Metal fabrication and machining are essential processes in various industries, including manufacturing, construction, and transportation. They involve shaping and forming metal into various components and structures, ranging from small parts to large-scale fabrications.

Editor’s Notes: Metal fabrication and machining play a critical role in modern society, enabling the production of countless products we rely on daily. Understanding these processes is essential for anyone involved in metalworking or related fields.

Through extensive research and analysis, we present this comprehensive guide to metal fabrication and machining, empowering you to make informed decisions and navigate the complexities of these processes.

Key Differences Between Metal Fabrication and Machining

| Metal Fabrication | Machining |

|---|---|

| Involves shaping metal using various techniques such as cutting, welding, and bending | Involves removing material from metal using cutting tools to achieve precise shapes and dimensions |

| Typically used for larger-scale projects and custom fabrications | Typically used for smaller-scale, precision parts and components |

Metal Fabrication Processes:

- Cutting: Shearing, sawing, laser cutting, waterjet cutting

- Welding: Arc welding, MIG welding, TIG welding

- Bending: Press brake bending, roll bending

- Forming: Rolling, stamping, forging

Machining Processes:

- Milling: Creating flat surfaces, slots, and pockets using rotating cutters

- Turning: Shaping cylindrical workpieces using a rotating cutter

- Drilling: Creating holes in metal using drill bits

- Grinding: Smoothing and finishing metal surfaces using abrasive wheels

Benefits of Metal Fabrication and Machining:

- Production of custom metal components and structures

- Precise shaping and forming of metal materials

- Creation of durable and long-lasting metal products

- Wide range of applications across industries

For further exploration, refer to the following resources:

- Wikipedia: Metal Fabrication and Machining

- YouTube: Metal Fabrication and Machining Tutorials

- Comparison: Metal Fabrication vs. Machining

Metal Fabrication and Machining

Metal fabrication and machining encompass various essential aspects that shape the industry. These key aspects provide a comprehensive understanding of the processes involved and their significance in shaping metal components.

- Materials: Diverse metals and alloys used, each with unique properties

- Processes: Cutting, welding, bending, and machining techniques employed

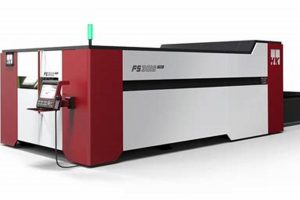

- Equipment: Advanced machinery and tooling for precise fabrication and machining

- Precision: Accurate shaping and forming of metal components

- Customization: Tailored solutions to meet specific design requirements

- Quality: Stringent standards and quality control measures

- Safety: Protocols and protective measures to ensure workplace safety

- Sustainability: Environmentally conscious practices and materials

- Innovation: Ongoing advancements in technologies and processes

These key aspects are interconnected, influencing the efficiency, precision, and quality of metal fabrication and machining. For instance, the choice of materials directly impacts the selection of fabrication and machining processes. Advanced equipment enables greater precision and efficiency, while stringent quality control measures ensure the reliability of the final product. Moreover, innovation drives the development of new techniques and technologies, pushing the boundaries of what is possible in metal fabrication and machining.

Materials

The foundation of metal fabrication and machining lies in the diverse range of metals and alloys employed, each possessing unique properties that dictate their suitability for specific applications. Understanding the characteristics of different materials is paramount to selecting the most appropriate metal for a given fabrication or machining project.

For instance, steel, an iron alloy, is widely used due to its strength, durability, and relatively low cost. It finds applications in construction, automotive, and manufacturing industries. Aluminum, on the other hand, is lightweight, corrosion-resistant, and easily machinable, making it ideal for aerospace, marine, and consumer electronics.

The choice of material also influences the fabrication and machining processes. For example, welding is a common technique for joining steel components, while aluminum is often machined using cutting tools due to its softer nature. The interplay between material properties and fabrication techniques requires careful consideration to achieve optimal results.

| Material | Properties | Applications |

|---|---|---|

| Steel | Strong, durable, low cost | Construction, automotive, manufacturing |

| Aluminum | Lightweight, corrosion-resistant, easily machinable | Aerospace, marine, consumer electronics |

| Titanium | Strong, lightweight, corrosion-resistant | Aerospace, medical, chemical processing |

| Copper | Excellent electrical and thermal conductivity | Electrical wiring, heat exchangers, plumbing |

Understanding the connection between materials and metal fabrication and machining empowers engineers and manufacturers to make informed decisions, ensuring the production of high-quality, fit-for-purpose metal components and structures.

