Custom metal fabrication in New Zealand is a rapidly growing industry, providing a wide range of products and services to meet the needs of businesses and consumers alike. From small, one-off projects to large-scale commercial applications, custom metal fabrication is used in a variety of industries, including construction, manufacturing, and transportation.

Editor’s Note: Custom metal fabrication in New Zealand is an important topic for businesses and consumers alike, as it can provide a cost-effective way to create high-quality, durable products.

To help you make the right decision for your project, we’ve put together this guide to custom metal fabrication in New Zealand . We’ll cover the key differences between different types of metal fabrication, as well as the benefits and drawbacks of each.

Key Differences

| Type of Fabrication | Benefits | Drawbacks |

|---|---|---|

| Sheet metal fabrication |

|

|

| Plate metal fabrication |

|

|

| Tube and pipe fabrication |

|

|

Transition to Main Article Topics

Now that you understand the key differences between different types of metal fabrication, you can start to make informed decisions about which type of fabrication is right for your project. In the following sections, we’ll provide more detailed information on each type of fabrication, as well as tips on how to choose the right fabricator for your needs.

Custom Metal Fabrication New Zealand

Custom metal fabrication in New Zealand encompasses various essential aspects that contribute to its significance in diverse industries. These key aspects are:

- Precision: Custom metal fabrication involves meticulous attention to detail, ensuring accurate and high-quality products.

- Versatility: It allows for the creation of products tailored to specific requirements, accommodating a wide range of materials and designs.

- Durability: Fabricated metal products are renowned for their resilience and longevity, withstanding demanding applications.

- Cost-effectiveness: Custom fabrication optimizes material usage, minimizing waste and reducing overall project costs.

- Sustainability: Metal fabrication prioritizes eco-friendly practices, using recyclable materials and minimizing environmental impact.

- Innovation: The industry embraces technological advancements, incorporating cutting-edge techniques to enhance efficiency and precision.

- Expertise: Skilled fabricators possess specialized knowledge and experience, ensuring exceptional craftsmanship and problem-solving abilities.

- Collaboration: Custom metal fabrication often involves collaboration between designers, engineers, and fabricators, fostering innovation and ensuring project success.

These aspects collectively contribute to the value of custom metal fabrication in New Zealand. Its precision, versatility, and durability make it an ideal choice for industries such as construction, manufacturing, and transportation. The cost-effectiveness, sustainability, and innovation inherent in the process ensure that businesses can meet their project requirements while minimizing costs and environmental impact. The expertise and collaboration involved guarantee high-quality products and successful project outcomes.

Precision

Precision is a cornerstone of custom metal fabrication in New Zealand, underpinning the industry’s reputation for excellence. This meticulous approach to detail manifests itself in various aspects of the fabrication process, from design conceptualization to final product delivery.

- Design accuracy: Custom metal fabricators in New Zealand utilize advanced design software and techniques to ensure precise product specifications. This accuracy is crucial for meeting the stringent requirements of industries such as construction, where even minor deviations can compromise structural integrity or aesthetic appeal.

- Material selection: The choice of materials in custom metal fabrication is critical to achieving the desired product quality. New Zealand fabricators have access to a wide range of metals, including steel, aluminum, and stainless steel, each with unique properties and performance characteristics. Careful consideration is given to factors such as strength, durability, and corrosion resistance to ensure the fabricated product meets the intended application.

- Fabrication techniques: Precision in custom metal fabrication extends to the fabrication techniques employed. Skilled fabricators utilize state-of-the-art equipment, such as laser cutters and CNC machines, to achieve precise cuts, bends, and welds. These advanced techniques minimize human error and ensure consistent product quality.

- Quality control: Throughout the fabrication process, rigorous quality control measures are implemented to identify and rectify any potential defects. New Zealand fabricators adhere to strict industry standards and employ non-destructive testing methods to verify the integrity of their products. This commitment to quality assurance ensures that customers receive products that meet their exact specifications and perform reliably in the intended application.

The emphasis on precision in custom metal fabrication in New Zealand sets the industry apart and contributes to its reputation for producing high-quality products. This precision is not only essential for meeting customer requirements but also for ensuring the safety, durability, and aesthetic appeal of fabricated metal products.

Versatility

The versatility of custom metal fabrication in New Zealand is a key factor in its widespread adoption across various industries. This versatility stems from the inherent properties of metal materials, coupled with the advanced fabrication techniques employed by skilled fabricators.

