What is customized metal fabrication services and why is it important? This question has been asked by business owners and manufacturers for decades as they seek to find the best way to create custom metal products.

Editor’s Notes: Customized metal fabrication services is a critical topic for businesses that need to create custom metal products. By understanding the different types of services available and the benefits of each, businesses can make informed decisions about the best way to meet their needs.

After doing extensive research and analysis, we’ve compiled this guide to aid businesses in understanding customized metal fabrication services and making the right decisions for their specific needs.

Key Differences or Key Takeaways| Feature | Customized Metal Fabrication Services ||—|—|| Definition | The process of creating custom metal products to meet the specific needs of a customer. || Benefits | Allows for the creation of unique and tailored metal products, often with shorter lead times and lower costs than traditional manufacturing methods. || Applications | Used in a wide range of industries, including automotive, aerospace, construction, and medical.

Transition to main article topics

In this article, we will explore the different types of customized metal fabrication services available, the benefits of using these services, and the factors to consider when choosing a provider. We will also provide some tips on how to get the most out of your customized metal fabrication services experience.

Customized Metal Fabrication Services

Customized metal fabrication services are essential for businesses that need to create custom metal products. These services offer a number of benefits, including the ability to create unique and tailored products, often with shorter lead times and lower costs than traditional manufacturing methods. Here are seven key aspects of customized metal fabrication services to consider:

- Design: Customized metal fabrication services can help you design and engineer your custom metal product, ensuring that it meets your specific needs and requirements.

- Materials: You can choose from a variety of materials, including steel, aluminum, stainless steel, and more, to create your custom metal product.

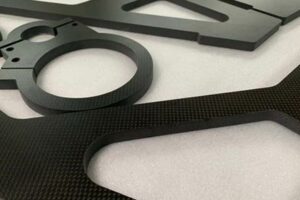

- Fabrication: The fabrication process involves cutting, bending, welding, and finishing the metal to create your custom product.

- Quality: Customized metal fabrication services can provide high-quality products that meet or exceed your expectations.

- Cost: Customized metal fabrication services can be cost-effective, especially for small businesses or businesses that need to create unique products.

- Timeline: Customized metal fabrication services can often provide quick turnaround times, so you can get your custom product when you need it.

- Experience: Choose a customized metal fabrication service with experience in your industry to ensure that they understand your needs and can provide the best possible service.

These are just a few of the key aspects of customized metal fabrication services to consider. By understanding these aspects, you can make informed decisions about the best way to meet your needs.

Design

Design is a critical aspect of customized metal fabrication services, as it ensures that the final product meets the specific needs and requirements of the customer. This involves working closely with the customer to understand their vision and then translating that vision into a design that can be fabricated. The design process typically includes:

- Consultation: The first step is to consult with the customer to understand their needs and requirements. This includes discussing the intended use of the product, the materials that will be used, and the budget.

- Design: Once the consultation is complete, the designer will create a design for the product. This design will be based on the customer’s needs and requirements, as well as the designer’s own experience and expertise.

- Engineering: Once the design is complete, the engineer will create a set of engineering drawings. These drawings will specify the dimensions of the product, the materials that will be used, and the fabrication process that will be followed.

- Prototyping: In some cases, the customer may request a prototype of the product before it is fabricated. This allows the customer to see the product and make any necessary changes before it is put into production.

By working closely with the customer throughout the design process, customized metal fabrication services can ensure that the final product meets their specific needs and requirements.

Materials

The choice of materials is a critical aspect of customized metal fabrication services, as it affects the final product’s properties, performance, and cost. Customized metal fabrication services can provide expert guidance on the selection of materials based on the specific needs and requirements of the customer. Here are some of the most common materials used in customized metal fabrication:

- Steel: Steel is a strong and durable material that is relatively inexpensive. It is often used for structural applications, such as beams, columns, and plates.

- Aluminum: Aluminum is a lightweight and corrosion-resistant material that is often used for applications where weight is a concern, such as aircraft and automotive parts.