Processes

In the realm of metal fabrication and machining, the processes employed play a pivotal role in shaping and transforming raw metal into functional components and structures. These processes encompass cutting, welding, bending, and machining techniques, each with its unique capabilities and applications.

-

Cutting:

Cutting techniques involve separating metal into desired shapes and sizes. Common methods include shearing, sawing, laser cutting, and waterjet cutting. These techniques are vital for creating intricate designs and precise component dimensions. -

Welding:

Welding processes join metal pieces together by melting and fusing them. Arc welding, MIG welding, and TIG welding are widely used techniques that offer strong and durable joints. Welding is essential for fabricating complex structures and repairing metal components. -

Bending:

Bending techniques shape metal by applying force to create angles and curves. Press brake bending and roll bending are common methods used to form metal sheets and plates into desired shapes. Bending is crucial for creating enclosures, brackets, and other components with specific angles. -

Machining:

Machining processes involve removing material from metal to achieve precise shapes and dimensions. Milling, turning, drilling, and grinding are fundamental machining techniques. These processes are essential for producing high-tolerance components and intricate features.

The interplay between these processes enables the creation of complex metal fabrications and machined components. The choice of process depends on factors such as material properties, design requirements, and production volume. Understanding the capabilities and limitations of each process empowers engineers and manufacturers to select the most appropriate techniques for their specific applications, ensuring the production of high-quality metal products.

Equipment

In the realm of metal fabrication and machining, advanced machinery and tooling play a pivotal role in achieving precise and efficient production processes. These sophisticated tools empower manufacturers to shape and form metal with remarkable accuracy, enabling the creation of complex components and structures.

One of the most significant advantages of advanced equipment is its ability to automate repetitive tasks, reducing the risk of human error and increasing productivity. Computer-controlled machines, such as CNC (Computer Numerical Control) routers and lathes, can execute complex operations with high precision, ensuring consistent quality and reducing production time.

Furthermore, advanced tooling options enhance the capabilities of fabrication and machining equipment. Specialized cutting tools, welding torches, and bending dies enable manufacturers to work with a wide range of materials and create intricate shapes and features. For instance, laser cutting systems utilize high-powered lasers to produce precise cuts with minimal heat-affected zones, making them ideal for delicate or complex components.

| Equipment | Capabilities | Applications |

|---|---|---|

| CNC Router | Computer-controlled cutting and engraving | Prototyping, sign making, furniture manufacturing |

| CNC Lathe | Computer-controlled turning and shaping | Precision parts manufacturing, automotive components, medical devices |

| Laser Cutter | Precise cutting using high-powered lasers | Electronics manufacturing, aerospace components, medical devices |

The integration of advanced machinery and tooling in metal fabrication and machining has revolutionized the industry, enabling the production of high-quality components with greater speed, precision, and efficiency. These advancements have paved the way for innovative applications in various sectors, including aerospace, automotive, and medical device manufacturing.

Precision

In the realm of metal fabrication and machining, precision stands as a cornerstone, dictating the accuracy and quality of the final product. Achieving precise shaping and forming of metal components is paramount to ensure proper functionality, reliability, and aesthetic appeal.

The level of precision required varies depending on the application. For instance, in aerospace engineering, components must meet stringent tolerances to ensure the safety and performance of aircraft. Similarly, in medical device manufacturing, precision is crucial for creating implants and surgical instruments that interact with the human body.

Metal fabrication and machining processes, such as cutting, welding, and bending, must be carefully controlled to achieve the desired precision. Advanced machinery, skilled craftsmanship, and rigorous quality control measures are essential to minimize errors and ensure consistent results.

| Process | Precision Techniques | Applications |

|---|---|---|

| CNC Machining | Computer-controlled cutting and shaping | Aerospace components, medical devices, automotive parts |

| Laser Cutting | High-powered lasers for precise cuts | Electronics manufacturing, jewelry making, medical stents |

| Wire EDM | Electrical discharge machining for intricate shapes | Tool and die making, aerospace components, medical implants |

Understanding the importance of precision in metal fabrication and machining empowers engineers and manufacturers to create high-quality products that meet the demands of various industries. Precision ensures that metal components function as intended, enhancing safety, reliability, and overall performance.

Customization

In the realm of metal fabrication and machining, customization plays a vital role in meeting the unique and often complex design requirements of various industries. This ability to tailor solutions empowers engineers and manufacturers to create metal components and structures that precisely align with their specific needs.

- Design Flexibility: Customization allows for the creation of metal fabrications and machined parts that meet precise specifications and geometries. This flexibility enables the production of components that fit seamlessly into complex assemblies or serve specialized functions.

