Custom steel fabrication is a crucial aspect of modern construction, offering numerous benefits and applications. This guide explores the realm of custom steel fabrication for construction, providing valuable insights into its significance and advantages.

Editor’s Note: Custom steel fabrication for construction is a topic of utmost importance due to its impact on the structural integrity, durability, and aesthetics of buildings and infrastructure.

Through extensive research and analysis, we have compiled this comprehensive guide to assist you in making informed decisions regarding custom steel fabrication for construction projects.

Key Differences or Key Takeaways:

Main Article Topics:

Custom Steel Fabrication for Construction

Custom steel fabrication for construction encompasses several essential aspects that contribute to its significance and versatility. These key aspects include:

- Precision: Custom steel fabrication allows for precise cutting, shaping, and welding, ensuring accurate dimensions and a perfect fit.

- Strength: Steel is renowned for its exceptional strength-to-weight ratio, making it an ideal material for load-bearing structures and components.

- Durability: Steel is highly resistant to corrosion, fire, and other environmental factors, ensuring long-lasting performance.

- Flexibility: Custom steel fabrication enables the creation of complex shapes and designs, accommodating various architectural and engineering requirements.

- Sustainability: Steel is a recyclable material, contributing to eco-friendly construction practices and reducing environmental impact.

- Cost-effective: Custom steel fabrication can be cost-effective compared to other materials, especially for large-scale projects.

- Aesthetic appeal: Steel offers a modern and sleek aesthetic, complementing various architectural styles.

- Fire resistance: Steel has inherent fire resistance properties, providing an added layer of safety in construction.

- Seismic resilience: Custom steel fabrication can enhance the seismic resilience of structures, making them better equipped to withstand earthquakes.

These key aspects collectively demonstrate the importance of custom steel fabrication for construction. By combining precision, strength, durability, flexibility, sustainability, cost-effectiveness, aesthetic appeal, fire resistance, and seismic resilience, custom steel fabrication enables the creation of robust, reliable, and visually appealing structures that meet the demands of modern construction.

Precision

Precision is a critical aspect of custom steel fabrication for construction. It enables the precise cutting, shaping, and welding of steel components, ensuring accurate dimensions and a perfect fit. This precision is achieved through the use of advanced fabrication techniques and equipment, such as computer-controlled cutting machines and robotic welding systems.

The importance of precision in custom steel fabrication cannot be overstated. Accurate dimensions and a perfect fit are essential for the structural integrity and stability of buildings and infrastructure. Precision ensures that steel components fit together seamlessly, creating a strong and durable structure. It also helps to prevent costly rework and delays during construction.

For example, in the construction of a skyscraper, precision is paramount to ensure that the steel beams and columns are cut and welded to exact specifications. Any Abweichungen from the plans could compromise the structural integrity of the building and pose a safety hazard. Similarly, in the construction of bridges, precision is essential to ensure that the steel components fit together perfectly, creating a strong and reliable structure that can withstand heavy traffic and environmental loads.

In conclusion, precision is a fundamental aspect of custom steel fabrication for construction. It ensures accurate dimensions and a perfect fit, which are essential for the structural integrity, stability, and safety of buildings and infrastructure.

Table: Key Insights

| Key Insight | Explanation |

|---|---|

| Precision is essential for the structural integrity of buildings and infrastructure. | Accurate dimensions and a perfect fit ensure that steel components fit together seamlessly, creating a strong and durable structure. |

| Precision helps to prevent costly rework and delays during construction. | When steel components are cut and welded to exact specifications, they fit together perfectly, reducing the need for rework and delays. |

| Advanced fabrication techniques and equipment enable high levels of precision. | Computer-controlled cutting machines and robotic welding systems ensure accurate and consistent results. |

Strength

The exceptional strength-to-weight ratio of steel makes it an ideal material for custom steel fabrication in construction. This strength-to-weight ratio enables steel components to withstand significant loads without becoming excessively heavy or bulky.

- Structural Integrity: Steel’s strength ensures the structural integrity of buildings and infrastructure. It can withstand heavy loads, such as those imposed by tall buildings, bridges, and industrial facilities.

- Seismic Resilience: Steel’s strength contributes to the seismic resilience of structures. Steel buildings and bridges can better withstand earthquakes due to steel’s ability to absorb and dissipate seismic energy.

- Durability: The strength of steel contributes to its durability. Steel structures can withstand harsh environmental conditions, such as strong winds, heavy snow loads, and corrosive elements, without compromising their integrity.

