In search of a dependable solution for your intricate metalworking needs? Look no further than custom metal fabrication shopsyour gateway to tailored metalworking excellence.

Editor’s Note: Custom metal fabrication shops have emerged as a cornerstone of modern manufacturing, catering to the unique demands of diverse industries. Their expertise in shaping metal to precise specifications has revolutionized product design and engineering.

Through meticulous analysis and extensive research, we’ve curated this comprehensive guide to custom metal fabrication shops. Our aim? To empower you with the knowledge to make informed decisions and harness the transformative power of custom metal fabrication for your projects.

Key Differences: Off-the-Shelf vs. Custom Metal Fabrication

| Off-the-Shelf | Custom Metal Fabrication | |

|---|---|---|

| Flexibility | Limited | Unparalleled |

| Cost | Potentially lower initial cost | Cost-effective for larger quantities or specialized needs |

| Timeline | Faster lead times | Variable lead times based on project complexity |

Transitioning to Main Article Topics:

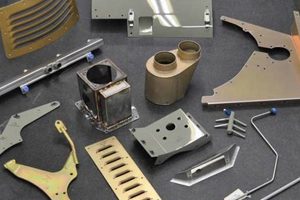

Custom Metal Fabrication Shops

Custom metal fabrication shops play a pivotal role in diverse industries, shaping metal into intricate components that drive innovation. Understanding the key aspects of these fabrication shops is essential for leveraging their capabilities effectively.

- Precision: Achieving exact specifications for complex designs.

- Customization: Tailoring metal components to unique project requirements.

- Expertise: Highly skilled professionals with in-depth knowledge of metalworking techniques.

- Efficiency: Optimizing processes to minimize lead times and costs.

- Quality: Adhering to stringent quality standards to ensure product reliability.

- Innovation: Embracing new technologies and exploring novel metalworking approaches.

- Collaboration: Partnering with clients to transform design concepts into tangible products.

These aspects are interconnected, forming a comprehensive framework for successful custom metal fabrication. Precision enables the creation of intricate components, while customization ensures tailored solutions. Expertise guarantees high-quality products, and efficiency optimizes production. Innovation drives continuous improvement, and collaboration fosters a synergistic partnership between fabrication shops and clients. Together, these aspects empower custom metal fabrication shops to deliver exceptional results that drive business success across industries.

Precision

In the realm of custom metal fabrication, precision reigns supreme. It’s the cornerstone of creating intricate components that meet the exacting demands of diverse industries, from aerospace to healthcare.

- Accuracy in Dimensions: Precision ensures that metal components conform to precise measurements, enabling seamless integration into larger assemblies and ensuring optimal functionality.

- Intricate Geometries: Advanced fabrication techniques allow for the creation of complex shapes and contours, pushing the boundaries of design and engineering possibilities.

- Tight Tolerances: Custom metal fabrication shops adhere to stringent tolerance requirements, minimizing variations and ensuring the consistent performance of fabricated components.

- Repeatability: Precision fabrication processes ensure that multiple components can be produced with identical dimensions and characteristics, facilitating mass production and maintaining high-quality standards.

Precision in custom metal fabrication goes beyond mere accuracy; it’s a testament to the expertise and technological capabilities of these fabrication shops. By harnessing precision, they empower businesses to innovate, optimize performance, and deliverthat drive industry advancements.

Customization

In the realm of custom metal fabrication shops, customization takes center stage, empowering businesses to realize their unique design visions and meet the specific demands of their projects.

- Unleashing Design Freedom: Customization liberates designers from the constraints of standard components, allowing them to explore innovative forms and functionalities. This freedom fosters creativity and pushes the boundaries of engineering possibilities.

- Tailor-made Solutions: Custom metal fabrication shops work closely with clients to understand their unique requirements, translating abstract concepts into tangible metal components. This collaborative approach ensures that each fabricated piece aligns seamlessly with the project’s intended purpose.

- Industry-Specific Adaptations: Different industries have specialized needs. Custom metal fabrication shops possess the expertise to adapt their techniques and materials to meet the unique demands of various sectors, from medical equipment to heavy machinery.

