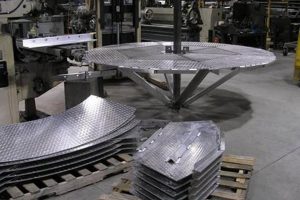

Custom fabrication can bring your metal project to life no matter how complex or simple it may be. CL Custom Fabrication provides top-notch fabrication services with a commitment to delivering excellence.

Editor’s Notes: Custom Fabrication is a critical process in various industries. It allows companies to create unique and tailored products that meet their specific requirements. This guide will provide valuable insights into the world of custom fabrication and its significance in today’s competitive market.

Through extensive research and analysis, we have compiled this comprehensive guide to help you make informed decisions about custom fabrication services. Our goal is to provide you with a clear understanding of the process, its benefits, and how it can transform your project into a reality.

Key Differences: Custom Fabrication vs. Standard Manufacturing

| Custom Fabrication | Standard Manufacturing | |

|---|---|---|

| Focus | Tailored to specific requirements | Mass production of standardized products |

| Flexibility | Highly adaptable to design changes | Limited flexibility due to fixed production lines |

| Cost | Typically higher due to customization | Lower due to economies of scale |

| Lead Time | Varies depending on complexity | Generally shorter due to established processes |

Transition to Main Article Topics

- Custom Fabrication Services

- Benefits of Custom Fabrication

- Materials Used in Custom Fabrication

- Applications of Custom Fabrication

- Custom Fabrication vs. Other Manufacturing Methods

CL Custom Fabrication

Custom fabrication plays a crucial role in various industries, enabling the creation of unique and tailored products. Here are 12 key aspects that highlight the significance of this process:

- Flexibility: Adaptable to specific design requirements

- Precision: High accuracy and attention to detail

- Quality: Commitment to delivering superior craftsmanship

- Innovation: Embracing new technologies and techniques

- Collaboration: Working closely with clients to achieve desired outcomes

- Expertise: Skilled professionals with in-depth knowledge

- Materials: Wide range of materials to suit diverse applications

- Processes: Advanced fabrication techniques to meet industry standards

- Industries: Serves various sectors, including aerospace, automotive, and construction

- Customization: Ability to create bespoke solutions

- Efficiency: Streamlined processes for timely delivery

- Cost-effectiveness: Balancing quality with affordability

These key aspects underscore the importance of custom fabrication in meeting specific project requirements. By leveraging flexibility, precision, and collaboration, CL Custom Fabrication provides tailored solutions that transform design concepts into tangible products. This process not only ensures quality and innovation but also enables cost-effectiveness and efficiency. Whether it’s complex machinery, architectural structures, or specialized components, custom fabrication plays a vital role in shaping the world around us.

Flexibility

Flexibility is a cornerstone of CL Custom Fabrication’s approach. It is the ability to adapt and modify designs to meet specific customer requirements, ensuring that each project aligns perfectly with its intended purpose. This adaptability is crucial in custom fabrication, as it allows for the accommodation of unique specifications, complex geometries, and specialized materials.

The importance of flexibility in custom fabrication is multifaceted. Firstly, it enables the creation of tailored solutions that meet precise functional demands. This is particularly valuable in industries such as aerospace and medical equipment, where adherence to strict design parameters is paramount.

Secondly, flexibility allows for the incorporation of design changes during the fabrication process. This agility is essential in responding to unforeseen circumstances, accommodating evolving project requirements, and ensuring that the final product meets or exceeds expectations.

CL Custom Fabrication’s commitment to flexibility is evident in its team of skilled engineers and craftsmen. They possess the expertise to interpret complex designs, identify potential challenges, and develop innovative solutions. This collaborative approach ensures that each project is executed with precision, meeting both the functional and aesthetic requirements of the client.

Real-life Example: A leading medical device manufacturer approached CL Custom Fabrication to create a prototype for a novel surgical instrument. The design required intricate components with tight tolerances. CL Custom Fabrication’s flexible approach allowed for the seamless integration of design modifications during the prototyping phase, resulting in a fully functional and compliant instrument that met the manufacturer’s exact specifications.