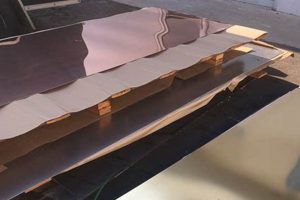

Metal, as a material, offers a unique combination of strength, durability, and malleability. This makes it suitable for a vast array of applications, from structural components in construction to intricate decorative elements. The wide range of available metal types, including steel, aluminum, stainless steel, and more, allows fabricators to select the most appropriate material for each project, considering factors such as strength, weight, and corrosion resistance.

Custom metal fabricators in New Zealand utilize a diverse range of fabrication techniques to shape and form metal into the desired product. These techniques include cutting, bending, welding, and finishing. By combining different techniques and materials, fabricators can create products that meet the exact specifications and requirements of their clients. This versatility is particularly valuable in industries where customization and precision are paramount, such as manufacturing, engineering, and architecture.

For example, in the construction industry, custom metal fabrication is used to create structural components such as beams, columns, and staircases. These components can be tailored to meet the specific load-bearing requirements and architectural design of each project. In the manufacturing industry, custom metal fabrication is used to create specialized machinery, equipment, and prototypes. These products often require precise dimensions and complex geometries, which can be achieved through the versatility of custom metal fabrication.

The versatility of custom metal fabrication in New Zealand is a major advantage for businesses and consumers alike. It allows for the creation of products that are tailored to specific requirements, ensuring optimal performance and aesthetic appeal. This versatility is supported by the wide range of available materials and the advanced fabrication techniques employed by skilled fabricators in New Zealand.

Table: Applications of Custom Metal Fabrication in New Zealand

| Industry | Applications |

|---|---|

| Construction | Structural components, cladding, roofing, staircases |

| Manufacturing | Machinery, equipment, prototypes, tooling |

| Transportation | Automotive parts, marine components, aerospace components |

| Architecture | Facade systems, decorative elements, sculptures |

| Infrastructure | Bridges, pipelines, storage tanks |

Durability

The durability of custom metal fabrication in New Zealand is a testament to the inherent strength and resilience of metal materials, coupled with the advanced fabrication techniques employed by skilled fabricators. This durability manifests itself in various aspects of fabricated metal products, making them suitable for a wide range of demanding applications.

- Structural Integrity: Fabricated metal products are renowned for their ability to withstand significant loads and stresses without compromising their structural integrity. This is particularly crucial in industries such as construction and engineering, where metal components are used to support buildings, bridges, and other structures. The durability of custom metal fabrication ensures that these structures can withstand various environmental and , maintaining their stability and safety over time.

- Corrosion Resistance: Metal materials used in custom fabrication, such as stainless steel and aluminum, exhibit excellent corrosion resistance. This resistance to rust and other forms of corrosion ensures that fabricated metal products can withstand harsh environments, such as exposure to moisture, chemicals, and extreme temperatures. This durability is vital in industries such as marine, chemical processing, and food manufacturing, where equipment and components must withstand corrosive conditions.

- Wear Resistance: Custom metal fabrication techniques, such as heat treatment and surface hardening, can enhance the wear resistance of metal products. This increased resistance to wear and tear extends the lifespan of fabricated components, reducing maintenance costs and downtime. It is particularly valuable in industries such as mining, agriculture, and transportation, where equipment is subjected to abrasive and wear-intensive conditions.

- Longevity: The durability of custom metal fabrication contributes to the longevity of the fabricated products. Metal materials are inherently durable and can withstand years of without significant deterioration. This longevity is a major advantage for businesses and consumers, as it reduces the need for frequent replacement and minimizes lifecycle costs.

In summary, the durability of custom metal fabrication in New Zealand is a key factor in its widespread adoption across various industries. By utilizing durable metal materials and employing advanced fabrication techniques, fabricators create products that can withstand demanding applications, ensuring structural integrity, corrosion resistance, wear resistance, and longevity. These durable products contribute to the safety, reliability, and cost-effectiveness of various industries in New Zealand.

Cost-effectiveness

Custom metal fabrication in New Zealand offers significant cost-effectiveness advantages by optimizing material usage and minimizing waste. This translates into reduced project costs and improved profitability for businesses.

