So, what exactly is cooper steel fabrication? And why is it important?

Editor’s Note: Cooper steel fabrication is the process of shaping and forming steel into various products. It is a vital part of many industries, including construction, manufacturing, and transportation.

At its core, cooper steel fabrication involves cutting, bending, and welding steel to create the desired shape or product. This can be a complex process, requiring specialized equipment and skilled workers. However, the end result is often a product that is both strong and durable.

There are many different types of cooper steel fabrication, each with its own unique set of benefits and applications. Some of the most common types include:

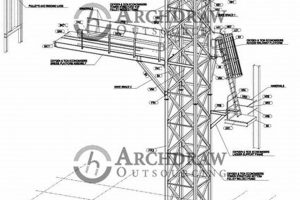

- Structural steel fabrication: This type of fabrication is used to create the framework for buildings and other structures. It involves cutting, bending, and welding steel beams, columns, and other structural components.

- Plate steel fabrication: This type of fabrication is used to create flat or curved steel plates. It involves cutting, bending, and welding steel plates to create the desired shape or product.

- Pipe steel fabrication: This type of fabrication is used to create pipes and other cylindrical steel products. It involves cutting, bending, and welding steel pipes to create the desired shape or product.

Cooper steel fabrication is an essential part of many industries. It is used to create a wide variety of products, from buildings to bridges to cars. The next time you see a steel product, take a moment to appreciate the skill and craftsmanship that went into its fabrication.

Cooper Steel Fabrication

Cooper steel fabrication is a vital process in many industries, including construction, manufacturing, and transportation. It involves shaping and forming steel into various products, from buildings to bridges to cars. Here are 9 key aspects of cooper steel fabrication:

- Cutting: Steel is cut using a variety of methods, including plasma cutting, laser cutting, and waterjet cutting.

- Bending: Steel is bent using a variety of methods, including press brakes, rolls, and hammers.

- Welding: Steel is welded using a variety of methods, including arc welding, MIG welding, and TIG welding.

- Structural: Structural steel fabrication is used to create the framework for buildings and other structures.

- Plate: Plate steel fabrication is used to create flat or curved steel plates.

- Pipe: Pipe steel fabrication is used to create pipes and other cylindrical steel products.

- Automotive: Cooper steel fabrication is used to create a variety of automotive parts, including chassis, frames, and bodies.

- Aerospace: Cooper steel fabrication is used to create a variety of aerospace parts, including wings, fuselages, and landing gear.

- Energy: Cooper steel fabrication is used to create a variety of energy components, including oil rigs, wind turbines, and solar panels.

These are just a few of the many key aspects of cooper steel fabrication. This versatile process is used to create a wide variety of products, from the everyday to the extraordinary.

Cutting

Cutting is one of the most important steps in cooper steel fabrication. It is the process of shaping steel into the desired form or shape. There are a variety of cutting methods that can be used, each with its own advantages and disadvantages.

Plasma cutting is a process that uses a plasma torch to cut through metal. It is a fast and efficient process, but it can produce a rough cut edge. Laser cutting is a process that uses a laser to cut through metal. It is a precise process that can produce a smooth cut edge. Waterjet cutting is a process that uses a high-pressure water jet to cut through metal. It is a slow process, but it can produce a very precise cut edge.

The choice of cutting method depends on the specific application. For example, plasma cutting is often used for cutting thick metal plates, while laser cutting is often used for cutting thin metal sheets. Waterjet cutting is often used for cutting complex shapes.

Cutting is a critical step in cooper steel fabrication. It is important to choose the right cutting method for the specific application in order to achieve the desired results.

| Cutting Method | Advantages | Disadvantages |

|---|---|---|

| Plasma cutting | Fast and efficient | Can produce a rough cut edge |

| Laser cutting | Precise | Can be slow |

| Waterjet cutting | Very precise | Slow |

Bending

Bending is an essential part of cooper steel fabrication. It is the process of shaping steel into the desired form or shape. There are a variety of bending methods that can be used, each with its own advantages and disadvantages.

Press brakes are used to bend steel by applying pressure to the metal. This can be done manually or using a hydraulic or pneumatic press. Rolls are used to bend steel by passing the metal through a series of rollers. This can be done to create a variety of shapes, including cylinders and cones. Hammers are used to bend steel by striking the metal with a hammer. This can be done to create a variety of shapes, including angles and curves.

The choice of bending method depends on the specific application. For example, press brakes are often used for bending thick metal plates, while rolls are often used for bending thin metal sheets. Hammers are often used for bending complex shapes.