In conclusion, the flexibility of CL Custom Fabrication is a key differentiator, enabling the creation of bespoke products that meet specific design requirements. This adaptability is essential in meeting the challenges of complex projects, accommodating design changes, and ensuring customer satisfaction.

| Benefits of Flexibility in Custom Fabrication | Practical Significance | |

|---|---|---|

| 1. | Tailored solutions to meet precise functional demands | Ensuring optimal performance and suitability for specific applications |

| 2. | Accommodation of design changes during fabrication | Responding to unforeseen circumstances and evolving project requirements |

| 3. | Collaboration between engineers and craftsmen | Leveraging expertise to interpret complex designs and develop innovative solutions |

Precision

Precision is an indispensable aspect of CL Custom Fabrication’s approach, ensuring that every project meets or exceeds expectations. It involves meticulous adherence to design specifications, tight tolerances, and impeccable attention to detail throughout the fabrication process.

- State-of-the-Art Equipment: CL Custom Fabrication utilizes advanced machinery and measuring instruments to achieve exceptional accuracy. This includes CNC (Computer Numerical Control) machines, laser cutters, and CMMs (Coordinate Measuring Machines) for precise cutting, forming, and inspection.

- Skilled Craftsmanship: Beyond the machinery, it’s the skilled hands of our craftsmen that bring the designs to life. Their experience and dedication ensure that each component is meticulously crafted to meet the exact specifications.

- Quality Control: Stringent quality control measures are implemented at every stage of production. This includes regular inspections, testing, and documentation to ensure that all products meet our rigorous quality standards.

- Industry Certifications: CL Custom Fabrication holds industry certifications and adheres to international quality standards, demonstrating our commitment to precision and quality.

The significance of precision in CL Custom Fabrication cannot be overstated. It directly impacts the performance, reliability, and longevity of our products. High accuracy ensures that components fit together seamlessly, operate smoothly, and meet the intended design objectives. Attention to detail guarantees that even the smallest aspects of the fabrication process are executed with the utmost care.

| Benefits of Precision in Custom Fabrication | Practical Significance | |

|---|---|---|

| 1. | Ensuring dimensional accuracy and tight tolerances | Optimal performance, reliability, and longevity of products |

| 2. | Facilitating seamless integration of components | Smooth operation and reduced downtime |

| 3. | Meeting industry standards and certification requirements | Compliance with regulations and customer expectations |

Quality

Quality is the cornerstone of CL Custom Fabrication’s approach, representing an unwavering commitment to delivering superior craftsmanship in every project we undertake. It encompasses the meticulous attention to detail, adherence to industry standards, and relentless pursuit of excellence that permeates every aspect of our fabrication process.

This commitment to quality is deeply rooted in the understanding that our products are more than just fabricated components; they are the foundation of our clients’ success. By delivering superior craftsmanship, we ensure that our clients receive products that meet their exact specifications, perform reliably, and stand the test of time.

Real-Life Example: Precision Engineering for Aerospace Components

In the demanding field of aerospace, precision and quality are paramount. CL Custom Fabrication was entrusted with manufacturing critical components for a leading aircraft manufacturer. Our team meticulously followed the stringent design specifications and quality control procedures, employing state-of-the-art CNC machines and CMMs to achieve exceptional accuracy. The resulting components met or exceeded the required tolerances, ensuring the aircraft’s structural integrity and flight performance.

| Practical Significance of Quality in Custom Fabrication | |

|---|---|

| 1. | Enhanced product performance and reliability: Superior craftsmanship ensures that products meet or exceed design specifications and perform consistently. |

| 2. | Reduced maintenance and downtime: Meticulous attention to detail minimizes defects and premature failures, leading to increased uptime and reduced maintenance costs. |

| 3. | Increased customer satisfaction and loyalty: Delivering high-quality products builds trust and fosters long-term partnerships with clients. |

| 4. | Compliance with industry standards and regulatory requirements: Adherence to quality standards ensures compliance with industry regulations and customer expectations. |

Our commitment to quality extends beyond the fabrication process. We believe that quality should be evident in every interaction with our clients, from the initial consultation to the final delivery. Our team is dedicated to providing exceptional customer service, ensuring that our clients are fully satisfied with their experience and the products they receive.

In conclusion, quality is not simply a buzzword for CL Custom Fabrication; it is the driving force behind everything we do. By delivering superior craftsmanship, we empower our clients with products that are built to perform, last, and exceed expectations.

Innovation

Innovation plays a pivotal role in CL Custom Fabrication, driving our commitment to delivering cutting-edge solutions that meet the evolving demands of our clients. By embracing new technologies and techniques, we push the boundaries of what is possible in custom fabrication, empowering our clients to achieve their most ambitious goals.