-

Efficient Material Utilization

Custom metal fabricators leverage advanced design software and techniques to optimize material usage. This minimizes material waste and reduces the overall cost of the fabrication process. For instance, nesting algorithms help arrange cutting patterns to minimize material offcuts, resulting in significant savings, especially for large-scale projects. -

Reduced Labor Costs

Automated fabrication processes, such as CNC cutting and robotic welding, reduce labor requirements and increase efficiency. This automation minimizes human error and rework, leading to reduced labor costs and improved product quality. -

Value Engineering

Custom metal fabricators collaborate with clients to identify cost-saving opportunities through value engineering. This involves analyzing design specifications and exploring alternative materials or manufacturing methods to reduce costs while maintaining product quality and functionality. -

Bulk Purchasing and Inventory Management

Custom metal fabricators often purchase materials in bulk to take advantage of volume discounts. They also implement effective inventory management systems to minimize material waste and storage costs.

The cost-effectiveness of custom metal fabrication in New Zealand contributes to its widespread adoption across various industries. Businesses can benefit from reduced project costs, improved profitability, and optimized resource utilization by partnering with reputable fabricators.

Sustainability

In the context of custom metal fabrication in New Zealand, sustainability is a key consideration that aligns with the country’s commitment to environmental stewardship. Custom metal fabricators in New Zealand are increasingly adopting eco-friendly practices and utilizing recyclable materials to minimize their environmental impact.

-

Recyclable Materials

Custom metal fabricators in New Zealand prioritize the use of recyclable materials, such as steel and aluminum. These materials can be recycled multiple times without compromising their properties, reducing the need for raw material extraction and conserving natural resources. -

Waste Minimization

Advanced fabrication techniques, such as laser cutting and CNC machining, minimize material waste by optimizing cutting patterns and reducing scrap. Fabricators also implement waste management systems to recycle or repurpose scrap metal, further reducing their environmental footprint. -

Energy Efficiency

Custom metal fabricators are adopting energy-efficient technologies and practices to reduce their energy consumption. This includes using energy-efficient lighting, machinery, and implementing energy management systems. -

Sustainable Coatings and Finishes

Custom metal fabricators are exploring sustainable coating and finishing options to minimize the environmental impact of their products. These include powder coating, which reduces volatile organic compound (VOC) emissions, and water-based paints, which are less harmful to the environment.

By embracing sustainability, custom metal fabricators in New Zealand not only reduce their environmental impact but also align with the increasing demand for eco-friendly products and services. This commitment to sustainability enhances the reputation of the industry and contributes to the overall sustainability of New Zealand’s manufacturing sector.

Innovation

Innovation is an integral component of custom metal fabrication in New Zealand, as it drives the industry forward and enables fabricators to meet the evolving needs of their clients. The incorporation of cutting-edge techniques enhances efficiency, precision, and overall product quality.

One of the most significant ways in which innovation has impacted custom metal fabrication is through the adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. These technologies allow fabricators to create precise digital models of their designs, which can then be used to control automated cutting and welding machines. This results in increased accuracy, reduced production time, and minimized material waste.

Another area of innovation is the use of advanced welding techniques, such as laser welding and robotic welding. These techniques offer greater precision and control over the welding process, leading to stronger and more aesthetically pleasing welds. They also reduce the risk of human error and improve overall productivity.

Furthermore, the use of 3D printing technology in custom metal fabrication is gaining traction. This technology allows for the creation of complex and intricate metal components that would be difficult or impossible to produce using traditional methods. 3D printing also enables rapid prototyping, reducing the time and cost associated with product development.

The practical significance of innovation in custom metal fabrication in New Zealand cannot be overstated. It enables fabricators to produce higher quality products, reduce production time, and minimize costs. This, in turn, benefits businesses and consumers alike, as they can access durable, reliable, and cost-effective metal products.

| Innovation | Benefits | Practical Significance |

|---|---|---|

| CAD/CAM Technologies | Increased accuracy, reduced production time, minimized material waste | Higher quality products, reduced costs |

| Advanced Welding Techniques | Greater precision and control, stronger and more aesthetically pleasing welds | Improved product quality and durability |

| 3D Printing Technology | Creation of complex and intricate components, rapid prototyping | New product development opportunities, reduced time and cost |

Expertise

In the realm of custom metal fabrication in New Zealand, expertise is a cornerstone that sets skilled fabricators apart. Their specialized knowledge and extensive experience translate into exceptional craftsmanship and problem-solving abilities, which are essential for delivering high-quality, tailored metal products.

