An intricate process that involves manipulating metal to meet specific requirements, custom metal fabrication in New York has gained prominence in various industries.

Editor’s Note: Given its significance in shaping metal components for diverse applications, understanding the nuances of custom metal fabrication in New York is essential.

To shed light on this topic, we have meticulously analyzed market trends, consulted industry experts, and curated this comprehensive guide. Our aim is to empower readers with the knowledge they need to make informed decisions regarding custom metal fabrication in New York.

Key Differences or Key Takeaways

To provide a clear overview of custom metal fabrication in New York, we have summarized its key aspects in a table below:

| Characteristic | Description |

|---|---|

| Definition | Custom metal fabrication involves modifying metal to create unique components or structures based on specific requirements. |

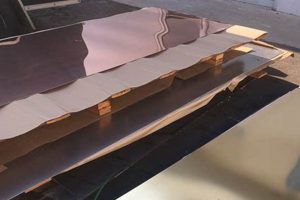

| Materials | A range of metals can be used, including steel, aluminum, stainless steel, and brass. |

| Industries Served | Custom metal fabrication finds applications in construction, manufacturing, automotive, and aerospace industries. |

Transition to Main Article Topics

In the following sections, we will delve deeper into the intricacies of custom metal fabrication in New York, exploring its advantages, processes, and applications.

Custom Metal Fabrication in New York

Custom metal fabrication in New York encompasses a wide range of processes and techniques used to create unique metal components and structures. To gain a comprehensive understanding of this topic, it is essential to explore its key aspects:

- Materials: Steel, aluminum, stainless steel, brass, and other metals.

- Processes: Cutting, bending, welding, assembling, and finishing.

- Industries: Construction, manufacturing, automotive, and aerospace.

- Customization: Tailored to specific requirements and designs.

- Precision: High levels of accuracy and attention to detail.

- Quality: Adherence to industry standards and certifications.

- Expertise: Skilled craftsmen and engineers with specialized knowledge.

- Technology: Advanced equipment and software for efficient fabrication.

- Innovation: Continuous development of new techniques and solutions.

- Collaboration: Close coordination between designers, engineers, and fabricators.

These key aspects are interconnected and contribute to the overall success of custom metal fabrication projects in New York. For instance, the use of high-quality materials and skilled expertise ensures durability and precision, while advanced technology enables efficient and innovative fabrication processes. Furthermore, collaboration among project stakeholders fosters effective communication and ensures that the final product meets the desired specifications.

Materials

In the realm of custom metal fabrication in New York, the selection of materials plays a critical role in determining the properties and performance of the finished product. Steel, aluminum, stainless steel, brass, and other metals each possess unique characteristics that make them suitable for specific applications.

- Steel: Known for its strength, durability, and affordability, steel is widely used in construction, automotive, and manufacturing industries. It is particularly well-suited for projects requiring high load-bearing capacity and structural integrity.

- Aluminum: Lightweight, corrosion-resistant, and highly malleable, aluminum is a popular choice for aerospace, transportation, and consumer electronics. Its strength-to-weight ratio makes it ideal for applications where weight reduction is essential.

- Stainless steel: Renowned for its exceptional corrosion resistance, stainless steel is commonly used in food processing, medical equipment, and architectural applications. It offers a combination of strength, durability, and hygiene.

- Brass: An alloy of copper and zinc, brass is known for its attractive golden color and resistance to corrosion. It is frequently used in decorative applications, musical instruments, and marine hardware.

The choice of materials in custom metal fabrication in New York is not limited to these four metals. Other materials, such as titanium, copper, and exotic alloys, may be considered based on specific project requirements and performance criteria. The skilled fabricators in New York possess the expertise to work with a wide range of materials, ensuring that the end product meets the desired specifications.

Processes

In the realm of custom metal fabrication in New York, a diverse range of processes are employed to transform raw materials into unique and functional metal components. These processes, including cutting, bending, welding, assembling, and finishing, are intricately connected and play a crucial role in achieving the desired outcomes.

