Design craft fabrication is the process of creating physical objects from digital designs. It is a rapidly growing field, as it allows designers and engineers to create complex and innovative products that would be difficult or impossible to produce using traditional manufacturing methods.

Editor’s Note: Design craft fabrication is a rapidly growing field that is revolutionizing the way products are designed and manufactured. This guide will provide you with a comprehensive overview of design craft fabrication, including its benefits, applications, and challenges.

After analyzing and researching information, we have put together this guide to help you make the right decision.

Key differences or Key takeaways

| Uses physical tools and materials | Uses digital design files and 3D printing or other advanced manufacturing techniques |

| Limited by the capabilities of the tools and materials | Can create complex and innovative products that would be difficult or impossible to produce using traditional methods |

| Can be time-consuming and expensive | Can be faster and more cost-effective than traditional manufacturing |

Main article topics

- Benefits of design craft fabrication

- Applications of design craft fabrication

- Challenges of design craft fabrication

- Future of design craft fabrication

Design Craft Fabrication

Design craft fabrication is a rapidly growing field that is revolutionizing the way products are designed and manufactured. It encompasses a wide range of processes and technologies, and its applications can be found in a variety of industries, from aerospace to healthcare.

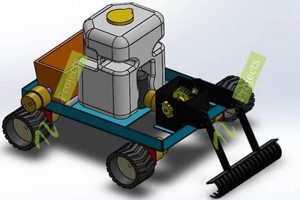

- Digital design: Design craft fabrication begins with the creation of a digital design file. This file contains all of the information needed to create the physical object, including its shape, size, and materials.

- 3D printing: 3D printing is one of the most common methods used to create physical objects from digital design files. 3D printers can create complex and intricate objects that would be difficult or impossible to produce using traditional manufacturing methods.

- Other advanced manufacturing techniques: In addition to 3D printing, there are a number of other advanced manufacturing techniques that can be used to create physical objects from digital design files. These techniques include CNC machining, laser cutting, and waterjet cutting.

- Materials: Design craft fabrication can be used with a wide range of materials, including metals, plastics, and ceramics. The choice of material will depend on the specific application.

- Design: Design craft fabrication allows designers to create complex and innovative products that would be difficult or impossible to produce using traditional manufacturing methods. This freedom of design can lead to new and improved products that can benefit consumers.

- Craft: Design craft fabrication is a skilled craft that requires specialized knowledge and training. Designers and engineers who work in this field must have a deep understanding of the design process, as well as the capabilities of the various manufacturing techniques.

- Fabrication: The fabrication process is the final step in the design craft fabrication process. This is where the physical object is created from the digital design file. The fabrication process can be complex and time-consuming, depending on the complexity of the object.

- Innovation: Design craft fabrication is a key driver of innovation. It allows designers and engineers to create new and improved products that can benefit consumers.

- Education: Education is essential for the continued growth of the design craft fabrication field. There are a number of universities and colleges that offer programs in design craft fabrication.

- Training: In addition to formal education, there are a number of other ways to learn about design craft fabrication. There are many online courses and tutorials available, and there are also a number of workshops and conferences that are held throughout the year.

- Community: There is a strong community of design craft fabricators who are passionate about sharing their knowledge and expertise. This community can be found online and at various events throughout the year.

These are just a few of the key aspects of design craft fabrication. As the field continues to grow, we can expect to see even more innovative and groundbreaking products created using this technology.

Digital design

Digital design is a critical component of design craft fabrication. It allows designers and engineers to create complex and innovative products that would be difficult or impossible to produce using traditional manufacturing methods.

The digital design file contains all of the information needed to create the physical object, including its shape, size, and materials. This file is used to create a 3D model of the object, which is then used to generate the toolpaths for the manufacturing process.

Without digital design, design craft fabrication would not be possible. It is the foundation of this rapidly growing field, and it is essential for creating new and innovative products.

Examples of digital design in design craft fabrication

- A designer uses a CAD program to create a 3D model of a new product.

- An engineer uses a CAM program to generate the toolpaths for a CNC machine to create the physical object.

