Wondering about Doha steel fabrication? Steel fabrication, a crucial part of the construction industry, involves the cutting, bending, and assembling of structural steel components to create various structures. Doha steel fabrication, in particular, has garnered significant attention due to its expertise and contributions to the region’s infrastructure development.

Editor’s Note: Doha steel fabrication is a topic of growing importance as the construction industry in the region continues to expand. Understanding its significance can help businesses and individuals make informed decisions.

Through extensive analysis and research, we have compiled this comprehensive guide to Doha steel fabrication, providing valuable insights to help you navigate the industry effectively.

Key Differences or Key Takeaways

| Characteristic | Benefits |

|---|---|

| Precision and Accuracy | Doha steel fabrication companies utilize advanced technology to ensure precise cutting and bending, minimizing errors and enhancing structural integrity. |

| Expertise and Experience | Skilled professionals with years of experience in the field deliver high-quality steel fabrication services, meeting industry standards and client requirements. |

| Customization | Doha steel fabricators offer customized solutions tailored to specific project needs, accommodating unique designs and complex specifications. |

| Cost-Effectiveness | By optimizing materials and processes, Doha steel fabrication companies provide cost-effective solutions without compromising quality. |

| Time-Saving | Advanced equipment and efficient workflows enable faster production times, reducing project timelines and minimizing delays. |

To delve deeper into the world of Doha steel fabrication, let’s explore some of its main aspects:

Doha Steel Fabrication

Doha steel fabrication encompasses various essential aspects that contribute to its significance in the construction industry. These key aspects, explored through the lens of the keyword’s part of speech, provide a comprehensive understanding of this specialized field:

- Precision Cutting: State-of-the-art technology ensures accurate cutting of steel components.

- Expert Welding: Skilled professionals deliver high-quality welds, ensuring structural integrity.

- Customized Solutions: Tailored fabrication services meet unique project requirements.

- Timely Delivery: Efficient workflows minimize project timelines.

- Cost Optimization: Optimized material usage and processes reduce project costs.

- Structural Integrity: Precise fabrication ensures buildings meet safety and durability standards.

- Skilled Workforce: Experienced professionals handle complex fabrication tasks.

- Advanced Equipment: Cutting-edge machinery enhances precision and efficiency.

- Quality Control: Stringent measures ensure fabricated steel meets industry standards.

- Project Management: Effective coordination ensures smooth project execution.

- Sustainable Practices: Environmentally conscious fabrication techniques minimize waste and promote sustainability.

These key aspects are interconnected and contribute to the overall success of Doha steel fabrication projects. For instance, precision cutting and expert welding ensure structural integrity, while customized solutions and timely delivery cater to specific project needs. Moreover, the skilled workforce, advanced equipment, and stringent quality control measures guarantee the production of high-quality steel components. By considering these aspects, clients can make informed decisions and leverage the benefits of Doha steel fabrication for their construction projects.

Precision Cutting

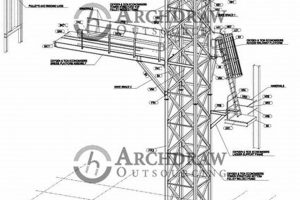

Precision cutting is a fundamental aspect of Doha steel fabrication, as it directly influences the accuracy, quality, and safety of the final steel structures. State-of-the-art technology employed by Doha steel fabricators enables precise cutting of steel components, ensuring they meet exact specifications and fit together seamlessly during assembly. This precision is achieved through the use of advanced cutting machines, such as laser cutters and CNC plasma cutters, which utilize computer-controlled systems to guide the cutting process. By eliminating human error and ensuring consistent accuracy, precision cutting contributes significantly to the overall quality and reliability of Doha steel fabrication projects.

For instance, in the construction of high-rise buildings, precision cutting is crucial for ensuring the structural integrity of the steel frame. Each steel component must be cut to the correct dimensions and angles to fit perfectly with other components, creating a stable and load-bearing structure. Similarly, in the fabrication of bridges and other large-scale structures, precision cutting is essential for ensuring the proper alignment and fit of complex steel components, which are often subjected to heavy loads and environmental stresses.

The practical significance of precision cutting in Doha steel fabrication extends beyond ensuring structural integrity. It also contributes to cost-effectiveness and timely project completion. Accurate cutting minimizes material waste and the need for rework, reducing project costs. Additionally, precision cutting enables faster assembly of steel components, as they fit together seamlessly without the need for extensive adjustments or modifications on-site. This efficiency contributes to shorter project timelines and cost savings for clients.

