What is industrial fabrication? Industrial fabrication in Gladstone is the process of creating metal structures and components for a variety of industries, including mining, construction, and manufacturing. It involves cutting, bending, welding, and assembling metal materials to create custom-made products.

Editor’s Notes: Industrial fabrication is a critical part of the manufacturing process, as it allows businesses to create the custom metal components they need to operate.

Our team of experts did some analysis, digging deep into information, and put together this industrial fabrication Gladstone guide to help you make the right decision.

Key differences or Key takeaways:

| One | |

| Two | |

| Three |

Main article topics:

- The different types of industrial fabrication

- The benefits of using industrial fabrication

- The challenges of industrial fabrication

- The future of industrial fabrication

Industrial Fabrication Gladstone

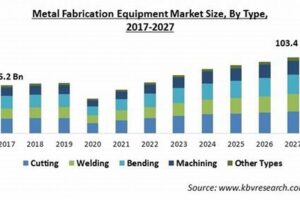

Industrial fabrication is a critical part of the manufacturing process, as it allows businesses to create the custom metal components they need to operate. There are many different aspects to industrial fabrication, including:

- Cutting

- Bending

- Welding

- Assembling

- Materials

- Equipment

- Safety

- Quality control

- Customer service

- Industry trends

- Future of industrial fabrication

Each of these aspects is important to the overall industrial fabrication process. By understanding these aspects, businesses can make informed decisions about their fabrication needs.

For example, businesses need to understand the different types of cutting and bending equipment available in order to choose the right equipment for their needs. They also need to be aware of the different types of materials that can be used in fabrication, as well as the strengths and weaknesses of each material. In addition, businesses need to have a quality control process in place to ensure that their fabricated products meet the required standards.

By understanding the key aspects of industrial fabrication, businesses can make informed decisions about their fabrication needs and ensure that they are getting the highest quality products possible.

Cutting

Cutting is one of the most important aspects of industrial fabrication. It is the process of removing material from a workpiece in order to create a desired shape or size. Cutting can be done using a variety of methods, including:

- Shearing

- Punching

- Laser cutting

- Water jet cutting

- Plasma cutting

The choice of cutting method depends on the material being cut, the thickness of the material, and the desired accuracy and finish. For example, shearing is a good choice for cutting thin sheet metal, while laser cutting is a good choice for cutting thick or complex shapes.

Cutting is a critical step in the industrial fabrication process. It is used to create the individual components that are then assembled into a finished product. Without cutting, it would be impossible to create the complex metal structures and components that are used in a wide variety of industries.

Challenges of cutting in industrial fabrication

There are a number of challenges associated with cutting in industrial fabrication. These challenges include:

- Accuracy: Cutting must be accurate in order to ensure that the finished product meets the desired specifications.

- Speed: Cutting must be fast enough to meet production demands.

- Cost: Cutting must be cost-effective in order to be profitable.

Overcoming the challenges of cutting in industrial fabrication

There are a number of ways to overcome the challenges of cutting in industrial fabrication. These include:

- Using the right equipment: The right cutting equipment can help to improve accuracy, speed, and cost.

- Proper training: Properly trained operators can help to ensure that the cutting process is efficient and accurate.

- Quality control: Quality control measures can help to ensure that the finished product meets the desired specifications.

By overcoming the challenges of cutting, industrial fabricators can produce high-quality products that meet the needs of their customers.

Bending

Bending is a metalworking process that involves applying a force to a workpiece to cause it to deform plastically. It is used to create a variety of shapes and angles in metal, and is an essential process in industrial fabrication. Bending can be done manually or using a variety of machines, such as press brakes and bending rolls.

-

Types of bending

There are many different types of bending, including:

- Angle bending: This is the most common type of bending, and involves bending a workpiece to a specific angle.

- Curving: This involves bending a workpiece to create a curved shape.

- Flanging: This involves bending the edge of a workpiece to create a flange.

- Hemming: This involves bending the edge of a workpiece to create a hem.

-

Materials that can be bent

A variety of materials can be bent, including:

- Steel

- Aluminum

- Copper

- Brass

-

Applications of bending in industrial fabrication

Bending is used in a wide variety of industrial fabrication applications, including:

- Creating structural components

- Creating enclosures

- Creating decorative elements

- Creating prototypes

-

Benefits of bending

Bending offers a number of benefits, including:

- Strength: Bending can make metal components stronger.

- Accuracy: Bending can be used to create precise shapes and angles.

- Efficiency: Bending is a relatively fast and efficient process.

- Versatility: Bending can be used to create a wide variety of shapes and angles.

