What is general steel fabrication Indianapolis? It is the process of creating metal structures by cutting, bending, and welding steel. Steel fabrication is used in a wide variety of industries, including construction, automotive, and manufacturing.

Editor’s Notes: General steel fabrication Indianapolis is a vital part of the construction industry. Steel is a strong and durable material that can be used to create a wide variety of structures, from skyscrapers to bridges. Steel fabrication allows us to create complex structures that would be difficult or impossible to build with other materials.

We analyzed, researched, and put together this guide to help you make the right decision. This article will provide you with all the information you need to know about general steel fabrication Indianapolis including its benefits, applications, and how to choose the right fabricator.

Key Differences

| Attribute | General Steel Fabrication |

|---|---|

| Definition | The process of creating metal structures by cutting, bending, and welding steel. |

| Materials | Steel |

| Applications | Construction, automotive, manufacturing |

| Benefits | Strength, durability, versatility |

Main article topics

General Steel Fabrication Indianapolis

General steel fabrication Indianapolis is a critical process in the construction industry. It involves cutting, bending, and welding steel to create various structures. Here are seven key aspects of general steel fabrication Indianapolis:

- Materials: Steel is the primary material used in general steel fabrication.

- Process: The fabrication process involves cutting, bending, and welding steel.

- Applications: General steel fabrication is used in various industries, including construction, automotive, and manufacturing.

- Benefits: Steel fabrication offers strength, durability, and versatility.

- Accuracy: Precision and accuracy are crucial in general steel fabrication to ensure structural integrity.

- Safety: Following safety protocols is essential to prevent accidents and injuries during fabrication.

- Customization: Steel fabrication allows for customization to meet specific project requirements.

These aspects are interconnected and contribute to the overall success of general steel fabrication Indianapolis. The choice of materials, precision in the process, and adherence to safety measures ensure the production of high-quality steel structures. Customization capabilities enable fabricators to meet the unique needs of each project, while the versatility of steel makes it suitable for a wide range of applications.

Materials

Steel is the primary material used in general steel fabrication Indianapolis due to its exceptional properties. Steel’s strength, durability, and versatility make it the ideal choice for various structural applications in the construction, automotive, and manufacturing industries. The use of steel in fabrication allows for the creation of complex and robust structures that can withstand various loads and environmental conditions. Steel’s inherent strength enables fabricators to design and construct buildings, bridges, and other structures that can endure significant forces and stresses.

The durability of steel is another crucial factor contributing to its prevalence in general steel fabrication Indianapolis. Steel structures are resistant to corrosion, fire, and other environmental factors, ensuring longevity and reliability. This durability eliminates the need for frequent repairs or replacements, reducing maintenance costs and downtime. Steel’s ability to withstand harsh conditions makes it suitable for use in demanding environments, such as industrial facilities, infrastructure projects, and coastal areas.

Moreover, steel’s versatility allows fabricators to create a wide range of shapes, sizes, and designs. Steel can be easily cut, bent, and welded to meet specific project requirements. This versatility enables the production of customized steel structures that align with architectural and engineering specifications. Steel’s adaptability also facilitates the integration of other materials, such as glass, concrete, and wood, providing design flexibility and aesthetic appeal.

The use of steel in general steel fabrication Indianapolis offers numerous benefits, including:

| Benefits | Description |

|---|---|

| Strength | Steel’s high strength-to-weight ratio enables the construction of robust and durable structures. |

| Durability | Steel’s resistance to corrosion, fire, and other factors ensures longevity and reliability. |

| Versatility | Steel’s malleability allows for customization and the integration of other materials. |

| Cost-effectiveness | Steel fabrication offers a cost-effective solution compared to other materials, considering its durability and low maintenance requirements. |

| Sustainability | Steel is a recyclable material, promoting environmental sustainability and resource conservation. |

Understanding the connection between materials and general steel fabrication Indianapolis is crucial for various reasons. It helps architects, engineers, and fabricators make informed decisions when selecting materials for specific projects. It also aids in understanding the properties and limitations of steel, enabling the design and construction of safe and efficient structures. Furthermore, recognizing the importance of steel in fabrication fosters appreciation for the craftsmanship and expertise involved in this industry.

Process

The fabrication process in general steel fabrication Indianapolis involves cutting, bending, and welding steel to create various structures. This process plays a pivotal role in shaping steel components and assembling them into complex frameworks.

