipment, and components. They understand the specific requirements for durability, precision, and efficiency in manufacturing processes, enabling them to deliver high-quality fabricated steel components that meet the demands of the industry.

| Industry | Key Considerations | Benefits of Industry Experience |

|---|---|---|

| Construction | Structural integrity, building codes, safety standards | Tailored solutions for bridges, skyscrapers, and industrial facilities |

| Manufacturing | Durability, precision, efficiency | Specialized services for machinery, equipment, and components |

| Energy | Corrosion resistance, high-temperature performance | Solutions for power plants, refineries, and renewable energy projects |

Overall, industry experience is a testament to a steel fabrication company’s ability to deliver high-quality products and services that meet the specific requirements of different industries. It demonstrates their expertise, understanding of industry standards, and commitment to providing tailored solutions that meet the unique challenges of each sector.

Quality Standards

Quality standards are an integral part of a steel fabrication company profile as they demonstrate the company’s dedication to delivering high-quality products and services. Adherence to industry standards and certifications provides assurance to customers that the company operates at a consistently high level of quality and professionalism.

Industry standards, such as ISO 9001 and AWS D1.1, establish a framework for quality management systems and welding procedures, respectively. By adhering to these standards, steel fabrication companies ensure that their processes and products meet specific requirements for quality, safety, and performance.

Certifications, such as the American Welding Society’s Certified Welder program, provide independent verification of a welder’s skills and knowledge. Hiring certified welders demonstrates a company’s commitment to employing a highly skilled workforce capable of producing high-quality welds that meet industry standards.

| Standard/Certification | Significance |

|---|---|

| ISO 9001 | Establishes a quality management system framework for continuous improvement and customer satisfaction |

| AWS D1.1 | Outlines welding procedure specifications and quality requirements for structural welding |

| AWS Certified Welder | Verifies a welder’s skills and knowledge, ensuring high-quality welds |

Maintaining high-quality standards is essential for steel fabrication companies to remain competitive and ensure customer satisfaction. By adhering to industry standards and certifications, they demonstrate their commitment to delivering products and services that meet or exceed customer expectations.

Equipment and Technology

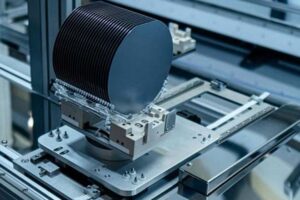

The section on equipment and technology in a steel fabrication company profile plays a crucial role in showcasing the company’s capabilities and commitment to innovation. Modern equipment and advanced technologies are essential for efficient and high-quality steel fabrication, enabling companies to meet the demands of complex projects and industry standards.

Advanced cutting technologies, such as laser cutting and waterjet cutting, provide precise and intricate cuts, reducing material waste and ensuring accuracy. Automated welding systems, including robotic welders, enhance productivity, consistency, and weld quality.

The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software allows for precise design and seamless integration with fabrication equipment. This integration streamlines the fabrication process, reducing errors and lead times.

| Equipment/Technology | Benefits |

|---|---|

| Laser cutting | Precise and intricate cuts, reduced material waste |

| Waterjet cutting | Clean and precise cuts on various materials |

| Automated welding systems | Increased productivity, consistency, and weld quality |

| CAD/CAM software | Precise design and seamless integration with fabrication equipment |

Investing in modern equipment and advanced technologies demonstrates a company’s commitment to quality, efficiency, and innovation. It enables them to handle complex projects, meet tight deadlines, and deliver high-quality steel fabrications that meet industry standards.

Project Gallery

Within a steel fabrication company profile, the project gallery plays a pivotal role in conveying the company’s expertise and craftsmanship. It serves as a visual testament to the company’s ability to transform raw materials into high-quality, functional steel fabrications.

Potential customers often rely on project galleries to assess a company’s capabilities and suitability for their specific needs. By showcasing a diverse range of completed projects, companies can demonstrate their versatility, technical proficiency, and commitment to delivering exceptional results.