- Prototyping and Iteration: Customization facilitates the rapid prototyping and iteration of metal designs. By quickly producing physical prototypes, engineers can evaluate design concepts, test functionality, and make necessary adjustments before committing to full-scale production.

- Low-Volume Production: Customization is particularly advantageous for low-volume production runs or one-off projects. It eliminates the need for costly tooling and enables the efficient production of small batches or custom-tailored components.

- Value-Added Features: Customization allows for the incorporation of unique features and enhancements that add value to metal fabrications and machined parts. These features can range from aesthetic elements to performance-enhancing modifications.

The ability to customize metal fabrications and machined parts offers a competitive edge in various industries, including aerospace, automotive, and medical device manufacturing. By embracing customization, engineers and manufacturers can create innovative solutions that meet the evolving demands of their customers and markets.

Quality

In the realm of metal fabrication and machining, quality stands as a cornerstone, dictating the reliability, durability, and overall performance of the final product. Stringent standards and rigorous quality control measures are essential to ensure that metal fabrications and machined parts meet the highest levels of excellence.

- Precision and Accuracy: Quality in metal fabrication and machining demands precise shaping and forming of components. Advanced machinery, skilled craftsmanship, and meticulous quality control processes work in tandem to achieve tight tolerances and dimensional accuracy, ensuring that parts fit together seamlessly and function as intended.

- Material Integrity: The quality of metal fabrications and machined parts is directly tied to the integrity of the materials used. Stringent quality control measures involve thorough inspections and testing of raw materials to ensure they meet specified standards. This helps prevent defects, ensures durability, and enhances the overall reliability of the final product.

- Process Control: Every step in the metal fabrication and machining process is subject to rigorous quality control. This includes monitoring cutting parameters, welding procedures, and bending techniques to ensure consistent results. By controlling these processes, manufacturers can minimize errors, reduce variability, and maintain high levels of quality throughout production.

- Inspection and Testing: Finished metal fabrications and machined parts undergo thorough inspection and testing to verify their compliance with design specifications and quality standards. Non-destructive testing methods, such as ultrasonic testing and radiographic inspection, are employed to detect any internal defects or imperfections. This ensures that only the highest quality components are released for use.

By adhering to stringent quality standards and implementing robust quality control measures, metal fabricators and machinists can produce components and structures that meet the demands of various industries, from aerospace and automotive to medical and construction. Quality is not merely an attribute but a fundamental pillar upon which the success and reputation of metal fabrication and machining businesses are built.

Safety

In the realm of metal fabrication and machining, safety stands paramount, dictating the well-being of workers and the overall productivity of the workplace. Stringent protocols and comprehensive protective measures are essential to mitigate hazards and create a safe working environment.

The connection between safety and metal fabrication/machining is inseparable. The inherent risks associated with these processes, such as exposure to sharp edges, heavy machinery, and hazardous materials, necessitate the implementation of robust safety measures. Failure to prioritize safety can lead to accidents, injuries, and even fatalities, disrupting operations and jeopardizing the health of workers.

Real-life examples underscore the importance of workplace safety in metal fabrication and machining. A study by the Occupational Safety and Health Administration (OSHA) revealed that the metal fabrication industry has a higher rate of non-fatal injuries and illnesses compared to other manufacturing sectors. Common incidents include lacerations, burns, and musculoskeletal disorders caused by improper handling of equipment or exposure to hazardous substances.

To address these challenges, metal fabrication and machining facilities adopt various safety protocols and protective measures. These include:

- Machine guarding: Installing physical barriers and safety devices around hazardous machinery to prevent contact with moving parts.

- Personal protective equipment (PPE): Providing workers with appropriate PPE such as safety glasses, gloves, earplugs, and respirators to minimize exposure to hazards.

- Training and education: Offering comprehensive training programs to ensure workers are knowledgeable about safety procedures, potential hazards, and emergency protocols.

- Regular inspections and maintenance: Conducting routine inspections of equipment, tools, and the workplace to identify and eliminate potential hazards.

By implementing these measures, metal fabrication and machining facilities can significantly reduce the risk of accidents and create a safer working environment. This not only protects the well-being of workers but also enhances productivity and reduces downtime caused by injuries or accidents.

