What is precise machine & fabrication? Precise machine & fabrication is the process of creating parts and components with precise dimensions and tolerances. It is used in a wide variety of industries, including aerospace, automotive, and medical.

Editor’s Note: Precise machine & fabrication is an important topic for anyone who works in a manufacturing environment. By understanding the basics of precise machine & fabrication, you can improve the quality of your products and reduce your costs.

We’ve done the analysis, dug into the information, and made comparisons. We put together this precise machine & fabrication guide to help you make the right decision.

Key Differences/Key Takeaways:

| Precise Machine | Fabrication | |

|---|---|---|

| Definition | The process of creating parts and components with precise dimensions and tolerances. | The process of shaping and assembling materials to create a product. |

| Equipment | Computer-controlled machines, such as CNC mills and lathes. | Hand tools, power tools, and welding equipment. |

| Applications | Aerospace, automotive, medical, and other industries where precision is critical. | Construction, manufacturing, and other industries where durability and strength are important. |

Main Article Topics:

- The benefits of precise machine & fabrication

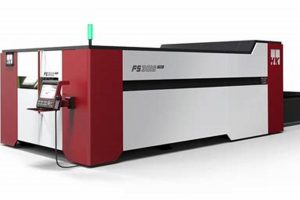

- The different types of precise machine & fabrication equipment

- The applications of precise machine & fabrication

- The future of precise machine & fabrication

Precise Machine & Fabrication

Precise machine & fabrication is a critical process in many industries, including aerospace, automotive, and medical. It involves the use of precision machinery and fabrication techniques to create parts and components with precise dimensions and tolerances.

- Accuracy: Precise machine & fabrication processes ensure that parts and components are manufactured to exact specifications.

- Precision: The use of precision machinery allows for the creation of parts and components with very tight tolerances.

- Repeatability: Precise machine & fabrication processes can be repeated over and over again, menghasilkan parts and components that are consistent in quality.

- Efficiency: Precise machine & fabrication processes are often automated, which can improve efficiency and reduce costs.

- Versatility: Precise machine & fabrication processes can be used to create a wide variety of parts and components, from simple to complex.

- Durability: Parts and components created using precise machine & fabrication processes are often more durable than those created using other methods.

- Quality: Precise machine & fabrication processes menghasilkan parts and components that are of high quality and meet or exceed industry standards.

- Innovation: Precise machine & fabrication processes are constantly being innovated, which allows for the creation of new and improved parts and components.

- Technology: Precise machine & fabrication processes rely on advanced technology, such as computer-controlled machines and software.

- Expertise: Precise machine & fabrication processes require skilled workers who have the expertise to operate and maintain precision machinery.

- Applications: Precise machine & fabrication processes are used in a wide range of applications, including aerospace, automotive, medical, and manufacturing.

These key aspects of precise machine & fabrication make it an essential process for many industries. By understanding these aspects, you can better understand the importance of precise machine & fabrication and how it can benefit your business.

Accuracy

Accuracy is one of the most important aspects of precise machine & fabrication. It refers to the ability to create parts and components that meet or exceed the specified tolerances. This is essential in many industries, such as aerospace, automotive, and medical, where even the smallest Abweichung can have serious consequences.

-

Components of Accuracy

There are several components to accuracy in precise machine & fabrication, including:

- Dimensional accuracy: This refers to the ability to create parts and components that are the correct size and shape.

- Geometric accuracy: This refers to the ability to create parts and components with the correct geometric features, such as roundness, flatness, and parallelism.

- Surface accuracy: This refers to the ability to create parts and components with the correct surface finish.

-

Examples of Accuracy in Precise Machine & Fabrication

There are many examples of accuracy in precise machine & fabrication, including:

- The manufacturing of aircraft parts, which must meet very tight tolerances in order to ensure the safety of the aircraft.

- The manufacturing of medical devices, which must be accurate in order to function properly.

- The manufacturing of automotive parts, which must be accurate in order to ensure the performance and reliability of the vehicle.

