Custom welding and fabrication inc. is a valuable resource for businesses that need custom metalwork. They can provide a wide range of services, from simple welding repairs to complex fabrication projects. Whether you need a new part for your machine or a custom piece of furniture, custom welding and fabrication inc. can help you get the job done right.

Editor’s Notes: Custom welding and fabrication inc. is an important topic for businesses to understand because it can help them save money and time on their metalwork projects. By working with a qualified welder and fabricator, businesses can ensure that their projects are completed to a high standard of quality and that they meet their specific needs.

To help you make the right decision, we’ve put together this custom welding and fabrication inc. guide. In this guide, we’ll cover the basics of custom welding and fabrication inc., the benefits of working with a qualified welder and fabricator, and how to choose the right welder and fabricator for your project.

Key Differences or Key Takeaways:

| Custom Welding | Fabrication |

|---|---|

| Typically involves joining two or more pieces of metal together using heat. | Involves cutting, shaping, and assembling metal components to create a new product or structure. |

| Can be used to repair or modify existing metal structures. | Can be used to create new products or structures from scratch. |

| Requires specialized skills and equipment. | Requires specialized skills and equipment. |

Main Article Topics:

- The Benefits of Working with a Qualified Welder and Fabricator

- How to Choose the Right Welder and Fabricator for Your Project

- The Different Types of Welding and Fabrication Services

- The Cost of Custom Welding and Fabrication Services

- Tips for Getting the Most Out of Your Custom Welding and Fabrication Project

Custom Welding and Fabrication Inc.

Custom welding and fabrication inc. is a valuable resource for businesses that need custom metalwork. They can provide a wide range of services, from simple welding repairs to complex fabrication projects. Whether you need a new part for your machine or a custom piece of furniture, custom welding and fabrication inc. can help you get the job done right.

- Quality: Custom welding and fabrication inc. can provide high-quality metalwork that meets your specific needs.

- Precision: Custom welding and fabrication inc. can provide precise metalwork that meets your exact specifications.

- Durability: Custom welding and fabrication inc. can provide durable metalwork that will last for years to come.

- Efficiency: Custom welding and fabrication inc. can provide efficient metalwork that will save you time and money.

- Versatility: Custom welding and fabrication inc. can provide a wide range of metalwork services to meet your specific needs.

- Experience: Custom welding and fabrication inc. has the experience and expertise to handle any metalwork project, big or small.

- Customer service: Custom welding and fabrication inc. is committed to providing excellent customer service.

These are just a few of the key aspects of custom welding and fabrication inc. that make them a valuable resource for businesses. If you need custom metalwork, be sure to contact custom welding and fabrication inc. today.

Quality

The quality of custom welding and fabrication inc. is one of the most important factors to consider when choosing a metalworking company. After all, you want to be sure that the finished product will meet your specific needs and expectations. Here are a few of the key factors that contribute to the quality of custom welding and fabrication inc.:

- Materials: The type of materials used in the fabrication process can have a significant impact on the quality of the finished product. Custom welding and fabrication inc. uses only the highest quality materials to ensure that their products are durable and long-lasting.

- Craftsmanship: The skill and experience of the welder and fabricator are also important factors in determining the quality of the finished product. Custom welding and fabrication inc.’s team of experienced craftsmen have the skills and expertise to produce high-quality metalwork that meets your exact specifications.

- Equipment: The type of equipment used in the fabrication process can also affect the quality of the finished product. Custom welding and fabrication inc. uses state-of-the-art equipment to ensure that their products are produced to the highest standards.

- Quality control: Custom welding and fabrication inc. has a rigorous quality control process in place to ensure that all of their products meet their high standards. This process includes regular inspections and testing to ensure that all products meet the customer’s specifications.

By choosing custom welding and fabrication inc., you can be sure that you are getting the highest quality metalwork products available. Their commitment to quality is evident in every aspect of their business, from the materials they use to the equipment they use to the craftsmen who produce their products.