- Advanced Design Software: Utilizing sophisticated CAD/CAM software, our engineers can create complex designs with precision and efficiency. This technology enables us to optimize designs for manufacturability, reducing lead times and ensuring the highest quality.

- 3D Printing and Rapid Prototyping: We leverage 3D printing and rapid prototyping techniques to create physical prototypes quickly and cost-effectively. This allows our clients to visualize their designs, test functionality, and make informed decisions before committing to full-scale production.

- Automated Fabrication Equipment: Our state-of-the-art fabrication equipment, including CNC machines and robotic welding systems, ensures precision, repeatability, and increased production efficiency. This automation streamlines the fabrication process, reducing costs and improving product quality.

- Materials Innovation: We are constantly exploring new and innovative materials that offer enhanced performance and durability. From high-strength alloys to lightweight composites, we select the optimal materials to meet the specific requirements of each project.

The integration of these innovative technologies and techniques enables CL Custom Fabrication to deliver unparalleled solutions that exceed our clients’ expectations. By harnessing the power of innovation, we empower our clients to stay at the forefront of their industries and achieve their business objectives.

Collaboration

Collaboration is the cornerstone of CL Custom Fabrication’s approach. It fosters a transparent and iterative partnership between our team and our clients, ensuring that we deliver tailored solutions that meet their specific needs and exceed their expectations.

- Understanding Project Goals and Objectives: We take time to thoroughly understand our clients’ project goals, timelines, and budgets. This in-depth understanding enables us to develop fabrication solutions that are aligned with their strategic objectives.

- Open Communication and Regular Updates: We maintain open lines of communication throughout the fabrication process. Regular updates and transparent discussions ensure that our clients are fully informed of progress, potential challenges, and alternative solutions.

- Client Involvement in Design and Development: We actively involve our clients in the design and development phases. This collaborative approach allows us to incorporate their feedback and ensure that the final product aligns with their vision.

- Flexibility and Adaptability: We understand that project requirements can evolve. Our flexible and adaptable approach allows us to accommodate changes and modifications during the fabrication process, ensuring that the final product meets the latest specifications.

Through our collaborative approach, we forge strong partnerships with our clients, fostering trust and mutual respect. This collaboration extends beyond the delivery of the final product, as we remain committed to providing ongoing support and maintenance to ensure the longevity and success of our clients’ projects.

Expertise

In the realm of custom fabrication, expertise is the cornerstone of excellence. CL Custom Fabrication boasts a team of highly skilled professionals who possess in-depth knowledge and a passion for delivering exceptional results.

- Design and Engineering Expertise: Our engineers and designers have a deep understanding of design principles, materials science, and manufacturing processes. They collaborate closely with clients to transform their concepts into tangible, high-performing products.

- Advanced Manufacturing Techniques: Our team is proficient in a wide range of fabrication techniques, including CNC machining, welding, forming, and assembly. Their mastery of these techniques ensures precision, efficiency, and adherence to the highest quality standards.

- Materials Expertise: Our professionals possess a comprehensive knowledge of various materials, their properties, and applications. They provide expert guidance in selecting the optimal materials for each project, ensuring durability, performance, and cost-effectiveness.

- Industry-Specific Knowledge: Our team has extensive experience in diverse industries, including aerospace, automotive, medical, and construction. This industry-specific knowledge enables us to anticipate challenges, understand regulatory requirements, and deliver tailored solutions that meet the unique demands of each sector.

The expertise of our professionals extends beyond technical proficiency. They are proactive problem-solvers, constantly seeking innovative solutions to meet complex design and manufacturing challenges. Their dedication to continuous learning ensures that they remain at the forefront of industry advancements, bringing the latest knowledge and techniques to every project.

Materials

In the realm of custom fabrication, the selection of materials plays a pivotal role in determining the success and performance of the final product. CL Custom Fabrication recognizes the importance of materials and offers a wide range of options to cater to the diverse needs of our clients.

The choice of materials is driven by various factors, including the intended application, environmental conditions, mechanical properties, and cost considerations. Our team of experts collaborates closely with clients to understand their specific requirements and recommend the most suitable materials for their project.

