How to Grow a Steel Fabrication Business is a question that many business owners ask themselves. With the right strategies, you can increase your revenue, expand your customer base, and reach your business goals.

Editor’s Note: How to Grow a Steel Fabrication Business is an important topic for business owners in this industry. By understanding how your business can grow, you can make the right decisions to help it succeed.

After doing some analysis and digging for information, we put together this how to grow a steel fabrication business guide to help you make the right decision.

Key Differences or Key Takeaways

There are a few key differences between a successful steel fabrication business and one that is struggling. Some important factors include:

| Successful Steel Fabrication Business | Struggling Steel Fabrication Business |

|---|---|

| Has a strong customer base | Has a weak customer base |

| Offers a variety of services | Offers a limited number of services |

| Is constantly innovating | Is not innovating |

| Has a strong marketing strategy | Has a weak marketing strategy |

Transition to Main Article Topics

In this article, we will discuss the following topics:

- The importance of having a strong customer base

- The benefits of offering a variety of services

- The importance of innovation

- The importance of having a strong marketing strategy

How to Grow a Steel Fabrication Business

The key aspects of growing a steel fabrication business include:

- Target Market: Identify and focus on your ideal customers./comparison

- Marketing: Develop and implement a comprehensive marketing strategy./comparison

- Sales: Build a strong sales team and develop effective sales strategies./comparison

- Operations: Streamline your operations to improve efficiency and productivity./comparison

- Quality: Ensure that your products and services meet the highest quality standards./comparison

- Customer Service: Provide excellent customer service to build strong relationships with your customers./comparison

- Innovation: Continuously innovate to stay ahead of the competition./comparison

- Technology: Invest in the latest technology to improve your operations and efficiency./comparison

Finances: Manage your finances effectively to ensure the financial health of your business./comparison Team: Build a strong team of employees who are committed to the success of your business./comparison

By focusing on these key aspects, you can develop a solid foundation for growth and success.

Target Market

Identifying and focusing on your ideal customers is essential for growing any business, including a steel fabrication business. By understanding your target market, you can develop marketing and sales strategies that are specifically tailored to their needs. This will help you to attract more customers, increase sales, and grow your business.

-

Facet 1: Understand Your Customer’s Needs

The first step to identifying your target market is to understand their needs. What are they looking for in a steel fabrication business? What are their pain points? What are their buying habits? By understanding your customer’s needs, you can develop products and services that meet their specific requirements. -

Facet 2: Define Your Target Market

Once you understand your customer’s needs, you can start to define your target market. This is a specific group of people who are most likely to be interested in your products or services. When defining your target market, consider factors such as demographics, firmographics, and psychographics. -

Facet 3: Develop Marketing and Sales Strategies

With your target market defined, you can start to develop marketing and sales strategies that are specifically tailored to their needs. Your marketing messages should be clear and concise, and they should highlight the benefits of your products or services that are most relevant to your target market. Your sales team should be trained to understand the needs of your target market and to be able to effectively communicate the benefits of your products or services. -

Facet 4: Monitor and Adjust Your Strategies

Your marketing and sales strategies should be monitored and adjusted on a regular basis to ensure that they are still effective. As your business grows and changes, your target market may also change. It is important to stay up-to-date on the latest trends and to make adjustments to your strategies as needed.

By following these steps, you can identify and focus on your ideal customers and develop marketing and sales strategies that are specifically tailored to their needs. This will help you to attract more customers, increase sales, and grow your steel fabrication business.

Marketing

Marketing is a critical component of growing any business, including a steel fabrication business. A comprehensive marketing strategy will help you to reach your target market, generate leads, and increase sales.

There are a number of different marketing channels that you can use to reach your target market. Some of the most effective channels for steel fabrication businesses include:

- Online marketing: Online marketing is a great way to reach a large audience of potential customers. You can use a variety of online marketing channels, such as search engine optimization (SEO), pay-per-click (PPC) advertising, and social media marketing, to promote your business.

- Trade shows: Trade shows are a great way to meet potential customers and generate leads. You can exhibit at trade shows that are relevant to your industry, such as the FABTECH trade show.