Bending is a critical process in industrial fabrication, and is used to create a variety of shapes and angles in metal. It is a versatile and efficient process that offers a number of benefits, including strength, accuracy, and versatility.

Welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by causing fusion. It is a highly valuable process in industrial fabrication gladstone, as it allows manufacturers to create strong and durable structures and components.

-

Types of Welding

There are many different types of welding, each with its own advantages and disadvantages. Some of the most common types of welding used in industrial fabrication gladstone include:

- Arc welding

- MIG welding

- TIG welding

- Spot welding

-

Applications of Welding in Industrial Fabrication Gladstone

Welding is used in a wide variety of industrial fabrication gladstone applications, including:

- Creating structural components

- Creating enclosures

- Creating decorative elements

- Creating prototypes

-

Benefits of Welding

Welding offers a number of benefits, including:

- Strength: Welded joints are very strong and durable.

- Versatility: Welding can be used to join a wide variety of materials.

- Efficiency: Welding is a relatively fast and efficient process.

- Cost-effectiveness: Welding is a relatively cost-effective fabrication process.

-

Challenges of Welding

Welding also has some challenges, including:

- Safety: Welding can be a dangerous process if proper safety precautions are not taken.

- Skill: Welding requires a high level of skill and training.

- Quality: Welded joints can be susceptible to defects if proper quality control measures are not in place.

Overall, welding is a valuable process in industrial fabrication gladstone. It allows manufacturers to create strong and durable structures and components in a relatively fast and efficient manner. However, it is important to be aware of the challenges associated with welding and to take proper safety precautions.

Assembling

Assembling is a critical step in industrial fabrication gladstone. It is the process of joining individual components together to create a finished product. This can be a complex and time-consuming process, but it is essential to ensure that the final product is of high quality and meets the customer’s specifications.

-

Planning and Preparation

The first step in assembling is planning and preparation. This involves gathering all of the necessary components and materials, as well as developing a detailed assembly plan. The assembly plan should specify the order in which the components will be assembled, as well as the tools and equipment that will be required.

-

Assembly

Once the planning and preparation is complete, the assembly process can begin. This involves carefully following the assembly plan and using the appropriate tools and equipment. It is important to take care to ensure that the components are assembled correctly and that the finished product meets the customer’s specifications.

-

Inspection and Testing

Once the assembly process is complete, the finished product should be inspected and tested to ensure that it meets the customer’s specifications. This may involve visual inspection, as well as functional testing to ensure that the product is working properly.

-

Packaging and Shipping

Once the inspection and testing is complete, the finished product can be packaged and shipped to the customer. It is important to ensure that the product is packaged properly to prevent damage during shipping.

Assembling is a critical step in industrial fabrication gladstone. By following the steps outlined above, manufacturers can ensure that their products are of high quality and meet the customer’s specifications.

Materials

Materials play a critical role in industrial fabrication gladstone. The type of material used will affect the strength, durability, and cost of the finished product. Industrial fabricators must carefully consider the properties of different materials when selecting the right one for a particular application.

Some of the most common materials used in industrial fabrication gladstone include:

- Steel

- Aluminum

- Stainless steel

- Plastic

- Composite materials

Each of these materials has its own unique properties that make it suitable for different applications. For example, steel is strong and durable, making it a good choice for structural components. Aluminum is lightweight and corrosion-resistant, making it a good choice for applications where weight is a concern. Stainless steel is corrosion-resistant and easy to clean, making it a good choice for applications in the food and beverage industry.

Industrial fabricators must have a good understanding of the properties of different materials in order to select the right one for a particular application. By carefully considering the material properties, industrial fabricators can ensure that their products are of high quality and meet the customer’s specifications.

Table of Material Properties

| Material | Strength | Durability | Cost |

|---|---|---|---|

| Steel | High | High | Moderate |

| Aluminum | Moderate | Moderate | High |

| Stainless steel | High | High | High |

| Plastic | Low | Low | Low |

| Composite materials | High | High | High |

This table provides a general overview of the properties of different materials. The actual properties of a particular material may vary depending on the specific alloy or grade.

Equipment

Equipment plays a critical role in industrial fabrication gladstone. It is used to cut, bend, weld, and assemble metal components into a finished product. Without the right equipment, it would be impossible to produce high-quality products in a cost-effective manner.

-

Cutting Equipment

Cutting equipment is used to cut metal into the desired shape and size. There are a variety of cutting equipment available, including shears, saws, and lasers. The type of cutting equipment used will depend on the thickness and type of metal being cut.

-

Bending Equipment

Bending equipment is used to bend metal into the desired shape. There are a variety of bending equipment available, including press brakes and bending rolls. The type of bending equipment used will depend on the thickness and type of metal being bent.