- Stainless steel: Stainless steel is a corrosion-resistant material that is often used for applications where hygiene is important, such as food processing equipment and medical devices.

In addition to these common materials, customized metal fabrication services can also work with a variety of other materials, including copper, brass, bronze, and titanium. The choice of material will depend on the specific needs and requirements of the customer.

By understanding the different materials available and their properties, customized metal fabrication services can help customers select the right material for their custom metal product.

Real-life examples:

- A customer needs a custom metal bracket for a new product. The bracket must be strong and durable, but it also needs to be lightweight. The customized metal fabrication service recommends using aluminum for the bracket, as it is lightweight and strong, and it can be easily welded and machined.

- A customer needs a custom metal enclosure for a new electronic device. The enclosure must be corrosion-resistant and able to withstand harsh environmental conditions. The customized metal fabrication service recommends using stainless steel for the enclosure, as it is corrosion-resistant and durable.

These are just a few examples of how customized metal fabrication services can help customers select the right materials for their custom metal products.

| Material | Properties | Applications |

|---|---|---|

| Steel | Strong, durable, inexpensive | Structural applications, beams, columns, plates |

| Aluminum | Lightweight, corrosion-resistant | Aircraft and automotive parts, applications where weight is a concern |

| Stainless steel | Corrosion-resistant | Food processing equipment, medical devices, applications where hygiene is important |

Fabrication

Fabrication is a critical step in the customized metal fabrication process, as it is where the raw materials are transformed into the finished product. This process involves a variety of techniques, including cutting, bending, welding, and finishing. Each of these techniques plays an important role in the fabrication process, and customized metal fabrication services have the expertise and experience to ensure that each step is performed to the highest quality standards.

- Cutting: Cutting is the process of separating the metal into the desired shapes and sizes. This can be done using a variety of methods, including waterjet cutting, laser cutting, and plasma cutting. Customized metal fabrication services can select the best cutting method for the specific material and application.

- Bending: Bending is the process of shaping the metal into the desired angles and curves. This can be done using a variety of methods, including press brake bending, roll bending, and hand bending. Customized metal fabrication services have the equipment and expertise to bend metal to precise specifications.

- Welding: Welding is the process of joining two or more pieces of metal together. This can be done using a variety of methods, including MIG welding, TIG welding, and spot welding. Customized metal fabrication services have the experience and expertise to select the best welding method for the specific material and application.

- Finishing: Finishing is the process of giving the metal product a desired surface finish. This can be done using a variety of methods, including painting, powder coating, and plating. Customized metal fabrication services can select the best finishing method for the specific material and application.

By understanding the fabrication process and the different techniques involved, customized metal fabrication services can ensure that your custom metal product is fabricated to the highest quality standards and meets your specific needs and requirements.

Quality

Quality is a critical aspect of customized metal fabrication services, as it ensures that the final product meets or exceeds the customer’s expectations. Customized metal fabrication services have a number of quality control measures in place to ensure that their products are of the highest quality, including:

- Material inspection: All materials are inspected before they are used in the fabrication process to ensure that they meet the required specifications.

- Process control: The fabrication process is closely controlled to ensure that all products are fabricated to the same high standards.

- Product inspection: All products are inspected before they are shipped to the customer to ensure that they meet the required specifications.

By implementing these quality control measures, customized metal fabrication services can ensure that their products are of the highest quality and meet or exceed the customer’s expectations.

There are a number of benefits to using customized metal fabrication services that provide high-quality products, including:

- Reduced risk of product failure: High-quality products are less likely to fail, which can save businesses time and money.

- Improved customer satisfaction: Customers are more likely to be satisfied with products that meet or exceed their expectations.

- Increased brand reputation: Businesses that provide high-quality products are more likely to develop a good reputation in the market.

Overall, using customized metal fabrication services that provide high-quality products can help businesses improve their bottom line and build a strong brand reputation.

| Benefit | Description |

|---|---|

| Reduced risk of product failure | High-quality products are less likely to fail, which can save businesses time and money. |

| Improved customer satisfaction | Customers are more likely to be satisfied with products that meet or exceed their expectations. |

| Increased brand reputation | Businesses that provide high-quality products are more likely to develop a good reputation in the market. |

Cost

Customized metal fabrication services can be a cost-effective option for businesses of all sizes, but they can be especially beneficial for small businesses and businesses that need to create unique products.