- Networking: Networking is a great way to build relationships with potential customers and referral partners. You can network at industry events, such as the American Welding Society (AWS) Annual Conference and Expo.

In addition to choosing the right marketing channels, it is also important to develop a strong marketing message. Your marketing message should be clear, concise, and persuasive. It should highlight the benefits of your products or services and why they are a good choice for your target market.

By developing and implementing a comprehensive marketing strategy, you can reach your target market, generate leads, and increase sales. This will help you to grow your steel fabrication business and achieve your business goals.

Here are some real-life examples of how steel fabrication businesses have used marketing to grow their businesses:

- A steel fabrication business in California used online marketing to reach a wider audience of potential customers. The business created a website and used SEO to optimize the site for relevant keywords. The business also used PPC advertising to target specific keywords and phrases. As a result of these efforts, the business saw a significant increase in website traffic and leads.

- A steel fabrication business in Texas used trade shows to generate leads and build relationships with potential customers. The business exhibited at a number of trade shows, including the FABTECH trade show. The business met with potential customers and generated a number of leads. The business also followed up with these leads and closed several deals.

- A steel fabrication business in Ohio used networking to build relationships with potential customers and referral partners. The business attended industry events and networked with other businesses. The business also joined a number of industry associations. As a result of these efforts, the business developed a strong network of relationships that helped to generate new business.

These are just a few examples of how steel fabrication businesses have used marketing to grow their businesses. By developing and implementing a comprehensive marketing strategy, you can reach your target market, generate leads, and increase sales. This will help you to grow your steel fabrication business and achieve your business goals.

Table: The Importance of Marketing for Steel Fabrication Businesses

| Benefit | How Marketing Helps |

|---|---|

| Reach a wider audience of potential customers | Marketing can help you reach a wider audience of potential customers through a variety of channels, such as online marketing, trade shows, and networking. |

| Generate leads | Marketing can help you generate leads by providing valuable information to potential customers and encouraging them to take action, such as contacting you for a quote or visiting your website. |

| Increase sales | Marketing can help you increase sales by generating leads, building relationships with potential customers, and persuading them to buy your products or services. |

Sales

Sales is a critical component of growing any business, including a steel fabrication business. A strong sales team and effective sales strategies can help you to reach your target market, generate leads, and close deals.

-

Facet 1: Build a Strong Sales Team

A strong sales team is the foundation of any successful sales operation. When building your sales team, look for individuals who are passionate about the steel fabrication industry and who have a proven track record of success. Your sales team should be well-trained and knowledgeable about your products and services. They should also be able to effectively communicate the benefits of your offerings to potential customers.Real-life example: A steel fabrication business in California built a strong sales team by hiring experienced salespeople who had a deep understanding of the industry. The sales team was able to quickly develop relationships with potential customers and close deals.

Implications for growing a steel fabrication business: Building a strong sales team can help you to reach your target market, generate leads, and close deals. This will help you to grow your business and achieve your business goals.

-

Facet 2: Develop Effective Sales Strategies

In addition to building a strong sales team, it is also important to develop effective sales strategies. Your sales strategies should be aligned with your marketing strategies and your overall business goals. Effective sales strategies should include a clear target market, a value proposition, and a sales process.Real-life example: A steel fabrication business in Texas developed an effective sales strategy by focusing on a specific target market and developing a value proposition that highlighted the quality and durability of their products. The sales strategy also included a clear sales process that helped the sales team to close deals efficiently.

Implications for growing a steel fabrication business: Developing effective sales strategies can help you to reach your target market, generate leads, and close deals. This will help you to grow your business and achieve your business goals.

By building a strong sales team and developing effective sales strategies, you can reach your target market, generate leads, and close deals. This will help you to grow your steel fabrication business and achieve your business goals.

Operations

In the competitive steel fabrication industry, streamlining operations is crucial for growth and success. By optimizing processes, businesses can enhance efficiency, increase productivity, and reduce costs, ultimately contributing to a stronger bottom line and a more robust competitive advantage.