CL Custom Fabrication has extensive experience working with a variety of materials, including:

- Metals (e.g., steel, aluminum, stainless steel, titanium)

- Plastics (e.g., ABS, polycarbonate, polyethylene)

- Composites (e.g., fiberglass, carbon fiber, Kevlar)

- Wood

- Glass

Each material offers unique advantages and drawbacks. For instance, metals are known for their strength and durability, while plastics provide lightweight and corrosion resistance. Composites offer a combination of strength, weight, and flexibility. Our experts carefully consider these factors to select the optimal material for each component.

The use of high-quality materials is essential for ensuring the longevity, reliability, and performance of custom fabricated products. By leveraging our expertise and access to a wide range of materials, CL Custom Fabrication delivers tailored solutions that meet the specific demands of each project.

| Material | Properties | Applications |

|---|---|---|

| Steel | High strength, durability, and machinability | Structural components, automotive parts, machinery |

| Aluminum | Lightweight, corrosion-resistant, and good electrical conductivity | Aerospace components, marine applications, consumer electronics |

| Stainless steel | Excellent corrosion resistance, strength, and heat resistance | Food processing equipment, medical devices, chemical processing |

| Titanium | High strength-to-weight ratio, corrosion resistance, and biocompatibility | Aerospace components, medical implants, sporting goods |

| ABS | Tough, lightweight, and resistant to chemicals | Automotive parts, consumer products, enclosures |

Processes

In the realm of custom fabrication, employing advanced fabrication techniques is paramount to achieving exceptional results and meeting the stringent demands of various industries. CL Custom Fabrication leverages a diverse range of state-of-the-art processes to ensure the highest levels of precision, efficiency, and adherence to industry standards.

-

Computer Numerical Control (CNC) Machining:

CNC machining utilizes computerized controls to operate machine tools, resulting in highly accurate and repeatable parts. This technique is ideal for complex geometries, tight tolerances, and high-volume production.

-

Laser Cutting:

Laser cutting employs a concentrated beam of light to precisely cut various materials. It offers intricate designs, smooth edges, and minimal heat distortion, making it suitable for delicate or intricate components.

-

Welding:

CL Custom Fabrication employs advanced welding techniques, including MIG, TIG, and spot welding, to create strong and durable joints. Our skilled welders ensure precise and aesthetically pleasing welds, meeting the highest quality standards.

-

Finishing:

The finishing process plays a crucial role in enhancing the functionality and aesthetics of fabricated parts. We offer a range of finishing options, including powder coating, anodizing, and electroplating, to meet specific requirements and environmental conditions.

By harnessing these advanced fabrication techniques, CL Custom Fabrication delivers exceptional products that meet the exacting standards of industries such as aerospace, medical, automotive, and construction. Our commitment to precision, efficiency, and quality ensures that our clients receive tailored solutions that exceed their expectations.

Industries

Custom fabrication plays a vital role in a diverse range of industries, each with unique requirements and challenges. CL Custom Fabrication’s expertise and capabilities extend across these sectors, providing tailored solutions that meet the specific demands of each industry.

-

Aerospace:

In the aerospace industry, precision and reliability are paramount. CL Custom Fabrication’s advanced manufacturing techniques and stringent quality control measures ensure the production of high-performance components that meet the exacting standards of the aerospace sector.

-

Automotive:

The automotive industry demands both durability and efficiency. CL Custom Fabrication’s expertise in materials selection and fabrication processes enables the production of lightweight, durable, and cost-effective components for a wide range of automotive applications.

-

Construction:

The construction industry requires structural integrity and aesthetic appeal. CL Custom Fabrication’s ability to work with various materials and its commitment to precision ensure the production of high-quality components that meet the functional and aesthetic requirements of construction projects.

CL Custom Fabrication’s ability to serve various industries stems from its commitment to innovation, quality, and customer satisfaction. By understanding the unique needs of each sector, CL Custom Fabrication delivers tailored solutions that drive success and innovation across a wide range of industries.

Customization

In the realm of fabrication, customization holds immense value, and CL Custom Fabrication stands out for its exceptional ability to create bespoke solutions tailored to unique requirements. This unparalleled level of customization empowers clients to bring their visions to life, ensuring that their projects perfectly align with their specific needs and goals.

-

Precision and Accuracy:

CL Custom Fabrication utilizes advanced machinery and skilled craftsmanship to achieve precise and accurate fabrication, resulting in products that meet exact specifications. This level of precision is crucial for industries such as aerospace and medical equipment, where adherence to strict design parameters is paramount.