-

Implications of Accuracy in Precise Machine & Fabrication

The accuracy of precise machine & fabrication processes has a number of implications, including:

- Improved quality: Accurate parts and components are more likely to meet or exceed the required specifications, resulting in improved quality.

- Reduced costs: Accurate parts and components are less likely to be rejected or fail, resulting in reduced costs.

- Increased safety: Accurate parts and components are more likely to function properly, resulting in increased safety.

Overall, accuracy is a critical aspect of precise machine & fabrication. It is essential for ensuring the quality, cost, and safety of manufactured products.

Precision

Precision is a critical aspect of precise machine & fabrication. It refers to the ability to create parts and components that meet or exceed the specified tolerances. This is essential in many industries, such as aerospace, automotive, and medical, where even the smallest Abweichung can have serious consequences.

The use of precision machinery is essential for achieving the high levels of precision required in precise machine & fabrication. Precision machinery is designed to operate with very tight tolerances, and it is capable of producing parts and components that are accurate to within microns.

There are many different types of precision machinery used in precise machine & fabrication, including:

- Computer-controlled machines, such as CNC mills and lathes

- Coordinate measuring machines (CMMs)

- Optical comparators

- Laser scanners

These machines allow manufacturers to create parts and components with very tight tolerances, and they are essential for ensuring the quality and accuracy of manufactured products.

Here are some examples of the practical applications of precision in precise machine & fabrication:

- The manufacturing of aircraft parts, which must meet very tight tolerances in order to ensure the safety of the aircraft.

- The manufacturing of medical devices, which must be accurate in order to function properly.

- The manufacturing of automotive parts, which must be accurate in order to ensure the performance and reliability of the vehicle.

Overall, precision is a critical aspect of precise machine & fabrication. It is essential for ensuring the quality, cost, and safety of manufactured products.

Table: The Connection Between Precision and Precise Machine & Fabrication

| Precision | Precise Machine & Fabrication |

|---|---|

| Definition | The ability to create parts and components with very tight tolerances. |

| Importance | Essential for ensuring the quality, cost, and safety of manufactured products. |

| Applications | Used in a wide range of industries, including aerospace, automotive, and medical. |

| Equipment | Requires the use of precision machinery, such as CNC mills and lathes. |

Repeatability

Repeatability is a critical aspect of precise machine & fabrication. It refers to the ability to create parts and components that are consistent in quality, even when they are produced in different batches or by different operators.

-

Role of Repeatability in Precise Machine & Fabrication

Repeatability is essential for ensuring the quality of manufactured products. When parts and components are consistent in quality, they are more likely to meet or exceed the required specifications. This can lead to improved performance, reliability, and safety.

-

Examples of Repeatability in Precise Machine & Fabrication

There are many examples of repeatability in precise machine & fabrication, including:

- The manufacturing of automotive parts, which must be consistent in quality in order to ensure the performance and reliability of the vehicle.

- The manufacturing of medical devices, which must be consistent in quality in order to function properly and safely.

- The manufacturing of aerospace parts, which must be consistent in quality in order to ensure the safety of the aircraft.

-

Implications of Repeatability in Precise Machine & Fabrication

The repeatability of precise machine & fabrication processes has a number of implications, including:

- Improved quality: Consistent quality of parts and components leads to improved quality of manufactured products.

- Reduced costs: Consistent quality of parts and components reduces the risk of rejects and rework, leading to reduced costs.

- Increased safety: Consistent quality of parts and components ensures that manufactured products are safe and reliable.

Overall, repeatability is a critical aspect of precise machine & fabrication. It is essential for ensuring the quality, cost, and safety of manufactured products.

Efficiency

Efficiency is a critical aspect of precise machine & fabrication. It refers to the ability to produce parts and components quickly and cost-effectively. Automation is one of the key factors that can improve efficiency in precise machine & fabrication.

Automated processes can be used to perform a variety of tasks in precise machine & fabrication, such as:

- Loading and unloading parts and materials

- Operating machines

- Inspecting parts and components

- Packaging and shipping products

By automating these tasks, manufacturers can reduce labor costs, improve productivity, and reduce lead times.