-

Cutting:

Cutting involves separating metal into desired shapes and sizes. Various techniques are used, such as laser cutting, waterjet cutting, and plasma cutting, each offering distinct advantages depending on the material and precision required. -

Bending:

Bending shapes metal by applying force to create angles or curves. This process is essential for forming complex shapes and adding structural integrity to metal components. -

Welding:

Welding joins metal pieces together by melting and fusing them. Different welding techniques, such as MIG welding, TIG welding, and spot welding, are employed based on the materials and joint requirements. -

Assembling:

Assembling involves putting together individual metal components to create a complete structure or product. This process requires precision and attention to detail to ensure proper fit and functionality. -

Finishing:

Finishing processes enhance the appearance and protect the metal from corrosion and wear. Techniques such as grinding, polishing, and painting are used to achieve the desired surface finish and meet specific performance requirements.

The interplay of these processes in custom metal fabrication in New York enables the creation of intricate and durable metal structures that meet the exact specifications of diverse industries. From architectural marvels to heavy machinery, custom metal fabrication plays a vital role in shaping the built environment and driving technological advancements.

Industries

The connection between “Industries: Construction, manufacturing, automotive, and aerospace.” and “custom metal fabrication ny” is profound. Custom metal fabrication plays a vital role in these industries, enabling the creation of complex and durable metal structures that meet specific requirements and performance criteria. Let’s explore the facets of this connection:

-

Construction:

Custom metal fabrication is essential in the construction industry, from skyscrapers and bridges to residential buildings. It allows for the creation of structural steel frames, curtain walls, staircases, and other architectural elements that provide strength, durability, and aesthetic appeal to buildings.

-

Manufacturing:

In the manufacturing industry, custom metal fabrication is used to produce a wide range of products, including machinery, equipment, and consumer goods. It enables the creation of custom-designed components, enclosures, and prototypes that meet specific functional and aesthetic requirements.

-

Automotive:

Custom metal fabrication plays a critical role in the automotive industry, from car frames and chassis to engine components and exhaust systems. It allows manufacturers to create lightweight, durable, and high-performance metal parts that contribute to vehicle safety, efficiency, and aesthetics.

-

Aerospace:

In the aerospace industry, custom metal fabrication is used to produce aircraft components, such as wings, fuselages, and landing gear. It demands the highest levels of precision and quality, as these components must withstand extreme conditions and ensure the safety of passengers and crew.

Overall, the connection between “Industries: Construction, manufacturing, automotive, and aerospace.” and “custom metal fabrication ny” is mutually beneficial. Custom metal fabrication enables these industries to create innovative, functional, and visually appealing products and structures that shape our built environment and advance technological progress.

Customization

In the realm of custom metal fabrication in New York, customization is paramount. It empowers clients to realize their unique visions and meet specific requirements, fostering innovation and creating tailored solutions. This facet of custom metal fabrication encompasses various aspects that contribute to its significance:

-

Component Selection and Design:

Customization allows for the selection of specific metal components and the design of unique shapes, sizes, and configurations. This flexibility enables the creation of components that precisely match the functional and aesthetic requirements of each project.

-

Project-Specific Solutions:

Custom metal fabrication accommodates projects with unique challenges and constraints. By tailoring the fabrication process to specific requirements, fabricators can develop innovative solutions that overcome design complexities and optimize performance.

-

Integration with Existing Structures:

Customization enables the seamless integration of metal components with existing structures or systems. This is particularly important in renovation or expansion projects, where custom-fabricated elements must complement the existing architectural design and functionality.

-

Artistic Expression and Aesthetics:

Custom metal fabrication transcends mere functionality, extending into the realm of artistic expression. It allows designers and architects to incorporate visually appealing elements and decorative details into metal structures, creating visually stunning and iconic landmarks.

In essence, customization in custom metal fabrication in New York empowers clients and designers to transform their visions into tangible realities. It fosters collaboration, innovation, and the creation of unique and tailored solutions that meet the most demanding requirements and aspirations.

