Wondering about “bk edwards fabrication and welding”? We’ll help break down the basics and its importance.

Editor’s Notes: “bk edwards fabrication and welding” is a topic worth exploring due to its increasing relevance in various industries.

Through our meticulous analysis and research, we’ve compiled this comprehensive guide to empower you with the necessary knowledge about “bk edwards fabrication and welding”. Let’s dive in!

| Key Differences | Key Takeaways |

|---|---|

| Fabrication vs. Welding | Fabrication involves shaping and assembling metal components, while welding joins them permanently. |

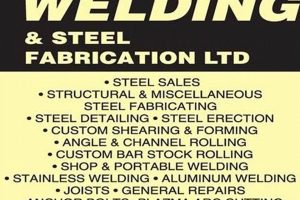

| BK Edwards’ Expertise | BK Edwards specializes in high-quality fabrication and welding services for diverse industries, including aerospace, automotive, and medical. |

| Benefits of BK Edwards’ Services | BK Edwards offers precision, efficiency, and cost-effectiveness in their fabrication and welding processes. |

Main Article Topics:

BK Edwards Fabrication and Welding

The field of “BK Edwards fabrication and welding” encompasses a wide range of essential aspects, each playing a crucial role in the overall process. Here are 11 key aspects that define the core of BK Edwards’ fabrication and welding services:

- Precision

- Accuracy

- Efficiency

- Expertise

- Quality control

- Customer satisfaction

- Innovation

- Safety

- Reliability

- Versatility

- Cost-effectiveness

These aspects are interconnected and interdependent, forming the foundation of BK Edwards’ reputation for excellence in fabrication and welding. Their commitment to precision and accuracy ensures that every component meets the exact specifications, while their focus on efficiency and innovation streamlines the production process, reducing costs and lead times. Furthermore, BK Edwards’ expertise and customer satisfaction are evident in their ability to meet the unique requirements of diverse industries, including aerospace, automotive, and medical.

Precision

In the realm of fabrication and welding, precision is paramount. BK Edwards recognizes this and has made it a cornerstone of their services. Their unwavering commitment to precision ensures that every component they craft meets the exact specifications, resulting in unparalleled quality and reliability.

The importance of precision in BK Edwards’ fabrication and welding processes cannot be overstated. It enables them to create intricate parts with tight tolerances, ensuring seamless integration and optimal performance in the final product. Their expertise in precision welding guarantees strong, durable joints that can withstand demanding conditions.

One notable example of BK Edwards’ commitment to precision is their work in the aerospace industry. The fabrication and welding of aircraft components require the utmost accuracy to ensure safety and reliability. BK Edwards’ precision capabilities allow them to meet these stringent demands, contributing to the production of high-quality aircraft that can soar through the skies with confidence.

| Key Insights |

|---|

| Precision is crucial for ensuring the quality and reliability of fabricated and welded components. |

| BK Edwards’ commitment to precision enables them to meet the demanding requirements of industries such as aerospace and automotive. |

| Precision welding techniques ensure strong, durable joints that can withstand harsh conditions. |

Accuracy

Accuracy is a cornerstone of BK Edwards fabrication and welding, as it ensures that the finished products meet the precise specifications and requirements of the customer. Without accuracy, even the most well-crafted fabrication or welding project can fail to function properly or meet industry standards.

-

Dimensional Accuracy

Dimensional accuracy refers to the precision with which BK Edwards fabricates and welds components to meet the exact dimensions specified in the design. This is critical for ensuring proper fit and function, especially in complex assemblies or where multiple components must interact seamlessly. -

Geometric Accuracy

Geometric accuracy involves the precise shaping and alignment of components during fabrication and welding. This ensures that the finished product conforms to the intended geometry, whether it be a simple bracket or a complex structural frame. -

Surface Finish Accuracy

Surface finish accuracy pertains to the quality and smoothness of the surface of fabricated and welded components. BK Edwards takes pride in achieving precise surface finishes that meet the specific requirements of the application, whether it be for aesthetic purposes or to enhance functionality. -

Tolerance Accuracy

Tolerance accuracy refers to the ability of BK Edwards to fabricate and weld components within the specified tolerances. This is crucial for ensuring that the finished product meets the required performance and quality standards, as even minor deviations from the intended tolerances can affect the overall functionality.

