What is elite machining and fabrication? It is a highly specialized and precise form of metalworking that involves shaping and forming metals into complex and intricate components. This process requires advanced machinery and skilled artisans who have mastered the art of working with metals.

Editor’s note: Elite machining and fabrication is a critical topic for anyone interested in the manufacturing industry. This guide will provide you with the information you need to make informed decisions about your machining and fabrication needs.

We’ve done the analysis, dug through the information, and put together this elite machining & fabrication guide to help you make the right decision.

| Key Differences | Elite Machining | Fabrication |

|---|---|---|

| Process | Uses advanced machinery to shape and form metals | Involves cutting, bending, and assembling metal components |

| Precision | Extremely precise, with tolerances of up to thousandths of an inch | Less precise, with tolerances of up to hundredths of an inch |

| Complexity | Can create highly complex and intricate components | Limited to simpler shapes and assemblies |

Main Article Topics

- The benefits of elite machining and fabrication

- The different types of elite machining and fabrication services

- How to choose the right elite machining and fabrication company

Elite Machining & Fabrication

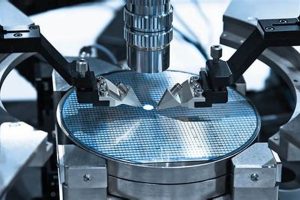

Elite machining and fabrication are essential processes used in various industries, including aerospace, automotive, and medical. They involve the use of advanced machinery and skilled artisans to transform metals into complex and precise components. Here are 12 key aspects of elite machining and fabrication:

- Precision: Tolerances of up to thousandths of an inch

- Accuracy: Components meet or exceed specifications

- Complexity: Ability to create intricate and complex shapes

- Materials: Work with a wide range of metals, including steel, aluminum, and titanium

- Equipment: Use advanced CNC machines, lathes, and mills

- Quality: Adherence to strict quality control standards

- Experience: Skilled artisans with years of experience

- Customization: Ability to create custom components to meet specific needs

- Versatility: Can be used for a variety of applications

- Efficiency: Use of automated processes to reduce lead times

- Cost-effectiveness: Competitive pricing and value for money

- Innovation: Continuously invest in new technologies and techniques

These aspects are all interconnected and contribute to the overall quality and efficiency of elite machining and fabrication. For example, precision and accuracy are essential for creating components that meet or exceed specifications. Complexity and versatility allow for the creation of a wide range of components for different applications. Quality and experience ensure that components are manufactured to the highest standards. Customization and cost-effectiveness make elite machining and fabrication a viable option for businesses of all sizes.

Precision

Precision is a critical aspect of elite machining and fabrication. It refers to the ability to create components that meet or exceed specified tolerances. In elite machining and fabrication, tolerances can be as tight as thousandths of an inch. This level of precision is essential for creating components that function properly and meet the demands of various industries.

For example, in the aerospace industry, precision machining is used to create components for aircraft engines. These components must meet exacting tolerances to ensure the safety and reliability of the aircraft. In the medical industry, precision machining is used to create components for surgical instruments and implants. These components must be precise to ensure that they function properly and do not cause harm to patients.

Achieving precision in machining and fabrication requires a combination of skilled artisans, advanced machinery, and rigorous quality control processes. Skilled artisans have the experience and expertise to operate machinery and create components to precise specifications. Advanced machinery, such as CNC machines and lathes, allows for precise cutting and shaping of metals. Rigorous quality control processes ensure that components meet or exceed specifications.

The precision of elite machining and fabrication is essential for a variety of applications. It ensures that components function properly, meet industry standards, and meet the demands of various industries. Without precision, it would be impossible to create the complex and intricate components that are essential for modern technology.

| Industry | Application | Importance of Precision |

|---|---|---|

| Aerospace | Aircraft engine components | Ensures safety and reliability |

| Medical | Surgical instruments and implants | Ensures proper function and patient safety |

| Automotive | Engine and transmission components | Ensures performance and fuel efficiency |

Accuracy

Accuracy is a critical component of elite machining and fabrication. It refers to the ability to create components that meet or exceed specified dimensions and tolerances. In elite machining and fabrication, accuracy is essential for ensuring that components function properly and meet the demands of various industries.

For example, in the automotive industry, accurate machining is essential for creating engine and transmission components that meet performance and fuel efficiency standards. In the medical industry, accurate machining is essential for creating surgical instruments and implants that function properly and do not cause harm to patients.