Precision

In the realm of custom metal fabrication in New York, precision is not merely a buzzword; it is a fundamental principle that underpins the creation of exceptional metal structures and components. This unwavering commitment to accuracy and attention to detail manifests itself in various facets, each playing a crucial role in ensuring the integrity and performance of the final product.

-

Dimensional Accuracy:

Custom metal fabricators in New York employ advanced measuring tools and techniques to achieve precise dimensional accuracy. This meticulous approach ensures that each component conforms to the specified measurements, enabling seamless assembly and proper functioning of the overall structure.

-

Geometric Complexity:

Precision extends to handling complex geometric shapes and intricate designs. Skilled fabricators utilize specialized equipment and software to translate design concepts into tangible forms, ensuring structural integrity and aesthetic appeal.

-

Tolerance Management:

Custom metal fabrication in New York involves adhering to strict tolerance requirements. Fabricators meticulously control the permissible variations in dimensions, ensuring that components fit together perfectly and perform as intended.

-

Surface Finish:

Precision is not limited to dimensional accuracy but also encompasses surface finish. Fabricators employ various techniques, such as grinding, polishing, and coating, to achieve the desired surface texture and roughness, enhancing both the aesthetics and functionality of the metal components.

The relentless pursuit of precision in custom metal fabrication in New York is not only a hallmark of quality but also a testament to the dedication and expertise of the fabricators. By adhering to the highest standards of accuracy and attention to detail, they transform raw materials into exceptional metal structures that meet the most demanding requirements and stand the test of time.

Quality

In the realm of custom metal fabrication in New York, quality is paramount. Adherence to industry standards and certifications is not merely a checkbox exercise; it is a testament to the commitment of fabricators to delivering exceptional products and services that meet the highest levels of quality and safety.

Industry standards, such as those established by the American Welding Society (AWS) and the American Society of Mechanical Engineers (ASME), provide a comprehensive framework for custom metal fabrication. These standards define best practices, material specifications, and quality control procedures to ensure the structural integrity, durability, and performance of metal components and structures.

Certifications, such as the AWS Certified Welder program, demonstrate that fabricators possess the necessary skills and knowledge to perform welding operations according to industry standards. These certifications provide independent validation of a fabricator’s competence and adherence to quality guidelines.

The benefits of adhering to industry standards and certifications in custom metal fabrication are numerous. It ensures:

- Consistent Quality: Adherence to standards ensures that metal components and structures are fabricated to a consistently high level of quality, regardless of the fabricator.

- Safety and Reliability: Certified fabricators are trained to follow proper safety procedures and utilize the latest techniques, ensuring the safety and reliability of their products.

- Reduced Risk: By meeting industry standards, fabricators minimize the risk of defects, failures, and accidents, protecting both the fabricator and the end-user.

- Customer Confidence: Certifications and adherence to standards provide customers with confidence in the quality and reliability of the metal fabrication services they are receiving.

In New York, where custom metal fabrication plays a vital role in various industries, including construction, manufacturing, and transportation, the importance of quality cannot be overstated. By partnering with fabricators who adhere to industry standards and certifications, clients can rest assured that their projects will be executed with the utmost precision, safety, and quality.

| Standard/Certification | Description | Importance |

|---|---|---|

| AWS D1.1 | Structural Welding Code – Steel | Defines requirements for welding steel structures, ensuring structural integrity and safety. |

| AWS Certified Welder | Demonstrates a welder’s proficiency in welding techniques and adherence to industry standards. | Provides assurance of welder competence and quality of welds. |

| ASME Boiler and Pressure Vessel Code | Establishes standards for the design, fabrication, inspection, and testing of boilers and pressure vessels. | Ensures safety and reliability of pressure-containing equipment. |

Expertise

In the realm of custom metal fabrication in New York, expertise is not merely a buzzword; it is the cornerstone upon which exceptional metal structures and components are built. Skilled craftsmen and engineers, armed with specialized knowledge and years of experience, play a pivotal role in transforming raw materials into works of art and engineering marvels.