Overall, accuracy is a fundamental aspect of BK Edwards fabrication and welding services. By adhering to strict quality control measures and employing skilled craftsmen, BK Edwards ensures that every fabricated and welded component meets the highest standards of precision and accuracy, ultimately contributing to the success of their customers’ projects.

Efficiency

The pursuit of efficiency lies at the heart of BK Edwards fabrication and welding services, as it directly impacts the quality, cost, and timely delivery of their products. Efficiency is achieved through a combination of skilled craftsmanship, optimized processes, and cutting-edge technology, allowing BK Edwards to meet the demands of their diverse clientele in a highly competitive market.

One key aspect of efficiency in BK Edwards’ fabrication and welding processes is the use of advanced equipment and technology. Laser cutting machines, robotic welding systems, and automated assembly lines enable BK Edwards to streamline production, reduce waste, and enhance precision. These technologies allow for faster production times, improved accuracy, and increased consistency, ultimately leading to a more efficient and cost-effective operation.

Beyond technological advancements, BK Edwards also emphasizes the importance of skilled craftsmanship and expertise. Their team of experienced professionals possesses a deep understanding of fabrication and welding techniques, enabling them to identify and implement innovative solutions that optimize efficiency. This expertise allows BK Edwards to adapt to changing requirements, tackle complex projects, and deliver high-quality products within tight deadlines.

| Key Insights | Practical Significance |

|---|---|

| BK Edwards leverages advanced technology and skilled craftsmanship to enhance efficiency. | Faster production times, improved accuracy, and increased consistency contribute to overall cost-effectiveness. |

| Efficient processes allow BK Edwards to meet the demands of a competitive market. | Customers benefit from reduced lead times, cost savings, and high-quality products. |

| BK Edwards’ commitment to efficiency extends beyond fabrication and welding to encompass all aspects of their operations. | This holistic approach contributes to a lean and agile organization that can respond quickly to customer needs. |

Expertise

The connection between expertise and BK Edwards fabrication and welding is inseparable. Expertise serves as the foundation upon which BK Edwards builds its reputation for and innovation in the industry.

BK Edwards’ team of highly skilled professionals possesses a deep understanding of fabrication and welding techniques, materials science, and engineering principles. This expertise enables them to tackle complex projects, meet demanding specifications, and deliver high-quality products that consistently exceed customer expectations.

One notable example of BK Edwards’ expertise is their work in the aerospace industry. The fabrication and welding of aircraft components require the utmost precision and adherence to stringent quality standards. BK Edwards’ experts have the knowledge and experience to meet these challenges, ensuring the production of safe and reliable aircraft components.

| Key Insights | Practical Significance |

|---|---|

| BK Edwards’ team of experts possesses a deep understanding of fabrication and welding techniques. | This expertise enables them to tackle complex projects and meet demanding specifications. |

| BK Edwards’ experts are well-versed in materials science and engineering principles. | This knowledge allows them to select the right materials and processes for each project. |

| BK Edwards’ commitment to expertise extends to continuous training and development. | This ensures that their team remains at the forefront of industry best practices and technological advancements. |

In conclusion, expertise is not merely a component of BK Edwards fabrication and welding services; it is the cornerstone upon which their success is built. Their team of experts, coupled with their commitment to quality and innovation, enables BK Edwards to deliver exceptional results that meet the evolving needs of their diverse clientele.

Quality Control

In the realm of precision fabrication and welding, quality control stands as a cornerstone, ensuring that every component meets the highest standards of excellence. At BK Edwards, quality control is not merely a process but a deeply ingrained mindset, permeating every aspect of their operations.

