What is custom stainless steel tank fabrication?

Editor’s Note: Custom stainless steel tank fabrication is the process of creating tanks that meet the specific requirements of a customer. These tanks can be used for a variety of purposes, including storing liquids, gases, or solids.

Custom stainless steel tank fabrication is a complex process that requires careful planning and execution. The first step is to design the tank, which must meet the customer’s specific requirements. Once the design is complete, the tank is fabricated using high-quality stainless steel. The tank is then tested to ensure that it meets all of the customer’s requirements.

Custom stainless steel tank fabrication offers a number of benefits over standard tanks. These benefits include:

- Tanks can be customized to meet the specific requirements of the customer.

- Tanks are made from high-quality stainless steel, which is durable and corrosion-resistant.

- Tanks are tested to ensure that they meet all of the customer’s requirements.

Custom stainless steel tank fabrication is a valuable service that can provide a number of benefits. If you are in need of a tank, contact a reputable fabricator to learn more about your options.

Custom Stainless Steel Tank Fabrication

Custom stainless steel tank fabrication is a complex and multifaceted process that requires careful planning and execution. To ensure a successful project, it is important to consider all of the key aspects involved.

- Design: The design of the tank is critical to its functionality and performance. Factors to consider include the tank’s size, shape, and material thickness.

- Materials: Stainless steel is a durable and corrosion-resistant material, making it ideal for tank fabrication. However, there are different grades of stainless steel, so it is important to select the right grade for the specific application.

- Fabrication: The fabrication process involves cutting, welding, and forming the stainless steel into the desired shape. This process must be carried out by experienced and qualified fabricators.

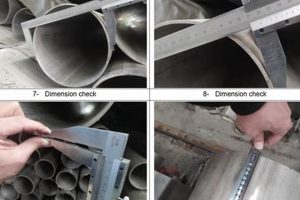

- Testing: Once the tank is fabricated, it must be tested to ensure that it meets all of the required specifications. This testing may include pressure testing, leak testing, and visual inspection.

- Installation: The tank must be properly installed in order to ensure its safe and efficient operation. This includes providing a level and stable foundation, as well as connecting the tank to the appropriate piping and equipment.

- Maintenance: Regular maintenance is essential to keep the tank in good working condition. This includes cleaning the tank, inspecting it for damage, and making any necessary repairs.

- Safety: Safety is a top priority when working with custom stainless steel tanks. It is important to follow all safety guidelines and procedures, and to wear the appropriate personal protective equipment.

- Cost: The cost of a custom stainless steel tank will vary depending on the size, complexity, and materials used. It is important to get quotes from multiple fabricators before making a decision.

- Lead time: The lead time for a custom stainless steel tank will vary depending on the fabricator’s schedule. It is important to allow for sufficient lead time when planning your project.

- Warranty: Most fabricators will offer a warranty on their work. This warranty will typically cover defects in materials and workmanship.

- Experience: When choosing a fabricator, it is important to consider their experience and expertise. Look for a fabricator with a proven track record of success.

By considering all of these key aspects, you can ensure that your custom stainless steel tank fabrication project is a success.

Design

The design of a custom stainless steel tank is critical to its functionality and performance. The tank’s size, shape, and material thickness must all be carefully considered in order to ensure that the tank meets the customer’s specific requirements.

The size of the tank is important for determining its capacity and overall dimensions. The shape of the tank is important for determining its structural integrity and ability to withstand pressure. The material thickness of the tank is important for determining its durability and corrosion resistance.

In addition to these factors, the design of the tank must also take into account the specific application for which it will be used. For example, a tank that will be used to store corrosive liquids will need to be made from a thicker material than a tank that will be used to store water.

By carefully considering all of these factors, the designer can create a custom stainless steel tank that meets the customer’s specific requirements and provides years of reliable service.

Here are some real-life examples of how the design of a custom stainless steel tank can impact its functionality and performance:

- A tank that is too small will not be able to hold the required amount of liquid.

- A tank that is not shaped properly may not be able to withstand the pressure of the liquid inside.

