South Africa is home to a thriving manufacturing industry, and fabrication companies play a vital role in this sector. These companies specialize in the creation of metal structures, components, and products for a wide range of industries, including construction, mining, and automotive.

Editor’s Note: This article provides a comprehensive overview of fabrication companies in South Africa, including their capabilities, services, and the benefits of working with them.

To help you make informed decisions about your fabrication needs, we’ve analyzed the market, compared different companies, and put together this guide. Whether you’re looking for a company to handle a small project or a large-scale manufacturing operation, we’ve got you covered.

Key Differences

| Characteristic | Key Difference |

|---|---|

| Capabilities | Some companies specialize in specific types of fabrication, such as welding, cutting, or forming. Others offer a full range of services. |

| Materials | Companies may specialize in working with certain materials, such as steel, aluminum, or stainless steel. |

| Capacity | Some companies have the capacity to handle large-volume orders, while others are better suited for smaller projects. |

| Location | The location of a company may be important if you need to work closely with them or if shipping costs are a concern. |

| Certifications | Some companies may have specific certifications, such as ISO 9001 or ASME, that indicate their commitment to quality and safety. |

Benefits of Working with Fabrication Companies

- Access to specialized expertise and equipment

- Cost savings through economies of scale

- Improved quality and consistency

- Reduced lead times

- Increased flexibility and responsiveness

Conclusion

Choosing the right fabrication company for your needs is essential for ensuring the success of your project. By considering the factors discussed in this guide, you can make an informed decision and find a partner that will help you achieve your goals.

Fabrication Companies in South Africa

Fabrication companies in South Africa play a crucial role in the country’s manufacturing sector. They provide a wide range of services, from custom metal fabrication to precision engineering. Here are 12 key aspects to consider when choosing a fabrication company in South Africa:

- Capabilities: The range of services offered by the company, such as welding, cutting, forming, and machining.

- Materials: The types of materials the company can work with, such as steel, aluminum, stainless steel, and exotic alloys.

- Capacity: The company’s ability to handle large-volume orders and meet tight deadlines.

- Quality: The company’s commitment to quality, as evidenced by certifications such as ISO 9001.

- Experience: The company’s track record and experience in the industry.

- Location: The company’s location relative to your own, which can impact shipping costs and lead times.

- Price: The company’s pricing structure and ability to meet your budget.

- Customer service: The company’s responsiveness, communication skills, and willingness to go the extra mile.

- Technology: The company’s use of advanced technology and equipment.

- Innovation: The company’s commitment to innovation and developing new products and processes.

- Sustainability: The company’s environmental practices and commitment to sustainability.

- Partnerships: The company’s partnerships with other businesses, which can provide access to additional resources and expertise.

These key aspects are interconnected and should be considered together when evaluating fabrication companies in South Africa. By carefully considering these factors, you can choose a company that meets your specific needs and helps you achieve your business goals.

Capabilities

The capabilities of a fabrication company refer to the range of services it can offer. These services typically include welding, cutting, forming, and machining. Welding is the process of joining two or more pieces of metal together using heat. Cutting is the process of separating two or more pieces of metal. Forming is the process of shaping metal into a desired shape. Machining is the process of removing material from a piece of metal to create a desired shape.

-

Welding

Welding is a critical process in the fabrication of metal structures and components. It is used to join two or more pieces of metal together, creating a strong and durable bond. There are many different welding processes, each with its own advantages and disadvantages. The most common welding processes used in fabrication include arc welding, MIG welding, and TIG welding. -

Cutting

Cutting is another essential process in fabrication. It is used to separate two or more pieces of metal, or to create a desired shape in a piece of metal. There are many different cutting processes, each with its own advantages and disadvantages. The most common cutting processes used in fabrication include laser cutting, waterjet cutting, and plasma cutting. -

Forming

Forming is the process of shaping metal into a desired shape. It is used to create a variety of different shapes, from simple bends to complex curves. There are many different forming processes, each with its own advantages and disadvantages. The most common forming processes used in fabrication include bending, rolling, and stamping. -

Machining

Machining is the process of removing material from a piece of metal to create a desired shape. It is used to create a variety of different shapes, from simple holes to complex contours. There are many different machining processes, each with its own advantages and disadvantages. The most common machining processes used in fabrication include milling, turning, and drilling.

The capabilities of a fabrication company are an important factor to consider when choosing a company to partner with. The capabilities of a company will determine the types of projects it can undertake, as well as the quality and precision of its work. When choosing a fabrication company, it is important to select a company that has the capabilities to meet your specific needs.