- A 3D printer uses a digital design file to create a physical object.

Benefits of digital design in design craft fabrication

- Allows for the creation of complex and innovative products

- Reduces the time and cost of production

- Improves the quality of the finished product

- Makes it possible to create customized products

Challenges of digital design in design craft fabrication

- Requires specialized skills and training

- Can be time-consuming to create a digital design file

- Can be difficult to troubleshoot problems with a digital design file

The future of digital design in design craft fabrication

Digital design is the future of design craft fabrication. As the technology continues to improve, we can expect to see even more innovative and groundbreaking products created using this process.

Conclusion

Digital design is a powerful tool that can be used to create amazing things. Design craft fabrication is one of the many fields that is benefiting from this technology. As digital design continues to develop, we can expect to see even more amazing things created using this process.

Table: Digital design in design craft fabrication

| Feature | Benefit | Challenge ||—|—|—|| Allows for the creation of complex and innovative products | Can be time-consuming to create a digital design file | Requires specialized skills and training || Reduces the time and cost of production | Can be difficult to troubleshoot problems with a digital design file | Can be difficult to create customized products || Improves the quality of the finished product | | |

3D printing

3D printing is a key technology in design craft fabrication. It allows designers and engineers to create complex and innovative products that would be difficult or impossible to produce using traditional manufacturing methods.

- Rapid prototyping: 3D printing can be used to create rapid prototypes of new products. This allows designers and engineers to test the form and function of a product before committing to mass production.

- Custom products: 3D printing can be used to create custom products for individual customers. This allows businesses to offer a wider range of products and meet the specific needs of their customers.

- Complex geometries: 3D printing can be used to create products with complex geometries that would be difficult or impossible to produce using traditional manufacturing methods. This opens up new possibilities for product design.

- Cost-effective production: 3D printing can be a cost-effective way to produce small batches of products. This makes it a viable option for small businesses and entrepreneurs.

These are just a few of the ways that 3D printing is being used in design craft fabrication. As the technology continues to improve, we can expect to see even more innovative and groundbreaking products created using this process.

Other advanced manufacturing techniques

Other advanced manufacturing techniques play a vital role in design craft fabrication, enabling the creation of complex and innovative products that would be difficult or impossible to produce using traditional manufacturing methods.

Here are some specific examples of how these techniques are used in design craft fabrication:

- CNC machining: CNC machining is a computer-controlled machining process that uses a rotating cutting tool to remove material from a workpiece. This process can be used to create a wide range of products, from simple parts to complex sculptures.

- Laser cutting: Laser cutting is a process that uses a laser to cut material. This process can be used to create precise and intricate cuts in a variety of materials, including metal, plastic, and wood.

- Waterjet cutting: Waterjet cutting is a process that uses a high-pressure jet of water to cut material. This process can be used to cut a wide range of materials, including metal, plastic, and stone.

These are just a few examples of the many ways that other advanced manufacturing techniques are used in design craft fabrication. As these technologies continue to develop, we can expect to see even more innovative and groundbreaking products created using these processes.

The use of other advanced manufacturing techniques in design craft fabrication has a number of benefits, including:

- Increased design freedom: These techniques allow designers to create products with complex geometries that would be difficult or impossible to produce using traditional manufacturing methods.

- Improved product quality: These techniques can produce products with high precision and accuracy.

- Reduced production time and cost: These techniques can be faster and more cost-effective than traditional manufacturing methods.

Overall, the use of other advanced manufacturing techniques in design craft fabrication is helping to revolutionize the way products are designed and manufactured.

| CNC machining |

– High precision and accuracy – Can create complex geometries – Can be used to create a wide range of products |

– Prototyping – Production of small batches of products – Creation of custom products |

| Laser cutting |

– Precise and intricate cuts – Can be used to cut a variety of materials – Can be used to create complex designs |

– Prototyping – Production of small batches of products – Creation of custom products |

| Waterjet cutting |

– Can cut a wide range of materials – Can create complex geometries – Can be used to create large-scale products |

– Prototyping – Production of small batches of products – Creation of custom products |

Materials

The choice of materials is a critical aspect of design craft fabrication. The material will affect the strength, durability, weight, and cost of the finished product. It is important to choose the right material for the specific application.