Bending is a critical step in cooper steel fabrication. It is important to choose the right bending method for the specific application in order to achieve the desired results.

| Bending Method | Advantages | Disadvantages |

|---|---|---|

| Press brakes | Precise | Can be slow |

| Rolls | Fast and efficient | Can produce a rough bend |

| Hammers | Versatile | Can be difficult to control |

Welding

Welding is an essential part of cooper steel fabrication. It is the process of joining two or more pieces of metal together by melting the metal at the joint. This can be done using a variety of welding methods, including arc welding, MIG welding, and TIG welding.

- Arc welding is a type of welding that uses an electric arc to melt the metal at the joint. This is the most common type of welding used in cooper steel fabrication.

- MIG welding (also known as metal inert gas welding) is a type of welding that uses a shielding gas to protect the weld from oxidation. This type of welding is often used for welding thin metal sheets.

- TIG welding (also known as tungsten inert gas welding) is a type of welding that uses a tungsten electrode to create the arc. This type of welding is often used for welding thick metal plates.

The choice of welding method depends on the specific application. For example, arc welding is often used for welding structural steel, while MIG welding is often used for welding sheet metal. TIG welding is often used for welding precision components.

Welding is a critical step in cooper steel fabrication. It is important to choose the right welding method for the specific application in order to achieve the desired results.

Structural

Structural steel fabrication is a critical part of cooper steel fabrication. It involves the cutting, bending, and welding of steel to create the framework for buildings and other structures. Structural steel is used in a wide variety of applications, including bridges, skyscrapers, and stadiums.

- Strength and durability: Structural steel is one of the strongest and most durable materials available. It is able to withstand high loads and forces, making it ideal for use in structures that need to be able to support heavy weights or withstand extreme weather conditions.

- Versatility: Structural steel can be used to create a wide variety of shapes and sizes. This makes it a versatile material that can be used in a variety of applications.

- Cost-effectiveness: Structural steel is a relatively cost-effective material. It is less expensive than many other materials, such as concrete or wood, making it a more affordable option for many projects.

- Sustainability: Structural steel is a sustainable material. It is made from recycled materials and can be recycled at the end of its lifespan.

Structural steel fabrication is an essential part of cooper steel fabrication. It is used to create the framework for buildings and other structures that are strong, durable, versatile, and cost-effective. Structural steel is also a sustainable material, making it a good choice for environmentally conscious projects.

Plate

Plate steel fabrication is a critical part of cooper steel fabrication. It involves the cutting, bending, and welding of steel to create flat or curved steel plates. These plates are used in a wide variety of applications, including bridges, buildings, and ships.

There are many advantages to using plate steel fabrication. One advantage is that it is a very strong and durable material. Steel plates are able to withstand high loads and forces, making them ideal for use in structures that need to be able to support heavy weights or withstand extreme weather conditions.

Another advantage of plate steel fabrication is that it is a very versatile material. Steel plates can be cut, bent, and welded into a wide variety of shapes and sizes. This makes them ideal for use in a variety of applications, from simple structural components to complex architectural features.

Plate steel fabrication is a cost-effective way to create strong and durable structures. Steel plates are relatively inexpensive, and they can be easily recycled at the end of their lifespan. This makes them a sustainable option for many projects.

Here are some examples of how plate steel fabrication is used in cooper steel fabrication:

- Bridges: Steel plates are used to create the girders and other structural components of bridges.

- Buildings: Steel plates are used to create the beams, columns, and other structural components of buildings.

- Ships: Steel plates are used to create the hulls and other structural components of ships.

Plate steel fabrication is an essential part of cooper steel fabrication. It is used to create strong, durable, and versatile structures that are used in a wide variety of applications.

| Characteristic | Plate Steel Fabrication |

|---|---|

| Strength | High |

| Durability | High |

| Versatility | High |

| Cost-effectiveness | High |

| Sustainability | High |

Pipe

Pipe steel fabrication is a critical part of cooper steel fabrication. It involves the cutting, bending, and welding of steel to create pipes and other cylindrical steel products. These products are used in a wide variety of applications, including plumbing, heating, and ventilation.

- Pipelines: Steel pipes are used to transport water, gas, and oil over long distances. They are also used in sewer systems and other industrial applications.

- HVAC systems: Steel pipes are used to distribute hot and cold air in HVAC systems. They are also used to create ductwork for ventilation systems.

- Boilers and pressure vessels: Steel pipes are used to create boilers and pressure vessels. These products are used to generate steam and store liquids under pressure.

- Automotive and aerospace: Steel pipes are used in a variety of automotive and aerospace applications, such as exhaust systems and fuel lines.