Achieving accuracy in machining and fabrication requires a combination of skilled artisans, advanced machinery, and rigorous quality control processes. Skilled artisans have the experience and expertise to operate machinery and create components to precise specifications. Advanced machinery, such as CNC machines and lathes, allows for precise cutting and shaping of metals. Rigorous quality control processes ensure that components meet or exceed specifications.

The accuracy of elite machining and fabrication is essential for a variety of applications. It ensures that components function properly, meet industry standards, and meet the demands of various industries. Without accuracy, it would be impossible to create the complex and intricate components that are essential for modern technology.

| Industry | Application | Importance of Accuracy |

|---|---|---|

| Aerospace | Aircraft engine components | Ensures safety and reliability |

| Medical | Surgical instruments and implants | Ensures proper function and patient safety |

| Automotive | Engine and transmission components | Ensures performance and fuel efficiency |

Complexity

Elite machining and fabrication is characterized by its ability to create intricate and complex shapes. This capability is essential for a variety of industries, including aerospace, medical, and automotive. Complex shapes are often required for components that must meet specific performance or aesthetic requirements.

-

Facet 1: Aerospace applications

In the aerospace industry, complex shapes are often required for components such as aircraft engine blades and airfoils. These components must be able to withstand high temperatures and stresses, and they must be manufactured to precise tolerances. Elite machining and fabrication techniques are used to create these complex shapes with the required accuracy and precision. -

Facet 2: Medical applications

In the medical industry, complex shapes are often required for components such as surgical instruments and implants. These components must be biocompatible and able to withstand the harsh conditions of the human body. Elite machining and fabrication techniques are used to create these complex shapes with the required precision and accuracy. -

Facet 3: Automotive applications

In the automotive industry, complex shapes are often required for components such as engine blocks and transmission housings. These components must be able to withstand high temperatures and stresses, and they must be manufactured to precise tolerances. Elite machining and fabrication techniques are used to create these complex shapes with the required accuracy and precision. -

Facet 4: Artistic applications

In addition to industrial applications, elite machining and fabrication techniques are also used to create complex shapes for artistic purposes. Artists use these techniques to create sculptures, jewelry, and other works of art. Elite machining and fabrication techniques allow artists to create complex shapes with a high degree of precision and accuracy.

The ability to create intricate and complex shapes is a key advantage of elite machining and fabrication. This capability allows manufacturers to create components that meet the demanding requirements of a variety of industries. Elite machining and fabrication techniques are also used to create works of art with a high degree of precision and accuracy.

Materials

In the realm of elite machining and fabrication, the selection of materials plays a pivotal role in determining the quality, durability, and performance of the finished product. Among the various materials used in this specialized field, steel, aluminum, and titanium stand out for their unique properties and suitability for a wide range of applications.

-

Facet 1: Strength and Durability of Steel

Steel is renowned for its exceptional strength and durability, making it an ideal choice for components that must withstand high loads and stresses. In elite machining and fabrication, steel is commonly used for structural components, gears, and shafts, where its inherent strength ensures longevity and reliability.

-

Facet 2: Lightweight and Versatility of Aluminum

Aluminum offers an excellent combination of strength and lightness, making it a preferred material for components that require both durability and weight reduction. In elite machining and fabrication, aluminum is frequently used for aerospace components, automotive parts, and electronic enclosures, where its lightweight nature is crucial.

-

Facet 3: Corrosion Resistance and Biocompatibility of Titanium

Titanium is highly resistant to corrosion and biocompatible, making it an ideal choice for components that must withstand harsh environments or be implanted into the human body. In elite machining and fabrication, titanium is commonly used for medical implants, marine components, and chemical processing equipment, where its resistance to corrosion and biocompatibility are essential.

These three metals, steel, aluminum, and titanium, represent just a fraction of the materials used in elite machining and fabrication. The choice of material depends on the specific requirements of the application, considering factors such as strength, durability, weight, corrosion resistance, and biocompatibility. By carefully selecting and utilizing the appropriate materials, elite machinists and fabricators can create components that meet the most demanding specifications and perform flawlessly in their intended applications.

Equipment

The use of advanced CNC machines, lathes, and mills is central to the process of elite machining and fabrication. These machines allow for precise and efficient cutting, shaping, and forming of metals, enabling the creation of intricate and complex components with high levels of accuracy and repeatability.

-

Facet 1: Precision and Accuracy

CNC machines, lathes, and mills are equipped with computer-controlled systems that guide the cutting tools with extreme precision. This allows for the creation of components with tight tolerances and complex geometries, which is essential for many applications in industries such as aerospace, medical, and automotive.