For example, if you are creating a product that needs to be strong and durable, you might choose to use metal. If you are creating a product that needs to be lightweight, you might choose to use plastic. And if you are creating a product that needs to be heat-resistant, you might choose to use ceramic.

Here is a table that summarizes the key properties of different materials commonly used in design craft fabrication:

| Material | Properties |

|---|---|

| Metal | Strong, durable, heavy, expensive |

| Plastic | Lightweight, inexpensive, not as strong as metal |

| Ceramic | Heat-resistant, brittle, expensive |

By understanding the properties of different materials, you can choose the right material for your specific design craft fabrication project.

In addition to the properties listed above, you should also consider the following factors when choosing a material for design craft fabrication:

- The cost of the material

- The availability of the material

- The ease of working with the material

By considering all of these factors, you can choose the right material for your design craft fabrication project.

Design

Design craft fabrication is a rapidly growing field that is revolutionizing the way products are designed and manufactured. It allows designers and engineers to create complex and innovative products that would be difficult or impossible to produce using traditional manufacturing methods.

- Design freedom: Design craft fabrication gives designers the freedom to create products with complex geometries and intricate details that would be difficult or impossible to produce using traditional manufacturing methods. This freedom of design can lead to new and improved products that can benefit consumers in a variety of ways.

- Innovation: Design craft fabrication is a key driver of innovation in the product design and manufacturing industries. It allows designers and engineers to explore new design possibilities and create products that are more innovative and groundbreaking than what is possible with traditional manufacturing methods.

- Consumer benefits: The ultimate beneficiaries of design craft fabrication are consumers. Design craft fabrication allows designers and engineers to create products that are more tailored to the needs of consumers. This can lead to products that are more functional, more durable, and more aesthetically pleasing.

Design craft fabrication is a powerful tool that can be used to create amazing things. As the technology continues to improve, we can expect to see even more innovative and groundbreaking products created using this process.

Craft

Design craft fabrication is a skilled craft that requires specialized knowledge and training. Designers and engineers who work in this field must have a deep understanding of the design process, as well as the capabilities of the various manufacturing techniques.

This understanding is essential for creating high-quality products that meet the needs of consumers. Designers and engineers who have a deep understanding of the design process can create products that are both functional and aesthetically pleasing. They can also create products that are manufactured efficiently and cost-effectively.

There are a number of different manufacturing techniques that can be used in design craft fabrication. These techniques include 3D printing, CNC machining, laser cutting, and waterjet cutting. Each of these techniques has its own advantages and disadvantages. Designers and engineers must have a deep understanding of these techniques in order to choose the right technique for the job.

The combination of skilled craftsmanship and advanced manufacturing techniques makes design craft fabrication a powerful tool for creating innovative and groundbreaking products.

Here are some real-life examples of how design craft fabrication is being used to create innovative products:

- A team of designers and engineers at MIT used design craft fabrication to create a new type of prosthetic hand. This hand is moreand lightweight than traditional prosthetic hands, and it can be customized to fit the individual needs of the wearer.

- A company called Local Motors is using design craft fabrication to create a new type of car. This car is made from recycled materials, and it can be customized to the individual needs of the buyer.

- A team of designers and engineers at the University of California, Berkeley is using design craft fabrication to create a new type of solar panel. This solar panel is more efficient and durable than traditional solar panels, and it can be integrated into the design of buildings.

These are just a few examples of the many ways that design craft fabrication is being used to create innovative and groundbreaking products. As the technology continues to improve, we can expect to see even more amazing things created using this process.