-

Flexibility and Adaptability:

Recognizing that design requirements can evolve, CL Custom Fabrication embraces flexibility and adaptability throughout the fabrication process. Their team can seamlessly accommodate design changes, ensuring that the final product meets or exceeds expectations, even in the face of unforeseen circumstances.

-

Innovative Solutions:

CL Custom Fabrication fosters a culture of innovation, leveraging cutting-edge technology and techniques to develop groundbreaking solutions. Their engineers and designers work closely with clients to translate complex concepts into tangible products, pushing the boundaries of what is possible in custom fabrication.

-

Collaborative Approach:

Collaboration is at the heart of CL Custom Fabrication’s approach. They actively involve clients in every stage of the fabrication process, ensuring that their insights and feedback are incorporated into the final product. This collaborative approach fosters a sense of ownership and satisfaction among clients, leading to long-lasting partnerships.

In conclusion, CL Custom Fabrication’s ability to create bespoke solutions stems from their unwavering commitment to precision, flexibility, innovation, and collaboration. By tailoring their services to each client’s unique needs, they empower their clients to achieve their project goals and drive success in their respective industries.

Efficiency

In the realm of custom fabrication, efficiency is paramount. CL Custom Fabrication’s commitment to streamlined processes ensures timely delivery, enabling clients to meet their project deadlines and achieve their business objectives.

-

Optimized Production Planning:

CL Custom Fabrication employs advanced planning and scheduling techniques to optimize production. By carefully coordinating resources and minimizing lead times, they ensure that projects are completed efficiently and on schedule.

-

Lean Manufacturing Principles:

Lean manufacturing principles are deeply ingrained in CL Custom Fabrication’s operations. They continuously strive to eliminate waste and inefficiencies, resulting in reduced production costs and faster turnaround times.

-

Automated Processes:

CL Custom Fabrication leverages automation to streamline repetitive tasks and improve overall efficiency. Automated equipment, such as CNC machines and robotic welding systems, enhance accuracy, reduce labor costs, and accelerate production.

-

Real-Time Monitoring and Control:

Advanced monitoring systems provide real-time visibility into the production process. This enables CL Custom Fabrication to identify and address potential bottlenecks, ensuring smooth and timely delivery of products.

The combination of these facets underscores CL Custom Fabrication’s unwavering commitment to efficiency. By streamlining processes and leveraging technology, they empower clients with timely delivery, enabling them to stay competitive and achieve greater success in their respective industries.

Cost-effectiveness

In the realm of custom fabrication, balancing cost-effectiveness with quality is a delicate art. CL Custom Fabrication excels in this regard, offering clients tailored solutions that meet their budgetary constraints without compromising quality.

-

Value Engineering:

CL Custom Fabrication employs value engineering principles to optimize designs and reduce costs without sacrificing performance. By analyzing materials, processes, and functionality, they identify areas for improvement, resulting in cost savings and enhanced value for clients.

-

Economies of Scale:

Understanding the benefits of economies of scale, CL Custom Fabrication leverages its production capabilities to reduce per-unit costs. By combining multiple orders or utilizing standardized components, they achieve cost savings that are passed on to clients, making custom fabrication more accessible.

-

Efficient Production Processes:

CL Custom Fabrication continuously invests in advanced machinery and efficient production processes to minimize waste and streamline operations. These investments result in reduced labor costs, shorter lead times, and improved cost-effectiveness, ultimately benefiting clients by lowering their overall project expenses.

-

Material Optimization:

Recognizing the significant impact of materials on cost, CL Custom Fabrication works closely with clients to select the most appropriate materials for each project. By considering factors such as durability, availability, and cost, they optimize material usage, reducing waste and ensuring cost-effective solutions.

Through its commitment to value engineering, economies of scale, efficient production processes, and material optimization, CL Custom Fabrication empowers clients to achieve their fabrication goals without exceeding their budgets. By striking the optimal balance between quality and affordability, they deliver cost-effective solutions that drive success and innovation.

FAQs about Custom Fabrication

Custom fabrication is a multifaceted process that offers immense benefits for various industries. To provide further clarification, here are answers to some frequently asked questions:

Question 1: What sets custom fabrication apart from standard manufacturing?

Custom fabrication prioritizes tailored solutions that align precisely with specific requirements. Unlike standard manufacturing, which focuses on mass production of standardized products, custom fabrication offers flexibility, precision, and adaptability to meet unique project demands.

Question 2: What are the key benefits of choosing custom fabrication?

