What is iron and steel fabrication? Iron and steel fabrication is the process of creating structures and products from iron and steel. These structures can range from small items like railings and fences to large-scale projects such as bridges and buildings.

Editor’s Note: Iron and steel fabrication is a vital part of the construction industry. It is used to create a wide variety of structures, from small projects like fences and gates to large-scale projects like bridges and buildings.

To help you understand iron and steel fabrication better, we’ve put together this comprehensive guide. In this guide, we will cover the basics of iron and steel fabrication, including the different types of fabrication processes, the materials used, and the benefits of using iron and steel.

Key Differences:

| Characteristic | Iron | Steel |

|---|---|---|

| Strength | Lower | Higher |

| Ductility | Higher | Lower |

| Malleability | Higher | Lower |

| Corrosion Resistance | Lower | Higher |

Main Article Topics:

- The History of Iron and Steel Fabrication

- The Different Types of Iron and Steel Fabrication Processes

- The Materials Used in Iron and Steel Fabrication

- The Benefits of Using Iron and Steel

- The Applications of Iron and Steel Fabrication

Iron and Steel Fabrication

Iron and steel fabrication is a vital part of the construction industry. It is used to create a wide variety of structures, from small projects like fences and gates to large-scale projects like bridges and buildings. To understand the importance of iron and steel fabrication, it is essential to consider its key aspects:

- Materials: Iron and steel are strong, durable, and relatively inexpensive materials. This makes them ideal for a wide range of fabrication projects.

- Processes: Iron and steel can be fabricated using a variety of processes, including welding, cutting, and forming. This allows fabricators to create complex and precise structures.

- Applications: Iron and steel fabrication is used in a wide range of applications, including construction, transportation, and manufacturing. This versatility makes iron and steel essential to the modern world.

- Benefits: Iron and steel fabrication offers a number of benefits, including strength, durability, and cost-effectiveness. This makes iron and steel a popular choice for a variety of projects.

- History: Iron and steel fabrication has a long and rich history. The first iron and steel structures were built in the 19th century, and the industry has continued to grow and evolve ever since.

- Design: Iron and steel fabrication can be used to create structures of any size or shape. This makes it a popular choice for architects and engineers.

- Safety: Iron and steel structures are strong and durable, making them safe for a variety of applications.

- Sustainability: Iron and steel are recyclable materials, making them a sustainable choice for fabrication projects.

- Innovation: Iron and steel fabrication is constantly evolving, with new technologies and techniques being developed all the time. This makes it an exciting and dynamic industry to be a part of.

- Careers: Iron and steel fabrication offers a variety of career opportunities, from entry-level positions to management positions. This makes it a great industry for people who are looking for a stable and rewarding career.

These key aspects highlight the importance of iron and steel fabrication in the construction industry. By understanding these aspects, you can make informed decisions about when and how to use iron and steel in your own projects.

Materials

The materials used in iron and steel fabrication play a vital role in the quality and durability of the final product. Iron and steel are two of the most common materials used in fabrication, due to their strength, durability, and relatively low cost. These properties make them ideal for a wide range of fabrication projects, from small items like railings and fences to large-scale projects like bridges and buildings.

The strength of iron and steel is one of their most important properties. Iron and steel are both strong and durable, making them able to withstand heavy loads and harsh conditions. This makes them ideal for use in structural applications, such as bridges and buildings. The durability of iron and steel is another important property. Iron and steel are resistant to corrosion and wear, making them able to withstand the elements and last for many years. This makes them ideal for use in outdoor applications, such as fences and gates. The relatively low cost of iron and steel is another important property. Iron and steel are relatively inexpensive materials, making them a cost-effective option for a wide range of fabrication projects. This makes them ideal for use in projects where cost is a major factor.

The combination of strength, durability, and low cost makes iron and steel ideal for a wide range of fabrication projects. These projects include:

- Structural applications, such as bridges and buildings

- Outdoor applications, such as fences and gates

- Industrial applications, such as machinery and equipment

- Transportation applications, such as cars and trucks

- Consumer products, such as appliances and furniture

The use of iron and steel in fabrication has a number of benefits, including:

- Strength and durability

- Corrosion resistance

- Wear resistance

- Low cost

- Versatility

These benefits make iron and steel ideal for a wide range of fabrication projects. By understanding the connection between the materials used in iron and steel fabrication and the quality and durability of the final product, you can make informed decisions about when and how to use iron and steel in your own projects.