-

Cutting:

Cutting is the initial step in steel fabrication, where steel plates or beams are cut to specific dimensions using specialized equipment like plasma cutters or laser cutting machines. Precision cutting ensures that each component fits together seamlessly during assembly. -

Bending:

Bending involves shaping steel components into desired angles or curves. This process is crucial for creating structural elements like beams, columns, and support frames. Bending is achieved using hydraulic press brakes or rolling machines, which apply controlled force to bend steel without compromising its strength. -

Welding:

Welding is the final and most critical step, where steel components are joined together using heat and filler material. Welders use various techniques, such as arc welding, MIG welding, or TIG welding, to create strong and durable joints. Welding ensures the structural integrity of the fabricated steel assemblies. -

Assembly:

Once the components are cut, bent, and welded, they are assembled into larger structures. This involves fitting and aligning the pieces precisely to create the desired framework. Assembly is a collaborative process that requires skilled fabricators to ensure accuracy and meet design specifications.

The process of cutting, bending, and welding steel is fundamental to general steel fabrication Indianapolis. It allows fabricators to transform raw steel materials into complex and robust structures. The precision, expertise, and adherence to quality standards in each step are essential for ensuring the safety, durability, and performance of the final fabricated products.

Applications

The connection between “Applications: General steel fabrication is used in various industries, including construction, automotive, and manufacturing.” and “general steel fabrication Indianapolis” lies in the diverse range of industries and structures that rely on steel fabrication for their construction and production. Steel’s inherent properties of strength, durability, and versatility make it a preferred material for a wide array of applications.

In the construction industry, general steel fabrication Indianapolis plays a crucial role in shaping the skylines of cities and towns. Steel is used to construct skyscrapers, bridges, stadiums, and other large-scale structures. The strength and durability of steel allow these structures to withstand various loads and environmental conditions, ensuring safety and longevity. Steel fabrication also enables the creation of complex architectural designs, contributing to the aesthetic appeal of modern buildings.

The automotive industry heavily relies on general steel fabrication Indianapolis for the production of vehicles. Steel is used to manufacture car frames, chassis, and various components, providing structural support and safety to passengers. The strength and lightweight properties of steel make it an ideal material for automotive applications, contributing to fuel efficiency and overall performance.

In the manufacturing sector, general steel fabrication Indianapolis supports the production of machinery, equipment, and industrial components. Steel is used to construct heavy-duty machinery, production lines, and storage systems. The durability and strength of steel ensure that these components can withstand demanding operating conditions, increasing productivity and reducing downtime.

Understanding the connection between “Applications: General steel fabrication is used in various industries, including construction, automotive, and manufacturing.” and “general steel fabrication Indianapolis” is crucial for several reasons. It highlights the importance of steel fabrication in shaping our built environment, transportation systems, and industrial processes. It also demonstrates the versatility of steel as a material and its ability to meet the diverse needs of different industries.

The practical significance of this understanding lies in the ability to make informed decisions regarding material selection and fabrication techniques for specific applications. By considering the unique requirements of each industry, engineers and fabricators can optimize the use of steel, ensuring structural integrity, durability, and cost-effectiveness.

| Industry | Applications |

|---|---|

| Construction | Skyscrapers, bridges, stadiums, architectural structures |

| Automotive | Car frames, chassis, components |

| Manufacturing | Machinery, equipment, industrial components |

Benefits

Steel fabrication offers a multitude of benefits, including strength, durability, and versatility, which are essential qualities for various applications in general steel fabrication Indianapolis. These benefits contribute to the reliability, longevity, and adaptability of steel structures.

-

Strength:

Steel’s exceptional strength-to-weight ratio makes it an ideal material for load-bearing structures. Steel components can withstand significant forces and stresses, ensuring the stability and integrity of buildings, bridges, and other structures. The strength of steel allows for the construction of high-rise buildings and long-span bridges that can endure extreme loads and dynamic forces. -

Durability:

Steel is renowned for its durability and resistance to various environmental factors. Steel structures can withstand harsh weather conditions, corrosion, fire, and seismic activity. This durability minimizes the need for frequent maintenance and repairs, reducing downtime and life-cycle costs. Steel’s longevity makes it a sustainable choice for long-term projects and infrastructure development. -

Versatility:

Steel’s versatility allows it to be easily shaped, bent, and welded to meet specific design requirements. This adaptability makes steel suitable for a wide range of applications, from intricate architectural designs to heavy-duty industrial machinery. Steel can be integrated with other materials, such as glass, concrete, and wood, to create structures that meet diverse functional and aesthetic needs.