Here are some examples of how automation is used to improve efficiency in precise machine & fabrication:

- In the automotive industry, automated welding robots are used to weld car bodies together. This has significantly improved the efficiency of the welding process and reduced labor costs.

- In the aerospace industry, automated CNC machines are used to machine complex aircraft parts. This has improved the accuracy and efficiency of the machining process and reduced lead times.

- In the medical device industry, automated assembly lines are used to assemble complex medical devices. This has improved the quality and efficiency of the assembly process and reduced costs.

Overall, automation is a key factor that can improve efficiency in precise machine & fabrication. By automating tasks, manufacturers can reduce labor costs, improve productivity, and reduce lead times.

Table: The Connection Between “Efficiency: Precise machine & fabrication processes are often automated, which can improve efficiency and reduce costs.” and “precise machine & fabrication”

| Efficiency | Precise Machine & Fabrication |

|---|---|

| Definition | The ability to produce parts and components quickly and cost-effectively. |

| Importance | Essential for reducing costs, improving productivity, and reducing lead times. |

| Automation | A key factor that can improve efficiency in precise machine & fabrication. |

| Examples | Automated welding robots, CNC machines, and automated assembly lines. |

Versatility

The versatility of precise machine & fabrication processes is one of their key advantages. These processes can be used to create a wide variety of parts and components, from simple to complex, and from a wide range of materials. This versatility makes precise machine & fabrication processes ideal for a wide range of applications, including:

- Aerospace

- Automotive

- Medical

- Manufacturing

The ability to create a wide variety of parts and components is essential for many industries. For example, in the aerospace industry, precise machine & fabrication processes are used to create complex parts for aircraft, such as wings, fuselages, and engines. In the automotive industry, precise machine & fabrication processes are used to create a variety of parts for cars, such as engines, transmissions, and suspension systems. In the medical industry, precise machine & fabrication processes are used to create a variety of medical devices, such as implants, surgical instruments, and prosthetics. In the manufacturing industry, precise machine & fabrication processes are used to create a variety of products, such as molds, dies, and fixtures.

The versatility of precise machine & fabrication processes is due to the use of advanced technology, such as computer-controlled machines and software. These machines and software allow manufacturers to create parts and components with precise dimensions and tolerances. Additionally, the use of automation can improve efficiency and reduce costs.

Overall, the versatility of precise machine & fabrication processes is a key advantage. These processes can be used to create a wide variety of parts and components, from simple to complex, and from a wide range of materials. This versatility makes precise machine & fabrication processes ideal for a wide range of applications.

Table: The Connection Between Versatility and Precise Machine & Fabrication

| Versatility | Precise Machine & Fabrication |

|---|---|

| Definition | The ability to create a wide variety of parts and components, from simple to complex. |

| Importance | Essential for a wide range of applications, including aerospace, automotive, medical, and manufacturing. |

| Benefits | Reduced costs, improved efficiency, and increased flexibility. |

| Examples | Aircraft parts, automotive parts, medical devices, and manufacturing tools. |

Durability

Durability is a critical aspect of precise machine & fabrication. It refers to the ability of parts and components to withstand wear and tear, and to maintain their structural integrity over time. Precise machine & fabrication processes can produce parts and components that are more durable than those created using other methods, due to the following factors:

- Precision: Precise machine & fabrication processes create parts and components with precise dimensions and tolerances. This ensures that parts and components fit together properly and function as intended.

- Accuracy: Precise machine & fabrication processes ensure that parts and components are manufactured to exact specifications. This reduces the risk of defects and failures.

- Repeatability: Precise machine & fabrication processes can be repeated over and over again, menghasilkan parts and components that are consistent in quality. This reduces the risk of variation and ensures that parts and components are durable.

The durability of parts and components created using precise machine & fabrication processes is essential for a variety of applications, including:

- Aerospace: Parts and components used in aircraft must be durable enough to withstand the stresses of flight.