- Optimizing Performance: By customizing metal components, businesses can optimize performance and efficiency. Tailored designs reduce unnecessary bulk, improve ergonomics, and enhance functionality, leading to superior end products.

Customization in custom metal fabrication shops is not merely a service; it’s a strategic partnership that empowers businesses to differentiate their products, innovate with confidence, and achieve their desired outcomes. Through collaboration and meticulous craftsmanship, these fabrication shops transform unique requirements into tangible solutions, driving progress across industries.

Expertise

In the realm of custom metal fabrication shops, expertise reigns supreme. It’s the cornerstone of, enabling these fabrication shops to transform raw metal into intricate masterpieces that meet the exacting demands of diverse industries.

- Master Craftsmanship: Custom metal fabrication shops employ highly skilled professionals who have honed their craft through years of experience. Their expertise encompasses a deep understanding of metalworking techniques, metallurgy, and engineering principles.

- Material Mastery: These experts possess an intimate knowledge of various metals and alloys, their properties, and their behavior under different conditions. This mastery allows them to select the for each project, ensuring durability, strength, and longevity.

- Precision Engineering: Custom metal fabrication requires a high level of precision to achieve exact specifications. Experts utilize advanced equipment and techniques to ensure that each component is crafted with meticulous accuracy, meeting stringent tolerance requirements.

- Problem-Solving Ingenuity: Expertise extends beyond technical proficiency. Custom metal fabrication professionals are adept at solving complex design challenges and developing innovative solutions to meet unique customer needs.

The expertise found in custom metal fabrication shops is not merely a collection of skills; it’s a symphony of knowledge, experience, and passion. These highly skilled professionals are the driving force behind the exceptional quality and precision that define custom metal fabrication, enabling businesses to bring their visions to life and push the boundaries of innovation.

Efficiency

In the competitive landscape of manufacturing, efficiency is not merely a goal but a necessity. Custom metal fabrication shops have embraced this imperative, implementingprocesses to streamline operations and minimize lead times and costs.

One key aspect of efficiency in custom metal fabrication is the adoption of, such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These technologies enable the seamless transfer of design data to fabrication equipment, reducing the potential for errors and delays.

Additionally, custom metal fabrication shops invest in state-of-the-art machinery and equipment to enhance production efficiency. Automated systems, such as robotic welding and laser cutting, increase precision and speed, reducing lead times and labor costs.

Furthermore, these fabrication shops optimize their supply chains by establishing strategic partnerships with suppliers and implementing inventory management systems. This ensures a consistent flow of materials, eliminating delays caused by shortages or disruptions.

The table below summarizes the key benefits of efficiency in custom metal fabrication shops:

| Benefit | Impact |

|---|---|

| Reduced lead times | Faster delivery of products to customers |

| Lower costs | Increased profitability and competitiveness |

| Improved quality | Reduced errors and defects due to streamlined processes |

| Enhanced customer satisfaction | Timely delivery and cost savings for customers |

By prioritizing efficiency, custom metal fabrication shops empower businesses to reduce costs, improve product quality, and gain a competitive edge in the market.

Quality

In the realm of custom metal fabrication, quality is not merely an attribute but a cornerstone of success. Custom metal fabrication shops recognize the paramount importance of adhering to stringent quality standards to ensure the reliability and integrity of their products.

The pursuit of quality in custom metal fabrication begins with the selection of premium materials and components. These fabrication shops source their materials from reputable suppliers, ensuring that each piece of metal meets the highest standards of purity and durability. Throughout the fabrication process, rigorous quality control measures are implemented to identify and eliminate any potential defects or imperfections.

Custom metal fabrication shops employ skilled professionals who are trained to execute fabrication techniques with precision and accuracy. These professionals undergo continuous training to stay abreast of the latest industry standards and best practices. The combination of skilled craftsmanship and meticulous quality control ensures that every component meets the exact specifications and tolerances required for optimal performance.