-

Facet 2: Efficiency and Speed

Advanced CNC machines, lathes, and mills operate at high speeds and can be programmed to perform repetitive tasks with minimal human intervention. This automation and efficiency result in shorter lead times and reduced production costs, making elite machining and fabrication a viable option for large-scale production.

-

Facet 3: Versatility and Flexibility

These machines are highly versatile and can be used to process a wide range of materials, including metals, plastics, and composites. They can also be equipped with various cutting tools and attachments, allowing for a diverse range of machining operations, from simple cutting to complex contouring and milling.

-

Facet 4: Complex Geometries and Intricate Designs

The advanced capabilities of CNC machines, lathes, and mills make it possible to create complex geometries and intricate designs that would be difficult or impossible to achieve using traditional machining methods. This enables the production of components with unique shapes and features, pushing the boundaries of design and innovation.

In summary, the use of advanced CNC machines, lathes, and mills is a defining characteristic of elite machining and fabrication. These machines provide the precision, efficiency, and versatility required to create complex and intricate components that meet the demands of modern industries. By leveraging the capabilities of these advanced machines, elite machinists and fabricators can produce high-quality components that meet or exceed the most stringent specifications.

Quality

In the realm of elite machining and fabrication, quality is paramount. Adherence to strict quality control standards is not merely a component of elite machining and fabrication; it is the very foundation upon which this specialized field is built. Without a rigorous commitment to quality, it would be impossible to achieve the precision, accuracy, and reliability that define elite machining and fabrication.

Real-life examples abound of the practical significance of quality in elite machining and fabrication. In the aerospace industry, for instance, the failure of a single component can have catastrophic consequences. As such, elite machining and fabrication techniques are employed to create aircraft components that meet the most stringent quality standards, ensuring the safety and reliability of aircraft.

The medical industry provides another compelling example of the importance of quality in elite machining and fabrication. Surgical instruments and implants must be manufactured to exacting standards to ensure patient safety and well-being. Elite machining and fabrication techniques enable the creation of medical devices that meet these high standards, giving surgeons the confidence to perform complex procedures with precision and accuracy.

| Industry | Application | Importance of Quality |

|---|---|---|

| Aerospace | Aircraft components | Ensures safety and reliability |

| Medical | Surgical instruments and implants | Ensures patient safety and well-being |

| Automotive | Engine and transmission components | Ensures performance and fuel efficiency |

The key insights that emerge from this exploration are clear: quality is not simply a desirable attribute in elite machining and fabrication; it is an absolute necessity. By adhering to strict quality control standards, elite machinists and fabricators can create components that meet the most demanding requirements, ensuring the safety, reliability, and performance of products in a wide range of industries.

Experience

In the realm of elite machining and fabrication, experience is not merely a desirable attribute; it is an indispensable component. Skilled artisans with years of experience possess a deep understanding of the materials, processes, and techniques involved in this specialized field. Their expertise enables them to create components that meet the most demanding specifications and perform flawlessly in their intended applications.

Real-life examples abound of the practical significance of experience in elite machining and fabrication. In the aerospace industry, for instance, the failure of a single component can have catastrophic consequences. As such, elite machinists with years of experience are entrusted with the task of creating aircraft components that meet the most stringent quality standards, ensuring the safety and reliability of aircraft.

The medical industry provides another compelling example of the importance of experience in elite machining and fabrication. Surgical instruments and implants must be manufactured to exacting standards to ensure patient safety and well-being. Elite machinists with years of experience possess the knowledge and skills necessary to create medical devices that meet these high standards, giving surgeons the confidence to perform complex procedures with precision and accuracy.

| Industry | Application | Importance of Experience |

|---|---|---|

| Aerospace | Aircraft components | Ensures safety and reliability |

| Medical | Surgical instruments and implants | Ensures patient safety and well-being |

| Automotive | Engine and transmission components | Ensures performance and fuel efficiency |

The key insights that emerge from this exploration are clear: experience is not simply a desirable attribute in elite machining and fabrication; it is an absolute necessity. Skilled artisans with years of experience possess the knowledge, skills, and expertise required to create components that meet the most demanding requirements, ensuring the safety, reliability, and performance of products in a wide range of industries.

Customization

In the realm of elite machining and fabrication, customization stands as a cornerstone, empowering the creation of bespoke components tailored to meet specific and often complex requirements. This ability to customize is a direct reflection of the specialized expertise and advanced capabilities that define elite machining and fabrication.