- Automotive: Parts and components used in cars must be durable enough to withstand the wear and tear of everyday use.

- Medical: Parts and components used in medical devices must be durable enough to withstand the rigors of sterilization and repeated use.

- Manufacturing: Parts and components used in manufacturing equipment must be durable enough to withstand the stresses of continuous use.

Overall, the durability of parts and components created using precise machine & fabrication processes is a key advantage. These parts and components are more likely to withstand wear and tear, and to maintain their structural integrity over time. This makes them ideal for a wide range of applications, where durability is essential.

Table: The Connection Between Durability and Precise Machine & Fabrication

| Durability | Precise Machine & Fabrication |

|---|---|

| Definition | The ability of parts and components to withstand wear and tear, and to maintain their structural integrity over time. |

| Importance | Essential for a wide range of applications, where parts and components must withstand stress, wear, and tear. |

| Benefits | Increased reliability, reduced maintenance costs, and longer service life. |

| Examples | Aircraft parts, automotive parts, medical devices, and manufacturing equipment. |

Quality

Quality is a critical aspect of precise machine & fabrication. It refers to the ability to create parts and components that meet or exceed the required specifications, and that are free from defects. Precise machine & fabrication processes are designed to produce high-quality parts and components, due to the following factors:

- Precision: Precise machine & fabrication processes create parts and components with precise dimensions and tolerances. This ensures that parts and components fit together properly and function as intended.

- Accuracy: Precise machine & fabrication processes ensure that parts and components are manufactured to exact specifications. This reduces the risk of defects and failures.

- Repeatability: Precise machine & fabrication processes can be repeated over and over again, menghasilkan parts and components that are consistent in quality. This reduces the risk of variation and ensures that parts and components meet the required standards.

The quality of parts and components created using precise machine & fabrication processes is essential for a variety of applications, including:

- Aerospace: Parts and components used in aircraft must be of the highest quality to ensure the safety of the aircraft and its passengers.

- Automotive: Parts and components used in cars must be of high quality to ensure the performance, reliability, and safety of the vehicle.

- Medical: Parts and components used in medical devices must be of the highest quality to ensure the safety and effectiveness of the device.

- Manufacturing: Parts and components used in manufacturing equipment must be of high quality to ensure the accuracy and efficiency of the equipment.

Overall, the quality of parts and components created using precise machine & fabrication processes is a key advantage. These parts and components are more likely to meet or exceed the required specifications, and are less likely to fail. This makes them ideal for a wide range of applications, where quality is essential.

Table: The Connection Between Quality and Precise Machine & Fabrication

| Quality | Precise Machine & Fabrication |

|---|---|

| Definition | The ability to create parts and components that meet or exceed the required specifications, and that are free from defects. |

| Importance | Essential for a wide range of applications, where parts and components must be reliable, safe, and efficient. |

| Benefits | Increased customer satisfaction, reduced warranty costs, and improved reputation. |

| Examples | Aircraft parts, automotive parts, medical devices, and manufacturing equipment. |

Innovation

Innovation is a key driver of progress in precise machine & fabrication. It is the process of developing new and improved methods, techniques, and technologies to create parts and components. Innovation in precise machine & fabrication is essential for a number of reasons:

- To improve the quality of parts and components: Innovation can lead to the development of new and improved processes that create parts and components with higher precision, accuracy, and repeatability.

- To reduce the cost of parts and components: Innovation can lead to the development of new and more efficient processes that reduce the time and cost of manufacturing parts and components.

- To create new and improved products: Innovation can lead to the development of new and improved products that are lighter, stronger, and more durable.

- To meet the demands of new and emerging markets: Innovation can help manufacturers to meet the demands of new and emerging markets by developing new and improved products that meet the specific needs of those markets.

There are many examples of innovation in precise machine & fabrication. One example is the development of new and improved cutting tools. These tools are designed to cut materials more precisely and efficiently, which can lead to improved quality and reduced costs.