- A tank that is made from a material that is too thin may not be able to withstand the corrosive effects of the liquid inside.

By understanding the connection between design and functionality, you can ensure that your custom stainless steel tank meets your specific requirements and provides years of reliable service.

Materials

The selection of the right grade of stainless steel is critical to the performance and longevity of a custom stainless steel tank. Different grades of stainless steel have different properties, such as corrosion resistance, strength, and weldability. The grade of stainless steel that is best for a particular application will depend on the specific requirements of that application.

For example, a tank that will be used to store corrosive liquids will need to be made from a grade of stainless steel that is highly resistant to corrosion. A tank that will be used to store food products will need to be made from a grade of stainless steel that is non-toxic and easy to clean.

By selecting the right grade of stainless steel, fabricators can ensure that their tanks meet the specific requirements of their customers and provide years of reliable service.

Here are some real-life examples of how the selection of the right grade of stainless steel can impact the performance and longevity of a custom stainless steel tank:

- A tank that is made from a grade of stainless steel that is not resistant to corrosion will quickly rust and deteriorate.

- A tank that is made from a grade of stainless steel that is not strong enough to withstand the pressure of the liquid inside may rupture.

- A tank that is made from a grade of stainless steel that is not weldable will be difficult to repair or modify.

By understanding the connection between the grade of stainless steel and the performance and longevity of a custom stainless steel tank, you can ensure that your tank meets your specific requirements and provides years of reliable service.

Table: Different grades of stainless steel and their properties

| Grade | Corrosion Resistance | Strength | Weldability |

|---|---|---|---|

| 304 | Good | Good | Good |

| 316 | Excellent | Good | Good |

| 316L | Excellent | Good | Good |

| 430 | Poor | Good | Good |

| 440C | Excellent | Excellent | Difficult |

Fabrication

The fabrication process is a critical step in the construction of a custom stainless steel tank. This process involves cutting, welding, and forming the stainless steel into the desired shape. It is important that this process is carried out by experienced and qualified fabricators in order to ensure that the tank is properly constructed and meets all of the customer’s requirements.

-

Facet 1: Cutting

Cutting is the process of separating the stainless steel into the desired shape. This can be done using a variety of methods, such as laser cutting, waterjet cutting, or plasma cutting. The choice of cutting method will depend on the thickness of the stainless steel and the desired accuracy of the cut. -

Facet 2: Welding

Welding is the process of joining two pieces of stainless steel together. This is done by melting the edges of the two pieces of stainless steel together and then allowing them to cool and solidify. The type of weld used will depend on the thickness of the stainless steel and the strength of the joint required. -

Facet 3: Forming

Forming is the process of shaping the stainless steel into the desired shape. This can be done using a variety of methods, such as rolling, bending, or pressing. The choice of forming method will depend on the thickness of the stainless steel and the desired shape of the tank. -

Facet 4: Finishing

Finishing is the final step in the fabrication process. This involves cleaning the tank and removing any burrs or sharp edges. The tank may also be polished or painted to improve its appearance and corrosion resistance.

By understanding the fabrication process and the role of experienced and qualified fabricators, customers can ensure that their custom stainless steel tanks are properly constructed and meet all of their requirements.

Testing

Testing is an essential part of the custom stainless steel tank fabrication process. It ensures that the tank meets all of the customer’s requirements and is safe for use. There are a variety of tests that can be performed on a stainless steel tank, including:

- Pressure testing: This test checks the tank’s ability to withstand internal pressure. The tank is filled with water or another liquid and then pressurized to a specified level. The tank is then inspected for any leaks or damage.

- Leak testing: This test checks the tank’s ability to hold liquids without leaking. The tank is filled with water or another liquid and then inspected for any leaks. This test can be performed using a variety of methods, including visual inspection, ultrasonic testing, and pressure testing.

- Visual inspection: This test involves visually inspecting the tank for any defects, such as cracks, dents, or scratches. The inspector will also check the welds to ensure that they are properly made.