Real-life examples abound, showcasing the practical significance of customization in elite machining and fabrication. In the aerospace industry, for instance, the need for custom components is paramount. Aircraft are designed to meet unique performance and safety criteria, and the components that comprise these aircraft must be tailored accordingly. Elite machinists and fabricators possess the skills and resources to create custom components that meet these exacting demands, ensuring the safety and reliability of aircraft.

The medical industry provides another compelling example of the importance of customization in elite machining and fabrication. Surgical instruments and implants must be designed to meet the specific needs of each patient. Elite machinists and fabricators work closely with surgeons to create custom components that are perfectly suited to each patient’s unique anatomy and condition. This customization ensures optimal outcomes and improves patient well-being.

| Industry | Application | Importance of Customization |

|---|---|---|

| Aerospace | Aircraft components | Ensures safety and reliability |

| Medical | Surgical instruments and implants | Ensures optimal outcomes and patient well-being |

| Automotive | Engine and transmission components | Enables performance optimization and fuel efficiency |

The ability to create custom components is not merely an ancillary aspect of elite machining and fabrication; it is a defining characteristic. By harnessing their expertise and leveraging advanced technologies, elite machinists and fabricators empower a wide range of industries to achieve their unique goals and objectives.

Versatility

The versatility of elite machining and fabrication lies in its ability to cater to a diverse range of applications across numerous industries. This versatility stems from the inherent flexibility and adaptability of the processes and techniques involved in elite machining and fabrication.

The ability to machine and fabricate a wide variety of materials, including metals, plastics, and composites, allows elite machinists and fabricators to create components for a vast array of applications. This versatility is particularly valuable in industries such as aerospace, medical, and automotive, where components must meet stringent requirements for precision, durability, and performance.

| Industry | Applications | Benefits of Versatility |

|---|---|---|

| Aerospace | Aircraft components, engine parts, structural elements | Enables customization and optimization for specific aircraft designs and performance requirements |

| Medical | Surgical instruments, implants, prosthetics | Allows for the creation of patient-specific components that are tailored to unique anatomical needs and medical conditions |

| Automotive | Engine components, transmission parts, suspension systems | Facilitates the development of high-performance and fuel-efficient vehicles through the production of lightweight and durable components |

The versatility of elite machining and fabrication extends beyond the variety of materials that can be processed. It also encompasses the ability to create components with complex geometries and intricate features. This versatility is made possible by the use of advanced CNC machines, lathes, and mills, which can be programmed to execute precise and complex machining operations.

The combination of material versatility and geometric complexity allows elite machinists and fabricators to produce components that meet the unique and often demanding requirements of various industries. This versatility is a key factor in the success and widespread adoption of elite machining and fabrication techniques.

Efficiency

In the realm of elite machining and fabrication, efficiency is paramount. The use of automated processes plays a pivotal role in reducing lead times, enabling the timely delivery of high-quality components to meet the demands of various industries.

-

Facet 1: Streamlined Production Processes

Automated processes, such as CNC machining and robotic welding, streamline production processes by eliminating manual intervention and repetitive tasks. This automation reduces cycle times, improves consistency, and minimizes the risk of errors, resulting in significant time savings.

-

Facet 2: Reduced Labor Costs

Automation reduces the need for manual labor, leading to lower labor costs and increased cost-effectiveness. This allows elite machining and fabrication companies to offer competitive pricing while maintaining high quality standards.

-

Facet 3: Increased Capacity and Flexibility

Automated processes enable manufacturers to increase their production capacity without the need to hire additional staff. This flexibility allows them to scale up or down production as needed, adapting to changing market demands.

-

Facet 4: Improved Quality Control

Automated processes provide greater control over production parameters, such as cutting speeds and temperatures. This consistent and precise control reduces the likelihood of defects and ensures the production of high-quality components.

In summary, the use of automated processes in elite machining and fabrication leads to reduced lead times, lower costs, increased flexibility, and improved quality control. These benefits make elite machining and fabrication a compelling choice for manufacturers seeking to optimize their production processes and meet the demands of a competitive global market.

Cost-effectiveness

In the competitive landscape of manufacturing, cost-effectiveness is a crucial factor for businesses seeking to optimize their operations and maximize their return on investment. Elite machining and fabrication stands out in this regard, offering competitive pricing and exceptional value for money.

-

Facet 1: Reduced Production Costs

Advanced automated processes and efficient production techniques employed in elite machining and fabrication significantly reduce production costs. By eliminating manual labor and minimizing waste, manufacturers can achieve economies of scale, passing on the savings to their customers.