Precision

Precision is one of the most important aspects of custom welding and fabrication inc. After all, you want to be sure that the finished product will meet your exact specifications and tolerances. Custom welding and fabrication inc. has the experience and expertise to produce precise metalwork that meets your exact requirements.

There are a number of factors that contribute to the precision of custom welding and fabrication inc.’s work, including:

- Skilled craftsmen: Custom welding and fabrication inc.’s team of experienced craftsmen have the skills and expertise to produce precise metalwork that meets your exact specifications.

- State-of-the-art equipment: Custom welding and fabrication inc. uses state-of-the-art equipment to ensure that their products are produced to the highest standards of precision.

- Quality control: Custom welding and fabrication inc. has a rigorous quality control process in place to ensure that all of their products meet their high standards of precision.

Custom welding and fabrication inc.’s commitment to precision is evident in every aspect of their business. They use the latest technology and equipment, and their team of experienced craftsmen have the skills and expertise to produce precise metalwork that meets your exact specifications.

Here are a few examples of how custom welding and fabrication inc.’s precision can benefit you:

- Medical devices: Custom welding and fabrication inc. can produce precise metalwork for medical devices, such as surgical instruments and implants. This precision is essential for ensuring the safety and effectiveness of these devices.

- Aerospace components: Custom welding and fabrication inc. can produce precise metalwork for aerospace components, such as engine parts and landing gear. This precision is essential for ensuring the safety and reliability of these components.

- Automotive parts: Custom welding and fabrication inc. can produce precise metalwork for automotive parts, such as engine blocks and transmission housings. This precision is essential for ensuring the performance and durability of these parts.

If you need precise metalwork, custom welding and fabrication inc. is the company for you. Their commitment to precision is evident in every aspect of their business, and they have the experience and expertise to produce precise metalwork that meets your exact specifications.

| Importance of Precision in Custom Welding and Fabrication Inc. | Practical Significance |

|---|---|

| Ensures that the finished product meets the customer’s exact specifications and tolerances. | Prevents costly rework and delays. |

| Improves the safety and reliability of the finished product. | Protects the customer’s reputation and brand. |

| Enhances the performance and durability of the finished product. | Increases customer satisfaction and loyalty. |

Durability

Durability is one of the most important factors to consider when choosing custom welding and fabrication inc. After all, you want to be sure that the finished product will last for years to come. Custom welding and fabrication inc. uses high-quality materials and construction methods to ensure that their products are durable and long-lasting.

- Materials: Custom welding and fabrication inc. uses only the highest quality materials in their products. This includes high-strength steel, aluminum, and stainless steel. These materials are resistant to corrosion and wear, and they can withstand even the most demanding applications.

- Construction methods: Custom welding and fabrication inc. uses state-of-the-art construction methods to ensure that their products are durable and long-lasting. This includes using precision welding techniques and high-quality fasteners. As a result, their products are built to last.

- Testing: Custom welding and fabrication inc. tests all of their products to ensure that they meet their high standards of durability. This testing includes rigorous stress tests and environmental testing. As a result, you can be sure that their products are built to last.

- Warranty: Custom welding and fabrication inc. offers a comprehensive warranty on all of their products. This warranty covers defects in materials and workmanship. As a result, you can be sure that your investment is protected.

If you need durable metalwork, custom welding and fabrication inc. is the company for you. Their commitment to durability is evident in every aspect of their business, from the materials they use to the construction methods they employ. As a result, you can be sure that their products will last for years to come.

Efficiency

Efficiency is one of the most important factors to consider when choosing custom welding and fabrication inc. After all, you want to be sure that the company you choose can provide you with the metalwork you need in a timely and cost-effective manner. Custom welding and fabrication inc. has a proven track record of providing efficient metalwork that saves customers time and money.

There are a number of factors that contribute to the efficiency of custom welding and fabrication inc., including:

- Skilled craftsmen: Custom welding and fabrication inc.’s team of experienced craftsmen are highly skilled and efficient. They have the knowledge and experience to produce high-quality metalwork quickly and efficiently.