- Non-destructive testing (NDT): This type of testing uses specialized techniques to inspect the tank without damaging it. NDT methods can be used to detect cracks, corrosion, and other defects that may not be visible to the naked eye.

By performing these tests, fabricators can ensure that their tanks meet all of the customer’s requirements and are safe for use. Testing is an important part of the custom stainless steel tank fabrication process and should not be overlooked.

Installation

Proper installation is a critical component of custom stainless steel tank fabrication. A poorly installed tank can be dangerous and inefficient, and may even void the manufacturer’s warranty. It is important to work with a qualified installer to ensure that your tank is installed correctly.

The first step in installing a custom stainless steel tank is to provide a level and stable foundation. The foundation should be made of concrete or another suitable material, and it should be strong enough to support the weight of the tank and its contents.

Once the foundation is in place, the tank can be connected to the appropriate piping and equipment. This includes connecting the tank to the water supply, the drain, and any other necessary equipment. It is important to use the correct fittings and materials to ensure that the connections are secure and leak-free.

Once the tank is installed, it should be tested to ensure that it is working properly. The test should include checking the tank for leaks, making sure that the water supply is working properly, and ensuring that the drain is functioning correctly.

By following these steps, you can ensure that your custom stainless steel tank is installed correctly and safely. This will help to extend the life of the tank and ensure that it operates efficiently.

Real-life example:

A customer ordered a custom stainless steel tank to store water for their home. The tank was installed by a qualified installer, but the customer did not have the tank tested after it was installed. A few months later, the tank began to leak water. The customer called the installer, who discovered that the leak was caused by a faulty fitting. The installer replaced the fitting and the tank has been working properly ever since.

This example shows how important it is to have a custom stainless steel tank installed by a qualified installer and to have the tank tested after it is installed. By following these steps, you can help to ensure that your tank is safe and efficient for years to come.

Table: Key insights on the connection between “Installation: The tank must be properly installed in order to ensure its safe and efficient operation. This includes providing a level and stable foundation, as well as connecting the tank to the appropriate piping and equipment.” and “custom stainless steel tank fabrication”

| Key Insight | Explanation |

|---|---|

| Proper installation is a critical component of custom stainless steel tank fabrication. | A poorly installed tank can be dangerous and inefficient, and may even void the manufacturer’s warranty. |

| It is important to work with a qualified installer to ensure that your tank is installed correctly. | A qualified installer will have the experience and expertise to install your tank safely and efficiently. |

| The first step in installing a custom stainless steel tank is to provide a level and stable foundation. | The foundation should be made of concrete or another suitable material, and it should be strong enough to support the weight of the tank and its contents. |

| Once the foundation is in place, the tank can be connected to the appropriate piping and equipment. | This includes connecting the tank to the water supply, the drain, and any other necessary equipment. |

| It is important to use the correct fittings and materials to ensure that the connections are secure and leak-free. | Using the correct fittings and materials will help to prevent leaks and ensure that your tank operates safely and efficiently. |

| Once the tank is installed, it should be tested to ensure that it is working properly. | The test should include checking the tank for leaks, making sure that the water supply is working properly, and ensuring that the drain is functioning correctly. |

| By following these steps, you can ensure that your custom stainless steel tank is installed correctly and safely. | This will help to extend the life of the tank and ensure that it operates efficiently. |

Maintenance

Proper maintenance is essential to ensure the longevity and performance of custom stainless steel tanks. Regular maintenance includes cleaning the tank, inspecting it for damage, and making any necessary repairs.

- Cleaning: Cleaning the tank regularly helps to remove dirt, debris, and other contaminants that can build up over time. This helps to prevent the growth of bacteria and other microorganisms, which can lead to corrosion and other problems. Cleaning the tank also helps to remove any residual chemicals or other substances that may have been left behind after the tank was used.

- Inspection: Inspecting the tank regularly for damage is important to identify any potential problems early on. This allows for timely repairs to be made, which can help to prevent more serious problems from developing. Inspectors should look for any signs of corrosion, cracks, leaks, or other damage.