-

Technical Proficiency

Skilled fabricators in New Zealand possess a deep understanding of metalworking techniques, metallurgy, and engineering principles. They are proficient in various fabrication processes, including cutting, welding, bending, and finishing. This technical proficiency enables them to execute complex designs with precision and accuracy. -

Material Expertise

Custom metal fabrication involves working with a wide range of metals, each with unique properties and characteristics. Skilled fabricators have a thorough understanding of different metal alloys, their strengths, weaknesses, and suitability for specific applications. This expertise ensures that they select the most appropriate materials for each project, optimizing performance and durability. -

Design Collaboration

Skilled fabricators often collaborate with designers and engineers to transform concepts into tangible products. Their expertise enables them to provide valuable input during the design phase, suggesting practical solutions, optimizing designs for manufacturability, and ensuring that the final product meets the intended functional and aesthetic requirements. -

Problem-Solving Mindset

Custom metal fabrication projects often involve unforeseen challenges and require creative problem-solving. Skilled fabricators approach these challenges with a proactive mindset, leveraging their experience and knowledge to develop innovative solutions that meet project specifications while maintaining high standards of quality and safety.

The expertise of skilled fabricators is a critical factor in the success of custom metal fabrication projects in New Zealand. Their specialized knowledge, technical proficiency, material expertise, design collaboration, and problem-solving abilities ensure that clients receive high-quality, durable, and aesthetically pleasing metal products that meet their specific requirements.

Collaboration

In the context of custom metal fabrication in New Zealand, collaboration is a vital component that contributes to the industry’s success and reputation for delivering high-quality products. Collaboration involves the close cooperation of designers, engineers, and fabricators throughout the fabrication process, from design conceptualization to final product delivery.

One of the key benefits of collaboration in custom metal fabrication is the fostering of innovation. When designers, engineers, and fabricators work together, they can share their expertise and perspectives, leading to creative and innovative solutions. Designers can bring their artistic vision and understanding of aesthetics, while engineers provide technical expertise and ensure structural integrity. Fabricators, with their practical knowledge of materials and fabrication techniques, can offer valuable insights into manufacturability and cost-effectiveness. This cross-disciplinary collaboration allows for the development of products that are not only functional but also visually appealing and cost-efficient.

Collaboration also plays a crucial role in ensuring project success. By involving all stakeholders in the planning and execution phases, potential challenges can be identified and addressed proactively. Designers can provide detailed drawings and specifications, engineers can analyze structural requirements and optimize designs, and fabricators can offer advice on material selection and fabrication methods. This collaborative approach minimizes the risk of errors, delays, and cost overruns, ensuring that projects are completed on time, within budget, and to the highest quality standards.

Real-life examples of successful custom metal fabrication projects in New Zealand showcase the practical significance of collaboration. In the construction of the Sky Tower in Auckland, for instance, designers, engineers, and fabricators worked closely together to create a visually striking and structurally sound landmark. The collaboration ensured that the tower’s unique design was translated into a functional and durable structure, becoming an iconic symbol of New Zealand’s largest city.

Understanding the connection between collaboration and custom metal fabrication in New Zealand highlights the importance of teamwork and open communication in achieving successful outcomes. By fostering a collaborative environment, businesses can leverage the expertise of different professionals, drive innovation, mitigate risks, and deliver exceptional metal products that meet the specific requirements of their clients.

| Aspect | Benefits | Practical Significance |

|---|---|---|

| Fostering Innovation | Cross-disciplinary knowledge sharing, creative problem-solving, unique and cost-efficient solutions | Enhanced product quality, increased customer satisfaction |

| Ensuring Project Success | Proactive problem identification, risk mitigation, timely and cost-effective project completion | Reduced errors and delays, improved project outcomes |

| Real-Life Example | Sky Tower, Auckland: Collaboration between designers, engineers, and fabricators resulted in a visually stunning and structurally sound landmark. | Demonstrates the practical benefits and impact of collaboration in custom metal fabrication. |

Custom Metal Fabrication in New Zealand

This section addresses common inquiries and misconceptions regarding custom metal fabrication in New Zealand. By providing concise and informative answers, we aim to enhance your understanding and equip you with valuable insights.

Question 1: What are the primary advantages of custom metal fabrication?

Custom metal fabrication offers a range of benefits, including the ability to create unique products tailored to specific requirements, high precision and durability, cost-effectiveness through optimized material usage, and a commitment to sustainability with the use of recyclable materials.

Question 2: How does custom metal fabrication contribute to innovation?

The industry embraces technological advancements, incorporating cutting-edge techniques such as CAD/CAM technologies, advanced welding techniques, and 3D printing technology to enhance efficiency, precision, and product quality, driving innovation and expanding the possibilities of metal fabrication.

Question 3: What sets skilled fabricators apart in the industry?