Table: Key Insights

| Characteristic | Importance |

|---|---|

| Strength | Iron and steel are strong and durable, making them able to withstand heavy loads and harsh conditions. |

| Durability | Iron and steel are resistant to corrosion and wear, making them able to withstand the elements and last for many years. |

| Cost | Iron and steel are relatively inexpensive materials, making them a cost-effective option for a wide range of fabrication projects. |

| Versatility | Iron and steel can be used in a wide range of fabrication projects, from small items like railings and fences to large-scale projects like bridges and buildings. |

Processes

The processes used in iron and steel fabrication play a vital role in the quality and precision of the final product. Iron and steel can be fabricated using a variety of processes, including welding, cutting, and forming. These processes allow fabricators to create complex and precise structures that meet the specific requirements of each project.

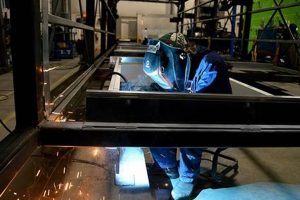

Welding is a process that joins two pieces of metal together by melting the metal at the joint. Welding is a strong and durable method of fabrication, and it can be used to create a wide variety of structures. Cutting is a process that removes material from a piece of metal. Cutting can be used to create a variety of shapes and sizes of metal components. Forming is a process that changes the shape of a piece of metal. Forming can be used to create a variety of curves and bends in metal components.

The combination of welding, cutting, and forming allows fabricators to create complex and precise structures from iron and steel. These structures can be used in a wide range of applications, including:

- Construction

- Transportation

- Industrial machinery

- Consumer products

The processes used in iron and steel fabrication are essential to the creation of high-quality and precise structures. By understanding the connection between the processes used in iron and steel fabrication and the quality and precision of the final product, you can make informed decisions about when and how to use iron and steel in your own projects.

Table: Key Insights

| Process | Importance |

|---|---|

| Welding | Welding is a strong and durable method of fabrication that can be used to create a wide variety of structures. |

| Cutting | Cutting can be used to create a variety of shapes and sizes of metal components. |

| Forming | Forming can be used to create a variety of curves and bends in metal components. |

Applications

Iron and steel fabrication is used in a wide range of applications because it is a versatile material that can be used to create a variety of structures and products. Iron and steel are strong, durable, and relatively inexpensive, making them ideal for a wide range of applications, including:

- Construction: Iron and steel are used in the construction of buildings, bridges, and other structures. Iron and steel are strong and durable, making them ideal for use in load-bearing applications.

- Transportation: Iron and steel are used in the construction of cars, trucks, trains, and other vehicles. Iron and steel are strong and durable, making them ideal for use in applications where safety is a concern.

- Manufacturing: Iron and steel are used in the manufacturing of a wide range of products, including appliances, furniture, and machinery. Iron and steel are strong and durable, making them ideal for use in applications where durability is a concern.

The versatility of iron and steel fabrication makes it essential to the modern world. Iron and steel are used in a wide range of applications, from the construction of buildings to the manufacturing of products. The strength, durability, and relatively low cost of iron and steel make it an ideal material for a wide range of applications.

Key Insights:

- Iron and steel fabrication is a versatile process that can be used to create a wide range of structures and products.

- Iron and steel are strong, durable, and relatively inexpensive, making them ideal for a wide range of applications.

- The versatility of iron and steel fabrication makes it essential to the modern world.

| Application | Importance |

|---|---|

| Construction | Iron and steel are used in the construction of buildings, bridges, and other structures. Iron and steel are strong and durable, making them ideal for use in load-bearing applications. |

| Transportation | Iron and steel are used in the construction of cars, trucks, trains, and other vehicles. Iron and steel are strong and durable, making them ideal for use in applications where safety is a concern. |

| Manufacturing | Iron and steel are used in the manufacturing of a wide range of products, including appliances, furniture, and machinery. Iron and steel are strong and durable, making them ideal for use in applications where durability is a concern. |

Benefits

Iron and steel fabrication offers a number of benefits that make it a popular choice for a variety of projects. These benefits include strength, durability, and cost-effectiveness.