-

Facet 1: Lean Manufacturing Principles

Adopting lean manufacturing principles can significantly improve operational efficiency. By eliminating waste, reducing cycle times, and optimizing inventory levels, businesses can streamline their production processes, leading to increased productivity and cost savings.Real-life example: A steel fabrication company implemented lean manufacturing principles, resulting in a 20% reduction in production time and a 15% decrease in material waste.

Implications for growing a steel fabrication business: Implementing lean manufacturing principles can help businesses reduce costs, improve quality, and increase customer satisfaction, all of which contribute to business growth.

-

Facet 2: Automation and Technology

Investing in automation and advanced technologies can greatly enhance productivity and efficiency in steel fabrication operations. Automated welding, robotic material handling, and digital inventory management systems can reduce manual labor, minimize errors, and improve overall production speed.Real-life example: A steel fabrication company invested in robotic welding, leading to a 30% increase in welding productivity and a reduction in welding defects by 50%.

Implications for growing a steel fabrication business: Automation and technology can help businesses increase production capacity, reduce labor costs, and improve product quality, driving business growth.

-

Facet 3: Employee Training and Development

A skilled and knowledgeable workforce is essential for efficient and productive operations. Providing comprehensive training programs and opportunities for professional development can enhance employee skills, improve job performance, and foster a culture of continuous improvement.Real-life example: A steel fabrication company implemented a comprehensive training program for its employees, leading to a 10% increase in productivity and a 15% reduction in production errors.

Implications for growing a steel fabrication business: Investing in employee training and development can improve employee morale, increase job satisfaction, and reduce employee turnover, all of which contribute to business growth and stability.

-

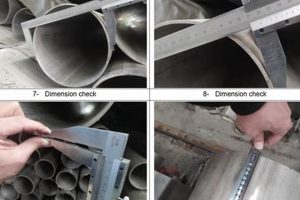

Facet 4: Quality Management Systems

Establishing a robust quality management system ensures that products meet customer specifications and industry standards. Implementing quality control processes, conducting regular inspections, and obtaining certifications can enhance product quality, reduce customer complaints, and increase customer satisfaction.Real-life example: A steel fabrication company obtained ISO 9001 certification, leading to a 25% increase in customer satisfaction and a 10% reduction in product returns.

Implications for growing a steel fabrication business: A strong quality management system can build customer trust, enhance brand reputation, and increase customer loyalty, all of which contribute to business growth and sustainability.

By implementing these facets of operational excellence, steel fabrication businesses can optimize their processes, enhance efficiency and productivity, and position themselves for sustainable growth and success in the competitive global marketplace.

Quality

In the competitive steel fabrication industry, delivering products and services that meet the highest quality standards is not just a matter of meeting customer expectations, but a fundamental pillar for business growth and long-term success. Customers in this sector demand reliability, durability, and precision, making quality an indispensable factor in driving growth.

-

Facet 1: Customer Satisfaction and Loyalty

Providing high-quality products and services leads to increased customer satisfaction and loyalty. Satisfied customers are more likely to return for repeat business, recommend your company to others, and provide positive reviews. This positive builds a strong customer base, fostering sustained growth.

-

Facet 2: Reduced Costs and Increased Efficiency

Implementing stringent quality control measures helps prevent defects and errors, reducing the need for rework, scrap, and warranty claims. Streamlining production processes and eliminating inefficiencies associated with poor quality enhances overall operational efficiency, leading to cost savings and increased profitability.

-

Facet 3: Enhanced Reputation and Market Differentiation

A reputation for high quality differentiates your business in the competitive steel fabrication market. Customers recognize and value consistent quality, making it a key factor in their purchasing decisions. A strong reputation attracts new customers, expands market reach, and supports premium pricing strategies.

-

Facet 4: Compliance and Regulatory Adherence

Meeting or exceeding industry standards and regulations is essential for steel fabrication businesses. Adhering to quality standards ensures compliance with safety, environmental, and other regulatory requirements. This not only minimizes legal risks but also enhances customer confidence and trust.

By prioritizing quality in all aspects of operations, steel fabrication businesses can establish a competitive advantage, increase customer satisfaction, reduce costs, enhance their reputation, and drive sustained growth.