Pipe steel fabrication is an essential part of cooper steel fabrication. It is used to create a wide variety of products that are used in a variety of industries. Steel pipes are strong, durable, and versatile, making them an ideal choice for a variety of applications.

Automotive

Cooper steel fabrication plays a critical role in the automotive industry. It is used to create a wide variety of automotive parts, including chassis, frames, and bodies. These components are essential for the safety, performance, and durability of vehicles.

The automotive industry relies heavily on steel due to its strength, durability, and versatility. Steel is able to withstand the high loads and forces that are encountered during driving, and it can be formed into a variety of shapes and sizes. This makes it an ideal material for use in a variety of automotive applications.

Cooper steel fabrication is a complex process that requires specialized equipment and skilled workers. The first step in the process is to cut the steel into the desired shape. This can be done using a variety of methods, including plasma cutting, laser cutting, and waterjet cutting.

Once the steel has been cut, it is bent into the desired shape. This can be done using a variety of methods, including press brakes, rolls, and hammers. The bending process is critical to ensuring that the steel components fit together properly.

The final step in the cooper steel fabrication process is welding. Welding is used to join the steel components together to create the final product. There are a variety of welding methods that can be used, including arc welding, MIG welding, and TIG welding.

Cooper steel fabrication is an essential part of the automotive industry. It is used to create a wide variety of automotive parts that are critical for the safety, performance, and durability of vehicles.

Here are some examples of how cooper steel fabrication is used in the automotive industry:

- Chassis: The chassis is the framework of a vehicle. It supports the engine, transmission, and other components. Cooper steel fabrication is used to create the chassis for a variety of vehicles, including cars, trucks, and SUVs.

- Frames: The frame is the structure of a vehicle. It supports the body and other components. Cooper steel fabrication is used to create the frames for a variety of vehicles, including cars, trucks, and buses.

- Bodies: The body is the exterior of a vehicle. It protects the occupants from the elements and provides a comfortable environment. Cooper steel fabrication is used to create the bodies for a variety of vehicles, including cars, trucks, and SUVs.

Cooper steel fabrication is a complex and challenging process, but it is essential for the automotive industry. It is used to create a wide variety of automotive parts that are critical for the safety, performance, and durability of vehicles.

| Component | Function | Cooper Steel Fabrication Process |

|---|---|---|

| Chassis | Supports the engine, transmission, and other components | Cutting, bending, and welding |

| Frame | Supports the body and other components | Cutting, bending, and welding |

| Body | Protects the occupants from the elements and provides a comfortable environment | Cutting, bending, and welding |

Aerospace

Cooper steel fabrication plays a critical role in the aerospace industry. It is used to create a wide variety of aerospace parts, including wings, fuselages, and landing gear. These components are essential for the safety, performance, and durability of aircraft.

- Strength and Durability: Steel is a strong and durable material, making it ideal for use in aerospace applications. Steel components can withstand the high loads and forces that are encountered during flight. This is especially important for components such as wings and landing gear, which must be able to support the weight of the aircraft and withstand the stresses of takeoff and landing.

- Lightweight: Steel is a relatively lightweight material, making it ideal for use in aerospace applications where weight is a critical factor. This is especially important for components such as wings, which must be lightweight in order to achieve optimal fuel efficiency.

- Corrosion Resistance: Steel is a corrosion-resistant material, making it ideal for use in aerospace applications where exposure to the elements is a concern. This is especially important for components such as fuselages, which must be able to withstand the harsh conditions of the atmosphere.

- Formability: Steel is a formable material, making it ideal for use in aerospace applications where complex shapes are required. This is especially important for components such as wings, which must be able to be formed into the desired shape in order to achieve optimal aerodynamic performance.

Cooper steel fabrication is a complex and challenging process, but it is essential for the aerospace industry. It is used to create a wide variety of aerospace parts that are critical for the safety, performance, and durability of aircraft.

Energy

Cooper steel fabrication plays a vital role in the energy sector. It is used to create a wide variety of energy components, including oil rigs, wind turbines, and solar panels. These components are essential for the production, distribution, and use of energy.

- Oil and Gas: Steel is used to create a variety of components for the oil and gas industry, including oil rigs, pipelines, and storage tanks. These components are essential for the exploration, production, and transportation of oil and gas.

- Wind Energy: Steel is used to create a variety of components for the wind energy industry, including wind turbines, towers, and blades. These components are essential for the generation of electricity from wind power.

- Solar Energy: Steel is used to create a variety of components for the solar energy industry, including solar panels, mounting systems, and tracking systems. These components are essential for the generation of electricity from solar power.