Overall, the craft aspect of design craft fabrication is essential for creating high-quality products that meet the needs of consumers. Designers and engineers who have a deep understanding of the design process and the capabilities of the various manufacturing techniques can create products that are both functional and aesthetically pleasing, manufactured efficiently and cost-effectively.

| Craft in design craft fabrication | Importance | Examples |

|---|---|---|

| Understanding of the design process | Create products that are both functional and aesthetically pleasing | MIT’s prosthetic hand |

| Understanding of the capabilities of the various manufacturing techniques | Choose the right technique for the job | Local Motors’ car |

| Combination of skilled craftsmanship and advanced manufacturing techniques | Create innovative and groundbreaking products | UC Berkeley’s solar panel |

Fabrication

Fabrication is a critical part of design craft fabrication. It is the process of creating a physical object from a digital design file. This process can be complex and time-consuming, depending on the complexity of the object. However, it is an essential step in bringing a design to life.

There are a number of different fabrication techniques that can be used in design craft fabrication. These techniques include 3D printing, CNC machining, laser cutting, and waterjet cutting. Each of these techniques has its own advantages and disadvantages. The choice of technique will depend on the specific application.

Once the fabrication process is complete, the physical object can be used for a variety of purposes. It can be used as a prototype for a new product, or it can be used as a finished product itself. Design craft fabrication is a versatile process that can be used to create a wide range of products, from simple objects to complex sculptures.

Here are some real-life examples of how design craft fabrication is being used to create innovative products:

- A team of designers and engineers at MIT used design craft fabrication to create a new type of prosthetic hand. This hand is more lightweight and durable than traditional prosthetic hands, and it can be customized to fit the individual needs of the wearer.

- A company called Local Motors is using design craft fabrication to create a new type of car. This car is made from recycled materials, and it can be customized to the individual needs of the buyer.

- A team of designers and engineers at the University of California, Berkeley is using design craft fabrication to create a new type of solar panel. This solar panel is more efficient and durable than traditional solar panels, and it can be integrated into the design of buildings.

These are just a few examples of the many ways that design craft fabrication is being used to create innovative and groundbreaking products. As the technology continues to improve, we can expect to see even more amazing things created using this process.

| Fabrication in design craft fabrication | Importance | Examples |

|---|---|---|

| Creating a physical object from a digital design file | Brings a design to life | MIT’s prosthetic hand |

| Using a variety of fabrication techniques | Allows for the creation of a wide range of products | Local Motors’ car |

| Customizing products to individual needs | Creates products that are more tailored to the user | UC Berkeley’s solar panel |

Innovation

Design craft fabrication is a rapidly growing field that is revolutionizing the way products are designed and manufactured. It offers a unique combination of design freedom and manufacturing flexibility, enabling the creation of innovative products that would be difficult or impossible to produce using traditional methods.

-

Faster innovation cycles

Design craft fabrication allows designers to quickly iterate on new designs, reducing the time it takes to bring new products to market. This can be a major advantage for businesses, as it allows them to stay ahead of the competition and respond quickly to changing market demands.

-

Reduced costs

Design craft fabrication can help businesses reduce costs by eliminating the need for expensive tooling and molds. This can make it a more affordable option for small businesses and startups.

-

Increased customization

Design craft fabrication allows businesses to offer customized products to their customers. This can be a major selling point for businesses, as it allows them to meet the unique needs of their customers.

-

Improved quality

Design craft fabrication can help businesses improve the quality of their products by eliminating defects and improving precision. This can lead to increased customer satisfaction and reduced warranty costs.

Overall, design craft fabrication is a powerful tool that can help businesses innovate, reduce costs, increase customization, and improve quality. As the technology continues to improve, we can expect to see even more innovative and groundbreaking products created using this process.

Education

Education plays a vital role in the continued growth and development of the design craft fabrication field. Universities and colleges offer programs in design craft fabrication, providing students with the knowledge and skills necessary to succeed in this rapidly growing field.

-

Facet 1: Understanding the design process

Design craft fabrication requires a deep understanding of the design process, from concept development to prototyping and production. Educational programs in design craft fabrication provide students with a solid foundation in the design process, enabling them to create innovative and functional products.