The strength of iron and steel makes it an ideal material for load-bearing applications. Iron and steel are used in the construction of buildings, bridges, and other structures. Iron and steel are also used in the construction of cars, trucks, trains, and other vehicles.

The durability of iron and steel makes it an ideal material for applications where longevity is important. Iron and steel are resistant to corrosion and wear, making them ideal for use in outdoor applications. Iron and steel are also resistant to fire, making them ideal for use in fire-rated applications.

The cost-effectiveness of iron and steel makes it an ideal material for a variety of projects. Iron and steel are relatively inexpensive materials, making them a cost-effective option for a wide range of applications. Iron and steel are also easy to work with, making them a popular choice for fabricators.

The combination of strength, durability, and cost-effectiveness makes iron and steel a popular choice for a variety of projects. Iron and steel are used in a wide range of applications, from the construction of buildings to the manufacturing of products.

Here are some examples of how the benefits of iron and steel fabrication are used in real-life applications:

- The Golden Gate Bridge in San Francisco, California is made of iron and steel. The bridge is over 8,000 feet long and is one of the most iconic landmarks in the world.

- The Empire State Building in New York City is made of iron and steel. The building is over 1,200 feet tall and is one of the tallest buildings in the world.

- The Ford F-150 is the best-selling truck in America. The truck is made of iron and steel and is known for its strength and durability.

These are just a few examples of how the benefits of iron and steel fabrication are used in real-life applications. Iron and steel are essential materials in the modern world and are used in a wide range of applications.

Table: Key Insights

| Benefit | Importance |

|---|---|

| Strength | Iron and steel are strong and durable, making them ideal for load-bearing applications. |

| Durability | Iron and steel are resistant to corrosion and wear, making them ideal for use in outdoor applications. |

| Cost-effectiveness | Iron and steel are relatively inexpensive materials, making them a cost-effective option for a wide range of applications. |

History

The history of iron and steel fabrication is closely connected to the development of iron and steel production. The first iron and steel structures were built in the 19th century, when the Bessemer process was developed. This process made it possible to produce large quantities of iron and steel, which led to the construction of the first iron and steel bridges, buildings, and other structures.

The development of iron and steel fabrication has had a significant impact on the modern world. Iron and steel are now used in a wide range of applications, from construction to transportation to manufacturing. The strength, durability, and cost-effectiveness of iron and steel make it an essential material for a variety of projects.

Here are some examples of how the history of iron and steel fabrication has influenced the modern world:

- The Eiffel Tower in Paris, France was built in 1889. The tower is made of iron and steel and is one of the most iconic landmarks in the world.

- The Brooklyn Bridge in New York City was built in 1883. The bridge is made of iron and steel and is one of the most famous bridges in the world.

- The Golden Gate Bridge in San Francisco, California was built in 1937. The bridge is made of iron and steel and is one of the most beautiful bridges in the world.

These are just a few examples of how the history of iron and steel fabrication has influenced the modern world. Iron and steel are essential materials in the modern world and are used in a wide range of applications.

Table: Key Insights

| Historical Development | Impact on Iron and Steel Fabrication |

|---|---|

| Development of the Bessemer process in the 19th century | Made it possible to produce large quantities of iron and steel, leading to the construction of the first iron and steel structures. |

| Industrial Revolution in the 19th century | Increased demand for iron and steel for use in construction, transportation, and manufacturing. |

| Development of new technologies in the 20th century | Led to the development of new and improved methods for iron and steel fabrication. |

Design

Iron and steel fabrication offers a great degree of design flexibility, making it a popular choice for architects and engineers. This flexibility stems from the inherent properties of iron and steel, as well as the advanced fabrication techniques employed in their shaping and assembly. Let’s delve into some key facets that highlight this connection:

- Structural Versatility: Iron and steel possess exceptional strength-to-weight ratios, allowing for the creation of structures that are both lightweight and robust. This versatility enables architects and engineers to design complex and innovative structures, pushing the boundaries of architectural expression.

- Formability: Iron and steel are highly malleable materials, making them suitable for a wide range of forming processes. This allows for the fabrication of intricate shapes and curved surfaces, adding aesthetic appeal and functional advantages to structures.

- Adaptability to Various Architectural Styles: Iron and steel fabrication seamlessly adapts to diverse architectural styles, from traditional to contemporary. The material’s inherent strength and durability make it suitable for both load-bearing and decorative elements, enabling architects to achieve their desired aesthetic vision.

