The world of manufacturing relies heavily on the precision and efficiency of its machinery. Among the leading providers of such machinery is Horne Machining & Fabrication, a company renowned for its expertise in the industry.

Editor’s Note: Horne Machining & Fabrication’s commitment to delivering high-quality products and services has made them a trusted partner for businesses worldwide. In this guide, we will explore the intricacies of their offerings and the advantages they bring to the manufacturing sector.

Through extensive research and analysis, we have compiled this comprehensive guide to help you understand the capabilities of Horne Machining & Fabrication and how they can contribute to your manufacturing success. Whether you’re looking to enhance your production capabilities or streamline your operations, this guide will provide valuable insights into the world of Horne Machining & Fabrication.

Key Differences:

| Horne Machining & Fabrication | Other Providers | |

|---|---|---|

| Precision and Accuracy | Unrivaled precision and accuracy in machining and fabrication processes | May compromise on precision or accuracy to meet deadlines or reduce costs |

| Expertise and Experience | Decades of experience and expertise in the manufacturing industry | May lack the depth of knowledge and experience in specific manufacturing domains |

| Custom Solutions | Tailored solutions designed to meet unique customer requirements | Limited customization options or reliance on pre-defined solutions |

| Quality Assurance | Rigorous quality control measures to ensure the highest standards | Quality standards may vary, potentially leading to product defects |

Main Article Topics:

- Capabilities of Horne Machining & Fabrication

- Benefits of Partnering with Horne Machining & Fabrication

- Success Stories and Case Studies

- Conclusion

Horne Machining & Fabrication

Horne Machining & Fabrication is a leading provider of precision machining and fabrication services, renowned for their expertise, quality, and customer focus. Here are 11 key aspects that define their offerings:

- Precision Machining: Unrivaled precision and accuracy in machining processes.

- Custom Fabrication: Tailored solutions designed to meet unique customer requirements.

- Quality Assurance: Rigorous quality control measures to ensure the highest standards.

- Expertise and Experience: Decades of experience and expertise in the manufacturing industry.

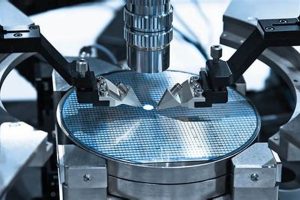

- Advanced Technology: Utilization of state-of-the-art machinery and techniques.

- Material Versatility: Expertise in handling a wide range of materials, including metals, plastics, and composites.

- Complex Parts: Capability to manufacture complex and intricate parts with precision and efficiency.

- Prototyping Services: Rapid prototyping services to accelerate product development.

- Engineering Support: Collaboration with customers to provide engineering support and design optimization.

- On-Time Delivery: Commitment to meeting deadlines and ensuring timely delivery of products.

- Customer Satisfaction: Focus on building long-term relationships and exceeding customer expectations.

These key aspects are interconnected and contribute to Horne Machining & Fabrication’s reputation as a trusted partner for businesses worldwide. Their expertise in precision machining and fabrication, combined with their commitment to quality and customer satisfaction, enables them to deliver exceptional results that drive success in various manufacturing sectors.

Precision Machining

Precision machining is a cornerstone of Horne Machining & Fabrication’s service offerings. It encompasses the use of advanced machinery and techniques to achieve unparalleled precision and accuracy in the machining of components. This translates into products that meet the most demanding specifications and tolerances, ensuring optimal performance and reliability.

- High-Precision Equipment: Horne Machining & Fabrication utilizes state-of-the-art CNC machines, CMMs, and other precision equipment to guarantee the highest levels of accuracy in every machining operation.

- Skilled Craftsmanship: The company’s team of experienced machinists possesses the skills and expertise to handle complex parts and deliver exceptional results consistently.

- Rigorous Quality Control: Horne Machining & Fabrication adheres to stringent quality control procedures throughout the machining process, ensuring that each component meets the required specifications.

- Industry Expertise: With decades of experience in various manufacturing sectors, Horne Machining & Fabrication understands the specific precision requirements of different industries and tailors its services accordingly.