Understanding the connection between safety and metal fabrication/machining is crucial for stakeholders at all levels. Employers have a legal and moral obligation to prioritize safety and provide a safe workplace. Employees must adhere to safety protocols and utilize PPE to protect themselves and their colleagues. By working together, metal fabrication and machining facilities can foster a culture of safety, ensuring the well-being of workers and the smooth operation of their businesses.

| Safety Protocol/Protective Measure | Purpose | Benefits |

|---|---|---|

| Machine guarding | Prevent contact with hazardous machinery | Reduced risk of lacerations, amputations, and crush injuries |

| Personal protective equipment (PPE) | Minimize exposure to hazards | Reduced risk of eye injuries, burns, hearing loss, and respiratory problems |

| Training and education | Increase awareness of safety procedures and hazards | Empowered workers who can identify and mitigate risks |

| Regular inspections and maintenance | Identify and eliminate potential hazards | Reduced risk of equipment failures and accidents |

Sustainability

The realm of metal fabrication and machining is increasingly intertwined with the principles of sustainability. Environmentally conscious practices and materials are not mere buzzwords but essential considerations that shape the industry’s future.

-

Energy Efficiency:

Metal fabrication and machining processes can be energy-intensive. Sustainable practices involve optimizing energy consumption through efficient equipment, renewable energy sources, and lean manufacturing techniques. This reduces the industry’s carbon footprint and contributes to a greener environment.

-

Material Selection:

Choosing environmentally friendly materials is a cornerstone of sustainable metal fabrication and machining. Recycled and recyclable metals, such as aluminum and steel, minimize waste and conserve natural resources. Sustainable materials also encompass alloys designed to reduce energy consumption during production and use.

-

Waste Reduction:

Minimizing waste is paramount to sustainable metal fabrication and machining. Techniques like lean manufacturing, scrap reduction programs, and closed-loop recycling systems help conserve resources and reduce landfill contributions. By optimizing material usage and implementing waste management strategies, the industry moves towards a circular economy.

-

Surface Treatments and Coatings:

Sustainable surface treatments and coatings play a crucial role in extending the lifespan of metal fabrications and machined parts. Environmentally friendly alternatives to traditional coatings, such as powder coating and water-based paints, reduce the use of hazardous chemicals and minimize environmental impact.

Embracing sustainability in metal fabrication and machining offers multifaceted benefits. It not only reduces the industry’s environmental footprint but also enhances its reputation, attracts eco-conscious customers, and fosters innovation in sustainable practices. By aligning with the principles of sustainability, metal fabrication and machining businesses position themselves as responsible corporate citizens and contribute to a more sustainable future.

Innovation

Innovation serves as the driving force behind the continuous evolution of metal fabrication and machining. Ongoing advancements in technologies and processes have revolutionized the industry, enabling manufacturers to produce complex and high-quality metal components with greater efficiency, precision, and cost-effectiveness.

One significant area of innovation lies in the adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These technologies allow engineers and designers to create intricate 3D models of metal fabrications and machined parts. By integrating CAD/CAM with advanced machinery, manufacturers can automate production processes, reducing errors and increasing productivity. For instance, CNC (computer numerical control) machines utilize CAM software to precisely control cutting, bending, and welding operations, leading to enhanced accuracy and consistency.

Another area of innovation is the development of new materials and surface treatments. The introduction of lightweight and high-strength alloys, such as titanium and aluminum-lithium, has enabled the production of lighter and more durable metal fabrications. Additionally, advancements in surface treatments, such as anodizing and powder coating, have improved the corrosion resistance and aesthetic appeal of metal components.

The practical significance of innovation in metal fabrication and machining is evident across various industries. In the aerospace sector, innovative technologies have led to the creation of lightweight and aerodynamic aircraft components, contributing to improved fuel efficiency and performance. In the automotive industry, advanced metal fabrication techniques have enabled the production of stronger and safer vehicle frames and bodies, enhancing passenger protection and overall vehicle reliability.

Furthermore, innovation has played a crucial role in promoting sustainability in metal fabrication and machining. The adoption of energy-efficient technologies and the use of recycled materials have reduced the environmental impact of the industry. Additionally, innovative surface treatments have extended the lifespan of metal components, reducing waste and promoting resource conservation.

| Innovation | Impact on Metal Fabrication and Machining | Practical Significance |

|---|---|---|

| CAD/CAM software | Automated production processes, reduced errors, increased productivity | Enhanced accuracy and consistency in metal fabrication and machining |

| New materials and surface treatments | Lightweight, durable components; improved corrosion resistance and aesthetic appeal | Advanced aircraft components, stronger vehicle frames, longer-lasting metal products |

| Energy-efficient technologies and recycled materials | Reduced environmental impact, resource conservation | Sustainable metal fabrication and machining practices, promoting a circular economy |

Understanding the connection between innovation and metal fabrication and machining is essential for businesses seeking to remain competitive in the global marketplace. By embracing new technologies and processes, manufacturers can improve the quality, efficiency, and sustainability of their operations, ultimately leading to increased profitability and customer satisfaction.