- Repairs: If any damage is found during an inspection, it is important to make repairs as soon as possible. This will help to prevent the damage from getting worse and causing more serious problems. Repairs should be made by a qualified technician who has experience working with stainless steel tanks.

By following these simple maintenance tips, you can help to ensure that your custom stainless steel tank provides years of reliable service.

Safety

When working with custom stainless steel tanks, safety must be the top priority. This includes following all safety guidelines and procedures, and wearing the appropriate personal protective equipment (PPE). Failure to do so can result in serious injury or even death.

-

Facet 1: Identifying and Assessing Hazards

The first step to working safely with custom stainless steel tanks is to identify and assess the hazards involved. This includes understanding the potential risks associated with the materials being used, the processes being performed, and the equipment being operated.

-

Facet 2: Implementing Control Measures

Once the hazards have been identified and assessed, control measures must be implemented to mitigate the risks. This may involve using engineering controls, such as ventilation systems or machine guards, or administrative controls, such as training programs or work procedures.

-

Facet 3: Using Personal Protective Equipment (PPE)

Even with control measures in place, it is important to wear the appropriate PPE when working with custom stainless steel tanks. This includes items such as gloves, eye protection, and respirators.

-

Facet 4: Emergency Preparedness

In the event of an emergency, it is important to be prepared to respond quickly and effectively. This includes having an emergency plan in place, training employees on the plan, and providing them with the necessary equipment.

By following these safety guidelines, you can help to ensure that you and your employees are safe when working with custom stainless steel tanks.

Cost

The cost of a custom stainless steel tank is a key consideration for any business or individual looking to purchase one. Several factors can affect the cost, including the size, complexity, and materials used.

-

Facet 1: Size

The size of the tank is a major factor in determining its cost. Larger tanks require more materials and labor to build, so they will typically cost more than smaller tanks.

-

Facet 2: Complexity

The complexity of the tank’s design will also affect its cost. Tanks with complex designs require more skilled labor to build, so they will typically cost more than tanks with simple designs.

-

Facet 3: Materials

The type of materials used to build the tank will also affect its cost. Stainless steel is a relatively expensive material, so tanks made from stainless steel will typically cost more than tanks made from other materials, such as carbon steel or plastic.

-

Facet 4: Fabrication

The cost of fabrication is another important factor to consider. The cost of fabrication will vary depending on the fabricator’s experience, expertise, and location.

It is important to get quotes from multiple fabricators before making a decision. This will help you ensure that you are getting the best possible price for your tank.

Lead time

Lead time is the time it takes for a fabricator to build a custom stainless steel tank. This can vary depending on the fabricator’s schedule, the size and complexity of the tank, and the availability of materials.

It is important to allow for sufficient lead time when planning your project. This will ensure that you have the tank you need when you need it.

If you are working on a tight deadline, it is important to communicate this to the fabricator. They may be able to accommodate your needs by working overtime or expediting the production process.

Here are some tips for reducing lead time:

- Choose a fabricator with a good reputation and a proven track record.

- Provide the fabricator with clear and detailed specifications for the tank.

- Be flexible with your delivery date.

- Be willing to pay a premium for expedited service.

By following these tips, you can help to reduce the lead time for your custom stainless steel tank.

Real-life example:

A customer needed a custom stainless steel tank for their new brewery. They contacted several fabricators and received quotes ranging from 8 to 12 weeks. The customer chose a fabricator with a good reputation and a proven track record. They also provided the fabricator with clear and detailed specifications for the tank. As a result, the fabricator was able to build the tank in 8 weeks and deliver it on time.

This example shows how important it is to allow for sufficient lead time when planning your project. By working with a reputable fabricator and providing them with clear and detailed specifications, you can help to ensure that you have the tank you need when you need it.

| Key Insight | Explanation |

|---|---|

| Lead time is an important factor to consider when planning a custom stainless steel tank fabrication project. | The lead time can vary depending on the fabricator’s schedule, the size and complexity of the tank, and the availability of materials. |

| It is important to allow for sufficient lead time to ensure that you have the tank you need when you need it. | If you are working on a tight deadline, it is important to communicate this to the fabricator. |

| There are several things you can do to reduce lead time, such as choosing a fabricator with a good reputation, providing the fabricator with clear and detailed specifications, and being flexible with your delivery date. | By following these tips, you can help to ensure that your custom stainless steel tank is delivered on time. |

Warranty

A warranty is a valuable form of protection for custom stainless steel tank fabrication projects. It provides peace of mind, knowing that the fabricator stands behind their work and will correct any defects that may arise.