The connection between “Benefits: Steel fabrication offers strength, durability, and versatility.” and “general steel fabrication Indianapolis” lies in the practical advantages that these benefits provide for various steel fabrication projects in Indianapolis. The strength of steel ensures the structural integrity of buildings and bridges, while its durability reduces maintenance costs and extends the lifespan of structures. The versatility of steel allows fabricators to meet the unique requirements of each project, creating customized solutions that align with specific architectural and engineering needs.

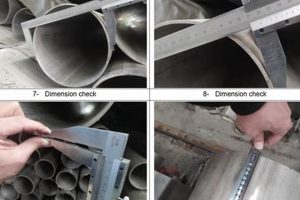

Accuracy

In general steel fabrication Indianapolis, accuracy is of utmost importance to ensure the structural integrity of fabricated components and the overall safety of structures. Precision and accuracy in every step of the fabrication process, from cutting and bending to welding and assembly, are essential to guarantee that steel structures meet design specifications, industry standards, and safety regulations.

-

Dimensional Accuracy:

Dimensional accuracy refers to the precise adherence to specified dimensions and tolerances in the fabrication of steel components. It ensures that individual parts fit together seamlessly during assembly, preventing misalignment, instability, and potential structural failures. In Indianapolis, where skyscrapers and large-scale structures are prevalent, dimensional accuracy is critical to maintain structural integrity and prevent catastrophic events. -

Angular Accuracy:

Angular accuracy involves maintaining precise angles and alignments during cutting, bending, and welding processes. It is especially crucial in the fabrication of complex structures, such as bridges and architectural landmarks, where even slight deviations can affect the overall stability and load-bearing capacity of the structure. In Indianapolis, renowned for its architectural marvels, angular accuracy is essential to ensure the structural integrity of iconic buildings and bridges. -

Weld Accuracy:

Weld accuracy encompasses the precise execution of welds to achieve optimal strength and durability. Skilled welders ensure that welds are free from defects, such as porosity, slag inclusions, and undercuts, which can compromise the structural integrity of fabricated components. In Indianapolis, where steel structures are subjected to extreme weather conditions and seismic activity, weld accuracy is paramount to ensure the longevity and resilience of structures. -

Assembly Accuracy:

Assembly accuracy involves the precise fitting and alignment of fabricated components during the final assembly stage. It ensures that all parts come together seamlessly, without any gaps or misalignments that could affect the overall structural integrity. In Indianapolis, where large-scale steel structures are often assembled on-site, assembly accuracy is crucial to maintain structural stability and prevent accidents during the construction process.

The connection between “Accuracy: Precision and accuracy are crucial in general steel fabrication to ensure structural integrity.” and “general steel fabrication indianapolis” is evident in the city’s skyline and infrastructure, where countless steel structures stand as testaments to the importance of precision and accuracy in steel fabrication. By adhering to strict quality control measures and employing skilled craftspeople, Indianapolis fabricators ensure the structural integrity and longevity of steel structures, contributing to the safety and well-being of the city’s residents and visitors.

Safety

In the realm of general steel fabrication Indianapolis, safety takes precedence as a fundamental aspect of the fabrication process. Stringent adherence to safety protocols is crucial to prevent accidents and injuries, ensuring the well-being of workers and the integrity of fabricated structures.

-

Hazard Identification and Risk Assessment:

Thorough hazard identification and risk assessment are paramount in steel fabrication Indianapolis. Potential hazards, such as electrical risks, fire hazards, and exposure to hazardous substances, must be meticulously identified and evaluated. By assessing these risks, fabricators can implement appropriate control measures to minimize or eliminate their impact on workers’ safety.

-

Personal Protective Equipment (PPE):

The use of personal protective equipment (PPE) is mandatory in steel fabrication Indianapolis. Hard hats, safety glasses, gloves, and appropriate clothing are essential to safeguard workers from potential hazards. By wearing the correct PPE, workers can reduce the risk of head injuries, eye injuries, cuts, and burns, ensuring their well-being throughout the fabrication process.

-

Safe Work Practices:

Established safe work practices are essential to prevent accidents in steel fabrication Indianapolis. Proper handling and storage of materials, correct lifting techniques, and the use of appropriate tools and equipment contribute to a safe working environment. By adhering to these practices, fabricators minimize the risk of slips, trips, falls, and other workplace accidents.