Materials

The types of materials that a fabrication company can work with is a crucial factor to consider when choosing a partner for your project. The material you select will impact the final product’s strength, durability, weight, and cost. Here are some of the most common materials used in fabrication:

-

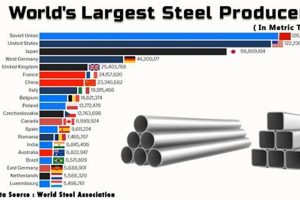

Steel

Steel is a strong and durable material that is relatively inexpensive. It is commonly used in a wide range of applications, including construction, automotive, and manufacturing. Steel is also available in a variety of grades, each with its own unique properties. -

Aluminum

Aluminum is a lightweight and corrosion-resistant material that is often used in aerospace, marine, and automotive applications. It is also a good conductor of heat and electricity, making it ideal for use in electrical components. -

Stainless steel

Stainless steel is a corrosion-resistant alloy of steel that is often used in food processing, medical, and chemical applications. It is also a popular choice for architectural and decorative purposes. -

Exotic alloys

Exotic alloys are materials that are designed for specific applications, such as high-temperature or high-strength applications. They are often more expensive than common materials, but they can offer unique properties that make them ideal for certain projects.

When choosing a fabrication company, it is important to select a company that has experience working with the materials you need. The company should also have the equipment and expertise to properly fabricate your project.

Capacity

Capacity is a critical factor to consider when choosing a fabrication company in South Africa. The company’s capacity will determine its ability to handle your project’s specific requirements, including the volume of work and the deadline. Here are some key points to consider:

- Volume: The company should have the capacity to handle the volume of work required for your project. If the company is too small, it may not be able to complete your project on time or to the required quality standards.

- Deadlines: The company should be able to meet your project’s deadlines. If the company is too busy, it may not be able to start your project on time or may have to rush the job, which could impact the quality of the work.

- Flexibility: The company should be flexible and able to accommodate changes to the project’s scope or schedule. This is important in case there are unforeseen delays or changes in the project requirements.

When choosing a fabrication company in South Africa, it is important to assess the company’s capacity carefully. The company should have the experience, equipment, and staff to handle your project’s specific requirements. By choosing a company with the right capacity, you can ensure that your project is completed on time, to the required quality standards, and within budget.

Here is a table summarizing the key points discussed above:

| Factor | Description |

|---|---|

| Volume | The company should have the capacity to handle the volume of work required for your project. |

| Deadlines | The company should be able to meet your project’s deadlines. |

| Flexibility | The company should be flexible and able to accommodate changes to the project’s scope or schedule. |

Quality

Quality is of paramount importance in the fabrication industry. A company’s commitment to quality is essential for ensuring that its products and services meet the highest standards of safety, reliability, and performance. One of the most recognized indicators of a company’s commitment to quality is ISO 9001 certification.

ISO 9001 is an international standard that sets out the requirements for a quality management system (QMS). A company that is ISO 9001 certified has demonstrated that it has a robust QMS in place that meets the requirements of the standard. This means that the company has a systematic approach to quality management, and that it is committed to continuous improvement.

For fabrication companies in South Africa, ISO 9001 certification is a valuable asset. It demonstrates to customers that the company is committed to quality and that it has the systems in place to ensure that its products and services meet the highest standards. This can give companies a competitive advantage and help them to win new business.

In addition, ISO 9001 certification can help fabrication companies to improve their efficiency and productivity. By following the requirements of the standard, companies can identify and eliminate waste in their processes, which can lead to cost savings and improved profitability.

Overall, ISO 9001 certification is a valuable tool for fabrication companies in South Africa. It demonstrates a company’s commitment to quality, and it can help to improve efficiency and productivity. For customers, ISO 9001 certification provides assurance that the company’s products and services meet the highest standards of quality.

Benefits of ISO 9001 Certification for Fabrication Companies in South Africa

| Benefit | Description |

|---|---|

| Improved quality | ISO 9001 certification helps companies to improve the quality of their products and services by providing a framework for identifying and eliminating waste in their processes. |

| Increased efficiency | By following the requirements of ISO 9001, companies can identify and eliminate waste in their processes, which can lead to cost savings and improved profitability. |

| Competitive advantage | ISO 9001 certification can give companies a competitive advantage by demonstrating their commitment to quality to customers. |

| Improved customer satisfaction | ISO 9001 certification can help companies to improve customer satisfaction by ensuring that their products and services meet the highest standards of quality. |

Experience

Experience is a crucial factor to consider when choosing a fabrication company in South Africa. A company with a long and successful track record in the industry is more likely to have the expertise and experience to handle your project successfully. Here are four key facets of experience to consider:

- Years in business: The number of years a company has been in business is a good indicator of its experience and stability. A company that has been in business for many years has had the opportunity to build up a strong track record and develop a deep understanding of the industry.