-

Facet 1: Coverage

Warranties typically cover defects in materials and workmanship. This means that if the tank fails due to a faulty material or poor craftsmanship, the fabricator will be responsible for repairing or replacing the tank.

-

Facet 2: Duration

The duration of a warranty can vary depending on the fabricator. Some fabricators offer warranties that last for several years, while others offer warranties that only last for a few months. It is important to compare the warranties of different fabricators before making a decision.

-

Facet 3: Exclusions

Most warranties do not cover damage caused by misuse, abuse, or neglect. It is important to read the warranty carefully to understand what is and is not covered.

-

Facet 4: Importance

A warranty is an important factor to consider when choosing a fabricator. A good warranty provides peace of mind and protects the customer from financial loss in the event of a defect.

By understanding the different aspects of warranties, customers can make informed decisions about custom stainless steel tank fabrication projects.

Experience

The experience of the fabricator is a critical factor to consider when choosing a fabricator for your custom stainless steel tank fabrication project. An experienced fabricator will have the knowledge and expertise to design and build a tank that meets your specific requirements and standards.

There are several benefits to working with an experienced fabricator:

- Experienced fabricators are more likely to be able to provide you with a high-quality tank that meets your specific requirements.

- Experienced fabricators are more likely to be able to identify and avoid potential problems during the fabrication process.

- Experienced fabricators are more likely to be able to complete your project on time and within budget.

When choosing a fabricator, it is important to look for a company with a proven track record of success. You can ask for references from previous customers or check online reviews to see what others have said about their experience working with the fabricator.

By working with an experienced fabricator, you can increase your chances of getting a high-quality custom stainless steel tank that meets your specific requirements and standards.

Real-life example:

A customer needed a custom stainless steel tank for their new brewery. They contacted several fabricators and received quotes ranging from 8 to 12 weeks. The customer chose a fabricator with a good reputation and a proven track record. They also provided the fabricator with clear and detailed specifications for the tank. As a result, the fabricator was able to build the tank in 8 weeks and deliver it on time.

This example shows how important it is to work with an experienced fabricator. By working with a reputable fabricator, the customer was able to get a high-quality tank that met their specific requirements and was delivered on time.

Table: Key insights on the connection between “Experience: When choosing a fabricator, it is important to consider their experience and expertise. Look for a fabricator with a proven track record of success.” and “custom stainless steel tank fabrication”

| Key Insight | Explanation |

|---|---|

| Experienced fabricators are more likely to be able to provide you with a high-quality tank that meets your specific requirements. | Experienced fabricators have the knowledge and expertise to design and build tanks that meet specific requirements and standards. |

| Experienced fabricators are more likely to be able to identify and avoid potential problems during the fabrication process. | Experienced fabricators have the knowledge and expertise to identify and avoid potential problems during the fabrication process. |

| Experienced fabricators are more likely to be able to complete your project on time and within budget. | Experienced fabricators have the experience and expertise to complete projects on time and within budget. |

Custom Stainless Steel Tank Fabrication FAQs

This section provides answers to frequently asked questions about custom stainless steel tank fabrication.

Question 1: What is custom stainless steel tank fabrication?

Answer: Custom stainless steel tank fabrication is the process of designing and building stainless steel tanks to meet specific requirements. These tanks can be used for a variety of purposes, such as storing liquids, gases, or solids.

Question 2: What are the benefits of custom stainless steel tanks?

Answer: Custom stainless steel tanks offer a number of benefits, including:

- Tanks can be customized to meet the specific requirements of the customer.

- Tanks are made from high-quality stainless steel, which is durable and corrosion-resistant.