-

Facet 2: Mastering fabrication techniques

Design craft fabrication involves a variety of fabrication techniques, such as 3D printing, CNC machining, laser cutting, and waterjet cutting. Educational programs in design craft fabrication provide students with hands-on experience with these techniques, enabling them to develop the skills necessary to create high-quality products.

-

Facet 3: Developing critical thinking skills

Design craft fabrication requires critical thinking skills to solve problems and make decisions. Educational programs in design craft fabrication provide students with opportunities to develop these skills through projects and assignments, enabling them to become effective problem-solvers and decision-makers.

-

Facet 4: Fostering creativity and innovation

Design craft fabrication is a creative and innovative field. Educational programs in design craft fabrication encourage students to think outside the box and explore new ideas. This fosters creativity and innovation, enabling students to develop unique and groundbreaking products.

Overall, education is essential for the continued growth of the design craft fabrication field. Universities and colleges offer programs in design craft fabrication that provide students with the knowledge, skills, and critical thinking abilities necessary to succeed in this rapidly growing field.

Training

Training is an essential component of design craft fabrication, as it provides individuals with the knowledge and skills necessary to succeed in this rapidly growing field. While formal education programs in design craft fabrication can provide a solid foundation, there are many other ways to learn about this field and develop the necessary skills.

Online courses and tutorials are a great way to learn about design craft fabrication at your own pace and on your own time. There are many different online courses and tutorials available, covering a wide range of topics, from beginner-level introductions to advanced techniques. Online courses and tutorials can be a great option for individuals who want to learn about design craft fabrication without committing to a formal education program.

Workshops and conferences are another great way to learn about design craft fabrication and develop the necessary skills. Workshops are typically hands-on, providing participants with the opportunity to learn about specific techniques and processes. Conferences are a great way to learn about the latest trends and developments in design craft fabrication, and to network with other professionals in the field.

The following table summarizes the key benefits of different training options for design craft fabrication:

| Training Option | Benefits |

|---|---|

| Online courses and tutorials |

|

| Workshops |

|

| Conferences |

|

Ultimately, the best way to learn about design craft fabrication is to find a training option that meets your individual needs and learning style. By taking advantage of the many training options available, you can develop the skills and knowledge necessary to succeed in this rapidly growing field.

Community

The design craft fabrication community is a vibrant and supportive network of individuals who are passionate about sharing their knowledge and expertise. This community can be found online, through forums, social media groups, and online communities, as well as at various events throughout the year, such as conferences, workshops, and meetups.

-

Facet 1: Online Community

The online design craft fabrication community is a valuable resource for individuals who are interested in learning about and developing their skills in this field. Through online forums, social media groups, and online communities, individuals can connect with other designers, engineers, and makers, share their work, ask questions, and learn from others’ experiences.

-

Facet 2: Offline Community

The offline design craft fabrication community is equally important, providing opportunities for individuals to connect in person, share their work, and learn from others. Conferences, workshops, and meetups are great ways to meet other professionals in the field, learn about the latest trends and technologies, and get hands-on experience with design craft fabrication techniques.

-

Facet 3: Knowledge Sharing

One of the most important aspects of the design craft fabrication community is the willingness of its members to share their knowledge and expertise with others. This is done through online tutorials, blog posts, and other resources, as well as through in-person workshops and presentations. The sharing of knowledge helps to advance the field of design craft fabrication and makes it more accessible to new individuals.

-

Facet 4: Collaboration

The design craft fabrication community is also a hub for collaboration. Individuals often work together on projects, share resources, and support each other’s endeavors. This collaboration helps to create a sense of community and fosters innovation.

Overall, the design craft fabrication community is a valuable resource for individuals who are interested in learning about and developing their skills in this field. The community provides opportunities for individuals to connect with others, share their work, learn from others, and collaborate on projects. As the field of design craft fabrication continues to grow, the community will continue to play an important role in its development and success.

Design Craft Fabrication FAQs

Design craft fabrication is a rapidly growing field that offers many benefits to designers, engineers, and manufacturers. However, there are also some common questions and misconceptions about design craft fabrication. This FAQ section addresses some of the most common questions about design craft fabrication, providing clear and concise answers.