- Design Flexibility: Steel’s strength allows for greater design flexibility. Engineers can create complex and innovative structural designs using steel, pushing the boundaries of architectural expression.

In conclusion, the exceptional strength-to-weight ratio of steel is a key factor in its suitability for custom steel fabrication in construction. It enables the creation of strong, durable, and resilient structures that can meet the demands of modern construction projects.

Durability

The durability of steel is a crucial aspect of custom steel fabrication for construction. Steel’s resistance to corrosion, fire, and other environmental factors ensures the longevity and reliability of steel structures.

- Corrosion Resistance: Steel’s resistance to corrosion, particularly when galvanized or coated with protective finishes, makes it suitable for use in harsh environments, such as coastal areas, industrial facilities, and chemical plants.

- Fire Resistance: Steel has inherent fire resistance properties. Steel structures can withstand high temperatures and maintain their structural integrity during a fire, providing valuable time for occupants to evacuate and firefighters to respond.

- Environmental Resilience: Steel is resistant to extreme weather conditions, such as strong winds, heavy snow loads, and seismic activity. Steel structures can withstand these environmental stressors without compromising their performance.

The durability of steel is a key factor in its suitability for custom steel fabrication in construction. By utilizing steel’s corrosion resistance, fire resistance, and environmental resilience, engineers can create structures that are built to last, ensuring the safety and longevity of buildings and infrastructure.

Real-Life Examples

- The Golden Gate Bridge in San Francisco, USA, is an iconic example of the durability of steel in construction. The bridge has withstood decades of harsh coastal conditions, including strong winds, fog, and salt spray, thanks to its steel construction and protective coatings.

- The Burj Khalifa in Dubai, UAE, the world’s tallest building, utilizes steel for its structural components. Steel’s strength and durability were crucial factors in the construction of this towering skyscraper, which is designed to withstand high winds and seismic activity.

Key Insights

- Steel’s durability ensures the longevity and reliability of custom steel fabricated structures.

- Steel’s resistance to corrosion, fire, and environmental factors makes it suitable for use in a wide range of construction applications.

- The durability of steel contributes to the overall safety and sustainability of buildings and infrastructure.

Table: Durability of Steel in Construction

| Property | Benefit |

|---|---|

| Corrosion Resistance | Suitable for harsh environments, extending the lifespan of structures. |

| Fire Resistance | Protects against fire damage, providing valuable time for evacuation and firefighting. |

| Environmental Resilience | Withstands extreme weather conditions and seismic activity, ensuring structural integrity. |

Flexibility

In the realm of construction, flexibility plays a pivotal role in realizing diverse architectural and engineering visions. Custom steel fabrication stands out as a versatile and adaptable solution, empowering the creation of intricate shapes and designs that cater to the unique demands of each project.

- Design Freedom: Custom steel fabrication grants architects and engineers the freedom to explore bold and innovative designs. The malleability of steel allows for the realization of complex curves, angles, and geometric patterns, pushing the boundaries of architectural expression.

- Adaptability to Site Constraints: Steel’s flexibility extends to accommodating challenging site conditions. Custom steel fabrication can be tailored to fit irregular or sloping sites, allowing for efficient use of space and adherence to specific design requirements.

- Integration with Other Materials: Steel’s compatibility with other building materials enhances its flexibility. It can be seamlessly integrated with concrete, glass, and timber, enabling the creation of hybrid structures that combine the advantages of multiple materials.

- Cost Optimization: Custom steel fabrication offers cost-effective solutions for complex designs. By optimizing the use of steel and minimizing material waste, it reduces overall construction costs while maintaining structural integrity and aesthetic appeal.

The flexibility of custom steel fabrication empowers architects and engineers to translate their creative visions into tangible structures. It unlocks the potential for innovative and sustainable designs that enhance the built environment and meet the evolving demands of modern construction.

Sustainability

The sustainability of steel is a key aspect of custom steel fabrication for construction. Steel is a recyclable material, which significantly contributes to eco-friendly construction practices and reduces environmental impact. The use of recycled steel minimizes the need for raw material extraction and reduces energy consumption during the production process.

Custom steel fabrication allows for the efficient use of steel materials, minimizing waste and optimizing resource utilization. By precisely cutting and shaping steel components, fabricators can reduce material wastage and create structures that are tailored to specific design requirements. This approach promotes sustainability by conserving resources and reducing the environmental footprint of construction projects.