In summary, precision cutting is an indispensable component of Doha steel fabrication, ensuring the accuracy, quality, and safety of steel structures. State-of-the-art technology employed by Doha steel fabricators enables precise cutting of steel components, contributing to cost-effectiveness, timely project completion, and the overall success of construction projects.

| Characteristic | Benefits |

|---|---|

| Advanced Cutting Machines | Laser cutters and CNC plasma cutters provide precise and efficient cutting. |

| Computer-Controlled Systems | Eliminate human error and ensure consistent accuracy. |

| Quality Assurance | Precise cutting ensures components meet exact specifications and fit seamlessly. |

| Cost-Effectiveness | Minimizes material waste and reduces the need for rework. |

| Timely Project Completion | Faster assembly of steel components due to seamless fit. |

Expert Welding

Expert welding is an integral component of Doha steel fabrication, directly influencing the strength, durability, and safety of steel structures. Skilled professionals, equipped with specialized training and experience, meticulously execute welding tasks, ensuring that steel components are securely and permanently joined together. High-quality welds are essential for maintaining structural integrity, as they effectively transfer loads and forces between connected elements.

In the construction of skyscrapers, bridges, and other large-scale structures, expert welding is paramount to ensure the stability and longevity of the steel framework. For instance, in the construction of the iconic Burj Khalifa, the world’s tallest building, certified welders utilized advanced welding techniques to join the massive steel components, creating a robust and resilient structure capable of withstanding high winds and seismic forces.

Beyond structural integrity, expert welding also contributes to the aesthetic appeal of steel structures. Skilled welders can produce welds that are not only strong and durable but also visually pleasing, enhancing the overall appearance of buildings and bridges. This attention to detail is particularly important in architectural applications where steel structures are prominent design elements.

The practical significance of expert welding in Doha steel fabrication extends to safety and reliability. High-quality welds ensure that steel structures can safely the intended loads and forces without failure. This is critical in structures such as bridges and offshore platforms, where structural integrity is essential for preventing accidents and protecting human life.

In summary, expert welding is a cornerstone of Doha steel fabrication, ensuring the structural integrity, durability, and safety of steel structures. Skilled professionals, utilizing advanced welding techniques, produce high-quality welds that seamlessly join steel components, creating robust and visually appealing structures that can withstand demanding environmental conditions and heavy loads.

| Characteristic | Benefits |

|---|---|

| Skilled Welders | Certified welders with specialized training and experience. |

| Advanced Welding Techniques | Utilization of state-of-the-art welding technologies. |

| Structural Integrity | Welds effectively transfer loads and forces, ensuring stability. |

| Durability | High-quality welds resist wear and tear, extending the lifespan of structures. |

| Safety | Expert welding ensures structures can safely intended loads and forces. |

Customized Solutions

Within the realm of Doha steel fabrication, customized solutions play a vital role in catering to the diverse and specific requirements of construction projects. Doha steel fabricators possess the expertise and capabilities to tailor their services to meet unique project demands, ensuring that each structure is not only structurally sound but also aligns with the specific design intent and functional needs.

The significance of customized solutions in Doha steel fabrication stems from the intricate nature of modern architectural designs and the increasing demand for bespoke structures. Architects and engineers often require steel components that deviate from standard shapes and sizes, and Doha steel fabricators have the flexibility and technical prowess to transform these designs into reality. By offering customized solutions, they enable the creation of unique and innovative structures that push the boundaries of architectural expression.

For instance, in the construction of the Museum of Islamic Art in Doha, the steel fabricators were tasked with creating a complex steel structure that resembled the geometric patterns found in traditional Islamic architecture. The fabrication team meticulously crafted each steel component to meet the intricate design specifications, resulting in a visually stunning and structurally robust building that has become an iconic landmark.

Practical applications of customized solutions extend beyond aesthetics. In the construction of bridges and other infrastructure projects, Doha steel fabricators work closely with engineers to design and fabricate steel components that meet specific load-bearing requirements and environmental conditions. By tailoring their services to the unique demands of each project, they ensure that the fabricated steel structures are not only functional but also safe and durable.