Custom fabrication empowers businesses with tailored solutions that enhance product performance, optimize functionality, and align seamlessly with their strategic objectives. It provides greater control over design, materials, and processes, ultimately resulting in superior end products.

Question 3: What industries can benefit from custom fabrication?

Custom fabrication finds applications across a wide range of industries, including aerospace, automotive, medical, construction, and many more. It enables the creation of specialized components, prototypes, and unique products that meet the specific requirements of each industry.

Question 4: How does custom fabrication ensure quality and precision?

Custom fabrication places utmost importance on quality and precision. It involves meticulous attention to detail, adherence to industry standards, and utilization of advanced machinery and skilled craftsmanship. This ensures that every fabricated product meets exact specifications and delivers optimal performance.

Question 5: Is custom fabrication cost-effective?

While custom fabrication may require higher upfront costs compared to mass production, it offers long-term cost-effectiveness. By creating products that precisely meet specific needs, custom fabrication minimizes waste, reduces maintenance costs, and enhances product longevity, ultimately providing a higher return on investment.

Question 6: How can I choose the right custom fabrication partner?

Selecting the ideal custom fabrication partner requires careful consideration. Look for a company with a proven track record, skilled professionals, advanced capabilities, and a commitment to delivering exceptional results. Clear communication, transparent pricing, and a collaborative approach are also crucial factors to ensure a successful partnership.

Summary: Custom fabrication offers a multitude of benefits, including tailored solutions, enhanced product performance, and industry-specific applications. By choosing the right fabrication partner and leveraging the advantages of custom fabrication, businesses can unlock innovation, drive efficiency, and achieve their unique project goals.

Transition to the next article section: To delve deeper into the realm of custom fabrication, let’s explore its diverse applications and the transformative impact it has across various industries.

Custom Fabrication Tips for Enhanced Projects

Custom fabrication offers a wealth of opportunities to transform concepts into tangible solutions. By embracing these tips, you can harness the full potential of custom fabrication and achieve exceptional results.

Tip 1: Define Clear Project Goals and Objectives

Clearly outlining your project goals and objectives is paramount. This provides a solid foundation for effective communication with your fabrication partner and ensures that the final product aligns precisely with your vision.

Tip 2: Leverage Advanced Design and Engineering Tools

Utilize advanced design and engineering software to create precise and detailed designs. This enables seamless integration of components, optimizes functionality, and reduces potential errors during fabrication.

Tip 3: Explore a Wide Range of Materials

Custom fabrication offers access to a vast array of materials. Explore different options to find the ideal combination of strength, durability, and aesthetics that meets your specific requirements.

Tip 4: Prioritize Quality and Precision

Insist on the highest standards of quality and precision throughout the fabrication process. This ensures that your end product meets or exceeds expectations and delivers exceptional performance over its lifespan.

Tip 5: Foster Open Communication with Your Fabrication Partner

Maintain open and regular communication with your fabrication partner. Discuss design modifications, material selection, and timelines to ensure that all parties are aligned and working towards a common goal.

Tip 6: Conduct Thorough Testing and Validation

Before deploying your fabricated product, conduct rigorous testing and validation to verify its functionality, safety, and compliance with industry standards. This step helps identify and rectify any potential issues, ensuring a successful implementation.

Summary: By adhering to these tips, you can maximize the benefits of custom fabrication and create innovative, high-quality products that meet your exact requirements. Embrace these guidelines to unlock the full potential of this transformative process.

Transition to the article’s conclusion: Custom fabrication empowers businesses to push the boundaries of innovation and achieve their unique project goals. By partnering with a skilled fabrication company and leveraging these tips, you can harness the power of custom fabrication to transform your vision into a tangible reality.

Conclusion

Custom fabrication has emerged as a cornerstone of innovation and precision engineering. Through its ability to create tailored solutions, CL Custom Fabrication empowers businesses to transcend the limitations of standard manufacturing and achieve their unique project goals. This comprehensive guide has explored the multifaceted world of custom fabrication, highlighting its key aspects, benefits, and applications across various industries.

As technology continues to advance, custom fabrication will undoubtedly play an even more pivotal role in shaping the future. CL Custom Fabrication stands at the forefront of this transformation, committed to delivering cutting-edge solutions that meet the evolving demands of our clients. By embracing the power of custom fabrication, businesses can unlock a world of possibilities, drive innovation, and achieve sustainable growth.