Another example of innovation in precise machine & fabrication is the development of new and improved 3D printing technologies. These technologies allow manufacturers to create complex parts and components with greater precision and accuracy. This can lead to the development of new and improved products, as well as the reduction of costs.

The connection between innovation and precise machine & fabrication is clear. By constantly innovating, manufacturers can improve the quality, reduce the cost, and create new and improved products. This can lead to a number of benefits, including increased profits, market share, and customer satisfaction.

Table: The Connection Between Innovation and Precise Machine & Fabrication

| Innovation | Precise Machine & Fabrication |

|---|---|

| Definition | The process of developing new and improved methods, techniques, and technologies to create parts and components. |

| Importance | Essential for improving quality, reducing costs, creating new products, and meeting market demands. |

| Examples | New cutting tools, improved 3D printing technologies, and advanced materials. |

| Benefits | Increased profits, market share, and customer satisfaction. |

Technology

The connection between technology and precise machine & fabrication is undeniable. Precise machine & fabrication processes rely on advanced technology, such as computer-controlled machines and software, to achieve the precision, accuracy, and repeatability required for many industries, including aerospace, automotive, and medical.

Computer-controlled machines, such as CNC mills and lathes, are used to create parts and components with complex geometries and tight tolerances. These machines are programmed to follow specific instructions, which ensures that parts and components are manufactured to exact specifications. Software is also used to design and simulate parts and components, which helps to optimize the manufacturing process and reduce errors.

The use of advanced technology in precise machine & fabrication has a number of benefits, including:

- Improved quality: Advanced technology allows manufacturers to create parts and components with higher precision and accuracy, which can lead to improved quality and performance.

- Reduced costs: Advanced technology can help to reduce manufacturing costs by automating processes and reducing the need for manual labor.

- Increased efficiency: Advanced technology can help to improve efficiency by reducing lead times and increasing productivity.

- New product development: Advanced technology enables manufacturers to develop new and innovative products that would not be possible using traditional methods.

The practical significance of understanding the connection between technology and precise machine & fabrication is that it allows manufacturers to make informed decisions about the equipment and processes they use. By investing in advanced technology, manufacturers can improve the quality, reduce the cost, and increase the efficiency of their manufacturing operations.

Table: The Connection Between Technology and Precise Machine & Fabrication

| Technology | Precise Machine & Fabrication |

|---|---|

| Definition | Advanced technology, such as computer-controlled machines and software, used in precise machine & fabrication processes to create parts and components with precise dimensions and tolerances. |

| Importance | Essential for achieving the precision, accuracy, and repeatability required for many industries, including aerospace, automotive, and medical. |

| Benefits | Improved quality, reduced costs, increased efficiency, and new product development. |

| Examples | CNC mills and lathes, design and simulation software, and automated inspection systems. |

Expertise

Precise machine & fabrication processes are highly dependent on the expertise of skilled workers who possess the knowledge and experience to operate and maintain precision machinery. This expertise is crucial for ensuring the accuracy, precision, and efficiency of these processes, which are essential for producing high-quality parts and components in various industries such as aerospace, automotive, and medical.

- Skilled Operation: Precise machine & fabrication processes involve operating sophisticated machinery, such as CNC mills and lathes, which require specialized training and expertise. Skilled workers must have a deep understanding of machine functions, programming, and safety protocols to effectively operate these machines and produce parts to exact specifications.

- Maintenance and Calibration: Precision machinery requires regular maintenance and calibration to ensure optimal performance and accuracy. Skilled workers must be proficient in diagnosing and resolving mechanical or electrical issues, as well as performing routine maintenance tasks such as lubrication, cleaning, and adjustments. Proper maintenance helps prevent breakdowns, extends machine life, and maintains the accuracy of the fabrication process.

- Quality Control: Skilled workers play a vital role in quality control by monitoring the fabrication process and inspecting finished parts. They use precision measuring instruments and techniques to ensure that parts meet the required tolerances and specifications. Their expertise in identifying and correcting deviations helps maintain the high quality and consistency of the fabricated products.