Customer Service

In the competitive steel fabrication industry, providing excellent customer service is not merely a support function but a strategic imperative that drives business growth and fosters long-term success. By prioritizing customer satisfaction and building strong relationships, steel fabrication businesses can differentiate themselves, increase customer loyalty, and drive repeat business.

-

Facet 1: Customer Retention and Loyalty

Excellent customer service is the cornerstone of customer retention and loyalty. When customers feel valued, heard, and supported, they are more likely to return for repeat business and become loyal advocates for your brand. This loyal customer base provides a solid foundation for sustained growth.

-

Facet 2: Positive Word-of-Mouth and Referrals

Satisfied customers are more inclined to share their positive experiences with others, generating valuable word-of-mouth marketing and referrals. Positive customer feedback builds credibility, attracts new customers, and expands your market reach.

-

Facet 3: Increased Sales and Revenue

Exceptional customer service can directly contribute to increased sales and revenue. By addressing customer needs promptly and effectively, resolving issues swiftly, and exceeding expectations, businesses can foster customer trust and encourage repeat purchases.

-

Facet 4: Competitive Advantage and Differentiation

In a competitive market, providing superior customer service can be a key differentiator for steel fabrication businesses. By consistently delivering exceptional support, businesses can stand out from competitors and establish a loyal customer base.

By embracing a customer-centric approach and investing in building strong customer relationships, steel fabrication businesses can unlock significant growth opportunities, increase customer lifetime value, and achieve long-term success in the industry.

Innovation

In the ever-evolving steel fabrication industry, innovation is the lifeblood of growth and competitiveness. Embracing a culture of continuous innovation allows businesses to stay ahead of the curve, meet changing customer demands, and secure a sustainable position in the market.

-

Facet 1: Advanced Technologies and Techniques

Adopting cutting-edge technologies and implementing innovative techniques can revolutionize steel fabrication processes. From utilizing robotics and automation to exploring advanced welding methods, businesses can enhance efficiency, precision, and product quality, gaining a competitive edge.

-

Facet 2: New Product Development and Market Expansion

Continuously developing new products and expanding into new markets is crucial for growth. By identifying unmet customer needs and exploring emerging industry trends, businesses can create innovative solutions, diversify their offerings, and capture new revenue streams.

-

Facet 3: Process Optimization and Efficiency

Innovation extends beyond product development to optimizing existing processes and enhancing efficiency. Implementing lean manufacturing principles, investing in digital tools, and streamlining workflows can reduce costs, improve productivity, and increase profitability.

-

Facet 4: Sustainable and Environmentally Friendly Solutions

Incorporating sustainable practices into steel fabrication processes is not only environmentally responsible but also aligns with growing customer demand for eco-friendly solutions. Developing innovative techniques for waste reduction, energy efficiency, and green materials can enhance brand reputation and appeal to environmentally conscious consumers.

By embracing innovation in all its facets, steel fabrication businesses can differentiate themselves, adapt to changing market dynamics, and drive sustainable growth. Continuous innovation is the key to staying competitive and securing future success in the industry.

Technology

In today’s competitive steel fabrication industry, embracing the latest technology is not merely an option but a strategic imperative for businesses seeking growth and sustained success. By investing in advanced technologies, steel fabrication businesses can significantly improve their operations, enhance efficiency, and gain a competitive edge.

One of the most significant impacts of technology on steel fabrication is the ability to automate and streamline production processes. Advanced technologies such as robotic welding, automated material handling systems, and digital inventory management tools can reduce manual labor, minimize errors, and increase overall production speed. For example, a steel fabrication company implemented robotic welding, resulting in a 30% increase in welding productivity and a reduction in welding defects by 50%.

Moreover, technology plays a crucial role in optimizing design and engineering processes. Computer-aided design (CAD) and finite element analysis (FEA) software allow engineers to create precise and efficient designs, reducing the need for physical prototyping and minimizing material waste. This not only saves time and costs but also enhances product quality and performance.

Furthermore, technology enables steel fabrication businesses to improve their supply chain management and customer service. Enterprise resource planning (ERP) systems and customer relationship management (CRM) software provide real-time data and insights, allowing businesses to optimize inventory levels, track orders efficiently, and respond promptly to customer inquiries. This leads to increased customer satisfaction and improved overall business performance.