- Lower tooling costs: Customized metal fabrication services often use less tooling than traditional manufacturing methods, which can save businesses money.

- Reduced material waste: Customized metal fabrication services can use advanced cutting techniques to minimize material waste, which can also save businesses money.

- Faster turnaround times: Customized metal fabrication services can often provide faster turnaround times than traditional manufacturing methods, which can help businesses get their products to market faster.

- Flexibility: Customized metal fabrication services can be flexible and responsive to changes in design or production schedules, which can be helpful for businesses that need to make quick changes to their products.

Overall, customized metal fabrication services can be a cost-effective option for businesses of all sizes, but they can be especially beneficial for small businesses and businesses that need to create unique products.

Timeline

Customized metal fabrication services are known for providing quick turnaround times, ensuring that businesses can get their custom products when they need them. This is a critical advantage, especially for businesses that operate in fast-paced industries or have urgent production needs. The ability to get custom metal products quickly can help businesses meet deadlines, reduce downtime, and respond to unexpected changes in demand.

- Reduced lead times: Customized metal fabrication services often have shorter lead times than traditional manufacturing methods, as they do not require the creation of expensive tooling or molds. This can be a significant advantage for businesses that need to get their products to market quickly.

- Flexibility: Customized metal fabrication services are flexible and responsive, which means that they can accommodate changes in design or production schedules. This can be helpful for businesses that need to make quick changes to their products or meet unexpected demand.

- Faster prototyping: Customized metal fabrication services can quickly create prototypes, which can help businesses test new designs and get feedback from customers before committing to full production.

Overall, the quick turnaround times offered by customized metal fabrication services provide businesses with a number of advantages, including reduced lead times, flexibility, and faster prototyping. These advantages can help businesses meet deadlines, reduce downtime, and respond to unexpected changes in demand.

Experience

When choosing a customized metal fabrication service, it is important to select a provider with experience in your industry. This is because a provider with industry experience will have a deep understanding of the specific needs and requirements of your business. They will be familiar with the materials, processes, and standards that are used in your industry, and they will be able to provide you with the best possible service.

For example, if you are a manufacturer of medical devices, you will need to choose a customized metal fabrication service that has experience in the medical industry. This is because medical devices are subject to strict regulations, and a provider with experience in the medical industry will be familiar with these regulations and will be able to ensure that your products meet all of the necessary requirements.

Another reason to choose a customized metal fabrication service with experience in your industry is that they will be able to provide you with valuable advice and guidance. They will be able to help you select the right materials for your products, and they will be able to recommend the best processes for fabricating your products. This advice and guidance can help you save time and money, and it can help you ensure that your products are of the highest quality.

Overall, choosing a customized metal fabrication service with experience in your industry is important for ensuring that you receive the best possible service. A provider with industry experience will have a deep understanding of your needs and requirements, and they will be able to provide you with valuable advice and guidance. This can help you save time and money, and it can help you ensure that your products are of the highest quality.

| Benefit | Description |

|---|---|

| Reduced risk of product failure | A provider with industry experience will be familiar with the materials, processes, and standards that are used in your industry. This means that they will be able to fabricate your products to the highest quality standards, reducing the risk of product failure. |

| Improved customer satisfaction | A provider with industry experience will be able to provide you with valuable advice and guidance. This can help you select the right materials for your products and the best processes for fabricating your products. This can lead to improved customer satisfaction, as you will be able to provide your customers with high-quality products that meet their needs. |

| Increased brand reputation | By choosing a provider with industry experience, you can help to increase your brand reputation. This is because a provider with industry experience will be able to provide you with high-quality products that meet the needs of your customers. This will help to build trust and loyalty with your customers, and it will help to increase your brand reputation. |

Customized Metal Fabrication Services

This FAQ section addresses common concerns and misconceptions about customized metal fabrication services, providing concise and informative answers.