- Tanks are tested to ensure that they meet all of the customer’s requirements.

Question 3: What factors should be considered when choosing a fabricator?

Answer: When choosing a fabricator, it is important to consider their experience, expertise, and reputation. It is also important to compare the warranties and lead times of different fabricators.

Question 4: What is the lead time for a custom stainless steel tank?

Answer: The lead time for a custom stainless steel tank will vary depending on the fabricator’s schedule, the size and complexity of the tank, and the availability of materials. It is important to allow for sufficient lead time when planning your project.

Question 5: What is the cost of a custom stainless steel tank?

Answer: The cost of a custom stainless steel tank will vary depending on the size, complexity, and materials used. It is important to get quotes from multiple fabricators before making a decision.

Question 6: What is the warranty for a custom stainless steel tank?

Answer: Most fabricators will offer a warranty on their work. This warranty will typically cover defects in materials and workmanship.

By understanding the answers to these frequently asked questions, you can make informed decisions about your custom stainless steel tank fabrication project.

Summary of key takeaways:

- Custom stainless steel tanks offer a number of benefits, including durability, corrosion resistance, and customizability.

- When choosing a fabricator, it is important to consider their experience, expertise, and reputation.

- The lead time and cost of a custom stainless steel tank will vary depending on the size, complexity, and materials used.

- Most fabricators will offer a warranty on their work, which typically covers defects in materials and workmanship.

Transition to the next article section:

Now that you have a better understanding of custom stainless steel tank fabrication, you can start to explore the different options available to you. In the next section, we will discuss the different types of stainless steel tanks and their applications.

Tips for Custom Stainless Steel Tank Fabrication

Custom stainless steel tank fabrication is a complex and demanding process, but by following these tips, you can ensure that your project is a success.

Tip 1: Choose the right fabricator.

The fabricator you choose will have a significant impact on the quality of your tank. Look for a fabricator with experience in fabricating stainless steel tanks, and who has a good reputation for quality and customer service.

Tip 2: Define your requirements clearly.

Before you start working with a fabricator, it is important to clearly define your requirements for the tank. This includes the size, shape, capacity, and materials. The more specific you are, the better the fabricator will be able to meet your needs.

Tip 3: Get multiple quotes.

Once you have defined your requirements, it is a good idea to get quotes from multiple fabricators. This will help you compare prices and services, and choose the fabricator that is best for your project.

Tip 4: Inspect the tank before it is installed.

Once the tank is fabricated, it is important to inspect it carefully before it is installed. This will help you identify any defects or problems that need to be corrected.

Tip 5: Follow the manufacturer’s instructions for installation and maintenance.

Once the tank is installed, it is important to follow the manufacturer’s instructions for installation and maintenance. This will help you keep the tank in good condition and extend its lifespan.

By following these tips, you can ensure that your custom stainless steel tank fabrication project is a success.

Summary of key takeaways:

- Choosing the right fabricator is essential for a successful project.

- Clearly defining your requirements will help the fabricator meet your needs.

- Getting multiple quotes will help you compare prices and services.

- Inspecting the tank before it is installed will help you identify any defects or problems.

- Following the manufacturer’s instructions for installation and maintenance will help you keep the tank in good condition and extend its lifespan.

Transition to the article’s conclusion:

Custom stainless steel tank fabrication is a complex and demanding process, but by following these tips, you can ensure that your project is a success. By choosing the right fabricator, defining your requirements clearly, getting multiple quotes, inspecting the tank before it is installed, and following the manufacturer’s instructions for installation and maintenance, you can ensure that your tank meets your needs and provides years of reliable service.

Conclusion

Custom stainless steel tank fabrication is a complex and demanding process, but it is also a highly rewarding one. By following the tips outlined in this article, you can ensure that your project is a success.

Custom stainless steel tanks are essential for a wide range of industries, including food and beverage, pharmaceutical, and chemical processing. They offer a number of advantages over other types of tanks, including durability, corrosion resistance, and customizability. By understanding the process of custom stainless steel tank fabrication, you can make informed decisions about your next project.