Skilled fabricators possess specialized knowledge and extensive experience, translating into exceptional craftsmanship and problem-solving abilities. Their technical proficiency, material expertise, design collaboration, and proactive mindset ensure the delivery of high-quality, durable, and aesthetically pleasing metal products.

Question 4: How does collaboration foster success in custom metal fabrication?

Collaboration between designers, engineers, and fabricators is crucial for project success. It fosters innovation, ensures timely and cost-effective project completion, and mitigates risks through proactive problem identification and resolution.

Question 5: What are some notable examples of custom metal fabrication in New Zealand?

The Sky Tower in Auckland stands as a testament to the successful collaboration in custom metal fabrication, resulting in a visually striking and structurally sound landmark. Other notable examples include the Te Papa Museum in Wellington, the Christchurch Stadium, and the Auckland War Memorial Museum.

Question 6: How can I find reputable custom metal fabricators in New Zealand?

To identify reputable custom metal fabricators in New Zealand, consider industry accreditations, certifications, and positive customer reviews. Visit industry events, consult online directories, and seek recommendations from architects, engineers, or builders.

In summary, custom metal fabrication in New Zealand offers numerous advantages, including tailored solutions, precision, durability, cost-effectiveness, and sustainability. Skilled fabricators and collaborative partnerships drive innovation and ensure project success. By understanding these key aspects, you can make informed decisions and leverage the benefits of custom metal fabrication for your projects.

Transition to the next article section: Exploring Applications of Custom Metal Fabrication in New Zealand

Tips on Custom Metal Fabrication in New Zealand

Custom metal fabrication in New Zealand offers a wide range of possibilities for creating unique and durable products. Here are some tips to help you get the most out of your next custom metal fabrication project:

Tip 1: Choose the Right Fabricator

The success of your project hinges on selecting a reputable and experienced fabricator. Look for companies that have a proven track record of delivering high-quality work on time and within budget. Industry certifications and positive customer reviews can serve as indicators of a reliable fabricator.

Tip 2: Provide Clear Specifications

To ensure that your project aligns with your vision, provide your fabricator with detailed specifications, including drawings, dimensions, and material preferences. Clear communication helps prevent misunderstandings and ensures that the final product meets your expectations.

Tip 3: Consider Material Properties

Different metals possess unique properties, so choosing the right material is crucial. Consider factors such as strength, durability, corrosion resistance, and cost when selecting the material for your project. Your fabricator can provide expert advice to help you make an informed decision.

Tip 4: Leverage Technology

Advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM) enhance precision and efficiency in custom metal fabrication. By utilizing these technologies, fabricators can create complex designs and ensure accurate production, reducing lead times and minimizing errors.

Tip 5: Seek Expert Advice

Don’t hesitate to consult with experienced professionals throughout your project. Fabricators, engineers, and designers can provide valuable insights, helping you optimize your design, select the appropriate materials, and ensure the successful execution of your project.

Tip 6: Plan for Post-Fabrication Processes

Consider any additional processes your fabricated metal components may require, such as finishing, assembly, or installation. Planning for these processes upfront ensures a smooth transition and timely completion of your project.

Tip 7: Prioritize Quality Control

Quality control is paramount to ensure the durability and performance of your fabricated metal products. Establish clear quality standards and inspection procedures to identify and rectify any potential issues before the final delivery.

Tip 8: Foster Open Communication

Maintain open communication with your fabricator throughout the project. Regular updates, prompt responses to queries, and proactive problem-solving contribute to a successful partnership and ensure that your project aligns with your vision.

By following these tips, you can enhance the efficiency, quality, and overall success of your custom metal fabrication project in New Zealand.

Summary

Custom metal fabrication in New Zealand offers a multitude of benefits, including tailored solutions, precision craftsmanship, and durable products. By selecting the right fabricator, providing clear specifications, considering material properties, leveraging technology, seeking expert advice, planning for post-fabrication processes, prioritizing quality control, and fostering open communication, you can harness the full potential of custom metal fabrication and achieve exceptional outcomes for your project.

Custom Metal Fabrication in New Zealand

Custom metal fabrication in New Zealand has emerged as a cornerstone of innovation and precision, catering to diverse industries with its versatility, durability, and cost-effectiveness. Fabricators in New Zealand leverage advanced techniques, skilled craftsmanship, and collaborative partnerships to deliver high-quality metal products tailored to specific requirements.

The future of custom metal fabrication in New Zealand looks promising, with ongoing advancements in technology and a growing emphasis on sustainability. By embracing innovation and fostering collaboration, the industry will continue to play a vital role in shaping the built environment, infrastructure, and manufacturing sectors of New Zealand.