-

Facet 2: High-Quality Materials and Precision Manufacturing

Elite machining and fabrication utilizes high-quality materials and precise manufacturing techniques, ensuring the durability and longevity of components. This reduces the need for frequent replacements or repairs, leading to lower maintenance costs and increased overall value.

-

Facet 3: Design Optimization and Value Engineering

Skilled engineers collaborate with clients to optimize designs and identify areas for cost reduction without compromising performance. Value engineering techniques are employed to find alternative materials or processes that maintain quality while minimizing expenses.

-

Facet 4: Long-Term Return on Investment

The durability and reliability of components produced through elite machining and fabrication result in a higher return on investment over the long term. Reduced maintenance costs, extended component life, and improved performance contribute to a favorable total cost of ownership.

In summary, elite machining and fabrication offers competitive pricing and exceptional value for money through reduced production costs, high-quality manufacturing, design optimization, and long-term return on investment. By partnering with skilled professionals in this field, businesses can gain a competitive edge and achieve their manufacturing goals within budget.

Innovation

In the realm of elite machining and fabrication, innovation is not merely a buzzword; it is a driving force that propels the industry forward. Elite machinists and fabricators continuously invest in new technologies and techniques to enhance their capabilities, push the boundaries of what is possible, and meet the ever-evolving demands of various industries.

The connection between innovation and elite machining & fabrication is multifaceted. Firstly, innovation fuels the development of new and improved materials, allowing elite machinists and fabricators to create components with enhanced properties such as strength, durability, and corrosion resistance. Secondly, innovation drives the advancement of cutting-edge machinery and software, enabling greater precision, efficiency, and flexibility in the machining and fabrication processes.

Real-life examples abound, showcasing the practical significance of innovation in elite machining and fabrication. In the aerospace industry, for instance, the development of lightweight and high-strength composite materials has revolutionized aircraft design, enabling the creation of more fuel-efficient and aerodynamic aircraft. In the medical industry, innovative machining techniques have made it possible to create patient-specific implants and surgical instruments with unprecedented precision, leading to improved patient outcomes.

The understanding of the connection between innovation and elite machining & fabrication is crucial for several reasons. Firstly, it highlights the importance of continuous investment in research and development to stay at the forefront of the industry. Secondly, it emphasizes the need for collaboration between elite machinists and fabricators, researchers, and end-users to identify and address emerging challenges and opportunities. Thirdly, it underscores the value of embracing new technologies and techniques to enhance productivity, efficiency, and competitiveness.

In summary, innovation is an indispensable component of elite machining and fabrication, driving the development of new materials, machinery, and techniques. By continuously investing in innovation, elite machinists and fabricators empower a wide range of industries to achieve their unique goals and objectives.

| Industry | Innovation | Impact |

|---|---|---|

| Aerospace | Lightweight composite materials | Fuel-efficient and aerodynamic aircraft |

| Medical | Patient-specific implants | Improved patient outcomes |

| Automotive | Advanced engine designs | Reduced emissions and improved performance |

FAQs on Elite Machining & Fabrication

This section addresses frequently asked questions to provide a comprehensive understanding of elite machining and fabrication.

Question 1: What sets elite machining and fabrication apart from traditional methods?

Answer: Elite machining and fabrication employs advanced machinery, skilled artisans, and rigorous quality control processes to achieve exceptional precision, accuracy, and complexity in component manufacturing. Traditional methods may lack the sophistication and expertise required for intricate and high-tolerance applications.

Question 2: What are the benefits of choosing elite machining and fabrication services?

Answer: Elite machining and fabrication services offer numerous advantages, including:

- Exceptional precision and accuracy for demanding specifications

- Ability to create intricate and complex shapes

- Use of advanced materials for enhanced durability and performance

- Skilled artisans with expertise in various machining techniques

- Rigorous quality control processes to ensure the highest standards

Question 3: What industries rely heavily on elite machining and fabrication?

Answer: Elite machining and fabrication services are essential in various industries, including:

- Aerospace: Precision components for aircraft engines and structural elements

- Medical: Surgical instruments, implants, and prosthetics

- Automotive: Engine components, transmission parts, and suspension systems

- Electronics: Fabrication of intricate circuit boards and electronic components

- Energy: Components for turbines, generators, and other power generation systems

Question 4: How does elite machining and fabrication contribute to innovation?