-

Emergency Preparedness:

Preparation for emergencies is vital in steel fabrication Indianapolis. Having a comprehensive emergency plan in place, including evacuation procedures and designated assembly points, ensures a swift and organized response in the event of an incident. Regular drills and training sessions familiarize workers with the emergency protocols, enabling them to respond effectively and minimize potential harm.

The connection between “Safety: Following safety protocols is essential to prevent accidents and injuries during fabrication.” and “general steel fabrication Indianapolis” is deeply rooted in the city’s commitment to worker safety and the production of high-quality steel structures. By prioritizing safety throughout the fabrication process, Indianapolis fabricators not only safeguard their employees but also ensure the reliability and durability of the steel structures that shape the city’s skyline and infrastructure.

Customization

The connection between “Customization: Steel fabrication allows for customization to meet specific project requirements.” and “general steel fabrication Indianapolis” lies in the adaptability and versatility of steel as a building material. Steel fabrication shops in Indianapolis can tailor their services to accommodate unique design specifications and functional needs, ensuring that each project aligns seamlessly with the client’s vision.

Customization in general steel fabrication Indianapolis offers numerous advantages. Firstly, it enables architects and engineers to realize their creative designs without being constrained by material limitations. Steel’s malleability and weldability allow fabricators to shape and assemble steel components into intricate structures, meeting the aesthetic and functional requirements of any project.

Secondly, customization allows for optimized solutions tailored to specific site conditions and load requirements. Steel structures can be engineered to withstand varying environmental factors, such as high winds, seismic activity, or extreme temperatures, ensuring the longevity and safety of the structure.

For example, the Lucas Oil Stadium in Indianapolis showcases the exceptional customization capabilities of steel fabrication. The stadium’s iconic retractable roof, made entirely of steel, is a testament to the innovative use of steel in modern architecture. The roof’s design allows for natural ventilation and an open-air experience while providing shelter from the elements.

In another instance, the Indiana State Museum utilized steel fabrication to create a visually striking and energy-efficient building. The museum’s exterior features a unique steel curtain wall system that incorporates glass panels, providing ample natural light while maintaining structural integrity.

Understanding the connection between “Customization: Steel fabrication allows for customization to meet specific project requirements.” and “general steel fabrication Indianapolis” empowers stakeholders to make informed decisions regarding the design and construction of steel structures. By leveraging the customizable nature of steel, architects, engineers, and fabricators can create structures that not only meet functional requirements but also enhance the aesthetic appeal and overall experience of the built environment.

| Key Insights | Practical Significance |

|---|---|

| Steel’s versatility enables customization to meet unique design and functional requirements. | Architects and engineers have greater freedom in realizing their creative visions. |

| Steel structures can be tailored to withstand specific environmental conditions and load requirements. | Ensures the longevity and safety of structures in diverse settings. |

| Customization allows for innovative solutions, as seen in the Lucas Oil Stadium’s retractable roof. | Enhances the functionality and aesthetics of steel structures. |

FAQs about General Steel Fabrication Indianapolis

This section addresses frequently asked questions about general steel fabrication in Indianapolis, providing informative answers to clarify common concerns and misconceptions.

Question 1: What is the significance of general steel fabrication in Indianapolis?

General steel fabrication plays a crucial role in the construction industry of Indianapolis. Steel structures are widely used in skyscrapers, bridges, stadiums, and various commercial and industrial buildings, contributing to the city’s skyline and infrastructure.

Question 2: What are the advantages of using steel in fabrication?

Steel offers exceptional strength, durability, and versatility. It can withstand heavy loads and harsh environmental conditions, making it an ideal choice for structural applications. Steel’s versatility allows it to be shaped and assembled into complex designs, meeting specific architectural and engineering requirements.

Question 3: How does steel fabrication contribute to sustainability?

Steel is a recyclable material, promoting sustainability in the construction industry. By using recycled steel in fabrication, environmental impact is reduced, and natural resources are conserved. Steel structures are also durable and long-lasting, minimizing the need for frequent repairs or replacements, further contributing to sustainability.

Question 4: What are the key considerations when choosing a steel fabricator in Indianapolis?