- Process Optimization: Skilled workers with expertise in precise machine & fabrication processes can identify areas for improvement and optimize the efficiency of the manufacturing process. They may suggest modifications to machine settings, tooling, or workholding methods to reduce cycle times, minimize material waste, and enhance overall productivity.

In conclusion, the expertise of skilled workers is indispensable for the success of precise machine & fabrication processes. Their knowledge, experience, and attention to detail ensure the production of high-quality parts and components, contribute to the efficiency and reliability of the manufacturing process, and ultimately support the success of various industries that rely on precise fabrication.

Applications

Precise machine & fabrication processes are indispensable in a vast array of industries, playing a pivotal role in the production of high-precision components and parts that meet stringent quality standards. Their applications span multiple sectors, including aerospace, automotive, medical, and manufacturing, where accuracy, precision, and reliability are of utmost importance.

The connection between applications and precise machine & fabrication is evident in the unique capabilities these processes offer. By employing advanced machinery and skilled expertise, precise machine & fabrication enables the creation of complex geometries, tight tolerances, and intricate features that are essential for various applications.

In the aerospace industry, precise machine & fabrication processes are utilized to manufacture critical aircraft components, such as engine parts, landing gear, and structural elements. The accuracy and precision achieved in these processes ensure the safety and reliability of aircraft, as even minor deviations can have catastrophic consequences.

Within the automotive sector, precise machine & fabrication processes are employed to produce high-performance components for engines, transmissions, and braking systems. The ability to create parts with precise dimensions and tolerances is crucial for optimizing engine efficiency, reducing emissions, and enhancing vehicle safety.

In the medical field, precise machine & fabrication processes are essential for manufacturing surgical instruments, implants, and medical devices. The accuracy and reliability of these components are paramount for successful surgeries, patient recovery, and overall healthcare outcomes.

Furthermore, precise machine & fabrication processes are widely used in the manufacturing industry to create molds, dies, fixtures, and other tooling components. These components play a vital role in mass production, ensuring the consistent and precise replication of parts, which is essential for maintaining product quality and efficiency.

Understanding the connection between applications and precise machine & fabrication is crucial for several reasons. It highlights the importance of these processes in various industries, emphasizing their role in producing high-quality, precision components. This understanding also guides manufacturers in selecting the appropriate techniques and machinery for their specific applications, ensuring optimal outcomes.

The practical significance of this understanding extends to the broader economic and technological landscape. By enabling the production of advanced components and devices, precise machine & fabrication processes contribute to innovation, drive industrial growth, and ultimately enhance our quality of life.

Table: Applications and Precise Machine & Fabrication

| Industry | Applications | Importance |

|---|---|---|

| Aerospace | Aircraft components, engine parts, landing gear | Safety, reliability, performance |

| Automotive | Engine components, transmission parts, braking systems | Efficiency, emissions reduction, safety |

| Medical | Surgical instruments, implants, medical devices | Precision, reliability, patient outcomes |

| Manufacturing | Molds, dies, fixtures, tooling components | Mass production, quality control, efficiency |

Frequently Asked Questions about Precise Machine & Fabrication

This section addresses common questions and misconceptions regarding precise machine & fabrication, providing informative answers to enhance your understanding of these processes and their applications.

Question 1: What is the significance of accuracy in precise machine & fabrication?

Answer: Accuracy is paramount in precise machine & fabrication as it ensures that parts and components meet exact specifications. This precision is critical in industries such as aerospace, automotive, and medical, where even slight deviations can compromise performance, safety, or reliability.

Question 2: How does repeatability contribute to the quality of fabricated parts?

Answer: Repeatability in precise machine & fabrication processes enables the consistent production of parts with identical dimensions and characteristics. This consistency minimizes variations, reduces the risk of defects, and ensures that manufactured products meet the required quality standards.

Question 3: What are the benefits of using advanced technology in precise machine & fabrication?