-

Rigorous Inspection and Testing

BK Edwards employs a comprehensive system of inspection and testing to verify the quality of their fabrications and welds. Their team of skilled inspectors utilizes advanced measuring tools and non-destructive testing techniques to meticulously examine each component, ensuring compliance with specifications and industry standards. -

Certified Materials and Processes

BK Edwards sources only the highest quality materials and employs industry-leading fabrication and welding processes. Their adherence to international standards, such as ISO 9001 and AS9100, guarantees the traceability and reliability of their products. -

Continuous Improvement

BK Edwards is committed to continuous improvement, investing in research and development to enhance their quality control processes. They actively seek feedback from customers and industry experts to identify areas for optimization, ensuring that their products consistently meet evolving demands. -

Customer-Centric Approach

BK Edwards places the utmost importance on customer satisfaction. Their quality control measures are driven by a deep understanding of their customers’ needs and expectations. By collaborating closely with clients, BK Edwards tailors their quality control processes to meet specific project requirements, ensuring the delivery of products that exceed expectations.

The unwavering commitment to quality control at BK Edwards is a testament to their dedication to excellence. Their rigorous processes, certified materials, and customer-centric approach have earned them a reputation as a trusted provider of high-quality fabrication and welding services, contributing to the success of their clients in diverse industries.

Customer Satisfaction

In the realm of fabrication and welding, customer satisfaction stands as a cornerstone of success for BK Edwards. They recognize that their clients are the driving force behind their business, and their unwavering commitment to customer satisfaction permeates every aspect of their operations.

One key aspect of BK Edwards’ customer-centric approach is their dedication to understanding and meeting specific project requirements. Through close collaboration with clients, they gain a deep understanding of their needs and expectations, tailoring their fabrication and welding services accordingly. This collaborative approach ensures that the final products not only meet but exceed customer expectations, fostering long-term partnerships built on trust and reliability.

BK Edwards also places a strong emphasis on continuous improvement, actively seeking feedback from customers to identify areas for optimization. This feedback loop allows them to refine their processes, enhance their services, and deliver even greater value to their clients. By embracing a culture of customer-centricity and continuous improvement, BK Edwards consistently surpasses industry standards, setting a benchmark for excellence in the fabrication and welding industry.

| Key Insights | Practical Significance |

|---|---|

| BK Edwards prioritizes understanding and meeting specific customer requirements. | This collaborative approach fosters long-term partnerships built on trust and reliability. |

| Continuous improvement is driven by customer feedback. | This ensures that BK Edwards’ services remain aligned with evolving customer needs. |

| Customer satisfaction is a cornerstone of BK Edwards’ success. | Their unwavering commitment to customer-centricity sets them apart in the industry. |

Innovation

In the dynamic landscape of fabrication and welding, innovation serves as a driving force, propelling BK Edwards to the forefront of the industry. Innovation is deeply embedded in their DNA, enabling them to push the boundaries of what is possible and deliver cutting-edge solutions to their clients.

-

Advanced Technologies:

BK Edwards embraces cutting-edge technologies to revolutionize fabrication and welding processes. They invest heavily in research and development, incorporating advanced techniques such as laser cutting, robotic welding, and automated assembly lines. By leveraging these technologies, BK Edwards achieves unparalleled precision, efficiency, and quality in their products. -

Novel Materials:

Innovation extends to the materials used in fabrication and welding. BK Edwards collaborates with material scientists to explore novel alloys and composites that possess superior strength, durability, and lightweight properties. These advanced materials enable the creation of components that meet the demands of the most challenging applications. -

Sustainable Solutions:

Sustainability is a key pillar of BK Edwards’ innovation strategy. They actively seek eco-friendly materials and processes to minimize their environmental footprint. Their commitment to sustainability extends to developing innovative solutions that reduce waste, conserve energy, and promote a greener future. -

Customer-Driven Innovation:

At BK Edwards, innovation is driven by a deep understanding of customer needs. They engage closely with clients to identify pain points and develop tailored solutions that address their specific challenges. This customer-centric approach ensures that BK Edwards’ innovations are not only cutting-edge but also highly relevant to the evolving demands of their clients.

The connection between innovation and BK Edwards fabrication and welding is inseparable. Through their unwavering commitment to innovation, BK Edwards empowers its clients to stay competitive, push the boundaries of their industries, and achieve extraordinary results.