The durability of steel structures also contributes to sustainability. Steel buildings and infrastructure have long lifespans, reducing the need for frequent replacements and renovations. This longevity reduces the overall environmental impact of construction and contributes to a more sustainable built environment.

Real-Life Examples

- The Mercedes-Benz Stadium in Atlanta, USA, is a LEED Platinum-certified stadium that incorporates recycled steel in its construction. The use of recycled steel helped reduce the stadium’s carbon footprint and achieve its sustainability goals.

- The Burj Khalifa in Dubai, UAE, the world’s tallest building, utilizes recycled steel in its structural components. The use of recycled steel contributed to the building’s LEED Gold certification, recognizing its sustainability and environmental performance.

Key Insights

- Custom steel fabrication promotes sustainability by utilizing recycled steel materials.

- Efficient use of steel and waste minimization contribute to resource conservation.

- Durable steel structures reduce the environmental impact of frequent replacements.

Table: Sustainability of Custom Steel Fabrication

| Aspect | Sustainability Benefit |

|---|---|

| Recycled Steel | Reduces raw material extraction and energy consumption. |

| Efficient Material Use | Minimizes waste and optimizes resource utilization. |

| Durable Structures | Reduces the need for frequent replacements and renovations. |

Cost-effective

Custom steel fabrication offers cost-effective solutions for construction projects, particularly those of large scale. Steel’s inherent strength and versatility allow for efficient use of materials, minimizing waste and reducing overall construction costs. Compared to other building materials, such as concrete or wood, steel can provide greater structural integrity and durability at a competitive price point.

The cost-effectiveness of custom steel fabrication is particularly evident in large-scale projects, such as skyscrapers, bridges, and industrial facilities. The ability to prefabricate steel components off-site and assemble them on-site streamlines the construction process, reducing labor costs and minimizing project delays. Additionally, the long lifespan of steel structures lowers maintenance and repair expenses over the building’s lifetime.

Real-Life Example

The Shanghai Tower, one of the tallest buildings in the world, utilized custom steel fabrication extensively. By optimizing the design and using high-strength steel, the project achieved significant cost savings compared to traditional construction methods. The use of prefabricated steel components also accelerated the construction timeline, reducing overall project costs.

Key Insights

- Custom steel fabrication offers cost-effective solutions for large-scale construction projects.

- Steel’s strength and versatility allow for efficient material use, minimizing waste and reducing costs.

- Prefabrication and off-site assembly streamline the construction process, saving on labor and time.

Table: Cost-effectiveness of Custom Steel Fabrication

| Aspect | Cost-saving Benefits |

|---|---|

| Material Efficiency | Minimizes waste and optimizes resource utilization. |

| Prefabrication | Streamlines construction process, reducing labor costs and project delays. |

| Durability | Lowers maintenance and repair expenses over the building’s lifetime. |

Aesthetic appeal

In the realm of construction, steel has emerged as a material of choice for its inherent aesthetic appeal. Custom steel fabrication unlocks the potential for architects and designers to create structures that are both visually striking and structurally sound.

-

Modern and Sleek Aesthetics

Steel’s smooth surface and metallic sheen lend a modern and sleek aesthetic to buildings. This aesthetic aligns with contemporary architectural trends, characterized by clean lines, sharp angles, and minimalist designs. Steel structures can seamlessly integrate with glass, concrete, and other materials, creating visually appealing facades and interiors. -

Versatility for Diverse Styles

Custom steel fabrication allows architects to explore a wide range of architectural styles, from traditional to contemporary. Steel’s flexibility enables the creation of intricate shapes and curves, accommodating both classic and avant-garde designs. This versatility makes steel an ideal choice for a variety of building types, including commercial, residential, and public structures. -

Durable Beauty

Steel’s durability ensures that its aesthetic appeal endures over time. Steel structures are resistant to corrosion, fading, and other environmental factors, maintaining their sleek appearance for decades. This durability eliminates the need for frequent repainting or repairs, preserving the building’s visual integrity and reducing maintenance costs. -

Sustainable Aesthetics

Steel’s sustainability credentials add to its aesthetic appeal. As a recyclable material, steel contributes to green building practices. Additionally, steel’s durability reduces the need for replacements and renovations, minimizing the environmental impact of construction and demolition.

In conclusion, custom steel fabrication for construction unlocks the potential for visually stunning and structurally sound buildings. Steel’s modern and sleek aesthetic, versatility for diverse styles, durable beauty, and sustainable qualities make it an ideal choice for architects and designers seeking to create iconic and enduring structures.