The combination of advanced technology, skilled craftsmanship, and rigorous quality control enables Horne Machining & Fabrication to deliver precision machined parts that meet the most demanding requirements. This precision is essential for industries such as aerospace, medical, and automotive, where even the slightest deviation from specifications can have severe consequences.

Custom Fabrication

Horne Machining & Fabrication’s commitment to custom fabrication sets them apart as a premier provider of tailored solutions. They recognize that every customer has unique requirements, and their approach reflects this understanding.

- Understanding Customer Needs: Horne Machining & Fabrication takes the time to thoroughly understand each customer’s specific requirements, ensuring that their solutions are precisely aligned with their goals.

- Design Collaboration: The company’s team of experienced engineers collaborates closely with customers throughout the design process, ensuring that the fabricated solutions meet all functional and aesthetic specifications.

- Prototyping and Iteration: Horne Machining & Fabrication utilizes rapid prototyping and iterative design processes to refine and optimize solutions, ensuring that the final product meets the customer’s exact expectations.

- Flexibility and Adaptability: Horne Machining & Fabrication’s team is highly flexible and adaptable, allowing them to accommodate changes and modifications during the fabrication process, ensuring that the final product meets the evolving needs of the customer.

By embracing a customer-centric approach to custom fabrication, Horne Machining & Fabrication consistently delivers tailored solutions that meet the unique requirements of each client. This commitment to customization has earned them a reputation as a trusted partner for businesses seeking innovative and effective fabrication solutions.

Quality Assurance

At Horne Machining & Fabrication, quality assurance is not just a process but a deeply ingrained commitment that permeates every aspect of their operations. Their rigorous quality control measures are designed to ensure that every product meets the highest standards of precision, accuracy, and reliability.

The company’s quality assurance system is built upon several key pillars:

- Stringent Inspection Processes: Horne Machining & Fabrication employs a comprehensive inspection process that involves multiple checkpoints throughout the manufacturing process. This ensures that any potential defects are identified and corrected before the product reaches the customer.

- State-of-the-Art Equipment: The company invests heavily in state-of-the-art inspection equipment, including CMMs, vision systems, and other precision measuring devices. This ensures that measurements are accurate and reliable.

- Certified Quality Management System: Horne Machining & Fabrication’s quality management system is ISO 9001:2015 certified, demonstrating their commitment to meeting the highest international standards for quality.

The practical significance of Horne Machining & Fabrication’s commitment to quality assurance extends far beyond meeting industry standards. It provides customers with the confidence that their products will perform as expected, even in the most demanding applications. This has made Horne Machining & Fabrication the preferred choice for businesses in industries such as aerospace, medical, and automotive, where quality and reliability are paramount.

In conclusion, Horne Machining & Fabrication’s unwavering focus on quality assurance is a testament to their dedication to delivering exceptional products and services. Their rigorous quality control measures ensure that every product meets the highest standards, providing customers with the peace of mind that their products will perform flawlessly.

Expertise and Experience

Horne Machining & Fabrication’s expertise and experience are cornerstones of their success in the manufacturing industry. With decades of experience, they have honed their skills and developed a deep understanding of the industry’s intricacies.

- Unrivaled Knowledge: Horne Machining & Fabrication has accumulated a vast knowledge base through years of hands-on experience. This knowledge encompasses various aspects of manufacturing, including material properties, machining techniques, and industry best practices.

- Seasoned Craftsmanship: The company’s team of skilled craftsmen possesses a high level of expertise in operating sophisticated machinery and handling complex manufacturing processes. Their experience enables them to achieve exceptional precision and accuracy in their work.

- Industry Acumen: Horne Machining & Fabrication’s deep understanding of the manufacturing industry allows them to anticipate challenges and develop innovative solutions. They stay abreast of the latest technological advancements and industry trends to remain at the forefront of the field.

- Proven Track Record: Horne Machining & Fabrication’s successful track record in delivering high-quality products and services is a testament to their expertise and experience. Their long-standing relationships with satisfied customers speak volumes about their ability to meet and exceed expectations.