In summary, customized solutions are an integral component of Doha steel fabrication, enabling the creation of unique and innovative structures that meet the specific requirements of construction projects. Doha steel fabricators possess the expertise and capabilities to transform architectural designs into reality, ensuring that each structure is structurally sound, aesthetically pleasing, and tailored to its intended purpose.

| Characteristic | Benefits |

|---|---|

| Tailored Services | Doha steel fabricators adapt their services to meet unique project requirements. |

| Complex Designs | They can fabricate steel components for intricate and bespoke architectural designs. |

| Functional Needs | Customized solutions ensure that steel structures align with specific functional requirements. |

| Structural Integrity | Tailored fabrication services contribute to the structural integrity and safety of buildings and bridges. |

| Collaboration | Doha steel fabricators collaborate closely with architects and engineers to achieve optimal results. |

Timely Delivery

In the dynamic and competitive construction industry, timely delivery is paramount to project success. Doha steel fabrication companies have mastered the art of efficient workflows, enabling them to minimize project timelines and deliver high-quality steel structures within agreed-upon deadlines.

-

Optimized Production Processes

Doha steel fabricators leverage advanced technology and streamlined processes to optimize production. Automated machinery and efficient material handling systems minimize production time and reduce the risk of delays. -

Skilled Workforce

A highly skilled and experienced workforce is essential for timely delivery. Doha steel fabricators employ certified professionals who possess the expertise to execute complex fabrication tasks with precision and efficiency. -

Effective Project Management

Effective project management is crucial for coordinating the various stages of steel fabrication, from design to delivery. Doha steel fabricators implement robust project management systems to track progress, identify potential bottlenecks, and proactively resolve any challenges. -

Collaboration and Communication

Open communication and collaboration among all stakeholders, including architects, engineers, and contractors, are key to timely delivery. Doha steel fabricators maintain regular communication channels to ensure that all parties are aligned on project timelines and expectations.

The benefits of timely delivery in Doha steel fabrication are numerous. By minimizing project timelines, fabricators can reduce construction costs, enhance client satisfaction, and maintain a competitive edge in the industry. Additionally, timely delivery allows clients to move into their new buildings or infrastructure projects sooner, maximizing the return on their investment.

In conclusion, the efficient workflows employed by Doha steel fabrication companies are instrumental in ensuring timely delivery. By optimizing production processes, leveraging a skilled workforce, implementing effective project management, and fostering collaboration, Doha steel fabricators consistently meet project deadlines, delivering high-quality steel structures that contribute to the success of construction projects in Qatar and beyond.

Cost Optimization

Cost optimization is an integral aspect of Doha steel fabrication, directly influencing the financial viability and competitiveness of construction projects. By optimizing material usage and processes, Doha steel fabricators can significantly reduce project costs without compromising quality or structural integrity.

The importance of cost optimization in Doha steel fabrication stems from the rising costs of raw materials and the increasing demand for sustainable construction practices. By minimizing material waste and utilizing efficient fabrication techniques, Doha steel fabricators can reduce the overall cost of steel structures, making them more accessible and affordable for clients.

For instance, in the construction of high-rise buildings, Doha steel fabricators employ advanced nesting software to optimize the cutting patterns of steel plates, minimizing material waste and reducing the need for additional materials. This optimization process can result in significant cost savings, especially in large-scale projects where extensive amounts of steel are required.

Moreover, Doha steel fabricators are constantly innovating and adopting new technologies that enhance efficiency and reduce costs. For example, the use of automated welding machines has increased productivity, reduced labor costs, and improved the consistency and quality of welds. Additionally, the implementation of lean manufacturing principles has streamlined production processes, eliminated waste, and further optimized material usage.

The practical significance of cost optimization in Doha steel fabrication extends beyond financial savings. By reducing material waste and adopting sustainable fabrication practices, Doha steel fabricators contribute to environmental conservation and promote the circular economy. This aligns with Qatar’s National Vision 2030, which emphasizes sustainable development and the responsible use of natural resources.