Fire resistance

The inherent fire resistance of steel is a key factor contributing to its suitability for custom steel fabrication in construction. This fire resistance provides an added layer of safety, ensuring the structural integrity of buildings during a fire, allowing for safe evacuation and effective firefighting.

-

Structural Stability

Steel’s high melting point and ability to maintain its strength at elevated temperatures ensure the structural stability of buildings during a fire. Steel structures can withstand intense heat without collapsing, providing valuable time for occupants to evacuate and firefighters to respond.

-

Compartmentalization

Custom steel fabrication allows for the creation of fire-resistant compartments within buildings. Steel walls and floors can be designed to contain a fire within a specific area, preventing its spread to other parts of the structure.

-

Fireproofing

Steel structures can be further enhanced with fireproofing materials, such as intumescent coatings or gypsum board. These materials expand and create a protective layer when exposed to heat, providing additional fire resistance and insulation.

-

Real-Life Examples

The World Trade Center towers in New York City withstood the intense heat of the 9/11 terrorist attacks due to their steel frames. The steel structures remained standing, allowing for the evacuation of many occupants.

In conclusion, the inherent fire resistance of steel is a crucial aspect of custom steel fabrication for construction. It provides structural stability, compartmentalization, and can be further enhanced with fireproofing materials, ensuring the safety of buildings and their occupants during a fire.

Seismic resilience

In earthquake-prone regions, custom steel fabrication plays a vital role in enhancing the seismic resilience of structures, ensuring their ability to withstand the forces of an earthquake and protect occupants.

Steel’s high strength-to-weight ratio and inherent ductility make it an ideal material for seismic-resistant construction. Steel structures can absorb and dissipate seismic energy through elastic and plastic deformation, preventing catastrophic failure. Custom steel fabrication allows engineers to design and construct structures with specific seismic performance objectives, considering factors such as ground motion intensity, soil conditions, and structural configuration.

One key aspect of seismic resilience is the use of moment-resisting frames (MRFs) in steel structures. MRFs are designed to resist lateral forces caused by earthquakes by transferring the forces through rigid connections between beams and columns. Custom steel fabrication enables the creation of strong and ductile MRFs that can withstand significant seismic loads without collapsing.

Another important aspect is the use of energy-dissipating devices in steel structures. These devices, such as dampers and base isolators, are designed to absorb and dissipate seismic energy, reducing the forces transmitted to the structure. Custom steel fabrication allows for the integration of these devices into the structural system, enhancing the overall seismic resilience of the building.

Real-life examples of the effectiveness of custom steel fabrication in seismic resilience include:

- The San Francisco-Oakland Bay Bridge, which withstood the Loma Prieta earthquake in 1989 with minimal damage, thanks to its innovative seismic design and the use of custom-fabricated steel components.

- The Taipei 101 skyscraper in Taiwan, which remained standing after the 1999 Chi-Chi earthquake due to its advanced seismic design and the use of high-strength steel.

In conclusion, custom steel fabrication is a crucial component of seismic-resistant construction, providing the strength, ductility, and energy-dissipating capabilities necessary to withstand earthquakes and protect lives.

| Key Insight | Practical Significance |

|---|---|

| Steel’s high strength-to-weight ratio and ductility make it an ideal material for seismic-resistant construction. | Custom steel fabrication allows engineers to design structures that can withstand significant seismic loads without collapsing. |

| Moment-resisting frames (MRFs) and energy-dissipating devices enhance the seismic resilience of steel structures. | Custom steel fabrication enables the integration of these elements into the structural system, improving the building’s ability to withstand earthquakes. |

| Real-life examples demonstrate the effectiveness of custom steel fabrication in seismic-resistant construction. | Structures designed and built using custom steel fabrication have successfully withstood major earthquakes, protecting occupants and minimizing damage. |

FAQs on Custom Steel Fabrication for Construction

This section addresses frequently asked questions about custom steel fabrication for construction, providing clear and informative answers to common concerns and misconceptions.

Question 1: What are the advantages of using custom steel fabrication in construction?

Custom steel fabrication offers several advantages, including precision, strength, durability, flexibility, cost-effectiveness, aesthetic appeal, fire resistance, and seismic resilience. Steel’s inherent properties and the ability to tailor it to specific project requirements make it an ideal material for a wide range of construction applications.

Question 2: Is custom steel fabrication expensive?

While the cost of custom steel fabrication can vary depending on the complexity of the project, it can be a cost-effective solution for large-scale projects. Steel’s strength-to-weight ratio allows for efficient use of materials, minimizing waste and reducing overall construction costs.