- Integration with Other Materials: Iron and steel can be easily integrated with other construction materials, such as glass, concrete, and timber. This allows for the creation of hybrid structures that combine the advantages of different materials, resulting in innovative and sustainable designs.

In summary, the design flexibility offered by iron and steel fabrication empowers architects and engineers to realize their creative visions. By leveraging the material’s strength, formability, adaptability, and compatibility with other materials, they can create structures that are both aesthetically pleasing and structurally sound.

Safety

The inherent strength and durability of iron and steel contribute significantly to the safety of structures fabricated using these materials. This connection is crucial because it ensures the reliability and longevity of structures, particularly in applications where safety is paramount.

Iron and steel’s exceptional strength enables them to withstand significant loads and forces without compromising their integrity. This makes them ideal for load-bearing structures such as bridges, buildings, and industrial facilities. Their resistance to deformation and collapse ensures the stability and safety of these structures, even under extreme conditions.

Furthermore, the durability of iron and steel structures enhances safety by providing long-term performance and resistance to environmental factors. These materials exhibit excellent corrosion resistance, preventing deterioration and maintaining structural integrity over extended periods. This is particularly important in applications where structures are exposed to harsh weather conditions, such as coastal areas or industrial environments.

The safety benefits of iron and steel fabrication extend to various applications, including:

- Construction: Iron and steel are widely used in the construction industry due to their ability to create safe and reliable structures. From skyscrapers to bridges, these materials provide the necessary strength and durability to ensure the safety of occupants and users.

- Transportation: Iron and steel are essential in the transportation sector, particularly in the construction of vehicles and infrastructure. Their strength ensures the safety of passengers and cargo, while their durability contributes to the longevity of transportation systems.

- Industrial Applications: Iron and steel are indispensable in industrial settings, where safety is crucial. These materials are used in the construction of machinery, equipment, and infrastructure, ensuring the safe operation of industrial processes and protecting workers.

Understanding the connection between safety and iron and steel fabrication is essential for architects, engineers, and construction professionals. By leveraging the inherent strength and durability of these materials, they can design and construct structures that meet rigorous safety standards, ensuring the well-being of occupants and users.

Key Insights:

| Characteristic | Safety Implications |

|---|---|

| Strength | Withstands significant loads and forces, ensuring structural stability and preventing collapse. |

| Durability | Resists environmental factors and corrosion, maintaining structural integrity over extended periods. |

| Reliability | Provides consistent performance and longevity, enhancing safety in critical applications. |

Sustainability

The connection between sustainability and iron and steel fabrication lies in the inherent recyclability of iron and steel. This characteristic makes these materials environmentally friendly and contributes to the circular economy, where materials are repeatedly used and recycled, minimizing waste and promoting resource conservation.

- Reduced Environmental Impact: Recycling iron and steel significantly reduces the need for virgin material extraction and production, conserving natural resources and minimizing environmental impact. This process conserves energy, reduces greenhouse gas emissions, and helps preserve ecosystems.

- Energy Efficiency: Recycling iron and steel requires less energy than producing new materials from raw ores. This energy efficiency contributes to reducing the carbon footprint of fabrication projects and supports efforts to mitigate climate change.

- Waste Reduction: By recycling iron and steel, fabrication projects contribute to waste reduction and landfill diversion. Scrap metal from fabrication processes can be reprocessed and reused, preventing it from ending up in landfills and reducing the environmental burden.

- Economic Benefits: Recycling iron and steel can provide economic benefits by reducing the cost of raw materials for fabrication projects. Recycled materials are often more affordable than virgin materials, making them a cost-effective choice for sustainable construction and manufacturing.

The sustainability of iron and steel fabrication extends beyond environmental benefits. It also aligns with the principles of social responsibility and economic viability. By incorporating recycled iron and steel into fabrication projects, businesses can demonstrate their commitment to environmental stewardship, reduce their ecological footprint, and contribute to a more sustainable future.

Innovation

The constant innovation in iron and steel fabrication stems from the industry’s commitment to progress and the relentless pursuit of improved materials and processes. This drive for innovation has profound implications for the future of iron and steel fabrication, as it opens up new possibilities for design, construction, and manufacturing.