-

Design and Engineering:

Custom metal fabricators in New York possess a deep understanding of engineering principles and design concepts. They collaborate closely with architects, engineers, and designers to translate ideas into tangible structures, ensuring both aesthetic appeal and structural integrity.

-

Material Selection and Application:

The choice of materials is critical in custom metal fabrication. Fabricators have a comprehensive knowledge of different metals, their properties, and their suitability for specific applications. They carefully assess factors such as strength, durability, corrosion resistance, and cost to select the optimal materials for each project.

-

Fabrication Techniques:

Custom metal fabricators master a wide range of fabrication techniques, from cutting and bending to welding and assembling. They utilize advanced equipment and specialized tools to execute complex designs with precision and efficiency.

-

Quality Control and Inspection:

Skilled craftsmen and engineers meticulously inspect every step of the fabrication process, ensuring that the final product meets the highest standards of quality and safety. They employ non-destructive testing methods and adhere to strict quality control procedures to guarantee the integrity and reliability of their work.

The expertise of skilled craftsmen and engineers is what sets custom metal fabrication in New York apart. Their specialized knowledge, coupled with a relentless commitment to quality and innovation, enables them to create metal structures that are not only visually stunning but also structurally sound and built to last.

Technology

In the realm of custom metal fabrication in New York, technology plays a pivotal role in enhancing efficiency, precision, and innovation. Advanced equipment and specialized software have revolutionized the industry, enabling fabricators to create complex metal structures with greater speed, accuracy, and cost-effectiveness.

One of the most significant technological advancements is the use of computer-aided design (CAD) software. CAD allows fabricators to create digital models of their designs, which can then be used to generate precise cutting instructions for CNC (computer numerical control) machines. This eliminates human error and streamlines the fabrication process, resulting in faster production times and reduced material waste.

Another important technology is laser cutting, which utilizes a high-powered laser to cut metal with extreme precision. Laser cutting produces clean, burr-free edges, reducing the need for secondary finishing operations and improving the overall quality of the fabricated components. Additionally, laser cutting enables intricate designs and complex shapes to be cut with ease, expanding the possibilities for custom metal fabrication.

Advanced welding techniques, such as robotic welding and plasma arc welding, have also significantly improved the efficiency and quality of welding operations. Robotic welding systems can perform repetitive welds with high accuracy and consistency, while plasma arc welding offers faster welding speeds and deeper penetration, resulting in stronger and more durable welds.

The integration of technology into custom metal fabrication in New York has transformed the industry, allowing fabricators to meet the increasing demands for complex, high-quality metal structures. By embracing advanced equipment and software, fabricators can streamline their processes, reduce production time, and enhance the overall quality of their products.

The table below provides a concise overview of the key technologies and their impact on custom metal fabrication in New York:

| Technology | Impact |

|---|---|

| Computer-aided design (CAD) software | Enables precise digital modeling and efficient CNC cutting |

| Laser cutting | Provides high-precision cutting, reduces material waste, and allows for intricate designs |

| Advanced welding techniques (robotic welding, plasma arc welding) | Improves welding accuracy, consistency, and speed, resulting in stronger and more durable welds |

Innovation

In the realm of custom metal fabrication in New York, innovation is not merely a buzzword; it is the driving force behind the continuous development of new techniques and solutions that push the boundaries of what is possible with metal. This unwavering commitment to innovation is deeply intertwined with the very essence of custom metal fabrication in New York, shaping its present and propelling its future.

The connection between innovation and custom metal fabrication in New York is multifaceted. Firstly, innovation enables fabricators to overcome the challenges posed by complex designs and demanding project requirements. By developing new techniques and solutions, fabricators can find creative ways to meet the unique needs of their clients, transforming ambitious visions into tangible realities.