Real-life examples illustrate the practical significance of project galleries. For instance, a company specializing in architectural steel fabrication can showcase projects such as intricate building facades, bridges, and sculptures. These projects highlight the company’s ability to handle complex designs, meet stringent aesthetic requirements, and ensure structural integrity.

| Project Gallery | Benefits |

|---|---|

| Demonstrates technical proficiency | Builds confidence in potential customers |

| Showcases versatility | Highlights the company’s ability to handle diverse projects |

| Provides visual evidence of craftsmanship | Enhances the company’s credibility |

Moreover, project galleries can serve as valuable references for potential customers. By examining the quality of previous work, customers can gain insights into the company’s attention to detail, adherence to industry standards, and ability to meet project deadlines.

In summary, the project gallery is an essential component of a steel fabrication company profile as it provides tangible evidence of the company’s capabilities, craftsmanship, and commitment to delivering exceptional results. It empowers potential customers to make informed decisions and select a partner that aligns with their project requirements and expectations.

Customer Testimonials

Customer testimonials are an integral part of a steel fabrication company profile as they provide valuable insights into the company’s ability to deliver exceptional products and services. Positive feedback from satisfied customers serves as a powerful endorsement, building trust and credibility among potential customers.

Testimonials offer real-life experiences that illustrate the company’s commitment to quality, customer satisfaction, and professional conduct. They provide concrete examples of successful projects, highlighting the company’s technical proficiency, attention to detail, and ability to meet or exceed customer expectations.

For instance, a testimonial from a satisfied customer in the construction industry might commend the company’s ability to deliver high-quality steel beams on time and within budget, ensuring the smooth progress of their project. Another testimonial from a manufacturing client could praise the company’s expertise in fabricating complex machinery components, enabling them to streamline their production processes.

| Customer Testimonials | Benefits |

|---|---|

| Build trust and credibility | Potential customers gain confidence in the company’s capabilities. |

| Provide social proof | Positive experiences from previous customers influence decision-making. |

| Showcase commitment to quality | Testimonials highlight the company’s dedication to delivering exceptional results. |

By including customer testimonials in their company profiles, steel fabrication companies demonstrate their transparency, accountability, and commitment to building long-lasting relationships with their clients. Positive testimonials serve as a testament to the company’s ability to consistently meet or exceed customer expectations, contributing to a strong reputation and increased business opportunities.

Sustainability Practices

In a steel fabrication company profile, the inclusion of sustainability practices demonstrates the company’s commitment to environmental responsibility and corporate social consciousness. Sustainability practices encompass measures taken to minimize the company’s ecological footprint, promote resource conservation, and reduce waste throughout its operations.

Consider the following cause-and-effect relationship: by implementing sustainable practices, steel fabrication companies can positively impact their operations, reduce their environmental impact, and enhance their reputation among eco-conscious customers and stakeholders.

Real-life examples illustrate the practical significance of sustainability practices in steel fabrication. Some companies have adopted eco-friendly technologies, such as energy-efficient equipment and LED lighting systems, to reduce their carbon emissions and energy consumption. Others have implemented waste reduction programs, recycling excess materials, and partnering with scrap metal recyclers to minimize their environmental impact.

| Sustainability Practice | Benefits for Steel Fabrication Companies |

|---|---|

| Use of recycled steel | Reduced reliance on raw materials, lower carbon footprint |

| Energy-efficient equipment | Reduced energy consumption, lower operating costs |

| Waste reduction programs | Minimized waste generation, improved resource utilization |

| Employee training on sustainability | Enhanced environmental awareness, improved waste management practices |

Understanding the connection between sustainability practices and steel fabrication company profiles highlights the importance of environmental stewardship in the industry. By embracing sustainable practices, steel fabrication companies can not only reduce their ecological impact but also align themselves with the growing demand for eco-friendly products and services.

FAQs on Steel Fabrication Company Profiles

This FAQ section addresses common questions and misconceptions related to steel fabrication company profiles.

Question 1: What is a steel fabrication company profile?

A steel fabrication company profile is a comprehensive overview of a company’s capabilities, experience, and expertise in the field of steel fabrication. It serves as a valuable tool for potential customers to assess a company’s suitability for their specific project needs.

Question 2: What key aspects are included in a steel fabrication company profile?

Key aspects of a steel fabrication company profile typically include services offered, materials expertise, industry experience, quality standards, equipment and technology, project gallery, customer testimonials, and sustainability practices.