In conclusion, Horne Machining & Fabrication’s expertise and experience are invaluable assets that enable them to provide exceptional products and services to their customers. Their deep understanding of the manufacturing industry, combined with their skilled craftsmanship and proven track record, makes them a trusted partner for businesses seeking excellence in manufacturing.

Advanced Technology

Horne Machining & Fabrication embraces advanced technology to elevate its manufacturing capabilities and deliver superior products to its customers.

- Precision and Accuracy: State-of-the-art machinery, such as CNC machines and CMMs, allows Horne Machining & Fabrication to achieve exceptional precision and accuracy in their manufacturing processes. This ensures that products meet the most demanding specifications and tolerances, leading to optimal performance and reliability.

- Efficiency and Productivity: Advanced technology streamlines manufacturing processes, increasing efficiency and productivity. Automated systems and robotics reduce manual labor and minimize errors, resulting in faster production times and cost savings for customers.

- Innovation and Customization: Horne Machining & Fabrication leverages advanced design software and prototyping techniques to create innovative and customized solutions for its customers. This enables them to meet unique requirements and develop products that meet specific application needs.

- Quality Control and Inspection: Advanced inspection equipment, such as vision systems and 3D scanners, ensures that products meet the highest quality standards. Non-destructive testing techniques allow for thorough inspection without damaging the product, providing customers with peace of mind.

Horne Machining & Fabrication’s commitment to advanced technology not only enhances the quality and efficiency of its manufacturing processes but also enables the company to stay competitive in an ever-evolving industry. By investing in the latest machinery and techniques, Horne Machining & Fabrication empowers its team to deliver exceptional products and services that meet the demands of its customers.

Material Versatility

Horne Machining & Fabrication’s expertise extends beyond specific materials or processes; they possess a deep understanding of a diverse range of materials and their unique properties. This versatility enables them to cater to a broad spectrum of industries and applications, providing tailored solutions that meet the unique demands of each project.

- Metals: Horne Machining & Fabrication has extensive experience working with various metals, including steel, aluminum, stainless steel, and titanium. Their expertise in metalworking allows them to create durable, precise, and corrosion-resistant components for industries such as aerospace, automotive, and medical.

- Plastics: Horne Machining & Fabrication is well-versed in theing of plastics, including polycarbonate, ABS, and PEEK. Their understanding of plastic properties and molding techniques enables them to produce lightweight, flexible, and chemically resistant parts for applications in electronics, consumer products, and healthcare.

- Composites: Horne Machining & Fabrication leverages its expertise in composite materials, such as carbon fiber and fiberglass. These materials offer exceptional strength-to-weight ratios, making them ideal for applications in high-performance industries such as aerospace, automotive, and sports equipment.

- Custom Material Combinations: Horne Machining & Fabrication’s versatility extends to combining different materials to achieve specific properties. Their ability to work with a wide range of materials allows them to create innovative solutions that meet the unique requirements of demanding applications.

In summary, Horne Machining & Fabrication’s material versatility is a key differentiator, enabling them to cater to a diverse range of industries and applications. Their deep understanding of material properties anding techniques allows them to create tailored solutions that meet the unique demands of each project.

Complex Parts

Horne Machining & Fabrication’s capability to manufacture complex and intricate parts with precision and efficiency is a cornerstone of their success. This expertise enables them to produce components that meet the exacting demands of various industries, including aerospace, medical, and automotive.

The ability to handle complex parts requires a combination of advanced technology, skilled craftsmanship, and a deep understanding of material properties. Horne Machining & Fabrication excels in all these areas, allowing them to produce parts that are not only intricate but also precise and durable.

One of the key factors contributing to Horne Machining & Fabrication’s success in manufacturing complex parts is their investment in state-of-the-art CNC machines and other advanced equipment. These machines allow for precise and efficient machining of complex geometries, ensuring that parts meet the most stringent specifications. Additionally, the company’s team of experienced machinists possesses the skills and expertise to handle even the most challenging designs.