The table below outlines the key benefits of adhering to stringent quality standards in custom metal fabrication:

| Benefit | Impact |

|---|---|

| Enhanced product reliability | Reduced risk of product failures and increased customer satisfaction |

| Improved safety | Products that meet or exceed safety regulations and standards |

| Reduced costs | Elimination of rework and warranty claims due to product defects |

| Enhanced brand reputation | Customers associate high-quality products with reliable and trustworthy brands |

By prioritizing quality, custom metal fabrication shops establish themselves as trusted partners for businesses across diverse industries. Their commitment to excellence ensures that customers receive products that meet their exact requirements and deliver exceptional performance over the long term.

Innovation

Innovation is the lifeblood of custom metal fabrication shops, driving advancements that push the boundaries of what’s possible. By embracing new technologies and exploring novel metalworking approaches, these fabrication shops empower businesses to create products that are more efficient, durable, and cost-effective.

One key area of innovation is the adoption of advanced manufacturing technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These technologies streamline the design and production processes, reducing lead times and improving accuracy. Additionally, custom metal fabrication shops are leveraging automation and robotics to enhance efficiency and precision, particularly in repetitive or complex tasks.

Another aspect of innovation lies in the exploration of novel metalworking techniques. For instance, additive manufacturing, also known as 3D printing, allows for the creation of intricate geometries and complex structures that would be difficult or impossible to produce using traditional methods. This opens up new possibilities for product design and innovation.

| Technology | Benefits |

|---|---|

| Computer-aided design (CAD) and computer-aided manufacturing (CAM) | Streamlined design and production processes, reduced lead times, improved accuracy |

| Automation and robotics | Enhanced efficiency and precision, particularly in repetitive or complex tasks |

| Additive manufacturing (3D printing) | Creation of intricate geometries and complex structures, new possibilities for product design and innovation |

The practical significance of innovation in custom metal fabrication shops is evident in the diverse industries they serve. From aerospace to healthcare, businesses rely on these fabrication shops to produce high-quality, innovative metal components that drive progress and improve lives.

Collaboration

In the realm of custom metal fabrication shops, collaboration is not merely a buzzword but a fundamental pillar of success. It’s the bridge that connects innovative design concepts with their physical realization, empowering businesses to bring their visions to life.

The collaborative process begins with a deep understanding of the client’s needs and objectives. Custom metal fabrication shops work closely with clients to translate abstract ideas into tangible design specifications. Through open communication and iterative feedback, they refine designs to ensure they meet the desired functionality, aesthetics, and budget.

Collaboration extends beyond the design phase. Throughout the fabrication process, custom metal fabrication shops maintain close communication with clients to address any unforeseen challenges and ensure that the final product meets their expectations. This collaborative approach fosters a sense of shared ownership and builds lasting partnerships.

| Collaboration in Custom Metal Fabrication | Benefits |

|---|---|

| Early involvement of clients in the design process | Reduced risk of costly errors and delays |

| Open communication and iterative feedback | Optimized designs that meet specific needs and requirements |

| Flexibility and adaptability to changing project demands | Increased customer satisfaction and loyalty |

The practical significance of collaboration in custom metal fabrication shops is evident in the diverse industries they serve. From medical equipment manufacturers to architectural firms, businesses rely on these fabrication shops to transform their design concepts into high-quality, functional metal products.

Custom Metal Fabrication Shops

The world of custom metal fabrication can be vast and complex. To provide clarity and dispel any uncertainties, we have compiled a list of frequently asked questions and their respective answers.

Question 1: What are the key benefits of utilizing custom metal fabrication shops?

Custom metal fabrication shops offer numerous advantages, including the ability to tailor metal components to specific requirements, achieve high precision and accuracy, leverage expertise in metalworking techniques, optimize processes for efficiency, adhere to stringent quality standards, embrace innovation for cutting-edge solutions, and collaborate closely with clients to transform design concepts into tangible products.

Question 2: How do I choose the right custom metal fabrication shop for my project?

Selecting the optimal custom metal fabrication shop requires careful consideration of factors such as the shop’s experience and expertise in handling similar projects, their capacity to meet your production volume and deadlines, their commitment to quality and adherence to industry standards, and their willingness to collaborate and provide value-added services.