Answer: Elite machining and fabrication play a vital role in innovation by enabling the creation of prototypes, custom components, and specialized parts. It supports research and development initiatives, allowing engineers and designers to explore new concepts and push the boundaries of what is possible.

Question 5: What are the key considerations when choosing an elite machining and fabrication provider?

Answer: When selecting an elite machining and fabrication provider, consider the following factors:

- Experience and expertise in the required machining techniques

- State-of-the-art machinery and equipment

- Quality control standards and certifications

- Capacity to handle the project’s and complexity

- Reputation for reliability and customer satisfaction

Question 6: How can companies leverage elite machining and fabrication to gain a competitive advantage?

Answer: Companies can leverage elite machining and fabrication to:

- Create innovative products with unique features and capabilities

- Optimize performance and efficiency through precision-engineered components

- Reduce production costs by utilizing advanced manufacturing techniques

- Enhance product quality and durability, leading to increased customer satisfaction

- Gain a technological edge over competitors by accessing cutting-edge machining and fabrication capabilities

Summary

Elite machining and fabrication represent the pinnacle of precision engineering, enabling the creation of complex and high-performance components for a wide range of industries. By partnering with experienced and reputable providers, companies can harness the power of elite machining and fabrication to drive innovation, enhance competitiveness, and achieve their manufacturing goals.

Transition to the next article section

For further insights into the world of elite machining and fabrication, explore our comprehensive articles covering specific aspects of this specialized field.

Tips for Optimizing Elite Machining & Fabrication

To harness the full potential of elite machining and fabrication, consider these valuable tips:

Tip 1: Define Clear Specifications

Precisely articulate your component requirements, including dimensions, tolerances, and material specifications. Clear specifications ensure that the fabrication process aligns with your intended outcomes.

Tip 2: Leverage Advanced Technologies

Embrace cutting-edge CNC machines, lasers, and automation to enhance precision, efficiency, and repeatability. Advanced technologies empower you to create complex geometries and achieve exceptional surface finishes.

Tip 3: Collaborate with Experienced Professionals

Seek partnerships with reputable elite machining and fabrication providers who possess in-depth knowledge and expertise. Their guidance can optimize your designs, material selection, and manufacturing processes.

Tip 4: Prioritize Quality Control

Implement rigorous quality control measures throughout the fabrication process. Utilize precision measuring tools, inspection techniques, and certifications to ensure that your components meet the highest standards.

Tip 5: Optimize Material Selection

Carefully consider the material properties and characteristics that align with your application requirements. Explore advanced materials, such as composites and alloys, to achieve optimal strength, durability, and performance.

Tip 6: Foster Continuous Improvement

Continuously evaluate your fabrication processes and seek opportunities for improvement. Embrace innovation, invest in training, and implement lean manufacturing principles to enhance efficiency and cost-effectiveness.

Tip 7: Consider Post-Processing Techniques

Explore post-processing techniques, such as heat treatment, surface treatments, and assembly, to enhance the functionality and aesthetics of your fabricated components.

Tip 8: Leverage Design for Manufacturability

Collaborate with your fabrication partner to incorporate design for manufacturability principles. This approach optimizes designs for efficient and cost-effective production, reducing lead times and minimizing material waste.

Summary

By adhering to these tips, you can effectively harness the capabilities of elite machining and fabrication to create high-quality, precision components that meet the demands of your industry. Remember to prioritize clear communication, collaboration, and continuous improvement to maximize the value of this specialized manufacturing process.

Transition to the article’s conclusion

As you delve deeper into the world of elite machining and fabrication, explore our comprehensive articles to gain further insights and best practices for this advanced manufacturing technique.

Conclusion

In the realm of manufacturing, elite machining and fabrication stand as a testament to human ingenuity and technological prowess. This specialized field empowers industries to create intricate and high-performance components that drive innovation and shape the future.

Throughout this article, we have explored the essential aspects of elite machining and fabrication, from precision and accuracy to complexity and versatility. We have highlighted the use of advanced machinery, skilled artisans, and rigorous quality control processes that define this specialized craft. By embracing elite machining and fabrication, industries can unlock a world of possibilities, creating components that meet the most demanding specifications and push the boundaries of what is possible.

As we look ahead, the future of elite machining and fabrication holds immense promise. Continuous advancements in technology and materials will further enhance the capabilities of this field, enabling the creation of even more complex and high-performance components. By partnering with experienced and reputable providers, industries can harness the power of elite machining and fabrication to drive innovation, gain a competitive edge, and shape the future of manufacturing.