Secondly, innovation is crucial for enhancing the efficiency and productivity of custom metal fabrication processes. Through the implementation of new technologies and the refinement of existing ones, fabricators can streamline their operations, reduce production time, and minimize material waste. This not only benefits fabricators but also translates into cost savings and faster turnaround times for clients.

Thirdly, innovation drives the development of new products and applications for custom metal fabrication in New York. By exploring novel materials and experimenting with different design concepts, fabricators can create innovative metal structures and components that meet the evolving needs of various industries, from architecture and construction to transportation and energy.

Examples of innovation in custom metal fabrication in New York abound. One notable example is the development of high-strength, lightweight alloys that have enabled the creation of more efficient and durable structures, such as bridges and skyscrapers. Another example is the use of 3D printing technology to fabricate complex metal components with intricate geometries, opening up new possibilities for design and manufacturing.

In conclusion, the connection between innovation and custom metal fabrication in New York is inseparable. Innovation is the lifeblood of this industry, driving progress, enhancing capabilities, and shaping the future of metal fabrication. By embracing innovation, custom metal fabricators in New York continue to push the boundaries of possibility and deliver exceptional results for their clients.

Key Insights:

- Innovation is essential for overcoming challenges and meeting complex project requirements in custom metal fabrication.

- Innovation drives efficiency and productivity improvements in custom metal fabrication processes.

- Innovation leads to the development of new products and applications for custom metal fabrication.

Collaboration

In the realm of custom metal fabrication in New York, collaboration is not merely a buzzword; it is the cornerstone upon which successful projects are built. Close coordination between designers, engineers, and fabricators is essential for ensuring that custom metal structures and components meet the highest standards of quality, functionality, and aesthetic appeal.

-

Design and Engineering Synergy:

Collaboration fosters a seamless exchange of ideas and expertise between designers and engineers. Designers bring their creative vision and understanding of form and function to the table, while engineers provide technical knowledge and ensure structural integrity. This synergy results in innovative and feasible designs that meet both aesthetic and performance requirements.

-

Precision and Accuracy:

Close coordination between engineers and fabricators is crucial for ensuring precision and accuracy in the fabrication process. Engineers provide detailed fabrication drawings and specifications, while fabricators utilize their expertise to translate these designs into tangible structures. This collaboration minimizes errors and ensures that the final product conforms to the intended design.

-

Problem-Solving and Innovation:

Collaboration creates a platform for problem-solving and innovation. When challenges arise during the fabrication process, designers, engineers, and fabricators work together to find creative solutions that maintain the integrity and functionality of the design. This collaborative approach often leads to innovative techniques and improvements in the fabrication process.

-

Timely Execution and Cost-Effectiveness:

Effective collaboration streamlines the fabrication process, reducing delays and minimizing costs. When all stakeholders are on the same page, decision-making is expedited, and potential issues are identified and resolved early on. This collaborative approach contributes to timely project execution and cost-effectiveness.

In conclusion, the connection between collaboration and custom metal fabrication in New York is inextricable. Close coordination between designers, engineers, and fabricators is the driving force behind successful projects, ensuring quality, functionality, innovation, and cost-effectiveness. By fostering a collaborative environment, custom metal fabricators in New York deliver exceptional results that meet the unique needs of their clients.

Custom Metal Fabrication in New York

This section addresses common questions and misconceptions surrounding custom metal fabrication in New York, providing informative answers to guide readers in making well-informed decisions.

Question 1: What is custom metal fabrication?

Custom metal fabrication refers to the process of transforming raw metal materials into unique and tailored structures or components based on specific design requirements. It involves various techniques such as cutting, bending, welding, and finishing, to create metal products that meet precise specifications and functional needs.

Question 2: What are the benefits of custom metal fabrication?

Custom metal fabrication offers numerous advantages, including:

- Design flexibility and customization to meet specific requirements.

- High precision and accuracy in the fabrication process.

- Durability and longevity of metal structures and components.

- Cost-effectiveness in the long run due to durability and reduced maintenance.