Question 1: What are the benefits of using customized metal fabrication services?

Answer: Customized metal fabrication services offer numerous benefits, including the ability to create unique and tailored metal products, often with shorter lead times and lower costs than traditional manufacturing methods.

Question 2: What materials are available for customized metal fabrication?

Answer: A wide range of materials is available, including steel, aluminum, stainless steel, copper, brass, bronze, and titanium. The choice of material depends on the specific needs and requirements of the application.

Question 3: How does the design process work for customized metal fabrication?

Answer: The design process typically involves consultation, design, engineering, and prototyping stages, ensuring that the final product meets the customer’s specifications and functional requirements.

Question 4: What industries commonly utilize customized metal fabrication services?

Answer: Customized metal fabrication services find applications in various industries, including automotive, aerospace, construction, medical, energy, and consumer products.

Question 5: How do I choose a reputable customized metal fabrication service provider?

Answer: Consider factors such as the provider’s experience in your industry, quality control measures, turnaround time, and customer reviews to make an informed decision.

Question 6: What are the cost considerations for customized metal fabrication services?

Answer: Costs can vary based on factors like material selection, complexity of design, production volume, and finishing requirements. It’s advisable to obtain quotes from multiple providers for comparison.

Summary: Customized metal fabrication services empower businesses to create tailored metal products that meet their specific needs. Understanding the materials, design process, and industry applications can help organizations leverage these services effectively.

Transition: To delve deeper into the capabilities and advantages of customized metal fabrication services, continue reading the comprehensive article.

Tips for Utilizing Customized Metal Fabrication Services

To maximize the benefits of customized metal fabrication services and ensure successful project outcomes, consider the following tips:

Tip 1: Define Clear Project Specifications: Clearly outline the desired product’s dimensions, materials, tolerances, and performance requirements. This provides a solid foundation for the fabrication process and minimizes miscommunication.

Tip 2: Leverage Design Expertise: Collaborate with the fabrication service provider to optimize the product’s design for manufacturability. Their expertise can enhance functionality, reduce costs, and improve production efficiency.

Tip 3: Select Suitable Materials: Choose materials that align with the product’s intended use, durability requirements, and environmental factors. Consider factors such as strength, corrosion resistance, and weight to ensure optimal performance.

Tip 4: Establish Quality Control Measures: Define clear quality standards and inspection procedures to ensure the fabricated product meets your expectations. This includes specifying tolerances, surface finishes, and any necessary testing or certifications.

Tip 5: Optimize Production Efficiency: Work with the fabrication service provider to streamline the production process. Explore options such as batch production, just-in-time delivery, and lean manufacturing principles to minimize lead times and costs.

Tip 6: Consider Post-Fabrication Services: Discuss any additional services required, such as finishing, assembly, or packaging. This ensures a seamless transition from fabrication to the final product.

Tip 7: Foster Open Communication: Maintain regular communication with the fabrication service provider throughout the project. This facilitates timely decision-making, problem-solving, and ensures alignment with project goals.

Tip 8: Seek Ongoing Support: Establish a long-term relationship with the fabrication service provider for ongoing support and maintenance. This can provide valuable insights for future projects and ensure continued product quality.

By following these tips, businesses can effectively utilize customized metal fabrication services to create innovative and tailored metal products that meet their specific requirements.

Transition to Conclusion: These tips empower organizations to harness the full potential of customized metal fabrication services, enabling them to achieve their manufacturing objectives efficiently and effectively.

Customized Metal Fabrication Services

Customized metal fabrication services have revolutionized the manufacturing industry, empowering businesses to create unique and tailored metal products that meet their specific requirements. This article has explored the various aspects of customized metal fabrication services, from design and materials to fabrication and quality control.

By leveraging these services effectively, organizations can gain a competitive edge, enhance product functionality, and optimize production efficiency. The tips provided in this article serve as a valuable guide for businesses seeking to harness the full potential of customized metal fabrication services. As technology continues to advance and new materials emerge, the possibilities for customized metal fabrication are limitless.