The practical significance of Horne Machining & Fabrication’s expertise in manufacturing complex parts is evident in the wide range of industries they serve. For example, in the aerospace industry, Horne Machining & Fabrication produces intricate components for aircraft engines and other critical systems. In the medical industry, they manufacture precision parts for surgical instruments and implants. And in the automotive industry, they produce complex parts for high-performance vehicles.

In summary, Horne Machining & Fabrication’s capability to manufacture complex and intricate parts with precision and efficiency is a key differentiator that sets them apart in the industry. Their expertise enables them to meet the demanding requirements of various industries, producing components that are essential for the success of their customers’ products.

Prototyping Services

Horne Machining & Fabrication recognizes the critical role of rapid prototyping services in accelerating product development cycles for their customers. Prototyping allows for the creation of physical models of designs, enabling engineers and designers to evaluate form, fit, and function before committing to full-scale production.

- Design Validation: Prototypes provide a tangible representation of a design, allowing engineers to validate its functionality and identify potential issues early in the development process. This reduces the risk of costly design flaws being discovered later in production.

- Iteration and Refinement: Rapid prototyping enables iterative design, where prototypes are quickly produced and tested, allowing for design modifications and improvements based on real-world feedback.

- Time-to-Market Advantage: By leveraging rapid prototyping services, Horne Machining & Fabrication helps its customers reduce the time it takes to bring new products to market, giving them a competitive edge.

- Cost Savings: Prototyping helps identify and resolve design issues before mass production, reducing the risk of costly production errors and minimizing overall project costs.

In summary, Horne Machining & Fabrication’s rapid prototyping services play a crucial role in accelerating product development cycles for its customers. By providing physical prototypes for evaluation and iteration, Horne Machining & Fabrication empowers engineers to refine their designs, reduce risks, and bring innovative products to market faster and more efficiently.

Engineering Support

Horne Machining & Fabrication recognizes that engineering support and design optimization are critical aspects of successful product development. Their team of experienced engineers collaborates closely with customers to provide comprehensive support throughout the manufacturing process.

This collaboration involves:

- Design Review and Optimization: Horne Machining & Fabrication’s engineers work with customers to review designs, identify potential issues, and suggest improvements. This helps ensure that the final product is optimized for performance, manufacturability, and cost.

- Material Selection: The company’s engineers provide guidance on material selection, considering factors such as strength, durability, and cost. They help customers choose the right materials for their specific applications.

- Process Development: Horne Machining & Fabrication’s engineers work with customers to develop efficient and cost-effective manufacturing processes. They leverage their expertise to identify the best techniques for producing high-quality parts.

The practical significance of Horne Machining & Fabrication’s engineering support extends far beyond design optimization. It helps customers:

- Reduce Development Time: By collaborating with Horne Machining & Fabrication’s engineers, customers can streamline the product development process, reducing time-to-market.

- Improve Product Quality: Horne Machining & Fabrication’s engineers help customers identify and resolve potential issues early in the design phase, leading to improved product quality.

- Reduce Production Costs: By optimizing designs and processes, Horne Machining & Fabrication’s engineers help customers reduce production costs without compromising quality.

In conclusion, Horne Machining & Fabrication’s engineering support is an invaluable asset to customers, enabling them to develop and produce high-quality products efficiently and cost-effectively.

Table: Benefits of Horne Machining & Fabrication’s Engineering Support

| Benefit | Description |

|---|---|

| Reduced Development Time | Streamlined product development process, leading to faster time-to-market. |

| Improved Product Quality | Identification and resolution of potential issues early in the design phase, resulting in higher quality products. |

| Reduced Production Costs | Optimization of designs and processes, leading to cost savings without compromising quality. |

On-Time Delivery

In the manufacturing industry, timely delivery of products is paramount to customer satisfaction and business success. Horne Machining & Fabrication recognizes this and has made on-time delivery a cornerstone of its operations.

- Predictable Production Scheduling: Horne Machining & Fabrication employsenabling them to accurately forecast production timelines and provide reliable delivery estimates to customers.