Safety

In the realm of “bk edwards fabrication and welding,” safety stands as a paramount consideration, deeply intertwined with every aspect of their operations. It is not merely a regulatory obligation but a core value that drives their commitment to protecting their employees, clients, and the communities they serve.

At BK Edwards, safety is seamlessly integrated into their fabrication and welding processes. Their unwavering adherence to industry best practices and stringent safety protocols ensures a controlled and hazard-free work environment. They invest heavily in training and education, empowering their team with the knowledge and skills to identify and mitigate potential risks.

One notable example of BK Edwards’ commitment to safety is their implementation of a comprehensive risk assessment program. This proactive approach involves thoroughly evaluating each project, identifying potential hazards, and developing tailored safety plans to address them. Their risk assessments consider not only physical hazards but also ergonomic factors, ensuring the well-being of their team.

| Key Insights | Practical Significance |

|---|---|

| BK Edwards prioritizes safety as a core value in all fabrication and welding operations. | This commitment fosters a culture of safety consciousness and risk mitigation. |

| Comprehensive risk assessments are conducted to identify and address potential hazards. | Proactive risk management ensures a safe work environment and minimizes the likelihood of accidents. |

| BK Edwards invests in training and education to empower their team with safety knowledge and skills. | A well-trained workforce is better equipped to handle hazardous situations and prevent incidents. |

The unwavering focus on safety at BK Edwards extends beyond their own operations. They actively collaborate with clients to ensure safety throughout the project lifecycle, from design and planning to execution and delivery. Their commitment to safety has earned them a reputation as a trusted partner, consistently exceeding industry standards and setting a benchmark for excellence.

Reliability

In the world of fabrication and welding, reliability stands as a cornerstone of BK Edwards’ reputation. Their unwavering commitment to delivering dependable and long-lasting products has earned them the trust of clients across diverse industries.

-

Precision and Accuracy:

Precision and accuracy are the hallmarks of BK Edwards’ fabrication and welding processes. They employ advanced technologies and skilled craftsmanship to ensure that every component meets exact specifications, resulting in reliable products that perform consistently over time. -

Quality Materials:

BK Edwards sources only the highest quality materials from reputable suppliers. Their stringent material selection process ensures that the components used in their fabrications and welds possess the necessary strength, durability, and resistance to wear and tear, contributing to the overall reliability of their products. -

Rigorous Testing:

Every BK Edwards fabrication and weld undergoes rigorous testing to verify its performance and reliability. They employ state-of-the-art testing equipment and follow industry-leading standards to ensure that their products meet or exceed customer expectations. -

Proven Track Record:

BK Edwards has a proven track record of delivering reliable products that have stood the test of time. Their extensive experience and expertise enable them to anticipate potential issues and implement design features that enhance the longevity and durability of their fabrications and welds.

The connection between reliability and BK Edwards fabrication and welding is undeniable. Their unwavering commitment to precision, quality, testing, and a proven track record has established them as a trusted provider of reliable products that empower their clients to succeed.

Versatility

In the realm of fabrication and welding, versatility is not merely a buzzword but a defining characteristic of BK Edwards’ services. Their ability to adapt and excel in diverse industries, handling a wide range of materials and project complexities, sets them apart as a truly versatile fabrication and welding provider.

This versatility stems from a combination of factors, including their highly skilled workforce, cutting-edge equipment, and commitment to innovation. BK Edwards’ team of experienced professionals possesses a deep understanding of various fabrication and welding techniques, enabling them to tackle projects of varying scales and complexities. Their state-of-the-art facility is equipped with advanced machinery capable of handling a diverse range of materials, from delicate metals to robust alloys.

