Do you require a one-of-a-kind solution to meet your specific needs or requirements? Custom fabrication is the answer!

Editor’s Note: Custom fabrication is a critical topic for those seeking unique and tailored solutions. As experts in this field, we’ve analyzed, researched, and compiled this comprehensive guide to help you make informed decisions.

Through our in-depth analysis, we’ve identified key differences and benefits of custom fabrication, presented in an easy-to-understand table format.

Now, let’s dive into the world of custom fabrication and explore its transformative potential!

Custom Fabrication

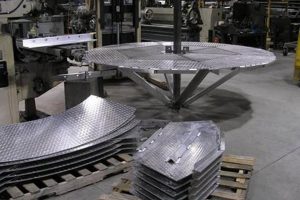

Custom fabrication is the process of creating unique and tailored products or components to meet specific requirements. It involves various aspects that contribute to its effectiveness and value.

- Customization: Products are tailored to exact specifications, ensuring a perfect fit for intended applications.

- Precision: Advanced technologies ensure precise manufacturing, resulting in high-quality and accurate products.

- Flexibility: Custom fabrication allows for quick adjustments and modifications to designs, accommodating changing needs.

- Efficiency: Optimized processes and specialized tools enhance production efficiency, reducing lead times and costs.

- Innovation: Custom fabrication fosters creativity and innovation, enabling the development of groundbreaking products.

- Durability: Products are designed and manufactured to withstand specific conditions, ensuring longevity and reliability.

- Cost-effectiveness: While upfront costs may be higher, custom fabrication often leads to long-term savings through reduced maintenance and increased efficiency.

In essence, custom fabrication empowers businesses and individuals to create solutions that meet their unique challenges and requirements. From prototyping and development to full-scale production, custom fabrication offers a comprehensive approach to product realization.

Customization

Customization lies at the heart of custom fabrication, enabling the creation of products that precisely align with specific requirements. By tailoring products to exact specifications, custom fabrication ensures a perfect fit for intended applications, leading to several key advantages:

- Enhanced performance: Custom-fabricated products can be precisely designed to meet the unique demands of an application, resulting in optimal performance and efficiency.

- Reduced downtime: Products that fit perfectly are less prone to failures and malfunctions, reducing downtime and maintenance costs.

- Improved safety: Custom fabrication allows for the integration of safety features and safeguards that are tailored to specific operating conditions, enhancing workplace safety.

- Increased productivity: Products designed for a specific purpose can streamline workflows and improve productivity, leading to increased output and efficiency.

For instance, in the manufacturing industry, custom-fabricated machinery and equipment can be tailored to the specific production requirements of a facility. This ensures optimal performance, reduces downtime, and enhances overall productivity.

Real-world examples like these underscore the practical significance of customization in custom fabrication. By creating products that are perfectly suited to their intended applications, businesses can gain a competitive edge and achieve their desired outcomes.

Precision

Precision is an indispensable aspect of custom fabrication, made possible by advanced technologies that enable precise manufacturing. This precision contributes significantly to the overall value and effectiveness of custom-fabricated products:

- Dimensional accuracy: Advanced technologies ensure that products are manufactured to exact dimensions, meeting even the most stringent tolerances. This precision is critical for applications where precise fit and alignment are crucial, such as in medical devices and aerospace components.

- Repeatability: Advanced technologies enable consistent and repeatable manufacturing processes, ensuring that each product meets the same high standards of quality and accuracy. This repeatability is essential for mass production of custom-fabricated products, maintaining uniformity and reliability.

- Reduced waste: Precise manufacturing minimizes material waste and reduces the need for rework or scrap. This efficiency translates into cost savings and environmental sustainability.

- Enhanced product performance: Precision manufacturing leads to products that function optimally, with reduced vibration, noise, and wear. This enhanced performance translates into increased productivity, efficiency, and safety.

In the automotive industry, for example, precision custom fabrication is used to manufacture high-performance engine components that meet exacting tolerances. These components contribute to improved engine efficiency, reduced emissions, and enhanced overall vehicle performance.

Precision in custom fabrication goes beyond dimensional accuracy and repeatability. It encompasses the entire manufacturing process, from design and engineering to production and quality control. By leveraging advanced technologies, custom fabricators can deliver high-quality and accurate products that meet the unique demands of their customers.

Flexibility

Flexibility is a key advantage of custom fabrication, enabling the quick adjustment and modification of designs to accommodate changing needs. This flexibility stems from the inherent adaptability of custom fabrication processes, which are not constrained by standardized or mass-produced components.

The importance of flexibility in custom fabrication cannot be overstated. It allows for:

- Rapid prototyping: Custom fabrication facilitates rapid prototyping, enabling designers to quickly create physical models for testing and validation, reducing development time and costs.

- Design iterations: Flexibility allows for iterative design changes, enabling engineers and designers to refine and improve products based on feedback and testing results.