-

Welding Equipment

Welding equipment is used to join metal components together. There are a variety of welding equipment available, including arc welders and MIG welders. The type of welding equipment used will depend on the thickness and type of metal being welded.

-

Assembly Equipment

Assembly equipment is used to assemble metal components into a finished product. There are a variety of assembly equipment available, including jigs and fixtures. The type of assembly equipment used will depend on the complexity of the product being assembled.

The choice of equipment used in industrial fabrication gladstone will depend on a number of factors, including the type of product being manufactured, the volume of production, and the budget. Industrial fabricators must carefully consider these factors when selecting equipment in order to ensure that they are using the most efficient and cost-effective equipment for their needs.

Safety

Safety is of paramount importance in industrial fabrication gladstone. It is not just about complying with regulations, but also about protecting employees, property, and the environment. Industrial fabricators must have a comprehensive safety program that addresses all aspects of their operations.

-

Hazard Identification and Risk Assessment

The first step to ensuring safety in industrial fabrication gladstone is to identify all potential hazards and assess the risks associated with them. This involves conducting a thorough inspection of the workplace, identifying potential hazards such as electrical hazards, fire hazards, and chemical hazards. Once the hazards have been identified, the risks associated with them must be assessed. This involves considering the likelihood of the hazard occurring and the severity of the consequences.

-

Safe Work Practices

Once the hazards have been identified and the risks have been assessed, safe work practices must be developed and implemented. These practices should be designed to eliminate or minimize the risks associated with the hazards. For example, if there is a risk of electrical shock, safe work practices may include using insulated tools and wearing rubber gloves.

-

Emergency Preparedness

Even with the best safety practices in place, accidents can happen. It is therefore important to be prepared for emergencies. This involves developing an emergency response plan and training employees on how to respond to emergencies. The emergency response plan should include procedures for evacuating the workplace, calling for help, and providing first aid.

-

Safety Training

Safety training is an essential part of any safety program. Employees must be trained on the hazards associated with their jobs and on the safe work practices that must be followed. Safety training should be provided regularly and should be updated as new hazards are identified or new safe work practices are developed.

By following these four steps, industrial fabricators can create a safe workplace and protect their employees, property, and the environment.

Quality control

Quality control is a critical component of industrial fabrication gladstone. It is the process of ensuring that products meet the required standards of quality. This involves inspecting products at various stages of the manufacturing process and taking corrective action when necessary.

Quality control is important for a number of reasons. First, it helps to ensure that products are safe and functional. Second, it helps to reduce costs by preventing the production of defective products. Third, it helps to improve customer satisfaction by ensuring that products meet the customer’s expectations.

There are a number of different quality control techniques that can be used in industrial fabrication gladstone. These techniques include:

- Visual inspection: This is the most basic quality control technique and involves inspecting products for defects by sight.

- Dimensional inspection: This technique involves measuring products to ensure that they meet the required dimensions.

- Functional testing: This technique involves testing products to ensure that they function properly.

- Statistical process control: This technique involves using statistical methods to monitor the manufacturing process and identify areas where improvements can be made.

The specific quality control techniques that are used will vary depending on the type of product being manufactured. However, all quality control techniques share the same goal: to ensure that products meet the required standards of quality.Quality control is an essential part of industrial fabrication gladstone. By implementing effective quality control measures, manufacturers can ensure that their products are safe, functional, and meet the customer’s expectations.

Table of Quality Control Techniques

| Technique | Description |

|---|---|

| Visual inspection | Inspecting products for defects by sight. |

| Dimensional inspection | Measuring products to ensure that they meet the required dimensions. |

| Functional testing | Testing products to ensure that they function properly. |

| Statistical process control | Using statistical methods to monitor the manufacturing process and identify areas where improvements can be made. |

Challenges of quality control in industrial fabrication gladstone

There are a number of challenges associated with quality control in industrial fabrication gladstone. These challenges include:

- The complexity of products: Industrial fabrication gladstone products are often complex and have a number of different components. This makes it difficult to inspect products for defects.

- The high volume of production: Industrial fabrication gladstone manufacturers often produce a high volume of products. This makes it difficult to inspect each product individually.

- The need for speed: Industrial fabrication gladstone manufacturers often need to produce products quickly in order to meet customer demand. This can make it difficult to implement effective quality control measures.

Despite these challenges, quality control is an essential part of industrial fabrication gladstone. By implementing effective quality control measures, manufacturers can ensure that their products are safe, functional, and meet the customer’s expectations.