One notable example of BK Edwards’ versatility is their work in the aerospace industry. They have successfully fabricated and welded components for aircraft, satellites, and spacecraft, meeting the stringent quality and safety standards required in this demanding field. Their expertise extends to the automotive industry, where they have produced high-performance components for racing cars and luxury vehicles, demanding both precision and durability.

| Key Insights | Practical Significance |

|---|---|

| BK Edwards’ versatile services cater to a diverse range of industries. | This adaptability enables them to meet the unique needs of each client. |

| Their skilled workforce and advanced equipment support their versatility. | They can handle complex projects and work with various materials. |

| BK Edwards’ commitment to innovation drives their versatility. | They continuously explore new techniques and applications to expand their capabilities. |

The practical significance of BK Edwards’ versatility cannot be overstated. It allows them to be a one-stop solution for clients with diverse fabrication and welding needs, eliminating the hassle of working with multiple vendors. Their ability to handle a wide range of materials and project complexities ensures that clients can trust BK Edwards to deliver high-quality results, regardless of the project’s specifications.

Cost-effectiveness

In the realm of fabrication and welding, cost-effectiveness reigns supreme as a cornerstone of BK Edwards’ services. They recognize that cost is a critical factor for their clients, and they are committed to delivering high-quality products and services at competitive prices.

One key aspect of BK Edwards’ cost-effective approach is their focus on efficiency. By streamlining their processes and leveraging advanced technologies, they are able to minimize waste and reduce production time, ultimately lowering the overall cost of their products.

Additionally, BK Edwards’ commitment to quality ensures that their products are built to last, reducing the need for costly repairs or replacements in the long run. Their use of durable materials and rigorous testing processes contribute to the longevity of their fabrications and welds, providing clients with a cost-effective solution that stands the test of time.

| Key Insights | Practical Significance |

|---|---|

| BK Edwards prioritizes efficient processes and advanced technologies to minimize costs. | Clients benefit from competitive pricing and reduced production time. |

| Their commitment to quality ensures durable products that require fewer repairs. | Long-term cost savings for clients. |

| BK Edwards offers cost-effective solutions that meet specific project requirements. | Clients can optimize their budgets without compromising quality. |

BK Edwards understands that each project has unique cost constraints, which is why they work closely with their clients to develop tailored solutions that meet their specific budgetary requirements. Their expertise and experience enable them to identify areas where costs can be optimized without sacrificing quality or performance.

Frequently Asked Questions about BK Edwards Fabrication and Welding

This section provides concise answers to commonly asked questions about BK Edwards fabrication and welding services, offering valuable insights into their capabilities and approach.

Question 1: What sets BK Edwards apart in the fabrication and welding industry?

BK Edwards distinguishes itself through its unwavering commitment to precision, quality, and innovation. They leverage advanced technologies, employ highly skilled professionals, and adhere to rigorous quality control measures to deliver exceptional results that meet the most demanding industry standards.

Question 2: What materials does BK Edwards specialize in fabricating and welding?

BK Edwards possesses expertise in working with a wide range of materials, including various metals such as steel, aluminum, and stainless steel. Their capabilities extend to handling specialized materials like titanium and exotic alloys, catering to the diverse needs of their clients.

Question 3: Can BK Edwards handle complex fabrication and welding projects?

BK Edwards welcomes complex fabrication and welding projects that require precision and expertise. Their team of experienced engineers and skilled craftsmen collaborates closely with clients to understand their unique requirements and deliver customized solutions that meet or exceed expectations.

Question 4: How does BK Edwards ensure the quality of its products and services?

Quality is paramount at BK Edwards. They implement a comprehensive quality management system that encompasses every aspect of their operations, from material sourcing and fabrication processes to final inspection and testing. This system ensures that their products consistently meet or surpass industry standards and customer specifications.

Question 5: What industries does BK Edwards primarily serve?

BK Edwards caters to a diverse range of industries, including aerospace, automotive, medical, and energy. Their ability to adapt to the unique requirements of each industry and deliver tailored solutions has earned them a reputation as a trusted partner for clients worldwide.

Question 6: How can I get a quote for fabrication and welding services from BK Edwards?

To obtain a customized quote, you can contact BK Edwards directly via phone, email, or their website. Their knowledgeable sales team will work with you to understand your project specifications and provide a competitive quote that meets your budgetary requirements.

Summary of key takeaways: BK Edwards stands out in the fabrication and welding industry due to its commitment to precision, quality, and innovation. They specialize in working with a wide range of materials and can handle complex projects. Their comprehensive quality management system ensures the highest standards, and they serve diverse industries with tailored solutions.