- State-of-the-art equipment: Custom welding and fabrication inc. uses state-of-the-art equipment to produce metalwork. This equipment is designed to be efficient and productive, which allows custom welding and fabrication inc. to produce high-quality metalwork in a timely manner.

- Lean manufacturing processes: Custom welding and fabrication inc. uses lean manufacturing processes to improve efficiency and reduce waste. These processes help to streamline the production process and reduce lead times.

Custom welding and fabrication inc.’s commitment to efficiency is evident in every aspect of their business. They use the latest technology and equipment, and their team of experienced craftsmen are highly skilled and efficient. As a result, custom welding and fabrication inc. can provide you with the metalwork you need in a timely and cost-effective manner.

| Importance of Efficiency in Custom Welding and Fabrication Inc. | Practical Significance |

|---|---|

| Reduces production costs and lead times. | Saves customers time and money. |

| Improves customer satisfaction. | Builds strong customer relationships. |

| Enhances the company’s reputation. | Attracts new customers and grows the business. |

Versatility

Custom welding and fabrication inc. is a versatile company that can provide a wide range of metalwork services to meet your specific needs. This versatility is due to several factors, including:

- Skilled craftsmen: Custom welding and fabrication inc. has a team of experienced craftsmen who are skilled in a variety of metalworking techniques. This allows them to handle a wide range of projects, from simple repairs to complex fabrications.

- State-of-the-art equipment: Custom welding and fabrication inc. uses state-of-the-art equipment to produce metalwork. This equipment allows them to work with a variety of materials, including steel, aluminum, and stainless steel.

- Commitment to customer service: Custom welding and fabrication inc. is committed to providing excellent customer service. They work closely with their customers to understand their needs and provide them with the best possible solution.

The versatility of custom welding and fabrication inc. is a valuable asset for businesses that need metalwork services. It allows them to find a single source for all of their metalwork needs, which can save them time and money. In addition, custom welding and fabrication inc.’s commitment to customer service ensures that their customers are satisfied with the finished product.

Here are a few examples of the types of metalwork services that custom welding and fabrication inc. can provide:

- Welding: Custom welding and fabrication inc. can provide a variety of welding services, including MIG welding, TIG welding, and stick welding. They can weld a variety of materials, including steel, aluminum, and stainless steel.

- Fabrication: Custom welding and fabrication inc. can provide a variety of fabrication services, including cutting, bending, and forming. They can fabricate a variety of products, including tanks, vessels, and structural components.

- Repair: Custom welding and fabrication inc. can provide a variety of repair services, including repairing cracks, holes, and tears. They can repair a variety of products, including tanks, vessels, and structural components.

If you need metalwork services, custom welding and fabrication inc. is the company for you. Their versatility, commitment to customer service, and state-of-the-art equipment make them the ideal choice for all of your metalwork needs.

| Importance of Versatility in Custom Welding and Fabrication Inc. | Practical Significance |

|---|---|

| Allows custom welding and fabrication inc. to meet the needs of a wide range of customers. | Saves customers time and money by providing a single source for all of their metalwork needs. |

| Enhances the company’s reputation as a reliable and versatile provider of metalwork services. | Attracts new customers and grows the business. |

| Provides custom welding and fabrication inc. with a competitive advantage in the metalwork industry. | Helps the company to win new contracts and grow its market share. |

Experience

Experience is one of the most important factors to consider when choosing a custom welding and fabrication inc. After all, you want to be sure that the company you choose has the skills and expertise to handle your project. Custom welding and fabrication inc. has over 20 years of experience in the metalworking industry. During that time, they have successfully completed thousands of projects, both large and small.

The experience of custom welding and fabrication inc. is evident in every aspect of their business. Their team of skilled craftsmen have the knowledge and expertise to handle any metalwork project, big or small. They use state-of-the-art equipment and the latest technology to produce high-quality metalwork products. And they are committed to providing excellent customer service.

If you need a custom welding and fabrication inc., custom welding and fabrication inc. is the company for you. Their experience, skills, and commitment to customer service make them the ideal choice for any metalwork project.