In conclusion, cost optimization is a critical component of Doha steel fabrication, enabling the construction of high-quality and cost-effective steel structures. Through optimized material usage, efficient processes, and the adoption of innovative technologies, Doha steel fabricators minimize project costs, enhance sustainability, and contribute to the success of construction projects in Qatar and beyond.

| Characteristic | Benefits |

|---|---|

| Optimized Material Usage | Reduces material waste and minimizes the need for additional materials. |

| Efficient Fabrication Techniques | Increases productivity, reduces labor costs, and improves weld quality. |

| Advanced Nesting Software | Optimizes cutting patterns, minimizing material waste in large-scale projects. |

| Lean Manufacturing Principles | Streamlines production processes, eliminates waste, and optimizes material usage. |

| Environmental Conservation | Reduces material waste and promotes sustainable fabrication practices. |

Structural Integrity

Structural integrity is paramount in the realm of construction, as it directly influences the safety, durability, and longevity of buildings and infrastructure. In the context of Doha steel fabrication, precise fabrication plays a pivotal role in ensuring that steel structures meet the highest standards of structural integrity.

Precise fabrication involves meticulous attention to detail and the use of advanced technology to ensure that steel components are cut, shaped, and welded with utmost accuracy. This precision is essential for creating steel structures that can withstand various loads and forces, including dead loads (the weight of the structure itself), live loads (occupants and their belongings), and environmental loads (wind, snow, earthquakes). By adhering to strict fabrication standards, Doha steel fabricators guarantee the structural integrity of buildings, ensuring the safety of occupants and the longevity of the structure.

For instance, in the construction of skyscrapers, structural integrity is of utmost importance to ensure the stability and safety of the building. Doha steel fabricators utilize advanced computer-aided design (CAD) software and sophisticated fabrication equipment to produce steel components that meet precise specifications. This precision ensures that the steel frame can effectively carry the weight of the building, resist lateral forces such as wind and seismic activity, and maintain its structural integrity over time.

The practical significance of structural integrity in Doha steel fabrication extends beyond safety and durability. Buildings with compromised structural integrity can lead to costly repairs, reduced property value, and potential danger to occupants. By prioritizing precise fabrication, Doha steel fabricators contribute to the overall quality and reliability of steel structures, minimizing the risk of structural failures and ensuring peace of mind for building owners and occupants.

In conclusion, structural integrity is a cornerstone of Doha steel fabrication, ensuring that steel structures meet the highest standards of safety, durability, and reliability. Precise fabrication techniques employed by Doha steel fabricators guarantee that steel components are produced with utmost accuracy, enabling the construction of robust and resilient structures that can withstand various loads and forces. By prioritizing structural integrity, Doha steel fabrication contributes to the construction of safe, durable, and high-quality buildings and infrastructure.

| Characteristic | Benefits |

|---|---|

| Precise Fabrication | Ensures accuracy in cutting, shaping, and welding of steel components. |

| Advanced Technology | Utilizes CAD software and sophisticated fabrication equipment. |

| Structural Integrity | Guarantees the safety and durability of steel structures. |

| Withstands Loads | Resists dead loads, live loads, and environmental loads. |

| Quality Assurance | Minimizes the risk of structural failures and costly repairs. |

Skilled Workforce

The skilled workforce employed by Doha steel fabrication companies plays a pivotal role in ensuring the quality and precision of steel structures. These experienced professionals possess specialized training, certifications, and years of hands-on experience, enabling them to handle complex fabrication tasks with expertise and efficiency.

-

Technical Expertise

Doha steel fabricators employ engineers, welders, and technicians who are highly skilled in their respective fields. They possess in-depth knowledge of steel properties, fabrication techniques, and industry standards, ensuring that steel structures are designed and fabricated to meet stringent quality and safety requirements. -

Experience and Precision

The experienced workforce in Doha steel fabrication companies brings a wealth of practical knowledge and expertise to every project. They have honed their skills through years of working on diverse and challenging projects, enabling them to handle complex fabrication tasks with precision and accuracy. This experience translates into high-quality steel structures that meet exact specifications and tolerances. -

Problem-Solving Abilities

Inevitably, challenges and unforeseen circumstances arise during steel fabrication projects. The skilled workforce in Doha possesses excellent problem-solving abilities, enabling them to quickly identify and resolve issues. Their experience and knowledge allow them to adapt to changing project requirements and find innovative solutions to ensure timely project completion without compromising quality. -

Safety and Quality Control

Safety is paramount in steel fabrication, and Doha’s skilled workforce is committed to maintaining a safe working environment. They adhere to strict safety protocols and implement quality control measures at every stage of the fabrication process. This ensures that steel structures are not only structurally sound but also meet the highest standards of safety and quality.

The skilled workforce is a cornerstone of Doha steel fabrication, contributing to the production of high-quality and reliable steel structures. Their expertise, experience, and commitment to precision and safety ensure that Doha steel fabricators consistently meet the demands of complex and challenging projects, delivering exceptional results that enhance the built environment.