Investing in technology also supports innovation and new product development. Advanced manufacturing techniques, such as additive manufacturing and 3D printing, open up new possibilities for creating complex and customized steel products. By embracing technology, businesses can stay ahead of the competition and meet the evolving demands of their customers.

In conclusion, technology is an indispensable component of growing a successful steel fabrication business. By investing in the latest technologies, businesses can improve their operations, enhance efficiency, optimize design and engineering processes, improve supply chain management, and drive innovation. This ultimately leads to increased productivity, reduced costs, enhanced customer satisfaction, and a stronger competitive position in the market.

Table: The Benefits of Technology for Steel Fabrication Businesses

| Benefit | How Technology Helps |

|---|---|

| Increased productivity and efficiency | Automating production processes, reducing manual labor, and minimizing errors |

| Improved design and engineering | Utilizing CAD and FEA software for precise and efficient designs, reducing material waste |

| Optimized supply chain management and customer service | Using ERP and CRM systems for real-time data, inventory optimization, and improved customer responsiveness |

| Innovation and new product development | Leveraging advanced manufacturing techniques for creating complex and customized steel products |

Team

In the competitive steel fabrication industry, building a strong team of employees who are committed to the success of your business is a critical component of achieving growth and sustained profitability.

A dedicated and skilled workforce forms the backbone of any successful steel fabrication operation. Employees who are passionate about their work, share the company’s values, and are committed to delivering high-quality products and services are invaluable assets. They are more likely to go the extra mile, collaborate effectively, and contribute to a positive and productive work environment.

Moreover, a strong team is essential for driving innovation and continuous improvement within a steel fabrication business. Employees who are encouraged to share their ideas and participate in decision-making are more likely to come up with creative solutions to challenges, identify opportunities for optimization, and contribute to the company’s overall success.

Furthermore, a cohesive and supportive team can help steel fabrication businesses navigate economic downturns and other challenges. When employees feel valued and connected to their colleagues and the company, they are more likely to stay loyal during difficult times and work together to overcome obstacles.

Real-life Example: A steel fabrication company in the United States attributed its success to its highly skilled and dedicated team of employees. The company invested heavily in training and development programs, creating a culture of continuous learning and improvement. As a result, the company experienced increased productivity, reduced errors, and improved customer satisfaction, all of which contributed to its growth and profitability.

Practical Significance: Understanding the connection between building a strong team and growing a steel fabrication business is crucial for business owners and managers. By prioritizing employee engagement, investing in training and development, and fostering a positive and supportive work environment, steel fabrication businesses can create a workforce that is committed to the company’s success and drives growth and profitability.

Table: The Benefits of Building a Strong Team for Steel Fabrication Businesses

| Benefit | Impact on Steel Fabrication Business |

|---|---|

| Increased productivity and efficiency | Reduced labor costs, faster production times, and improved product quality |

| Enhanced innovation and continuous improvement | Development of new products and processes, leading to increased competitiveness and market share |

| Improved customer satisfaction | Higher quality products and services, leading to increased customer loyalty and repeat business |

| Increased resilience and adaptability | Ability to navigate economic downturns and other challenges, ensuring business continuity and growth |

FAQs on Growing a Steel Fabrication Business

This section addresses frequently asked questions and provides informative answers to guide business owners and managers in developing effective strategies for growth in the steel fabrication industry.

Question 1: What are the key factors that contribute to the growth of a steel fabrication business?

Answer: Key factors driving growth in steel fabrication include: establishing a strong customer base, offering a diverse range of services, embracing innovation, developing an effective marketing strategy, and maintaining a commitment to quality and customer service.

Question 2: How can steel fabricators differentiate themselves in a competitive market?

Answer: Differentiation in the steel fabrication market can be achieved through specialization in niche areas, investing in advanced technologies, providing exceptional customer service, and building a reputation for reliability and quality.

Question 3: What are the challenges faced by steel fabrication businesses, and how can they be overcome?