Cooper steel fabrication is a complex and challenging process, but it is essential for the energy sector. It is used to create a wide variety of energy components that are critical for the production, distribution, and use of energy.

FAQs on Steel Fabrication

This section provides answers to commonly asked questions about steel fabrication, addressing concerns and clarifying any misconceptions.

Question 1: What is steel fabrication?

Answer: Steel fabrication encompasses various processes that transform raw steel into customized structures, components, and products. It involves cutting, bending, welding, and assembling steel to achieve desired shapes, sizes, and functionalities.

Question 2: What are the common methods used in steel fabrication?

Answer: Steel fabrication utilizes techniques like plasma cutting, laser cutting, waterjet cutting, press braking, rolling, and welding. Each method serves specific purposes and offers advantages depending on the project requirements and material thickness.

Question 3: What industries rely heavily on steel fabrication?

Answer: Steel fabrication plays a crucial role in industries such as construction, automotive, aerospace, energy, and shipbuilding. It enables the creation of structural components, vehicle parts, aircraft components, energy infrastructure, and ship hulls.

Question 4: What factors influence the cost of steel fabrication?

Answer: The cost of steel fabrication can vary based on several factors, including the complexity of the design, material grade and thickness, fabrication methods employed, and labor costs. It’s essential to consider these factors when budgeting for a steel fabrication project.

Question 5: How can I ensure the quality of steel fabrication?

Answer: To ensure quality, it’s important to partner with reputable steel fabricators who adhere to industry standards and quality control measures. Seeking certifications, such as ISO 9001, can provide assurance of the fabricator’s commitment to quality.

Question 6: What are the advantages of using steel in fabrication?

Answer: Steel offers numerous advantages in fabrication: it is strong, durable, versatile, cost-effective, and recyclable. These properties make steel an ideal choice for a wide range of applications, from structural beams to intricate architectural elements.

In conclusion, steel fabrication is a versatile and essential process that transforms steel into customized products for various industries. Understanding the methods, applications, and factors involved in steel fabrication empowers individuals to make informed decisions and achieve successful project outcomes.

Moving forward, we will explore specific types of steel fabrication and their applications in greater detail.

Steel Fabrication Tips

Steel fabrication involves shaping and forming steel into various products and structures. Here are some crucial tips to consider for effective and efficient steel fabrication:

Tip 1: Choose the Right Steel Grade

Selecting the appropriate steel grade is crucial for ensuring the desired properties and performance of the fabricated product. Consider factors such as strength, corrosion resistance, formability, and weldability when choosing the steel grade.

Tip 2: Optimize Cutting Processes

Employ efficient cutting techniques to minimize material waste and ensure precision. Explore options like plasma cutting, laser cutting, or waterjet cutting based on the thickness and complexity of the steel being cut.

Tip 3: Utilize Precision Bending Techniques

Accurate bending is essential for achieving the desired shape and dimensions. Utilize press brakes or bending rolls to achieve precise bends while minimizing distortion or damage to the steel.

Tip 4: Employ Proper Welding Techniques

Welding is a critical process in steel fabrication. Ensure proper joint preparation, select the appropriate welding method (e.g., MIG, TIG, or arc welding), and follow best practices to achieve strong and durable welds.

Tip 5: Consider Post-Fabrication Processes

Additional processes like heat treatment, surface treatments, or painting can enhance the properties and appearance of the fabricated steel product. Explore options that align with the intended application and environmental conditions.

Tip 6: Ensure Quality Control

Implement rigorous quality control measures throughout the fabrication process. This includes regular inspections, testing, and adherence to industry standards to ensure the fabricated product meets specifications and safety requirements.

Tip 7: Partner with Experienced Fabricators

Collaborating with experienced and reputable steel fabricators is essential. They can provide expertise, specialized equipment, and a commitment to quality, ensuring successful project outcomes.

Summary:

By incorporating these tips into your steel fabrication practices, you can optimize processes, enhance product quality, and ensure efficient and effective project execution. Remember to consider the specific requirements and applications of your project when implementing these tips.

Cooper Steel Fabrication

In conclusion, cooper steel fabrication stands as a pivotal process in various industries, transforming raw steel into countless products and structures that shape our world. From towering skyscrapers to intricate automotive components, steel fabrication plays a vital role in our built environment, transportation systems, and energy infrastructure.

As technology continues to advance, we can expect even more innovative and sophisticated applications of cooper steel fabrication. With its exceptional strength, versatility, and durability, steel remains the material of choice for countless engineering challenges. Embracing the latest fabrication techniques and partnering with skilled professionals ensures that the possibilities for cooper steel fabrication are limitless.