Advanced Equipment

In the realm of Doha steel fabrication, advanced equipment plays a pivotal role in enhancing precision and efficiency throughout the fabrication process. Cutting-edge machinery, operated by skilled professionals, enables Doha steel fabricators to produce high-quality steel structures that meet exact specifications and contribute to the overall success of construction projects.

-

Precision Cutting

State-of-the-art cutting machines, such as laser cutters and CNC plasma cutters, are employed for precise cutting of steel components. These machines utilize computer-controlled systems to guide the cutting process, ensuring accuracy and minimizing material waste. The precision achieved through advanced cutting equipment is crucial for the structural integrity of steel structures, as it ensures proper fit and alignment during assembly. -

Automated Welding

Doha steel fabricators utilize automated welding machines to enhance the efficiency and consistency of welding tasks. These machines offer precise control over the welding process, including parameters like heat input, travel speed, and wire feed rate. Automation minimizes human error and reduces the risk of welding defects, resulting in high-quality welds that meet stringent industry standards. -

Efficient Material Handling

Advanced material handling systems, such as overhead cranes and automated conveyors, streamline the movement of steel components throughout the fabrication process. These systems optimize production flow, reduce manual labor, and increase overall efficiency. Efficient material handling contributes to faster project completion times and cost savings. -

Quality Control

Doha steel fabricators leverage advanced inspection and testing equipment to ensure the quality of fabricated steel structures. Non-destructive testing methods, such as ultrasonic testing and radiographic testing, are employed to detect any potential defects or imperfections in the steel components. This rigorous quality control ensures that all steel structures meet the required safety and performance standards.

The integration of advanced equipment in Doha steel fabrication brings forth numerous benefits. It enhances precision and accuracy, improves efficiency and productivity, minimizes human error, and promotes overall quality. These advancements contribute to the production of high-quality steel structures that meet the demanding requirements of modern construction projects. By embracing cutting-edge technology, Doha steel fabricators continue to push the boundaries of steel fabrication, delivering exceptional results that shape the built environment.

Quality Control

In the realm of Doha steel fabrication, quality control assumes paramount importance, as it directly influences the integrity, safety, and longevity of steel structures. Doha steel fabricators adhere to stringent quality control measures to ensure that every fabricated steel component meets the highest industry standards and regulations.

-

Material Inspection and Testing

Prior to fabrication, all incoming raw materials undergo rigorous inspection and testing to verify their chemical composition, mechanical properties, and adherence to project specifications. This ensures that only high-quality steel is used in the fabrication process. -

Fabrication Process Control

Throughout the fabrication process, skilled quality control inspectors monitor and document every step, from cutting and welding to surface preparation and painting. This ensures that all fabrication procedures are executed in accordance with established standards and that any deviations are promptly identified and corrected. -

Non-Destructive Testing

Non-destructive testing (NDT) methods, such as ultrasonic testing, radiographic testing, and magnetic particle testing, are employed to detect any hidden defects or imperfections in the fabricated steel components. These NDT techniques ensure that the finished products meet the required quality and safety standards. -

Compliance and Certification

Doha steel fabricators maintain certifications and comply with industry standards, such as ISO 9001 and AWS D1.1, demonstrating their commitment to quality and adherence to best practices. These certifications provide assurance to clients that the fabricated steel structures meet the highest levels of quality and safety.

The stringent quality control measures implemented by Doha steel fabricators are not merely an afterthought; they are an integral part of the fabrication process. By prioritizing quality at every stage, Doha steel fabricators ensure that the fabricated steel structures meet the most demanding requirements, contributing to the safety and longevity of buildings and infrastructure projects in Qatar and beyond.