Answer: Advanced technology, such as computer-controlled machines and software, enhances precision, efficiency, and innovation in precise machine & fabrication. It automates processes, reduces errors, optimizes production, and enables the creation of complex geometries and intricate features.

Question 4: Why is expertise crucial in precise machine & fabrication processes?

Answer: Skilled workers with expertise in precise machine & fabrication possess the knowledge, experience, and attention to detail necessary to operate and maintain precision machinery effectively. Their expertise ensures accuracy, efficiency, and adherence to quality standards, ultimately contributing to the success of fabrication processes.

Question 5: What are the key applications of precise machine & fabrication across industries?

Answer: Precise machine & fabrication processes find applications in diverse industries, including aerospace, automotive, medical, and manufacturing. They are essential for producing high-precision components, such as aircraft parts, engine components, surgical instruments, and tooling, which play critical roles in ensuring safety, performance, and quality.

Question 6: How does precise machine & fabrication contribute to innovation and industrial growth?

Answer: Precise machine & fabrication processes enable the creation of advanced components and devices, fostering innovation and driving industrial growth. They support the development of new technologies, enhance product functionality, and contribute to the overall advancement of various industries.

Summary: Precise machine & fabrication processes are characterized by accuracy, repeatability, and the use of advanced technology and skilled expertise. Their applications span multiple industries, contributing to the production of high-quality components and devices. Understanding these processes is essential for appreciating their significance in technological advancements and industrial growth.

Transition to the next article section:

Precise machine & fabrication processes continue to evolve, driven by technological advancements and the increasing demand for precision and efficiency in various industries. As we explore further, we will delve into the latest innovations and trends shaping the future of precise machine & fabrication.

Precise Machine & Fabrication Tips

Precise machine & fabrication processes are essential for a wide range of industries, including aerospace, automotive, medical, and manufacturing. By following these tips, you can improve the quality, efficiency, and accuracy of your precise machine & fabrication processes.

Tip 1: Use the right tools and equipment.

The right tools and equipment can make a big difference in the quality of your precise machine & fabrication work. Make sure you have the right tools for the job, and that they are in good working condition.

Tip 2: Follow the instructions carefully.

It is important to follow the instructions carefully when operating precise machine & fabrication equipment. This will help you to avoid mistakes and accidents.

Tip 3: Take your time.

Precision machine & fabrication work takes time and patience. Don’t try to rush the process, or you may end up making mistakes.

Tip 4: Inspect your work regularly.

It is important to inspect your work regularly to make sure that it is meeting your specifications. This will help you to catch any errors early on, before they become bigger problems.

Tip 5: Maintain your equipment.

Proper maintenance is essential for keeping your precise machine & fabrication equipment in good working condition. Make sure to clean and lubricate your equipment regularly, and to have it serviced by a qualified technician on a regular basis.

Summary: By following these tips, you can improve the quality, efficiency, and accuracy of your precise machine & fabrication processes. With a little care and attention, you can produce high-quality parts and components that meet your exact specifications.

Transition to the article’s conclusion:

Precise machine & fabrication is a critical process in many industries. By understanding the basics of precise machine & fabrication, you can improve the quality of your products and reduce your costs. We hope that these tips have been helpful. If you have any questions, please don’t hesitate to contact us.

Conclusion

Precise machine & fabrication is a critical process in many industries. It is used to create parts and components with precise dimensions and tolerances. These parts and components are essential for a wide range of products, from aircraft to medical devices.

In this article, we have explored the basics of precise machine & fabrication. We have discussed the different types of precise machine & fabrication processes, the benefits of using precise machine & fabrication, and the applications of precise machine & fabrication. We have also provided some tips for improving the quality, efficiency, and accuracy of your precise machine & fabrication processes.

As technology continues to advance, precise machine & fabrication processes will become even more important. New technologies are making it possible to create parts and components with even greater precision and accuracy. This will open up new possibilities for a wide range of products and applications.

If you are interested in learning more about precise machine & fabrication, there are a number of resources available online and in libraries. You can also find training courses that can teach you the skills you need to operate precise machine & fabrication equipment.