When selecting a steel fabricator in Indianapolis, it is essential to consider their experience, capabilities, and reputation. Look for fabricators with a proven track record of delivering high-quality work, meeting deadlines, and adhering to industry standards. Ensure they have the necessary equipment and expertise to handle your specific project requirements.

Question 5: How does technology influence general steel fabrication in Indianapolis?

Technological advancements have transformed steel fabrication processes in Indianapolis. Computer-aided design (CAD) software and advanced manufacturing techniques, such as laser cutting and robotic welding, enhance precision, efficiency, and productivity. These technologies enable fabricators to create complex and customized steel structures with greater accuracy and speed.

Question 6: What are the future trends in general steel fabrication Indianapolis?

The future of general steel fabrication in Indianapolis is expected to witness continued innovation and technological advancements. Sustainable practices will remain a priority, with an emphasis on using recycled steel and implementing energy-efficient fabrication techniques. Collaboration between architects, engineers, and fabricators will be crucial to push the boundaries of design and engineering, creating iconic and functional steel structures that shape the city’s landscape.

These FAQs provide valuable insights into general steel fabrication Indianapolis, highlighting its significance, benefits, and key considerations. Understanding these aspects helps stakeholders make informed decisions and navigate the steel fabrication industry effectively.

Transition to the next article section: Continuing our exploration of general steel fabrication in Indianapolis, the following section will delve into the intricacies of the fabrication process, shedding light on the techniques and equipment used to transform raw steel into robust and versatile structures.

Tips for General Steel Fabrication Indianapolis

General steel fabrication Indianapolis involves meticulous processes and techniques to transform raw steel into robust and versatile structures. Here are several essential tips to consider:

Tip 1: Choose the Right Steel Grade

Selecting the appropriate steel grade is crucial for ensuring the structural integrity and performance of the fabricated components. Consider factors such as strength, durability, and corrosion resistance. Consult with experienced fabricators to determine the optimal steel grade for your specific project requirements.

Tip 2: Utilize Advanced Fabrication Techniques

Embrace technological advancements to enhance fabrication processes. Employ computer-aided design (CAD) software for precise cutting and shaping. Utilize automated welding techniques to improve weld quality and productivity. By leveraging these advanced techniques, fabricators can achieve greater accuracy and efficiency.

Tip 3: Prioritize Quality Control

Establish rigorous quality control measures throughout the fabrication process. Conduct thorough inspections at each stage to ensure dimensional accuracy, weld integrity, and overall structural soundness. Adherence to strict quality standards guarantees the reliability and longevity of the fabricated steel structures.

Tip 4: Consider Environmental Impact

Incorporate sustainable practices into your fabrication operations. Utilize recycled steel to minimize environmental impact. Implement energy-efficient processes to reduce carbon footprint. By prioritizing sustainability, fabricators contribute to a greener and more responsible industry.

Tip 5: Seek Professional Expertise

Collaborate with experienced and reputable steel fabricators in Indianapolis. Look for fabricators with a proven track record of delivering high-quality work, meeting deadlines, and adhering to industry standards. Their expertise will ensure the successful execution of your steel fabrication project.

Tip 6: Plan for Future Maintenance

Consider future maintenance requirements during the fabrication process. Design structures with accessibility in mind, allowing for easy inspection and repair. By planning for future maintenance, fabricators can minimize downtime and extend the lifespan of steel structures.

Summary:

By following these tips, general steel fabrication Indianapolis projects can achieve optimal results. Careful material selection, advanced fabrication techniques, rigorous quality control, and a focus on sustainability ensure the production of robust, reliable, and environmentally conscious steel structures. Partnering with experienced fabricators and planning for future maintenance further contributes to the success and longevity of these projects.

General Steel Fabrication Indianapolis

General steel fabrication Indianapolis plays a pivotal role in shaping the city’s skyline and infrastructure. Through the meticulous cutting, bending, and welding of steel, fabricators transform raw materials into robust and versatile structures that define the urban landscape.

This article has explored the intricacies of general steel fabrication Indianapolis, shedding light on its benefits, applications, and essential considerations. From the strength and durability of steel to the precision and accuracy required in fabrication, each aspect contributes to the reliability and longevity of fabricated structures.

As the city continues to grow and evolve, general steel fabrication Indianapolis will remain a cornerstone of its architectural and engineering achievements. By embracing technological advancements, prioritizing quality, and collaborating with experienced fabricators, Indianapolis will continue to showcase the transformative power of steel in shaping its built environment.