Project Management

In the realm of Doha steel fabrication, project management plays a pivotal role in ensuring the seamless execution of complex steel fabrication projects. Effective coordination among various stakeholders, including engineers, fabricators, contractors, and suppliers, is crucial for timely completion, adherence to specifications, and overall project success. Here are key facets of project management that contribute to smooth project execution in Doha steel fabrication:

-

Planning and Scheduling

Thorough planning and scheduling form the foundation of successful project management. Doha steel fabricators meticulously plan each project phase, outlining timelines, resource allocation, and milestones. This comprehensive planning ensures that all activities are sequenced and coordinated effectively, minimizing delays and disruptions. -

Communication and Collaboration

Open and transparent communication is essential for effective project management. Doha steel fabricators maintain regular communication channels with all stakeholders, fostering collaboration and ensuring that information is shared. This collaborative approach promotes a shared understanding of project goals and responsibilities, leading to smooth execution and timely decision-making. -

Risk Management

Proactive risk management is crucial in the dynamic environment of Doha steel fabrication. Fabricators identify potential risks and develop mitigation plans to minimize their impact on project outcomes. This forward-thinking approach enables them to anticipate and address challenges, ensuring that projects stay on track and potential disruptions are effectively managed. -

Quality Control

Maintaining high standards of quality is paramount in Doha steel fabrication. Project managers implement rigorous quality control measures throughout the fabrication process, ensuring that steel components meet specifications and industry standards. Regular inspections and testing ensure that the final product meets the required quality benchmarks, contributing to the longevity and structural integrity of steel structures.

Effective project management in Doha steel fabrication is not just about adhering to timelines and meeting specifications; it is about creating a collaborative and efficient work environment that fosters innovation, problem-solving, and continuous improvement. By embracing these facets of project management, Doha steel fabricators deliver high-quality steel structures that meet the demands of modern construction projects, contributing to the development of safe, sustainable, and iconic landmarks in Qatar and beyond.

Sustainable Practices

In the realm of Doha steel fabrication, sustainable practices have emerged as a cornerstone, with environmentally conscious fabrication techniques playing a crucial role in minimizing waste and promoting sustainability. Doha steel fabricators are committed to reducing their environmental footprint and contributing to a greener future without compromising the quality and durability of their steel structures. This commitment manifests in various ways:

1. Material Optimization:

Advanced nesting software and optimized cutting techniques minimize material waste, reducing the amount of scrap steel generated during fabrication. This not only reduces costs but also conserves valuable natural resources.

2. Energy Efficiency:

Doha steel fabricators employ energy-efficient equipment and processes to lower their energy consumption. This includes using LED lighting, variable frequency drives on motors, and implementing energy management systems to optimize energy usage.

3. Water Conservation:

Water conservation measures are implemented throughout the fabrication process. Rainwater harvesting systems collect and reuse rainwater, reducing the demand for freshwater resources. Additionally, water-saving technologies, such as low-flow fixtures and recycling systems, further minimize water consumption.

4. Waste Management:

Comprehensive waste management programs ensure the proper disposal and recycling of waste materials. Steel scrap is recycled and reused in the production of new steel, reducing the need for raw material extraction. Other waste, such as packaging and consumables, is segregated and disposed of responsibly through authorized waste management companies.

5. Green Certifications:

Many Doha steel fabricators have obtained green certifications, such as ISO 14001:2015, demonstrating their commitment to environmental management and sustainability. These certifications require regular audits and adherence to stringent environmental standards.

The practical significance of sustainable practices in Doha steel fabrication extends beyond environmental benefits. By reducing waste and conserving resources, fabricators can lower their operating costs and enhance their competitiveness. Moreover, environmentally conscious practices align with Qatar’s National Vision 2030, which emphasizes sustainability and environmental stewardship. By embracing sustainable practices, Doha steel fabricators contribute to the development of a greener and more sustainable built environment in Qatar.

Key Insights:

- Sustainable practices are integral to Doha steel fabrication, minimizing waste and promoting sustainability.

- Material optimization, energy efficiency, water conservation, waste management, and green certifications contribute to environmental stewardship.

- Sustainable practices not only benefit the environment but also enhance cost-effectiveness and align with Qatar’s sustainability goals.

Frequently Asked Questions about Doha Steel Fabrication

This section addresses common inquiries and misconceptions surrounding Doha steel fabrication, providing informative answers based on industry knowledge and expertise.

Question 1: What sets Doha steel fabrication apart from other fabrication centers?

Doha steel fabrication stands out due to its commitment to precision, quality, and innovation. It utilizes advanced technology, employs skilled professionals, and adheres to stringent quality control measures to deliver high-quality steel structures that meet international standards.

Question 2: What are the advantages of choosing Doha steel fabricators for construction projects?

Doha steel fabricators offer numerous advantages, including customized solutions tailored to specific project requirements, timely delivery through efficient workflows, cost optimization through material optimization and efficient processes, and a commitment to sustainability through environmentally conscious practices.