- Changing requirements: Custom fabrication accommodates changing requirements, whether due to evolving specifications or unforeseen circumstances, ensuring that products remain aligned with project objectives.

In the medical device industry, for example, custom fabrication provides the flexibility to modify designs based on patient-specific needs. This enables the creation of personalized medical devices that are tailored to individual anatomies and conditions.

The flexibility of custom fabrication empowers businesses to respond to dynamic market demands and changing customer needs. It enables them to stay competitive and innovative, delivering products that meet the evolving requirements of the modern marketplace.

| Feature | Benefit |

|---|---|

| Rapid prototyping | Reduced development time and costs |

| Design iterations | Improved product quality and performance |

| Changing requirements | Flexibility to adapt to evolving specifications |

Efficiency

Efficiency is a cornerstone of custom fabrication, achieved through optimized processes and specialized tools. This efficiency translates into reduced lead times and costs, offering tangible benefits to businesses and customers alike.

The connection between efficiency and custom fabrication lies in the ability to streamline and optimize production processes. By leveraging specialized tools and implementing efficient methodologies, custom fabricators can reduce production time without compromising quality.

Real-life examples abound in various industries. In the aerospace sector, custom fabrication techniques have enabled the production of complex aircraft components with reduced lead times. This efficiency has contributed to faster aircraft assembly and reduced overall production costs.

The practical significance of efficiency in custom fabrication cannot be overstated. It allows businesses to:

- Meet tight deadlines and deliver products to market faster

- Reduce production costs, leading to increased profitability

- Increase productivity and output, maximizing resource utilization

| Efficiency Factor | Benefit |

|---|---|

| Optimized processes | Reduced production time and costs |

| Specialized tools | Increased productivity and precision |

| Streamlined workflows | Faster delivery and improved customer satisfaction |

In essence, efficiency is the driving force behind the success and adoption of custom fabrication. It empowers businesses to produce high-quality products with reduced lead times and costs, ultimately contributing to increased competitiveness and customer satisfaction.

Innovation

The connection between innovation and custom fabrication is symbiotic. Custom fabrication provides the freedom and flexibility for designers and engineers to push the boundaries of creativity and innovation, resulting in the development of groundbreaking products that would not be possible through standardized manufacturing processes.

Real-life examples showcase the transformative power of custom fabrication in driving innovation. In the automotive industry, custom fabrication has enabled the creation of lightweight and aerodynamic vehicles that prioritize fuel efficiency and performance. In the medical field, custom-fabricated medical devices and implants have improved patient outcomes and revolutionized healthcare practices.

The practical significance of understanding this connection lies in its potential to unlock new possibilities and address complex challenges. By embracing custom fabrication as a catalyst for innovation, businesses can gain a competitive edge, create unique products that meet specific customer needs, and contribute to the advancement of their respective industries.

To further illustrate the connection between innovation and custom fabrication, consider the following table:

| Innovation Factor | Impact on Custom Fabrication |

|---|---|

| Creativity and experimentation | Custom fabrication enables the exploration of unconventional designs and solutions. |

| Rapid prototyping | Custom fabrication facilitates the quick creation of physical prototypes, accelerating the innovation cycle. |

| Collaboration and knowledge sharing | Custom fabrication fosters collaboration among designers, engineers, and manufacturers, leading to cross-pollination of ideas. |

In summary, the connection between innovation and custom fabrication is undeniable. Custom fabrication empowers innovators to break free from the limitations of standardized manufacturing and create truly groundbreaking products that shape the future.

Durability

The connection between durability and custom fabrication is inseparable. Custom fabrication provides the flexibility to design and manufacture products that can withstand specific conditions, ensuring longevity and reliability. Unlike mass-produced products, custom-fabricated products can be tailored to meet the unique demands of specific applications and environments.

Real-life examples abound in various industries. In the construction sector, custom-fabricated steel structures are designed to withstand high winds, seismic activity, and other environmental factors, ensuring the longevity and safety of buildings. Custom-fabricated medical devices, such as implants and prosthetics, are designed to withstand the harsh conditions of the human body, providing reliable performance over extended periods.

The practical significance of understanding the connection between durability and custom fabrication lies in its ability to improve product performance, reduce maintenance costs, and enhance safety. By designing and manufacturing products that can withstand specific conditions, businesses can ensure that their products perform reliably, minimizing downtime and costly repairs.

| Durability Factor | Impact on Custom Fabrication |

|---|---|

| Tailored design | Products are designed to meet specific performance requirements, ensuring optimal durability. |

| Specialized materials | Custom fabrication allows for the use of specialized materials that enhance product durability. |

| Rigorous testing | Custom-fabricated products undergo rigorous testing to ensure they meet durability standards. |

In summary, the connection between durability and custom fabrication is critical for creating products that can withstand the rigors of real-world applications. By embracing custom fabrication, businesses can enhance product longevity, reliability, and overall performance.