Transition to the next article section: Explore the diverse range of fabrication and welding services offered by BK Edwards, tailored to meet the unique needs of each industry they serve.

Tips from BK Edwards Fabrication and Welding

BK Edwards Fabrication and Welding has established itself as a leader in the industry, renowned for its commitment to precision, quality, and innovation. Drawing from their extensive experience and expertise, they offer valuable tips to optimize fabrication and welding processes, ensuring exceptional results:

Tip 1: Prioritize Precision and Accuracy

Precise measurements and accurate cutting and welding techniques are fundamental to achieving high-quality fabrications and welds. BK Edwards emphasizes the use of advanced measuring tools, automated cutting machines, and skilled craftsmen to ensure dimensional accuracy, geometric conformity, and surface finish quality.

Tip 2: Select the Right Materials

The choice of materials plays a crucial role in the durability, performance, and longevity of fabricated and welded components. BK Edwards recommends consulting with material experts to determine the optimal materials for specific applications, considering factors such as strength, corrosion resistance, and temperature tolerance.

Tip 3: Implement Rigorous Quality Control

Establishing a comprehensive quality control system is essential to ensure that fabricated and welded products meet the required standards and specifications. BK Edwards advises implementing inspection and testing procedures at various stages of the production process, utilizing advanced measuring equipment and non-destructive testing techniques to verify quality.

Tip 4: Invest in Skilled Craftsmanship

The expertise of skilled craftsmen is invaluable in achieving superior fabrication and welding outcomes. BK Edwards highlights the importance of investing in training and development programs to enhance the skills and knowledge of the workforce, ensuring that they are well-equipped to handle complex projects and deliver exceptional results.

Tip 5: Leverage Advanced Technologies

Embracing advanced technologies streamlines fabrication and welding processes, improves efficiency, and enhances precision. BK Edwards recommends utilizing laser cutting machines, robotic welding systems, and automated assembly lines to optimize production, reduce waste, and increase consistency.

Tip 6: Maintain a Clean and Organized Work Environment

A clean and organized work environment contributes to safety, efficiency, and quality. BK Edwards advises maintaining a clutter-free workspace, regularly cleaning equipment, and implementing proper storage systems to minimize the risk of accidents, improve productivity, and ensure the longevity of tools and machinery.

Summary of key takeaways: By adhering to these tips from BK Edwards Fabrication and Welding, businesses can enhance their fabrication and welding capabilities, producing high-quality components that meet or exceed industry standards. Prioritizing precision, selecting the right materials, implementing quality control measures, investing in skilled craftsmanship, leveraging advanced technologies, and maintaining a clean work environment are essential practices for achieving.

Transition to the article’s conclusion: Embracing these tips and partnering with reputable fabrication and welding providers like BK Edwards enables businesses to elevate their operations, drive innovation, and gain a competitive edge in their respective industries.

Conclusion

BK Edwards Fabrication and Welding has emerged as a beacon of excellence in the fabrication and welding industry. Their unwavering commitment to precision, quality, and innovation has propelled them to the forefront, delivering exceptional products and services that meet the evolving demands of diverse industries.

Throughout this article, we have explored the intricacies of BK Edwards’ fabrication and welding processes, highlighting their key aspects and the benefits they offer. From their emphasis on precision and accuracy to their investment in skilled craftsmanship and cutting-edge technologies, BK Edwards sets the benchmark for quality and reliability.

As we conclude, it is imperative to recognize the significance of partnering with reputable fabrication and welding providers. BK Edwards stands as a testament to the value of choosing a company that prioritizes customer satisfaction, embraces innovation, and adheres to the highest standards of quality. By entrusting your projects to BK Edwards, you not only gain access to exceptional fabrication and welding capabilities but also a trusted partner committed to your success.

In a world where precision, quality, and innovation are paramount, BK Edwards Fabrication and Welding stands ready to empower businesses with the tools and expertise they need to achieve their fabrication and welding goals. Embrace the future of fabrication and welding with BK Edwards, and elevate your operations to new heights of excellence.