Answer: Common challenges include fluctuating raw material prices, skilled labor shortages, and intense competition. To overcome these challenges, businesses can implement cost-effective production techniques, invest in employee training and development, and explore strategic partnerships.

Question 4: How can steel fabricators stay updated with industry trends and technological advancements?

Answer: Staying abreast of industry trends and advancements is crucial. Attending trade shows, reading industry publications, and engaging with industry associations can provide valuable insights and networking opportunities.

Question 5: What are some best practices for managing a steel fabrication business efficiently?

Answer: Best practices for efficient management include implementing lean manufacturing principles, optimizing supply chain operations, investing in technology, and fostering a strong and motivated workforce.

Question 6: What are the growth opportunities for steel fabrication businesses in emerging markets?

Answer: Emerging markets present significant growth opportunities for steel fabrication businesses due to increasing infrastructure development, urbanization, and industrialization. Capitalizing on these opportunities requires thorough market research and strategic planning.

Summary:Understanding the key factors, challenges, and best practices associated with growing a steel fabrication business is essential for success in this competitive industry. By embracing innovation, differentiation, and operational efficiency, steel fabricators can position themselves for sustainable growth and profitability.

Transition:To further enhance their growth strategies, steel fabrication businesses should consider exploring additional resources and seeking professional guidance when necessary.

Tips for Growing a Steel Fabrication Business

To achieve sustained growth in the competitive steel fabrication industry, consider implementing these valuable tips:

Tip 1: Define Your Target Market and Niche

Identify your ideal customers and specialize in meeting their specific needs. This focused approach allows for tailored marketing strategies and enhanced customer satisfaction.

Tip 2: Invest in Advanced Technology

Embrace automation, robotics, and digital tools to streamline operations, improve efficiency, and enhance product quality. Technological advancements can lead to cost savings and increased productivity.

Tip 3: Prioritize Quality and Customer Service

Establish rigorous quality control measures and provide exceptional customer service to build a strong reputation and foster customer loyalty. Satisfied customers are more likely to return for repeat business and recommend your services.

Tip 4: Focus on Innovation and Product Development

Continuously explore new products, processes, and technologies to stay ahead of the competition. Innovation can lead to unique offerings that meet evolving customer demands and create new revenue streams.

Tip 5: Develop a Comprehensive Marketing Strategy

Implement a multifaceted marketing strategy that includes online advertising, social media engagement, content marketing, and industry networking. A well-executed marketing plan can increase brand visibility, generate leads, and drive sales.

Tip 6: Build a Strong Team and Foster a Positive Work Environment

Hire skilled and motivated employees, provide ongoing training opportunities, and create a supportive work culture. A dedicated and engaged workforce is crucial for driving innovation, productivity, and customer satisfaction.

Tip 7: Explore Strategic Partnerships and Joint Ventures

Collaborate with complementary businesses or form joint ventures to expand your market reach, share resources, and access new opportunities. Strategic partnerships can accelerate growth and mitigate risks.

Tip 8: Stay Informed and Adapt to Industry Trends

Monitor industry trends, attend trade shows, and engage with industry associations to stay abreast of technological advancements, market shifts, and best practices. Adapting to industry changes ensures competitiveness and long-term success.

Summary:By implementing these tips, steel fabrication businesses can enhance their operations, differentiate their offerings, and position themselves for sustained growth in the industry.

Conclusion:Growing a steel fabrication business requires a strategic approach, a commitment to quality, and continuous adaptation to industry dynamics. By leveraging these tips and seeking professional guidance when needed, businesses can unlock their full potential and achieve long-term profitability.

Conclusion

Growing a steel fabrication business requires a comprehensive and strategic approach. By understanding the key factors that drive growth, embracing innovation, and prioritizing quality, businesses can position themselves for success in this competitive industry. Implementing effective marketing strategies, investing in advanced technology, and building a strong team are crucial elements for achieving sustainable growth.

The future of steel fabrication holds both challenges and opportunities. With the increasing demand for steel in construction, infrastructure, and manufacturing, businesses that can adapt to changing market dynamics and evolving customer needs will be well-positioned to thrive. Continued investment in research and development, combined with a commitment to environmental sustainability, will be essential for long-term growth and success.