Cost-effectiveness

Custom fabrication offers cost-effectiveness despite potentially higher upfront costs. By tailoring products to specific requirements, custom fabrication optimizes performance, reduces maintenance needs, and enhances efficiency.

- Reduced Maintenance Costs: Custom-fabricated products are designed to meet specific operating conditions, minimizing wear and tear. This reduces maintenance frequency and associated costs, leading to long-term savings.

- Increased Efficiency: Custom-fabricated products are optimized for efficiency, reducing energy consumption, production waste, and downtime. Improved efficiency translates into operational cost savings and increased productivity.

- Enhanced Product Life: Custom fabrication considers specific environmental factors and usage patterns, resulting in products with extended lifespans. This reduces replacement costs and improves return on investment.

- Design Optimization: Custom fabrication allows for design optimization to reduce material usage and minimize production costs while maintaining product integrity.

In summary, while upfront costs may be higher, custom fabrication offers significant cost-effectiveness benefits through reduced maintenance, increased efficiency, enhanced product life, and optimized design. These advantages make custom fabrication a valuable investment for businesses seeking long-term savings and operational efficiency.

Frequently Asked Questions about Custom Fabrication

Custom fabrication offers unique solutions for specific needs. To clarify common misconceptions and provide valuable insights, we present this FAQ section.

Question 1: What are the benefits of custom fabrication over mass production?

Answer: Custom fabrication offers tailored solutions, enhanced performance, reduced maintenance costs, increased efficiency, and optimized designs, leading to long-term cost-effectiveness.

Question 2: How does custom fabrication ensure product quality?

Answer: Custom fabrication involves precise manufacturing, rigorous testing, and quality control measures to ensure products meet exact specifications and industry standards.

Question 3: What industries benefit from custom fabrication?

Answer: Custom fabrication finds applications in diverse industries, including automotive, aerospace,, construction, and manufacturing, to name a few.

Question 4: How does custom fabrication contribute to innovation?

Answer: Custom fabrication fosters creativity, enables rapid prototyping, and supports experimentation, leading to groundbreaking product development.

Question 5: What factors affect the cost of custom fabrication?

Answer: Material selection, complexity of design, production volume, and testing requirements influence the cost of custom fabrication projects.

Question 6: How can I find a reputable custom fabrication company?

Answer: Look for companies with experience, expertise, certifications, positive customer reviews, and a commitment to quality.

In summary, custom fabrication offers tailored solutions, ensures product quality, supports innovation, benefits various industries, and requires careful consideration of factors that influence its cost. By understanding these aspects, businesses can harness the advantages of custom fabrication to meet their unique requirements.

Transition to the next article section…

Custom Fabrication Tips for Optimal Results

Custom fabrication offers a world of possibilities to meet specific requirements. By following these expert tips, you can maximize the benefits and achieve optimal outcomes.

Tip 1: Define Clear Specifications

Precisely define your product requirements, including dimensions, materials, performance criteria, and environmental conditions. Clear specifications ensure accurate fabrication and minimize costly errors.

Tip 2: Choose the Right Fabrication Partner

Select a reputable custom fabrication company with proven experience, expertise, and a commitment to quality. Look for certifications, positive customer reviews, and a willingness to collaborate.

Tip 3: Leverage Advanced Technologies

Embrace advanced manufacturing technologies such as CNC machining, 3D printing, and laser cutting to achieve high precision, repeatability, and cost-effectiveness.

Tip 4: Optimize Design for Production

Consider manufacturability during the design phase. Design for efficient material utilization, ease of assembly, and reduced production time to minimize costs and improve lead times.

Tip 5: Test and Validate Thoroughly

Conduct rigorous testing and validation to ensure product performance meets specifications. This includes functional testing, environmental testing, and quality control inspections.

Tip 6: Consider Long-Term Costs

While upfront costs may be higher than mass-produced products, consider the long-term savings from reduced maintenance, increased efficiency, and extended product life.

Tip 7: Foster Collaboration and Communication

Maintain open communication with the fabrication partner throughout the project. Share design updates, provide feedback, and address any challenges promptly to ensure alignment and timely delivery.

By implementing these tips, you can harness the full potential of custom fabrication. From precise specifications to rigorous testing and long-term cost considerations, these insights will guide you towards successful custom fabrication projects.

Conclusion

Custom fabrication has emerged as a transformative force in various industries, empowering businesses and individuals to create tailored solutions that meet their unique requirements. Throughout this exploration, we have highlighted the key aspects of custom fabrication, including its emphasis on customization, precision, flexibility, efficiency, innovation, durability, and cost-effectiveness.

Custom fabrication is not merely a manufacturing process; it is a mindset that embraces creativity, adaptability, and a relentless pursuit of excellence. By embracing custom fabrication, businesses can differentiate themselves in the marketplace, respond swiftly to changing demands, and drive innovation. It is a strategic investment that pays dividends in the form of enhanced performance, reduced costs, and increased customer satisfaction.