- Project portfolio: A company’s project portfolio is a great way to assess its experience. Look for a company that has experience in projects similar to yours. This will give you confidence that the company has the expertise to handle your project successfully.

- Customer testimonials: Customer testimonials are another valuable source of information about a company’s experience. Read testimonials from past customers to get an idea of the company’s quality of work, customer service, and overall reliability.

- Industry awards and recognition: Industry awards and recognition are a testament to a company’s experience and expertise. Look for a company that has been recognized by industry organizations for its work.

By considering these four facets of experience, you can choose a fabrication company in South Africa that has the expertise and experience to handle your project successfully.

Location

When choosing a fabrication company in South Africa, it is important to consider the company’s location relative to your own. The location of the company can impact shipping costs and lead times.

If the fabrication company is located far from your own location, shipping costs will be higher and lead times will be longer. This is because the parts will have to be transported over a longer distance.

In addition, if the fabrication company is located in a different country, there may be additional customs and import duties that need to be paid. This can further increase the cost of the parts and the lead time.

Therefore, it is important to consider the location of the fabrication company when making your decision. If shipping costs and lead times are a concern, you may want to choose a company that is located closer to your own location.

| Factor | Description |

|---|---|

| Shipping costs | The cost of shipping the parts from the fabrication company to your location. |

| Lead times | The amount of time it takes for the parts to be shipped from the fabrication company to your location. |

| Customs and import duties | Taxes and duties that may be imposed on the parts when they are imported into your country. |

Price

Price is an important factor to consider when choosing a fabrication company in South Africa. The company’s pricing structure and ability to meet your budget will impact the overall cost of your project.

- Cost of materials: The cost of materials is a major factor in the overall price of a fabrication project. Fabrication companies typically charge for materials at cost, plus a markup. The cost of materials will vary depending on the type of material used and the quantity required.

- Labor costs: Labor costs are another major factor in the overall price of a fabrication project. Fabrication companies typically charge for labor at an hourly rate. The labor rate will vary depending on the skill level of the workers and the complexity of the project.

- Overhead costs: Overhead costs are the indirect costs of running a fabrication business, such as rent, utilities, and insurance. Fabrication companies typically include overhead costs in their pricing structure.

- Profit margin: Fabrication companies need to make a profit in order to stay in business. The profit margin is the difference between the total cost of a project and the price charged to the customer. The profit margin will vary depending on the company’s business model and the competitiveness of the market.

When choosing a fabrication company in South Africa, it is important to get quotes from multiple companies and compare prices. Be sure to compare the total cost of the project, including materials, labor, overhead, and profit margin. Also, be sure to consider the company’s payment terms and any discounts that may be available.

Customer service

Customer service is an essential component of any business, but it is especially important for fabrication companies in South Africa. This is because fabrication projects are often complex and time-consuming, and customers need to be able to trust that the company they are working with is responsive, communicative, and willing to go the extra mile.

There are a number of reasons why customer service is so important for fabrication companies in South Africa:

- To build trust: Customers need to be able to trust that the fabrication company they are working with will be able to deliver on their promises. This means being responsive to inquiries, communicating regularly about the progress of the project, and being willing to go the extra mile to meet the customer’s needs.

- To resolve issues quickly: Fabrication projects can be complex and time-consuming, and there is always the potential for things to go wrong. When issues do arise, it is important to have a fabrication company that is responsive and communicative, and that is willing to work with the customer to resolve the issue quickly and efficiently.

- To build long-term relationships: Fabrication projects are often ongoing, and customers need to be able to trust that the fabrication company they are working with will be there for them in the long run. This means providing excellent customer service throughout the entire project, and being willing to go the extra mile to build a strong relationship with the customer.

There are a number of things that fabrication companies in South Africa can do to improve their customer service:

- Be responsive to inquiries: Customers should be able to get a response to their inquiries quickly and easily. This means having a dedicated customer service team that is available to answer questions and provide information.

- Communicate regularly about the progress of the project: Customers need to be kept up-to-date on the progress of their project. This means providing regular updates, and being available to answer any questions that the customer may have.