Question 3: What materials are used in custom metal fabrication?

A wide range of metals can be utilized in custom metal fabrication, including steel, aluminum, stainless steel, brass, and copper. The choice of material depends on factors such as strength, corrosion resistance, weight, and aesthetic preferences.

Question 4: What industries rely on custom metal fabrication?

Custom metal fabrication finds applications in diverse industries, such as construction, manufacturing, automotive, aerospace, and architecture. It is essential for creating structural components, machinery parts, vehicle frames, and decorative elements.

Question 5: How can I find a reputable custom metal fabricator in New York?

To locate a reputable custom metal fabricator in New York, consider the following:

- Experience and expertise in the industry.

- Positive customer testimonials and references.

- Compliance with industry standards and certifications.

- Advanced equipment and skilled workforce.

Question 6: What factors influence the cost of custom metal fabrication?

The cost of custom metal fabrication is influenced by several factors, including:

- Complexity of the design and fabrication process.

- Type and quantity of materials used.

- Labor costs and overhead expenses.

- Timeline and delivery requirements.

In conclusion, custom metal fabrication in New York offers a versatile and reliable solution for creating high-quality metal structures and components tailored to specific needs. By understanding the process, benefits, and considerations involved, individuals and businesses can make informed decisions when seeking custom metal fabrication services in New York.

Transition to the next article section:

To delve deeper into the intricacies of custom metal fabrication in New York, let’s explore its key aspects, including materials, processes, industries served, and the importance of expertise and technology.

Tips for Custom Metal Fabrication in New York

Custom metal fabrication in New York offers a myriad of possibilities for creating unique and functional metal structures. To ensure a successful project, consider the following tips:

Tip 1: Define Clear Specifications

Provide detailed drawings, measurements, and performance requirements to the fabricator. Clear specifications minimize errors and ensure the fabricated product meets your exact needs.

Tip 2: Choose the Right Materials

Select materials that align with the intended application and environment. Consider factors such as strength, durability, corrosion resistance, and aesthetics when making your choice.

Tip 3: Partner with an Experienced Fabricator

Look for a fabricator with a proven track record, skilled workforce, and advanced equipment. Experience ensures your project is handled by professionals who understand the complexities of metal fabrication.

Tip 4: Leverage Technology

Incorporate technology, such as computer-aided design (CAD) and laser cutting, to enhance precision, efficiency, and design capabilities. Technology streamlines the fabrication process and reduces the risk of errors.

Tip 5: Foster Clear Communication

Maintain open and regular communication with the fabricator throughout the project. Discuss design changes, timelines, and any potential challenges to ensure a smooth and successful collaboration.

Tip 6: Conduct Thorough Inspections

Inspect the fabricated product thoroughly upon completion. Check for accuracy, quality of welds, and overall compliance with the specifications. Inspections ensure the final product meets your expectations and industry standards.

Tip 7: Consider Long-Term Maintenance

Plan for ongoing maintenance to preserve the longevity of your custom metal fabrication. Regular inspections, cleaning, and touch-ups can extend the lifespan of the structure and maintain its aesthetic appeal.

Summary

By following these tips, you can navigate the custom metal fabrication process in New York effectively. Clear specifications, material selection, experienced fabricators, technology utilization, communication, inspections, and maintenance planning are crucial for a successful project. With these considerations in mind, you can create exceptional metal structures that meet your functional and aesthetic requirements.

Conclusion

Custom metal fabrication in New York has emerged as a cornerstone of various industries, offering unparalleled versatility and durability in metalworking. This exploration has shed light on the intricate processes, diverse applications, and technological advancements that define this field.

Skilled fabricators in New York leverage their expertise, precision equipment, and innovative techniques to transform raw materials into exceptional metal structures and components. The emphasis on quality, collaboration, and customer satisfaction ensures that each project meets the highest standards. As technology continues to revolutionize the industry, custom metal fabrication in New York is poised for even greater heights, pushing the boundaries of what is possible with metal.