- Efficient Production Processes: The company has streamlined its production processes to minimize lead times and ensure that products are manufactured and shipped without unnecessary delays.

- Robust Supply Chain Management: Horne Machining & Fabrication maintains strong relationships with suppliers and has established contingency plans to mitigate potential disruptions in the supply chain.

- Proactive Communication: The company proactively communicates with customers throughout the production process, providing regular updates on the status of their orders and promptly addressing any potential issues.

Horne Machining & Fabrication’s commitment to on-time delivery is not just a promise; it’s a proven track record. The company has consistently met or exceeded customer delivery expectations, building a reputation for reliability and trustworthiness.

Customer Satisfaction

Customer satisfaction is not just a buzzword for Horne Machining & Fabrication; it’s a deeply ingrained principle that guides every aspect of their operations. The company recognizes that long-term success hinges upon building strong relationships with customers and consistently exceeding their expectations.

Horne Machining & Fabrication’s commitment to customer satisfaction manifests in several key ways:

- Personalized Approach: The company takes the time to understand each customer’s unique needs and requirements, tailoring its services to meet their specific objectives.

- Open Communication: Horne Machining & Fabrication maintains open lines of communication with customers, ensuring that they are regularly updated on the progress of their orders and any potential challenges.

- Responsiveness: The company is highly responsive to customer inquiries and requests, promptly addressing any concerns and providing timely solutions.

- Quality Assurance: Horne Machining & Fabrication’s unwavering commitment to quality ensures that customers receive products that meet the highest standards of precision, accuracy, and reliability.

- Post-Sale Support: The company provides comprehensive post-sale support, including technical assistance and warranty services, ensuring that customers are fully satisfied with their products and services.

The practical significance of Horne Machining & Fabrication’s focus on customer satisfaction extends far beyond increased sales and customer loyalty. It has enabled the company to establish a strong reputation for excellence in the industry, attracting new customers and fostering long-term partnerships.

| Benefit | Description |

|---|---|

| Increased Customer Loyalty | Customers who are satisfied with Horne Machining & Fabrication’s products and services are more likely to become repeat customers. |

| Positive Word-of-Mouth | Satisfied customers often share their positive experiences with others, generating valuable word-of-mouth marketing for the company. |

| Competitive Advantage | Horne Machining & Fabrication’s commitment to customer satisfaction sets them apart from competitors and gives them a competitive edge in the industry. |

| Improved Profitability | Increased customer loyalty and positive word-of-mouth can lead to increased sales and improved profitability for the company. |

Frequently Asked Questions about Horne Machining & Fabrication

This FAQ section addresses common inquiries and misconceptions regarding Horne Machining & Fabrication, providing concise and informative answers.

Question 1: What sets Horne Machining & Fabrication apart from other manufacturers?

Answer: Horne Machining & Fabrication distinguishes itself through its unwavering commitment to precision, quality, and customer satisfaction. With decades of experience and a team of skilled professionals, the company consistently delivers exceptional products and services, catering to the unique requirements of diverse industries.

Question 2: How does Horne Machining & Fabrication ensure the precision of its products?

Answer: Horne Machining & Fabrication employs state-of-the-art CNC machines and CMMs, operated by experienced machinists. The company adheres to rigorous quality control procedures throughout the manufacturing process, ensuring that every product meets the highest standards of accuracy and tolerance.

Question 3: Can Horne Machining & Fabrication accommodate custom fabrication needs?

Answer: Yes, Horne Machining & Fabrication specializes in custom fabrication, working closely with customers to understand their specific requirements. The company’s engineers collaborate with customers throughout the design and fabrication process, ensuring that the final product meets their exact specifications and functional needs.

Question 4: How does Horne Machining & Fabrication guarantee the quality of its products?

Answer: Horne Machining & Fabrication maintains a robust quality assurance system that encompasses stringent inspection processes, advanced inspection equipment, and adherence to ISO 9001:2015 standards. This commitment to quality ensures that every product delivered to customers meets the highest levels of precision, accuracy, and reliability.