Question 3: Why is it important to review a steel fabrication company profile before selecting a partner?

Reviewing a steel fabrication company profile helps potential customers make informed decisions by providing insights into the company’s capabilities, experience, and commitment to quality. It enables them to select a partner that aligns with their project requirements, industry knowledge, and values.

Question 4: What are some common services offered by steel fabrication companies?

Common services offered by steel fabrication companies include cutting, bending, welding, and assembly. These services encompass the core capabilities and expertise of the company in shaping and assembling steel components.

Question 5: How does industry experience enhance a steel fabrication company’s profile?

Industry experience demonstrates a steel fabrication company’s understanding of the unique challenges, requirements, and standards associated with specific industry sectors. This expertise enables them to provide tailored solutions that meet the specific needs of their clients.

Question 6: Why is it beneficial to have a project gallery in a steel fabrication company profile?

A project gallery showcases a portfolio of completed projects, providing tangible evidence of a steel fabrication company’s capabilities and craftsmanship. It allows potential customers to assess the quality of previous work and gain confidence in the company’s ability to deliver exceptional results.

Summary: Steel fabrication company profiles are essential for potential customers to evaluate a company’s capabilities and suitability for their projects. By understanding the key aspects included in these profiles, customers can make informed decisions and select a partner that aligns with their specific requirements and expectations.

Transition: To further explore the significance of steel fabrication company profiles, let’s examine how they contribute to the decision-making process for selecting the right partner for your project.

Tips for Evaluating Steel Fabrication Company Profiles

When selecting a steel fabrication company for your project, carefully reviewing their company profile is crucial. Here are some valuable tips to guide your assessment:

Tip 1: Scrutinize the Company’s Experience and Expertise:

Assess the company’s track record in the industry, particularly in projects similar to yours. Look for specific examples of their capabilities and successful project outcomes.

Tip 2: Examine their Commitment to Quality:

Verify the company’s adherence to industry standards and certifications, such as ISO 9001 and AWS D1.1. These certifications demonstrate their commitment to delivering high-quality products and services.

Tip 3: Evaluate their Equipment and Technology:

Inquire about the company’s equipment and technology. Advanced equipment, such as laser cutting and automated welding systems, ensures precision, efficiency, and adherence to specifications.

Tip 4: Review their Project Gallery and Customer Testimonials:

Examine the company’s project gallery to assess the quality and diversity of their work. Read customer testimonials to gain insights into their professionalism, reliability, and ability to meet or exceed expectations.

Tip 5: Consider their Sustainability Practices:

In today’s environmentally conscious landscape, evaluate the company’s commitment to sustainability. Look for initiatives such as energy-efficient practices, waste reduction programs, and the use of recycled materials.

Tip 6: Request References and Visit their Facility:

Contact the company for references from previous clients. If possible, schedule a visit to their facility to observe their operations firsthand and assess their capabilities.

Tip 7: Compare Multiple Profiles and Seek Independent Advice:

Review company profiles from several potential partners to compare their offerings and identify the best fit for your project. Consider seeking advice from industry experts or consultants to gain objective insights.

By following these tips, you can thoroughly evaluate steel fabrication company profiles and make an informed decision that aligns with your project requirements and expectations.

Conclusion: A comprehensive analysis of steel fabrication company profiles is essential for selecting a partner that can deliver high-quality, reliable, and cost-effective steel fabrication solutions.

Conclusion

Steel fabrication company profiles play a pivotal role in the decision-making process for selecting the right partner for your project. They provide a comprehensive overview of a company’s capabilities, experience, and commitment to quality, enabling potential customers to make informed choices.

By carefully evaluating steel fabrication company profiles, you can assess their expertise, craftsmanship, and alignment with your project requirements. Consider factors such as industry experience, adherence to standards, advanced equipment, successful project examples, and customer testimonials. Remember to compare multiple profiles and seek independent advice if necessary.

Choosing the right steel fabrication company is crucial for ensuring the success of your project. By investing time in evaluating their profiles, you can identify a partner that can deliver high-quality, reliable, and cost-effective solutions that meet your specific needs.