- Advanced Materials: Innovation in iron and steel fabrication includes the development of advanced materials with enhanced properties. These materials may possess higher strength, improved corrosion resistance, or increased durability, expanding the range of applications for iron and steel.

- New Fabrication Techniques: The industry is also witnessing the emergence of new fabrication techniques that enhance efficiency, accuracy, and precision. These techniques, such as advanced welding technologies and automated processes, enable the creation of complex and intricate structures with greater speed and consistency.

- Digitalization: Digitalization is transforming iron and steel fabrication by integrating digital tools and technologies into the design, production, and management processes. This integration improves communication, streamlines workflows, and optimizes resource allocation, leading to increased productivity and reduced costs.

- Sustainability: Innovation in iron and steel fabrication also focuses on sustainability. Researchers and industry professionals are exploring ways to reduce the environmental impact of fabrication processes and develop more sustainable materials and techniques. This includes exploring renewable energy sources, optimizing material usage, and promoting recycling.

The continuous innovation in iron and steel fabrication promises a future filled with exciting possibilities. As new technologies and techniques emerge, the industry will continue to push the boundaries of what is possible, shaping the future of construction, infrastructure, and manufacturing.

Careers

The connection between careers and iron and steel fabrication is multifaceted. Iron and steel fabrication offers a wide range of career opportunities because it is a growing industry with a high demand for skilled workers. The industry is also stable, with a long history of providing good-paying jobs. This makes it a great option for people who are looking for a long-term career with the potential for advancement.

Some of the entry-level positions in iron and steel fabrication include welder, fitter, and fabricator. These positions require some training, but they can be learned on the job. As workers gain experience, they can move up to more advanced positions, such as supervisor, manager, or engineer. These positions require more training and education, but they also offer higher pay and more responsibility.

Iron and steel fabrication is a great career choice for people who are interested in working with their hands and who are looking for a stable and rewarding career. The industry offers a variety of opportunities for advancement, and there is a high demand for skilled workers.

Key Insights:

| Characteristic | Importance |

|---|---|

| Variety of Career Opportunities | Iron and steel fabrication offers a wide range of career opportunities, from entry-level positions to management positions. |

| Growing Industry | The iron and steel fabrication industry is growing, with a high demand for skilled workers. |

| Stable Industry | The iron and steel fabrication industry is stable, with a long history of providing good-paying jobs. |

| Potential for Advancement | There is a high potential for advancement in the iron and steel fabrication industry. |

Frequently Asked Questions about Iron and Steel Fabrication

Iron and steel fabrication is a multifaceted industry, and it’s natural to have questions about its processes, applications, and benefits. This FAQ section aims to address some common concerns and misconceptions, providing informative answers to enhance your understanding.

Question 1: Is iron and steel fabrication only suitable for large-scale projects?

Answer: No, iron and steel fabrication encompasses projects of varying scales. While it’s true that iron and steel are often used in large-scale construction and infrastructure projects, they are equally versatile for smaller applications. From custom railings and fences to intricate furniture pieces, iron and steel fabrication offers tailored solutions for diverse needs.

Question 2: Are iron and steel structures vulnerable to corrosion?

Answer: While iron and steel are susceptible to corrosion under certain conditions, modern fabrication techniques and protective measures effectively mitigate this concern. Advanced coatings, galvanizing, and stainless steel alloys enhance corrosion resistance, ensuring the longevity and integrity of iron and steel structures.

Question 3: Is iron and steel fabrication an environmentally friendly process?

Answer: Iron and steel fabrication embraces sustainability through recycling and eco-conscious practices. Iron and steel are highly recyclable materials, reducing waste and conserving natural resources. Furthermore, advancements in fabrication technologies prioritize energy efficiency and reduced emissions, contributing to a greener industry.

Question 4: Are iron and steel structures fire-resistant?

Answer: Yes, iron and steel possess excellent fire-resistant properties. Their high melting points and inherent strength make them ideal for fire-rated applications. Iron and steel structures can withstand intense heat and maintain their structural integrity, providing enhanced safety and protection during fire events.

Question 5: Is iron and steel fabrication a cost-effective solution?

Answer: The cost-effectiveness of iron and steel fabrication varies depending on project specifications and material choices. However, iron and steel generally offer competitive pricing compared to alternative materials. Their durability, low maintenance requirements, and long lifespans contribute to overall cost savings over time.