FAQs on Metal Fabrication and Machining

This section addresses common questions and misconceptions surrounding metal fabrication and machining, providing informative answers to enhance understanding.

Question 1: What is the difference between metal fabrication and machining?

Metal fabrication involves shaping and forming metal using techniques like cutting, welding, and bending, often for larger-scale projects. Machining, on the other hand, utilizes cutting tools to remove material from metal, resulting in precise, smaller-scale components.

Question 2: What are the key considerations when choosing a metal fabrication or machining company?

Factors to consider include the company’s experience, capabilities, quality standards, lead times, and customer service. It is important to assess their expertise in handling specific materials, project complexity, and adherence to industry regulations.

Question 3: How does metal fabrication and machining contribute to sustainability?

Sustainable practices in these processes include using recycled materials, optimizing energy consumption, minimizing waste, and employing eco-friendly surface treatments. These measures reduce environmental impact and promote resource conservation.

Question 4: What are the latest technological advancements in metal fabrication and machining?

Innovations include the adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) software, advanced materials with enhanced properties, and automated processes. These advancements improve accuracy, efficiency, and the production of complex geometries.

Question 5: How can metal fabrication and machining benefit my business?

These processes enable the production of custom metal components and structures that meet specific design requirements. They enhance product durability, increase production efficiency, and provide cost-effective solutions for various industries.

Question 6: What safety measures are essential in metal fabrication and machining?

Safety protocols include machine guarding, proper ventilation, use of personal protective equipment, regular maintenance, and adherence to industry standards. These measures protect workers from potential hazards and ensure a safe working environment.

Summary: Metal fabrication and machining are vital processes that shape metal into useful components and structures. Understanding the differences between these processes, selecting reputable companies, and embracing sustainable practices are crucial. Technological advancements and safety measures further enhance the industry’s capabilities and ensure its continued relevance in various sectors.

Transition to the next article section: These FAQs provide a deeper understanding of metal fabrication and machining, empowering readers to make informed decisions and navigate the industry effectively.

Metal Fabrication and Machining Tips

To achieve optimal results in metal fabrication and machining, consider the following expert tips:

Tip 1: Material Selection

Selecting the appropriate metal alloy is crucial for ensuring the component’s properties, such as strength, durability, and corrosion resistance, align with the application requirements. Thorough research and understanding of material characteristics are essential.

Tip 2: Precision and Accuracy

Precise cutting, bending, and machining techniques are paramount to achieving accurate dimensions and tolerances. Utilizing high-quality machinery, skilled operators, and proper measuring tools ensures the fabricated or machined components meet design specifications.

Tip 3: Surface Finishing

Surface finish plays a significant role in the component’s aesthetics, functionality, and longevity. Selecting the appropriate surface treatment, such as polishing, anodizing, or powder coating, enhances the surface properties and protects against corrosion, wear, or other environmental factors.

Tip 4: Quality Control

Implementing a rigorous quality control process is essential to ensure the fabricated or machined components meet the required standards. Regular inspections, testing, and documentation help maintain consistent quality and minimize defects.

Tip 5: Safety First

Prioritize workplace safety by adhering to industry regulations, providing proper training to operators, and utilizing appropriate safety equipment. Safe work practices minimize the risk of accidents and ensure a healthy work environment.

Tip 6: Continuous Improvement

Stay updated with the latest advancements in metal fabrication and machining technologies. Invest in training, research, and equipment upgrades to enhance efficiency, precision, and overall capabilities.

Tip 7: Collaboration and Communication

Effective communication and collaboration between designers, engineers, and fabricators ensure that the project’s objectives are clearly understood and executed seamlessly. Regular communication helps avoid errors, delays, and ensures the final product meets expectations.

Summary: By incorporating these tips into your metal fabrication and machining practices, you can optimize quality, enhance precision, and ensure the longevity and functionality of your metal components. Continuous improvement, coupled with a commitment to safety and collaboration, will elevate your projects to the highest standards.

Conclusion

Metal fabrication and machining stand as foundational processes that shape the world around us. From towering skyscrapers to intricate medical devices, metal components play a vital role in countless industries and applications. This article has explored the diverse aspects of metal fabrication and machining, shedding light on their significance, techniques, and advancements.

As we look towards the future, metal fabrication and machining will continue to evolve, driven by technological innovations and sustainable practices. The integration of advanced automation, additive manufacturing, and eco-friendly materials will redefine the possibilities of metalworking. By embracing these advancements, we can harness the full potential of metal fabrication and machining to create innovative solutions that address global challenges and shape a better tomorrow.