- Be willing to go the extra mile: Fabrication projects can be complex and time-consuming, and there is always the potential for things to go wrong. When issues do arise, it is important to be willing to go the extra mile to resolve the issue quickly and efficiently.

By providing excellent customer service, fabrication companies in South Africa can build trust, resolve issues quickly, and build long-term relationships with their customers.

Technology

Technology plays a pivotal role in the success of fabrication companies in South Africa. Advanced technology and equipment enable these companies to produce high-quality products, reduce costs, and improve efficiency. Here’s why technology is crucial for fabrication companies in South Africa:

1. Improved Accuracy and Precision: Advanced technology, such as computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, allows fabrication companies to achieve a high level of accuracy and precision in their work. This is essential for producing parts that meet exact specifications and tolerances, which is especially important in industries such as aerospace, automotive, and medical.

2. Increased Efficiency and Productivity: Automated machinery and robotic systems help fabrication companies to increase their efficiency and productivity. These technologies can perform repetitive tasks faster and more accurately than manual labor, freeing up workers to focus on more complex and value-added tasks. As a result, fabrication companies can produce more products in a shorter amount of time.

3. Reduced Costs: Advanced technology can help fabrication companies to reduce their costs. Automated systems can reduce labor costs, while efficient machinery can reduce material waste and energy consumption. Additionally, technology can improve inventory management and supply chain optimization, further reducing costs.

4. Innovation and New Product Development: Technology enables fabrication companies to innovate and develop new products. Advanced design software and prototyping technologies allow companies to experiment with new designs and materials, leading to the creation of innovative products that meet the changing needs of customers.

5. Competitive Advantage: Fabrication companies that invest in technology gain a competitive advantage over those that do not. They can produce higher quality products, at a lower cost, and in a shorter amount of time. This allows them to win more contracts and grow their businesses.

In conclusion, technology is essential for fabrication companies in South Africa to remain competitive and successful. By investing in advanced technology and equipment, these companies can improve their accuracy, efficiency, productivity, and innovation, ultimately leading to increased profits and customer satisfaction.

Real-Life Examples:

- XYZ Fabrication, a leading fabrication company in South Africa, uses CAD/CAM systems to design and manufacture complex parts for the automotive industry. This technology allows XYZ Fabrication to produce parts with high precision and accuracy, meeting the demanding requirements of automotive manufacturers.

- ABC Fabrication, another prominent fabrication company in South Africa, has invested in robotic welding systems. These systems have increased ABC Fabrication’s productivity by 30%, while also improving the quality of welds and reducing labor costs.

Innovation

In the competitive landscape of fabrication, innovation is a driving force for companies to stay ahead of the curve and meet evolving customer demands. Fabrication companies in South Africa are embracing innovation to enhance their capabilities, expand their offerings, and drive growth.

-

New Product Development:

Innovation is crucial for fabrication companies to develop new products that cater to the changing needs of their customers. By investing in research and development, these companies can identify market opportunities and create products that solve specific problems or offer unique features. -

Process Improvement:

Innovation extends beyond product development to include process improvements that enhance efficiency, productivity, and quality. Fabrication companies are implementing innovative technologies, such as automation and robotics, to streamline their manufacturing processes, reduce production time, and minimize errors. -

Material Exploration:

Innovation in materials is another key area for fabrication companies in South Africa. By exploring new materials and experimenting with different combinations, they can develop products with improved properties, such as increased strength, durability, or corrosion resistance. -

Sustainable Manufacturing:

Sustainability is becoming increasingly important in the fabrication industry. Innovative fabrication companies are adopting eco-friendly practices, such as using recycled materials, implementing energy-efficient processes, and reducing waste, to minimize their environmental impact.

By embracing innovation, fabrication companies in South Africa can differentiate themselves, increase their competitiveness, and drive growth in the dynamic and demanding fabrication market.

Sustainability

In today’s environmentally conscious landscape, sustainability has become an essential consideration for fabrication companies in South Africa. As the world grapples with the effects of climate change and resource depletion, businesses are increasingly expected to operate in a responsible and sustainable manner.

For fabrication companies, sustainability encompasses a range of practices and commitments aimed at minimizing their environmental impact and promoting the well-being of future generations. These practices include:

- Waste Reduction: Implementing waste management programs to reduce, reuse, and recycle materials, thereby diverting waste from landfills and conserving natural resources.

- Energy Efficiency: Employing energy-efficient technologies and practices to reduce energy consumption, lower greenhouse gas emissions, and minimize operating costs.