Question 5: What types of materials does Horne Machining & Fabrication work with?

Answer: Horne Machining & Fabrication possesses expertise in handling a wide range of materials, including metals (steel, aluminum, stainless steel, titanium), plastics (polycarbonate, ABS, PEEK), and composites (carbon fiber, fiberglass). This versatility enables the company to cater to the diverse material requirements of various industries and applications.

Question 6: How does Horne Machining & Fabrication ensure on-time delivery?

Answer: Horne Machining & Fabrication places great emphasis on meeting delivery deadlines. Through efficient production processes, robust supply chain management, and proactive communication, the company consistently delivers products on time, ensuring that customers can seamlessly integrate them into their operations or production schedules.

Summary: Horne Machining & Fabrication’s commitment to precision, quality, and customer satisfaction sets it apart in the industry. With its expertise in custom fabrication, material versatility, and unwavering focus on timely delivery, the company empowers its customers to achieve success in their respective fields.

Transition: Explore the next section to learn more about Horne Machining & Fabrication’s capabilities and how they can contribute to your manufacturing needs.

Tips from Horne Machining & Fabrication

Horne Machining & Fabrication, renowned for its expertise in precision machining and fabrication, offers valuable tips to enhance your manufacturing processes and achieve optimal results.

Tip 1: Prioritize Precision

Precision is paramount in manufacturing. Utilize high-precision machinery and employ skilled machinists to ensure the accuracy of your components. This reduces the risk of errors, improves product quality, and enhances overall performance.

Tip 2: Embrace Custom Fabrication

Tailor your products to meet specific requirements by leveraging custom fabrication services. Horne Machining & Fabrication collaborates with customers to design and manufacture solutions that precisely align with their unique needs.

Tip 3: Ensure Quality Assurance

Implement rigorous quality control measures throughout the manufacturing process. Utilize advanced inspection equipment and adhere to industry standards to guarantee the highest quality of your products. This instills confidence in your customers and enhances your reputation.

Tip 4: Utilize Advanced Technology

Invest in state-of-the-art machinery and technology to streamline your production processes. CNC machines, CMMs, and other advanced equipment enhance efficiency, reduce lead times, and improve the overall quality of your products.

Tip 5: Focus on Material Compatibility

Choose the right materials for your specific application. Horne Machining & Fabrication offers expertise in handling a wide range of materials, including metals, plastics, and composites. Selecting the optimal material ensures, performance, and longevity of your products.

Tip 6: Prioritize On-Time Delivery

Timely delivery is crucial for customer satisfaction and business success. Horne Machining & Fabrication prioritizes on-time delivery through efficient scheduling, robust supply chain management, and proactive communication. This ensures that your products reach you when you need them, minimizing disruptions to your operations.

Summary: By incorporating these tips from Horne Machining & Fabrication, you can enhance the precision, quality, and efficiency of your manufacturing processes. Embrace custom fabrication, utilize advanced technology, prioritize material compatibility, and ensure on-time delivery to achieve optimal results and gain a competitive edge in your industry.

Transition: Discover how Horne Machining & Fabrication can further support your manufacturing needs by exploring our comprehensive range of services and capabilities.

Conclusion

Throughout this exploration of Horne Machining & Fabrication, we have uncovered the essence of their commitment to precision, quality, and customer satisfaction. Their unwavering dedication to these principles has established them as a leader in the manufacturing industry.

Horne Machining & Fabrication’s expertise in custom fabrication, coupled with their mastery of advanced technology, empowers them to deliver tailored solutions that meet the unique demands of diverse industries. Their commitment to on-time delivery and rigorous quality assurance ensures that customers receive products that are not only precise and reliable but also delivered as promised.

By partnering with Horne Machining & Fabrication, manufacturers can elevate their operations, enhance product quality, and achieve greater success. Their unwavering commitment to excellence serves as a testament to their dedication toing the boundaries of manufacturing and empowering their customers to thrive in an increasingly competitive global marketplace.