Customer service

Customer service is a critical aspect of industrial fabrication gladstone. It is the process of providing support to customers before, during, and after the sale of a product or service. Good customer service can help to build strong relationships with customers, increase sales, and improve profitability.

-

Responsiveness

One of the most important aspects of customer service is responsiveness. Customers want to know that they can get help when they need it. Industrial fabrication gladstone companies should make it easy for customers to contact them, and they should respond to inquiries promptly and professionally.

-

Knowledge

Another important aspect of customer service is knowledge. Customers want to know that they are dealing with a company that knows its products and services. Industrial fabrication gladstone companies should have well-trained staff who can answer customer questions and provide helpful advice.

-

Problem-solving

Customers also want to know that they can count on a company to solve their problems. Industrial fabrication gladstone companies should have a process in place for handling customer complaints and resolving issues quickly and efficiently.

-

Personalization

Finally, customers want to feel like they are valued. Industrial fabrication gladstone companies can personalize the customer experience by remembering customer preferences, offering discounts and promotions, and sending personalized communications.

By providing excellent customer service, industrial fabrication gladstone companies can build strong relationships with customers, increase sales, and improve profitability.

Industry trends

Industrial fabrication gladstone is a constantly evolving industry, and it is important for businesses to stay up-to-date on the latest trends. These trends can impact everything from the materials used in fabrication to the way that products are designed and manufactured.

-

The use of new materials

One of the most significant trends in industrial fabrication gladstone is the use of new materials. These materials are often lighter, stronger, and more durable than traditional materials, which can lead to improved product performance and reduced costs. For example, the use of composite materials in the automotive industry has helped to reduce the weight of vehicles and improve fuel efficiency.

-

The adoption of new technologies

Another major trend in industrial fabrication gladstone is the adoption of new technologies. These technologies can automate tasks, improve accuracy, and reduce lead times. For example, the use of computer-aided design (CAD) software has helped to streamline the design process and reduce errors.

-

The increasing demand for customization

Customers are increasingly demanding customized products that meet their specific needs. This trend is being driven by the rise of e-commerce and the ability to purchase products online. Industrial fabrication gladstone companies are responding to this demand by offering a wider range of customization options.

-

The growing focus on sustainability

There is a growing focus on sustainability in all industries, and industrial fabrication gladstone is no exception. Industrial fabrication gladstone companies are looking for ways to reduce their environmental impact, such as by using recycled materials and reducing energy consumption.

These are just a few of the trends that are shaping the industrial fabrication gladstone industry. By staying up-to-date on these trends, businesses can ensure that they are well-positioned to meet the needs of their customers and compete in the global marketplace.

Future of industrial fabrication

The future of industrial fabrication is closely tied to the future of industrial fabrication gladstone. As the industry continues to evolve, new technologies and trends will emerge that will shape the way that products are designed, manufactured, and delivered.

-

Increased adoption of automation

One of the most significant trends in the future of industrial fabrication is the increased adoption of automation. This includes the use of robots, automated guided vehicles (AGVs), and other automated systems to perform tasks that are currently done manually. Automation can help to improve productivity, reduce costs, and improve safety.

-

Greater use of additive manufacturing

Additive manufacturing, also known as 3D printing, is another technology that is expected to have a major impact on the future of industrial fabrication. This technology allows for the creation of complex parts and geometries that would be difficult or impossible to produce using traditional manufacturing methods. Additive manufacturing can also help to reduce lead times and costs.

-

Increased focus on sustainability

There is a growing focus on sustainability in all industries, and industrial fabrication is no exception. This is leading to the development of new materials and processes that are more environmentally friendly. For example, some companies are now using recycled materials to create new products.

-

Greater collaboration between designers and manufacturers

In the future, there will be a greater need for collaboration between designers and manufacturers. This is because the design of a product can have a significant impact on its manufacturability. By working together, designers and manufacturers can create products that are both functional and easy to produce.

These are just a few of the trends that are expected to shape the future of industrial fabrication gladstone. As these trends continue to develop, it is important for businesses to stay up-to-date on the latest technologies and trends. By doing so, businesses can ensure that they are well-positioned to meet the needs of their customers and compete in the global marketplace.

FAQs about Industrial Fabrication in Gladstone

Industrial fabrication is a critical part of the manufacturing process, as it allows businesses to create the metal structures and components they need to operate. Here are some frequently asked questions about industrial fabrication in Gladstone:

Question 1: What is industrial fabrication?

Answer: Industrial fabrication is the process of creating metal structures and components for a variety of industries, including mining, construction, and manufacturing. It involves cutting, bending, welding, and assembling metal materials to create custom-made products.