- Sustainable Material Sourcing: Using environmentally friendly materials and working with suppliers who prioritize sustainability in their operations.

- Employee Education and Engagement: Educating and engaging employees on sustainability initiatives, fostering a culture of environmental stewardship within the organization.

- Compliance and Certifications: Adhering to environmental regulations and obtaining certifications such as ISO 14001, demonstrating a commitment to environmental management and sustainability.

The importance of sustainability for fabrication companies in South Africa cannot be overstated. By embracing sustainable practices, these companies can:

- Reduce their environmental footprint: Minimize their impact on the environment, contributing to a cleaner and healthier planet.

- Enhance their reputation: Demonstrate their commitment to corporate social responsibility and attract environmentally conscious customers and partners.

- Gain a competitive advantage: Differentiate themselves in the market and appeal to clients who prioritize sustainability in their supply chains.

- Secure long-term viability: Ensure the long-term sustainability of their operations by managing environmental risks and adapting to evolving regulations.

Examples of fabrication companies in South Africa that have embraced sustainability include:

- AECI: A leading manufacturer of explosives and chemicals, AECI has implemented a comprehensive sustainability program, including initiatives to reduce water consumption, waste generation, and energy usage.

- ArcelorMittal South Africa: A major steel producer, ArcelorMittal has invested heavily in environmental technologies, such as a state-of-the-art flue gas desulfurization system, to minimize its carbon footprint.

In conclusion, sustainability has become an indispensable aspect of fabrication companies in South Africa. By adopting sustainable practices, these companies can reduce their environmental impact, enhance their reputation, gain a competitive advantage, and secure long-term viability, contributing to a more sustainable and responsible manufacturing sector.

Partnerships

In the dynamic and competitive landscape of fabrication in South Africa, partnerships play a crucial role in enhancing the capabilities and competitiveness of fabrication companies. Strategic alliances with other businesses can provide access to a wider range of resources, expertise, and market opportunities, enabling fabrication companies to expand their offerings, improve efficiency, and gain a competitive edge.

-

Complementary Expertise and Resources:

Partnerships allow fabrication companies to combine their strengths and expertise with those of other businesses. By collaborating with companies that specialize in different areas, such as design, engineering, or materials sourcing, fabrication companies can offer a more comprehensive range of services and meet the diverse needs of their customers. -

Access to New Technologies and Innovations:

Partnerships with technology providers or research institutions can give fabrication companies access to cutting-edge technologies, innovative processes, and specialized knowledge. This enables them to stay at the forefront of industry advancements, adopt new techniques, and offer differentiated products and services. -

Expanded Market Reach and Distribution Channels:

Partnering with companies that have established market networks or distribution channels can help fabrication companies expand their reach and access new customer segments. By leveraging their partners’ existing relationships and infrastructure, fabrication companies can increase their sales volume and grow their market share. -

Risk and Cost Sharing:

Partnerships can spread the risks and costs associated with new projects or ventures. By collaborating with other businesses, fabrication companies can share the financial burden and reduce the potential impact of setbacks or unexpected challenges.

Examples of successful partnerships in the South African fabrication industry include:

- A partnership between a fabrication company and a design firm to offer integrated design and manufacturing services to clients.

- A collaboration between a fabrication company and a materials supplier to develop and supply specialized alloys for high-performance applications.

- A joint venture between a fabrication company and a technology provider to introduce innovative welding technologies into the manufacturing process.

In conclusion, partnerships are essential for fabrication companies in South Africa to enhance their capabilities, expand their offerings, and gain a competitive edge. By strategically aligning with other businesses, fabrication companies can access additional resources, expertise, and market opportunities, enabling them to meet the evolving demands of the industry and deliver innovative solutions to their customers.

Frequently Asked Questions about Fabrication Companies in South Africa

This section addresses common queries and misconceptions regarding fabrication companies in South Africa, providing concise and informative answers.

Question 1: What are the key capabilities of fabrication companies in South Africa?

Answer: Fabrication companies in South Africa offer a diverse range of capabilities, including welding, cutting, forming, and machining. They work with various materials such as steel, aluminum, stainless steel, and exotic alloys. Their services encompass custom metal fabrication, precision engineering, and specialized manufacturing.

Question 2: How can I assess the quality of fabrication companies?

Answer: To evaluate the quality of fabrication companies, consider their certifications, experience, reputation, and commitment to quality control. ISO 9001 certification is a recognized indicator of a robust quality management system. Additionally, examining their project portfolio, customer testimonials, and industry recognition can provide valuable insights into their capabilities and quality standards.