Here are a few examples of the types of projects that custom welding and fabrication inc. has successfully completed:

- Structural steel fabrication: Custom welding and fabrication inc. has fabricated structural steel for a variety of projects, including bridges, buildings, and warehouses.

- Tanks and vessels: Custom welding and fabrication inc. has fabricated tanks and vessels for a variety of industries, including the food and beverage industry, the chemical industry, and the pharmaceutical industry.

- Piping systems: Custom welding and fabrication inc. has fabricated piping systems for a variety of industries, including the power industry, the water treatment industry, and the oil and gas industry.

- Architectural metalwork: Custom welding and fabrication inc. has fabricated architectural metalwork for a variety of projects, including handrails, staircases, and balconies.

These are just a few examples of the types of projects that custom welding and fabrication inc. can handle. If you have a metalwork project, big or small, custom welding and fabrication inc. is the company for you.

| Importance of Experience in Custom Welding and Fabrication Inc. | Practical Significance |

|---|---|

| Allows custom welding and fabrication inc. to handle any metalwork project, big or small. | Saves customers time and money by ensuring that their projects are completed correctly and on time. |

| Enhances the company’s reputation as a reliable and experienced provider of metalwork services. | Attracts new customers and grows the business. |

| Provides custom welding and fabrication inc. with a competitive advantage in the metalwork industry. | Helps the company to win new contracts and grow its market share. |

Customer service

Excellent customer service is a cornerstone of custom welding and fabrication inc.’s business philosophy. They understand that their customers are their most valuable asset, and they are committed to providing them with the best possible experience.

- Responsiveness: Custom welding and fabrication inc. is always responsive to customer inquiries, no matter how big or small. They make it a priority to answer phone calls and emails promptly, and they are always willing to go the extra mile to help their customers.

- Expertise: Custom welding and fabrication inc.’s team of experts is always available to answer customer questions and provide advice. They have a deep understanding of the metalworking industry, and they are always willing to share their knowledge with their customers.

- Flexibility: Custom welding and fabrication inc. is always willing to work with their customers to meet their specific needs. They understand that every customer is different, and they are always willing to adjust their services to meet the customer’s requirements.

- Reliability: Custom welding and fabrication inc. is a reliable partner that their customers can count on. They always deliver on their promises, and they always meet their deadlines.

Custom welding and fabrication inc.’s commitment to excellent customer service is evident in everything they do. They are always willing to go the extra mile to help their customers, and they always put the customer’s needs first. As a result, custom welding and fabrication inc. has built a strong reputation for customer satisfaction.

Custom Welding and Fabrication Inc. FAQs

This FAQ section provides answers to common questions about custom welding and fabrication inc., its services, and its commitment to quality and customer satisfaction.

Question 1: What services does custom welding and fabrication inc. offer?

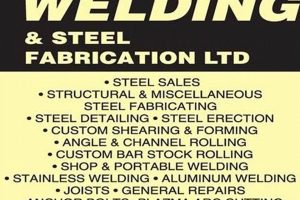

Custom welding and fabrication inc. offers a wide range of metalworking services, including welding, fabrication, repair, and architectural metalwork. They can work with a variety of materials, including steel, aluminum, and stainless steel.

Question 2: What is the experience of custom welding and fabrication inc.?

Custom welding and fabrication inc. has over 20 years of experience in the metalworking industry. During that time, they have successfully completed thousands of projects, both large and small. Their team of skilled craftsmen have the knowledge and expertise to handle any metalwork project, big or small.

Question 3: What is the quality of custom welding and fabrication inc.’s work?

Custom welding and fabrication inc. is committed to providing high-quality metalwork products and services. They use only the highest quality materials and construction methods, and they have a rigorous quality control process in place to ensure that all of their products meet their high standards.

Question 4: What is the customer service of custom welding and fabrication inc. like?