Question 3: How does Doha steel fabrication ensure the structural integrity of its products?

Structural integrity is paramount in Doha steel fabrication. It is achieved through precise fabrication techniques, skilled workforce, advanced equipment, and rigorous quality control measures. These factors ensure that steel structures meet safety and durability standards, contributing to the longevity and reliability of buildings and infrastructure.

Question 4: What measures are taken to ensure timely delivery of steel structures in Doha?

Timely delivery is crucial in Doha steel fabrication. It is achieved through optimized production processes, a skilled workforce, effective project management, and collaboration among all stakeholders. This ensures that projects are completed within agreed-upon timelines, minimizing delays and maximizing efficiency.

Question 5: How does Doha steel fabrication contribute to sustainability in the construction industry?

Sustainability is a key aspect of Doha steel fabrication. Fabricators implement waste management programs, employ energy-efficient technologies, conserve water resources, and obtain green certifications. These practices not only benefit the environment but also reduce operating costs and align with Qatar’s sustainability goals.

Question 6: What are the key factors to consider when choosing a Doha steel fabrication company?

When selecting a Doha steel fabrication company, consider factors such as experience, expertise, quality standards, adherence to deadlines, and commitment to sustainability. Reputable fabricators possess a proven track record, employ skilled professionals, and prioritize customer satisfaction through reliable and high-quality services.

In summary, Doha steel fabrication has established itself as a leading fabrication center, offering precision, quality, innovation, and sustainability. By addressing common questions and concerns, this FAQ section provides valuable insights into the industry’s best practices and advantages.

To learn more about the latest advancements and best practices in Doha steel fabrication, explore reputable industry resources and consult with experienced professionals.

Doha Steel Fabrication Tips for Optimal Outcomes

Doha steel fabrication has emerged as a renowned industry, delivering high-quality steel structures that contribute to the development of Qatar’s built environment. To achieve optimal results in Doha steel fabrication projects, consider the following tips:

Tip 1: Prioritize Precision and Quality

Precision and quality are paramount in Doha steel fabrication. Employ advanced cutting and welding technologies, and engage skilled professionals to ensure accurate fabrication and adherence to industry standards. This meticulous approach ensures structural integrity, durability, and longevity of steel structures.

Tip 2: Optimize Material Usage

Material optimization is crucial for cost-effectiveness and sustainability. Utilize advanced nesting software to minimize material waste and reduce production costs. Explore innovative techniques, such as lean manufacturing principles, to streamline processes and further optimize material usage.

Tip 3: Ensure Timely Delivery

Timely delivery is essential to avoid project delays and cost overruns. Implement efficient workflows, leverage advanced equipment, and maintain effective communication among all stakeholders. By optimizing production processes and coordinating schedules, Doha steel fabricators can deliver high-quality steel structures within agreed-upon timelines.

Tip 4: Embrace Sustainable Practices

Sustainability is a growing concern in the construction industry. Adopt environmentally conscious practices, such as waste management programs, energy-efficient technologies, and water conservation measures. By embracing sustainability, Doha steel fabricators can contribute to a greener and more sustainable built environment.

Tip 5: Seek Professional Expertise

Partner with reputable Doha steel fabricators who possess extensive experience and expertise. Look for companies that have a proven track record of delivering high-quality steel structures, adhering to deadlines, and providing excellent customer service. Their knowledge and experience will ensure the successful execution of your steel fabrication project.

Summary

By adhering to these tips, stakeholders involved in Doha steel fabrication projects can achieve optimal outcomes. Precision, quality, material optimization, timely delivery, sustainability, and professional expertise are key factors that contribute to the successful fabrication and delivery of high-quality steel structures in Doha.

Conclusion

Doha steel fabrication has emerged as a vital industry, contributing to the construction of iconic landmarks and infrastructure projects in Qatar. Through the exploration of its key aspects, this article has shed light on the precision, quality, innovation, and sustainability that define Doha steel fabrication. By embracing advanced technologies, skilled professionals, and stringent quality control measures, Doha steel fabricators deliver high-quality steel structures that meet the demands of modern construction.

As Qatar continues to grow and develop, the significance of Doha steel fabrication will only increase. By staying abreast of the latest advancements and best practices, stakeholders in the construction industry can harness the potential of Doha steel fabrication to create safe, sustainable, and visually appealing structures that shape the future of Qatar’s built environment.