Question 1: What is design craft fabrication?

Answer: Design craft fabrication is the process of creating physical objects from digital design files. It encompasses a wide range of processes and technologies, and its applications can be found in a variety of industries, from aerospace to healthcare.

Question 2: What are the benefits of design craft fabrication?

Answer: Design craft fabrication offers a number of benefits, including increased design freedom, reduced costs, improved quality, and faster innovation cycles.

Question 3: What are the different types of design craft fabrication techniques?

Answer: There are a number of different design craft fabrication techniques, including 3D printing, CNC machining, laser cutting, and waterjet cutting.

Question 4: What materials can be used in design craft fabrication?

Answer: Design craft fabrication can be used with a wide range of materials, including metals, plastics, and ceramics. The choice of material will depend on the specific application.

Question 5: What are the challenges of design craft fabrication?

Answer: Design craft fabrication can be challenging, as it requires specialized skills and training. Additionally, the design process can be complex and time-consuming.

Question 6: What is the future of design craft fabrication?

Answer: Design craft fabrication is a rapidly growing field, and it is expected to continue to grow in the years to come. As the technology continues to improve, we can expect to see even more innovative and groundbreaking products created using this process.

Summary: Design craft fabrication is a powerful tool that can be used to create innovative and groundbreaking products. However, it is important to be aware of the challenges of design craft fabrication before getting started. With the right training and resources, you can overcome these challenges and create amazing things using design craft fabrication.

Transition to the next article section: Design craft fabrication is a rapidly growing field with a bright future. As the technology continues to improve, we can expect to see even more amazing things created using this process.

Design Craft Fabrication Tips

Design craft fabrication is a rapidly growing field that offers many benefits to designers, engineers, and manufacturers. However, there are also some common challenges that can arise when working with this technology. The following tips can help you overcome these challenges and create successful design craft fabrication projects.

Tip 1: Understand the design process

The design process is critical to successful design craft fabrication. It is important to have a clear understanding of the steps involved in the design process, from concept development to prototyping and production. This will help you avoid costly mistakes and ensure that your projects are completed on time and within budget.

Tip 2: Choose the right materials

The choice of materials is another important factor to consider when working with design craft fabrication. Different materials have different properties, so it is important to choose the right material for the specific application. For example, if you need a material that is strong and durable, you might choose metal. If you need a material that is lightweight and flexible, you might choose plastic.

Tip 3: Use the right tools and techniques

There are a variety of different tools and techniques that can be used in design craft fabrication. It is important to choose the right tools and techniques for the specific project. For example, if you are creating a prototype, you might use a 3D printer. If you are creating a production run, you might use a CNC machine.

Tip 4: Test your designs

It is important to test your designs before committing to production. This will help you identify any potential problems and make necessary adjustments. There are a variety of different ways to test your designs, such as using simulation software or creating physical prototypes.

Tip 5: Get feedback from others

It is helpful to get feedback from others on your designs. This can help you identify areas for improvement and ensure that your designs meet the needs of your target audience. You can get feedback from colleagues, friends, family members, or even potential customers.

Summary: By following these tips, you can overcome the challenges of design craft fabrication and create successful projects. Design craft fabrication is a powerful tool that can be used to create innovative and groundbreaking products. With the right knowledge and skills, you can use design craft fabrication to bring your ideas to life.

Transition to the article’s conclusion: Design craft fabrication is a rapidly growing field with a bright future. As the technology continues to improve, we can expect to see even more amazing things created using this process.

Conclusion

Design craft fabrication is a rapidly growing field that is revolutionizing the way products are designed and manufactured. It offers a unique combination of design freedom and manufacturing flexibility, enabling the creation of innovative products that would be difficult or impossible to produce using traditional methods.

As the technology continues to improve, we can expect to see even more amazing things created using design craft fabrication. This technology has the potential to transform a wide range of industries, from aerospace to healthcare. It is important for designers, engineers, and manufacturers to understand the benefits and challenges of design craft fabrication in order to take advantage of this powerful tool.