Question 3: What factors influence the cost of fabrication services?

Answer: The cost of fabrication services is influenced by several factors, including the complexity of the project, the materials used, labor costs, overhead expenses, and the company’s profit margin. It is advisable to obtain quotes from multiple companies and compare their pricing structures to make informed decisions.

Question 4: How important is customer service in the fabrication industry?

Answer: Customer service plays a crucial role in the fabrication industry. Fabrication projects are often complex and time-consuming, and clients rely on responsive, communicative, and supportive companies. Excellent customer service fosters trust, facilitates issue resolution, and builds long-term relationships.

Question 5: What role does innovation play in the success of fabrication companies?

Answer: Innovation is a driving force for fabrication companies to stay competitive and meet evolving customer demands. They invest in research and development to create new products, improve processes, explore sustainable materials, and adopt advanced technologies. Innovation enables them to differentiate their offerings, increase efficiency, and respond to emerging market trends.

Question 6: How can I choose the right fabrication company for my project?

Answer: To select the right fabrication company, consider their capabilities, experience, quality standards, location, pricing, and customer service. Assess their alignment with your project requirements and budget. It is recommended to request references and visit their facilities to gain a comprehensive understanding of their operations and capabilities.

In summary, fabrication companies in South Africa provide diverse services, and their capabilities vary. Quality assessment involves examining certifications, experience, and reputation. The cost of fabrication depends on project complexity and materials used. Customer service is paramount for project success. Innovation drives competitiveness and product development. Choosing the right fabrication company requires careful evaluation based on project requirements and company capabilities.

Transitioning to the next article section…

Tips from Fabrication Companies in South Africa

Fabrication companies in South Africa possess extensive knowledge and expertise in metalworking, offering a wide range of services to meet diverse industry needs. Here are some valuable tips they recommend to optimize your fabrication projects:

Tip 1: Define Project Requirements Clearly

Thoroughly define your project requirements, including specifications, materials, and timelines. Clear communication helps fabrication companies understand your needs accurately, ensuring project success.

Tip 2: Choose the Right Materials

Selecting the appropriate materials is crucial for the functionality and longevity of your project. Fabrication companies can guide you in choosing materials that align with your specific requirements and budget.

Tip 3: Leverage Technology for Precision

Embrace advanced fabrication technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), to achieve high levels of precision and accuracy in your project.

Tip 4: Prioritize Quality Control

Establish rigorous quality control measures throughout the fabrication process. This ensures adherence to specifications and minimizes the risk of defects, leading to a high-quality end product.

Tip 5: Foster Open Communication

Maintain open communication channels with the fabrication company throughout the project. Regular updates and feedback exchange facilitate timely adjustments and ensure project alignment.

Tip 6: Seek Professional Advice

Don’t hesitate to seek professional advice from experienced fabrication companies. Their expertise can provide valuable insights, helping you make informed decisions and optimize your project outcomes.

Tip 7: Plan for Contingencies

Anticipate potential challenges and develop contingency plans to mitigate risks. This proactive approach ensures minimal disruptions and keeps the project on track.

Tip 8: Value Long-Term Partnerships

Establishing long-term partnerships with reputable fabrication companies offers numerous benefits. They gain a deep understanding of your business needs, leading to efficient and cost-effective solutions for future projects.

By adhering to these tips, you can harness the expertise of fabrication companies in South Africa to achieve successful project outcomes, enhance product quality, and drive innovation in your industry.

Transitioning to the article’s conclusion…

Conclusion

Fabrication companies in South Africa play a vital role in various industries, providing essential metalworking services that shape the country’s manufacturing landscape. Their capabilities, expertise, and commitment to quality are crucial for meeting the diverse needs of clients.

Through their ability to transform raw materials into complex and precise components, fabrication companies contribute to innovation, economic growth, and infrastructure development. By embracing technological advancements, partnering with suppliers, and prioritizing sustainability, these companies remain at the forefront of the industry, delivering exceptional results for their clients.

Choosing the right fabrication company is essential for successful project outcomes. By considering factors such as capabilities, experience, quality standards, and customer service, businesses can select a partner that aligns with their specific requirements. Effective communication, clear project definition, and open collaboration between clients and fabrication companies are key to achieving optimal results.

The future of fabrication in South Africa is bright, with companies continuously investing in technology, expanding their services, and exploring new materials to meet the evolving demands of the market. Their commitment to quality, innovation, and sustainability positions them as valuable partners for businesses seeking to optimize their fabrication needs.