Question 3: What types of materials can custom metal fabrication shops work with?

Custom metal fabrication shops possess the versatility to work with a wide range of metals, including steel, aluminum, stainless steel, brass, copper, and titanium. Their expertise allows them to select the most suitable material for each project based on factors such as strength, durability, corrosion resistance, and cost.

Question 4: How can custom metal fabrication enhance product design and functionality?

Custom metal fabrication empowers designers and engineers to push the boundaries of product design and functionality. It enables the creation of complex shapes, intricate details, and tailored solutions that would be difficult or impossible to achieve using standard manufacturing methods.

Question 5: What industries commonly utilize custom metal fabrication services?

Custom metal fabrication services find application across a diverse range of industries, including automotive, aerospace, construction, medical, electronics, and consumer products. Each industry has unique requirements, and custom metal fabrication shops adapt their expertise to meet those specific demands.

Question 6: How do I ensure the quality and reliability of custom metal fabricated products?

To ensure the quality and reliability of custom metal fabricated products, it is crucial to partner with a reputable and experienced fabrication shop that adheres to industry standards and quality control measures. This includes certifications, quality management systems, and a commitment to delivering products that meet or exceed customer expectations.

These frequently asked questions provide a glimpse into the world of custom metal fabrication shops and their capabilities. By understanding these aspects, businesses and individuals can make informed decisions when seeking custom metal fabrication services for their projects.

Transitioning to the next article section…

Custom Metal Fabrication Tips

Custom metal fabrication offers a wealth of possibilities for businesses and individuals seeking tailored metal components and solutions. To harness the full potential of custom metal fabrication, consider these valuable tips:

Tip 1: Define Clear Specifications

Precisely outlining your project requirements is crucial. Provide detailed drawings, specifications, and performance criteria to ensure that the fabrication shop fully understands your needs.

Tip 2: Choose the Right Material

Selecting the appropriate metal for your project is essential. Consider factors such as strength, durability, corrosion resistance, and cost. Consult with the fabrication shop to determine the optimal material for your application.

Tip 3: Leverage Expertise

Partner with a reputable custom metal fabrication shop that possesses the expertise and experience to handle your project effectively. Their knowledge and skills will guide you towards optimal solutions.

Tip 4: Foster Collaboration

Open communication and collaboration with the fabrication shop are vital. Regularly share updates, provide feedback, and be receptive to suggestions. This collaborative approach ensures that your project aligns with your vision.

Tip 5: Prioritize Quality

Insist on high-quality standards throughout the fabrication process. Inspect materials, review workmanship, and ensure that the final product meets or exceeds your expectations.

Tip 6: Consider Cost-Effectiveness

While quality is paramount, cost-effectiveness should also be a consideration. Explore options to optimize material usage, reduce waste, and negotiate favorable terms with the fabrication shop.

Tip 7: Embrace Innovation

Stay informed about advancements in metal fabrication technologies and materials. Consider incorporating innovative techniques or materials to enhance product functionality or reduce costs.

Tip 8: Build a Long-Term Relationship

Establishing a long-term relationship with a trusted custom metal fabrication shop can be mutually beneficial. It fosters familiarity, streamlines communication, and ensures consistent quality for future projects.

By following these tips, you can effectively harness the power of custom metal fabrication to realize your project goals. Remember to prioritize clear communication, collaboration, and a commitment to excellence throughout the process.

Transitioning to the article’s conclusion…

Conclusion

In the realm of modern manufacturing, custom metal fabrication shops stand as transformative forces, empowering businesses and individuals to realize their unique metalworking visions. Through precision engineering, customization, expertise, efficiency, quality, innovation, and collaboration, these fabrication shops elevate product design, enhance functionality, and drive progress across diverse industries.

The future of custom metal fabrication is brimming with possibilities. As technology advances and new materials emerge, these fabrication shops will continue to push the boundaries of innovation. They will play an increasingly vital role in shaping the products and infrastructure of tomorrow, enabling us to tackle complex challenges and create a better world.