Question 2: What are the benefits of using industrial fabrication?

Answer: Industrial fabrication offers a number of benefits, including:

- The ability to create custom-made products

- Reduced lead times

- Lower costs

- Improved quality

- Increased safety

Question 3: What are the challenges of industrial fabrication?

Answer: Industrial fabrication can be a challenging process, as it requires a high level of skill and expertise. Some of the challenges associated with industrial fabrication include:

- The need for specialized equipment

- The potential for safety hazards

- The need to meet strict quality standards

Question 4: What is the future of industrial fabrication?

Answer: The future of industrial fabrication is bright, as the demand for custom-made metal products is expected to continue to grow. Some of the trends that are expected to shape the future of industrial fabrication include:

- The increased adoption of automation

- The greater use of additive manufacturing

- The increased focus on sustainability

- The greater collaboration between designers and manufacturers

Question 5: How can I find a reputable industrial fabrication company in Gladstone?

Answer: There are a number of reputable industrial fabrication companies in Gladstone. To find a company that is right for you, it is important to consider the following factors:

- The company’s experience

- The company’s capabilities

- The company’s reputation

- The company’s prices

Question 6: What are some tips for working with an industrial fabrication company?

Answer: To ensure a successful partnership with an industrial fabrication company, it is important to:

- Communicate your needs clearly

- Be realistic about your budget and timeline

- Be open to suggestions and feedback

- Build a strong relationship with the company

By following these tips, you can find a reputable industrial fabrication company in Gladstone and ensure a successful partnership.

Industrial fabrication is a critical part of the manufacturing process, and it is important to choose a reputable company that can meet your needs. By following the tips above, you can find a company that will help you create the custom-made metal products you need.

Transition to the next article section:

For more information on industrial fabrication in Gladstone, please contact a local company or visit the website of the Gladstone Chamber of Commerce.

Tips for Industrial Fabrication in Gladstone

Industrial fabrication is a critical part of the manufacturing process, as it allows businesses to create the custom metal structures and components they need to operate. By following these tips, you can ensure that your industrial fabrication project is a success:

Tip 1: Choose the Right Company

The first step to a successful industrial fabrication project is choosing the right company. Consider the company’s experience, capabilities, reputation, and prices. It is also important to find a company that is located near you and that has a good understanding of your industry.

Tip 2: Communicate Your Needs Clearly

Once you have chosen a company, it is important to communicate your needs clearly. This includes providing the company with detailed drawings and specifications. It is also important to be realistic about your budget and timeline.

Tip 3: Be Open to Suggestions and Feedback

The industrial fabrication company you choose will have a wealth of experience and knowledge. Be open to their suggestions and feedback. They may be able to help you save money or improve the quality of your product.

Tip 4: Build a Strong Relationship with the Company

Building a strong relationship with the industrial fabrication company you choose is essential to the success of your project. This means being communicative, responsive, and flexible. It also means being willing to work together to solve problems.

Tip 5: Inspect the Final Product Carefully

Once the industrial fabrication project is complete, it is important to inspect the final product carefully. This will ensure that the product meets your specifications and that it is free of defects.

Summary of Key Takeaways or Benefits

By following these tips, you can ensure that your industrial fabrication project is a success. You will be able to choose the right company, communicate your needs clearly, be open to suggestions and feedback, build a strong relationship with the company, and inspect the final product carefully.

Transition to the Article’s Conclusion

Industrial fabrication is a critical part of the manufacturing process, and it is important to choose a reputable company that can meet your needs. By following the tips above, you can find a company that will help you create the custom-made metal products you need.

Industrial fabrication gladstone

Industrial fabrication gladstone is a critical part of the manufacturing process, enabling businesses to create the custom metal structures and components they need to operate. It involves cutting, bending, welding, and assembling metal materials to create products for a wide range of industries.

This article has explored the various aspects of industrial fabrication gladstone, including the different types of fabrication, the benefits of using industrial fabrication, the challenges of industrial fabrication, and the future of industrial fabrication. We have also provided tips for choosing an industrial fabrication company and for ensuring the success of your industrial fabrication project.

Industrial fabrication gladstone is a complex and challenging process, but it is also an essential one. By understanding the key aspects of industrial fabrication, businesses can make informed decisions about their fabrication needs and ensure that they are getting the highest quality products possible.

The future of industrial fabrication gladstone is bright, as the demand for custom-made metal products is expected to continue to grow. New technologies and trends are emerging that will shape the way that products are designed, manufactured, and delivered. By staying up-to-date on these trends, businesses can ensure that they are well-positioned to meet the needs of their customers and compete in the global marketplace.