Question 6: What are the career opportunities in iron and steel fabrication?

Answer: Iron and steel fabrication offers a wide range of career opportunities, catering to diverse skill sets and interests. From entry-level positions in welding, fitting, and fabrication to advanced roles in engineering, management, and design, the industry provides growth opportunities for individuals seeking stable and rewarding careers.

Summary: Iron and steel fabrication is a versatile and dynamic industry that addresses various concerns through innovative techniques and sustainable practices. Its applications span multiple industries, and career opportunities are abundant for those seeking fulfilling and long-term employment.

Transition to the next article section: To delve deeper into the world of iron and steel fabrication, let’s explore its fascinating history and the advancements that have shaped this remarkable field.

Iron and Steel Fabrication Tips

Iron and steel fabrication is a critical process in various industries, requiring precision, expertise, and adherence to safety standards. Here are some valuable tips to optimize your iron and steel fabrication practices:

Tip 1: Choose the Right Materials: Selecting the appropriate iron and steel alloys is essential for ensuring the structural integrity and performance of your fabrication project. Consider factors such as strength, durability, corrosion resistance, and intended application to determine the optimal material.

Tip 2: Optimize Fabrication Techniques: Employing efficient fabrication techniques can improve productivity and accuracy. Utilize advanced welding methods, such as gas metal arc welding (GMAW) or flux-cored arc welding (FCAW), for precise and reliable welding. Laser cutting and waterjet cutting offer high-precision cutting solutions, minimizing material waste and enhancing design flexibility.

Tip 3: Ensure Quality Control: Implement rigorous quality control measures throughout the fabrication process to maintain high standards and prevent defects. Establish clear specifications, conduct regular inspections, and utilize non-destructive testing methods, such as ultrasonic testing or radiographic testing, to ensure the structural integrity and safety of your fabricated components.

Tip 4: Prioritize Safety: Safety should be paramount in any iron and steel fabrication operation. Provide comprehensive safety training to your team, enforce the use of appropriate personal protective equipment (PPE), and establish clear safety protocols. Regularly inspect equipment and ensure proper ventilation to minimize hazards and create a safe working environment.

Tip 5: Embrace Innovation: The iron and steel fabrication industry is constantly evolving, with new technologies emerging to enhance efficiency and precision. Stay abreast of industry advancements, invest in modern equipment, and explore innovative fabrication techniques to optimize your processes and stay competitive.

Tip 6: Seek Professional Expertise: For complex or specialized fabrication projects, consider consulting with experienced iron and steel fabricators. Their expertise can guide you in selecting the optimal materials, designing efficient fabrication processes, and ensuring adherence to industry standards and safety regulations.

Tip 7: Maintain Equipment: Regular maintenance of fabrication equipment is crucial for ensuring precision, safety, and longevity. Establish a preventive maintenance schedule, conduct routine inspections, and promptly address any issues to minimize downtime and maintain optimal equipment performance.

Tip 8: Optimize Material Utilization: Efficient material utilization can reduce waste and save costs. Explore techniques such as nesting, which optimizes cutting patterns to minimize material scrap. Implement inventory management systems to track material usage and avoid overstocking or shortages.

Summary: By incorporating these tips into your iron and steel fabrication practices, you can enhance the quality, efficiency, and safety of your operations. Embrace continuous improvement, seek professional guidance when needed, and stay informed about industry advancements to optimize your fabrication processes and deliver exceptional results.

Transition to the article’s conclusion: As the iron and steel fabrication industry continues to evolve, these tips provide a solid foundation for optimizing your practices and staying at the forefront of innovation.

Conclusion

The exploration of iron and steel fabrication throughout this article has illuminated its multifaceted nature and critical role in shaping the modern world. It is a testament to the ingenuity and perseverance of engineers, architects, and fabricators who have harnessed the unique properties of iron and steel to create structures, machines, and infrastructure that have transformed our lives.

As we look to the future of iron and steel fabrication, sustainability and innovation will undoubtedly be at the forefront. The industry must continue to embrace eco-conscious practices, reduce its environmental impact, and develop innovative materials and techniques that push the boundaries of what is possible. By doing so, iron and steel fabrication will remain a cornerstone of modern industry, enabling us to build a more sustainable and prosperous future.