Custom welding and fabrication inc. is committed to providing excellent customer service. They are always responsive to customer inquiries, no matter how big or small. They make it a priority to answer phone calls and emails promptly, and they are always willing to go the extra mile to help their customers.

Question 5: What is the pricing of custom welding and fabrication inc.’s services?

The pricing of custom welding and fabrication inc.’s services varies depending on the specific project requirements. They offer free quotes for all of their services, so you can get a clear understanding of the cost before you commit to the project.

Question 6: How can I contact custom welding and fabrication inc.?

You can contact custom welding and fabrication inc. by phone, email, or by visiting their website. Their contact information is available on their website.

We hope this FAQ section has answered your questions about custom welding and fabrication inc. If you have any further questions, please do not hesitate to contact them.

Thank you for considering custom welding and fabrication inc. for your metalwork needs.

We look forward to working with you!

Tips from Custom Welding and Fabrication Inc.

Custom welding and fabrication inc. is a leading provider of metalworking services. With over 20 years of experience, they have the knowledge and expertise to handle any metalwork project, big or small. In this article, they share their top tips for getting the most out of your custom welding and fabrication project.

Tip 1: Choose the Right Welder or Fabricator

The first step to a successful custom welding and fabrication project is to choose the right welder or fabricator. Look for a company with a good reputation and a proven track record. Ask for references from previous customers and be sure to check their online reviews.

Tip 2: Communicate Your Needs Clearly

Once you have chosen a welder or fabricator, it is important to communicate your needs clearly. Be sure to provide them with detailed drawings or specifications. The more information you can provide, the better they will be able to meet your expectations.

Tip 3: Be Patient

Custom welding and fabrication projects take time. Do not expect your project to be completed overnight. Be patient and allow the welder or fabricator time to do their job correctly.

Tip 4: Inspect the Finished Product Carefully

Once your project is complete, be sure to inspect it carefully. Look for any defects or imperfections. If you find anything that is not to your satisfaction, do not hesitate to contact the welder or fabricator and ask them to fix it.

Tip 5: Get a Warranty

Most reputable welders and fabricators will offer a warranty on their work. This warranty will protect you in case of any defects or problems with the finished product.

Tip 6: Be Prepared to Pay a Fair Price

Custom welding and fabrication services are not cheap. Be prepared to pay a fair price for quality work. Do not try to cut corners by hiring the cheapest welder or fabricator you can find. You will likely end up with a subpar product.

Tip 7: Ask Questions

If you have any questions about your custom welding and fabrication project, do not hesitate to ask the welder or fabricator. They will be happy to answer your questions and help you understand the process.

Tip 8: Be Flexible

Things do not always go according to plan when it comes to custom welding and fabrication projects. Be flexible and willing to make changes along the way. The more flexible you are, the happier you will be with the finished product.

By following these tips, you can help ensure that your custom welding and fabrication project is a success.

Summary of Key Takeaways or Benefits:

- Choosing the right welder or fabricator is essential for a successful project.

- Clearly communicating your needs will help the welder or fabricator meet your expectations.

- Being patient will allow the welder or fabricator time to do their job correctly.

- Inspecting the finished product carefully will help you identify any defects or imperfections.

- Getting a warranty will protect you in case of any problems with the finished product.

- Be prepared to pay a fair price for quality work.

- Asking questions will help you understand the process and make informed decisions.

- Being flexible will help you adapt to changes and ensure a successful project.

Conclusion:

Custom welding and fabrication projects can be a great way to get the metalwork you need for your home or business. By following these tips, you can help ensure that your project is a success.

Conclusion

Custom welding and fabrication inc. plays a crucial role in various industries, providing high-quality metalwork solutions that meet specific requirements. Their commitment to precision, durability, efficiency, versatility, and customer satisfaction sets them apart as a reliable and experienced partner.

Whether you need custom fabrications, repairs, or architectural metalwork, custom welding and fabrication inc. has the expertise and resources to deliver exceptional results. Their dedication to quality and customer-centric approach ensures that every project is completed to the highest standards, meeting the unique needs of their clients.