Question 3: How durable are steel structures?

Steel structures are renowned for their exceptional durability. Steel’s resistance to corrosion, fire, and other environmental factors ensures long-lasting performance. Proper maintenance and protective coatings further enhance steel’s durability, resulting in structures that can withstand the test of time.

Question 4: Can custom steel fabrication accommodate complex designs?

Custom steel fabrication excels in accommodating complex and innovative designs. Steel’s flexibility allows for the creation of intricate shapes and angles, enabling architects and engineers to translate their creative visions into tangible structures.

Question 5: How does custom steel fabrication contribute to sustainability?

Custom steel fabrication promotes sustainability through the use of recycled materials and efficient material utilization. Steel is a recyclable material, reducing the need for raw material extraction and minimizing environmental impact. Additionally, steel structures’ durability reduces the frequency of replacements and renovations, further contributing to sustainability.

Question 6: What are the fire resistance properties of steel?

Steel has inherent fire resistance properties due to its high melting point and ability to maintain structural integrity at elevated temperatures. Custom steel fabrication allows for the creation of fire-resistant compartments and the integration of fireproofing materials, enhancing the safety of buildings and occupants during a fire.

Summary

Custom steel fabrication for construction offers numerous benefits and applications, making it a versatile and reliable solution for various building and infrastructure projects. Its precision, strength, durability, flexibility, cost-effectiveness, aesthetic appeal, fire resistance, and seismic resilience make it an ideal choice for architects, engineers, and construction professionals seeking to create safe, durable, and visually stunning structures.

Transition to the next article section

The next section will delve into the specific applications of custom steel fabrication in different construction sectors, exploring its role in shaping modern skylines and infrastructure.

Tips for Custom Steel Fabrication in Construction

Custom steel fabrication offers a multitude of advantages for construction projects. By following these tips, you can harness its full potential and achieve optimal results:

Tip 1: Plan meticulously

Thorough planning is crucial for successful custom steel fabrication. Clearly define project requirements, including dimensions, specifications, and timelines. Collaboration between architects, engineers, and fabricators ensures smooth execution and avoids costly delays.

Tip 2: Choose the right steel grade

Selecting the appropriate steel grade is essential for structural integrity and performance. Consider factors such as strength, corrosion resistance, and weldability. Consult with material experts to determine the optimal grade for your specific application.

Tip 3: Utilize advanced fabrication techniques

Modern fabrication techniques, such as laser cutting and robotic welding, ensure precision and efficiency. These technologies minimize material waste, enhance structural accuracy, and expedite project completion.

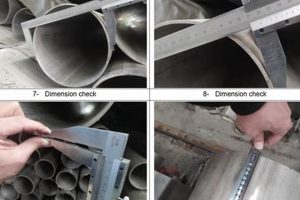

Tip 4: Ensure quality control

Implement rigorous quality control measures throughout the fabrication process. Inspect materials, monitor workmanship, and conduct non-destructive testing to guarantee the structural integrity and safety of the final product.

Tip 5: Consider sustainability

Embrace sustainable practices by using recycled steel and minimizing material waste. Design structures for durability to reduce the need for frequent replacements and renovations. This contributes to environmental conservation and resource preservation.

Summary

By adhering to these tips, you can leverage the full potential of custom steel fabrication for construction projects. Meticulous planning, careful material selection, advanced fabrication techniques, stringent quality control, and sustainability considerations will result in robust, durable, and visually appealing structures that stand the test of time.

Transition to the conclusion

Custom steel fabrication is a powerful tool in the hands of architects, engineers, and construction professionals. By embracing best practices and harnessing its versatility, we can create structures that are not only functional and safe but also aesthetically pleasing and sustainable.

Conclusion

Custom steel fabrication has emerged as a cornerstone of modern construction, offering a unique combination of precision, strength, durability, flexibility, cost-effectiveness, aesthetic appeal, fire resistance, and seismic resilience. This comprehensive exploration has shed light on the remarkable properties and diverse applications of custom steel fabrication, demonstrating its potential to transform the built environment.

As we continue to push the boundaries of architectural design and engineering innovation, custom steel fabrication will undoubtedly play an increasingly vital role. Its versatility empowers architects and engineers to realize their creative visions, while its durability and sustainability ensure structures that endure the test of time. By embracing the potential of custom steel fabrication, we can create a built environment that is not only functional and safe but also aesthetically pleasing and environmentally responsible.