Quality control in steel fabrication is the process of ensuring that steel products meet the required specifications and standards. It is a critical part of the steel fabrication process, as it helps to ensure the safety, reliability, and durability of steel structures.

Editor’s Note: Quality control in steel fabrication is an essential topic for anyone involved in the construction industry. By understanding the importance of quality control, you can help to ensure that your projects are safe, reliable, and durable.

To help you understand quality control in steel fabrication, we’ve put together this comprehensive guide. In this guide, we’ll cover the following topics:

Key Differences Between Quality Control and Quality Assurance

| Quality Control | Quality Assurance |

|---|---|

| Focuses on the inspection and testing of steel products | Focuses on the prevention of defects |

| Is a reactive process | Is a proactive process |

| Can be performed by third-party inspectors | Is typically performed by the steel fabricator |

Quality Control in Steel Fabrication

Quality control in steel fabrication is essential for ensuring the safety, reliability, and durability of steel structures. It involves a range of key aspects, including:

- Inspection: Verifying that steel products meet specifications.

- Testing: Conducting tests to assess the properties of steel products.

- Documentation: Maintaining records of all quality control activities.

- Corrective action: Taking steps to correct any non-conformances.

- Preventive action: Identifying and addressing potential problems before they occur.

- Training: Ensuring that all personnel involved in steel fabrication are properly trained.

- Certification: Obtaining certification from a recognized quality control organization.

- Continuous improvement: Regularly reviewing and improving quality control processes.

- Customer satisfaction: Ensuring that customers are satisfied with the quality of steel products.

- Regulatory compliance: Meeting all applicable regulatory requirements.

- Cost control: Minimizing the cost of quality control activities.

- Risk management: Identifying and mitigating risks associated with steel fabrication.

These key aspects are interrelated and essential for maintaining a high level of quality control in steel fabrication. By focusing on these aspects, steel fabricators can help to ensure that their products are safe, reliable, and durable.

Inspection

Inspection is a critical part of quality control in steel fabrication. It involves verifying that steel products meet the required specifications and standards. This is essential to ensure the safety, reliability, and durability of steel structures.

- Facet 1: Visual inspection

Visual inspection is the most common type of inspection used in steel fabrication. It involves examining steel products for any visible defects, such as cracks, dents, or scratches.

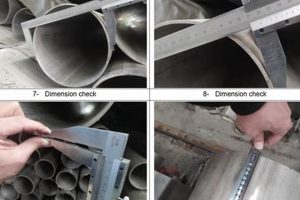

Facet 2: Dimensional inspection

Dimensional inspection is used to verify that steel products meet the required dimensions. This is important to ensure that steel structures are properly assembled and fit together correctly.

Facet 3: Material testing

Material testing is used to assess the properties of steel products, such as their strength, hardness, and toughness. This is important to ensure that steel products are suitable for their intended use.

Facet 4: Non-destructive testing

Non-destructive testing is used to inspect steel products without damaging them. This is important for detecting hidden defects that may not be visible during visual inspection.

These four facets of inspection are essential for ensuring the quality of steel products. By conducting thorough inspections, steel fabricators can help to ensure that their products are safe, reliable, and durable.

Testing

Testing is an essential part of quality control in steel fabrication. It involves conducting tests to assess the properties of steel products, such as their strength, hardness, and toughness. This is important to ensure that steel products are suitable for their intended use.

- Mechanical testing

Mechanical testing is used to assess the mechanical properties of steel products, such as their strength, hardness, and toughness. This is important to ensure that steel products can withstand the loads and forces that they will be subjected to in service.

Chemical testing

Chemical testing is used to assess the chemical composition of steel products. This is important to ensure that steel products meet the required specifications and standards. The chemical composition of steel can affect its properties, such as its strength, hardness, and corrosion resistance.

Metallurgical testing

Metallurgical testing is used to assess the microstructure of steel products. This is important to ensure that steel products have the desired microstructure for their intended use. The microstructure of steel can affect its properties, such as its strength, hardness, and toughness.

Non-destructive testing

Non-destructive testing is used to inspect steel products without damaging them. This is important for detecting hidden defects that may not be visible during visual inspection. Non-destructive testing methods include ultrasonic testing, radiographic testing, and magnetic particle testing.

These four facets of testing are essential for ensuring the quality of steel products. By conducting thorough testing, steel fabricators can help to ensure that their products are safe, reliable, and durable.

Documentation

Documentation is an essential part of quality control in steel fabrication. It involves maintaining records of all quality control activities, including inspections, tests, and corrective actions. This is important for several reasons:

- Traceability: Documentation provides a record of all quality control activities that have been performed on a steel product. This allows steel fabricators to trace the history of a product and identify any potential problems.

- Accountability: Documentation provides a record of who performed each quality control activity and when it was performed. This helps to ensure accountability and responsibility for quality control.

- Improvement: Documentation can be used to identify trends and areas for improvement in quality control processes. This helps steel fabricators to continuously improve their quality control systems.

- Compliance: Documentation is essential for demonstrating compliance with quality control standards and regulations. This is important for steel fabricators who want to maintain their certification and reputation.

In addition to these benefits, documentation can also be used to support legal claims in the event of a product failure. By maintaining accurate and complete records of all quality control activities, steel fabricators can help to protect themselves from liability.

Here are some examples of how documentation is used in quality control in steel fabrication:

- Inspection reports document the results of visual inspections, dimensional inspections, and material testing.

- Test reports document the results of mechanical testing, chemical testing, and metallurgical testing.

- Corrective action reports document the steps that were taken to correct any non-conformances.

- Quality control plans document the quality control procedures that will be followed for a specific project.

- Quality control manuals document the overall quality control system that is in place at a steel fabrication company.

By maintaining accurate and complete documentation, steel fabricators can ensure that their products are safe, reliable, and durable.

Corrective action

Corrective action is an essential part of quality control in steel fabrication. It involves taking steps to correct any non-conformances that are identified during inspection or testing. This is important to ensure that steel products meet the required specifications and standards. In addition to preventing steel products with defects from entering the market, effective corrective action provides numerous other benefits, including:

- Identifying and eliminating the root cause of non-conformances.

- Preventing the recurrence of non-conformances.

- Improving the overall quality of steel products.

- Maintaining customer satisfaction.

There are several key steps involved in taking corrective action. These steps include:

- Identifying the non-conformance.

- Investigating the root cause of the non-conformance.

- Developing and implementing a corrective action plan.

- Verifying that the corrective action plan has been effective.

By following these steps, steel fabricators can help to ensure that their products are safe, reliable, and durable.

Preventive action

Preventive action is an essential part of quality control in steel fabrication. It involves identifying and addressing potential problems before they occur. This is important for several reasons:

- It helps to prevent defects from occurring in the first place. Defects can be costly to fix, and they can also lead to safety hazards. By taking preventive action, steel fabricators can help to ensure that their products are free of defects.

- It helps to improve the overall quality of steel products. By identifying and addressing potential problems before they occur, steel fabricators can help to ensure that their products meet the highest quality standards.

- It helps to reduce costs. Preventing defects from occurring in the first place can help to reduce costs associated with rework, scrap, and warranty claims.

- It helps to improve customer satisfaction. Customers are more likely to be satisfied with products that are free of defects. By taking preventive action, steel fabricators can help to ensure that their customers are satisfied with their products.

There are several key steps involved in taking preventive action. These steps include:

- Identifying potential problems. This can be done by conducting risk assessments, analyzing data, and listening to customer feedback.

- Developing and implementing preventive action plans. These plans should outline the steps that will be taken to prevent potential problems from occurring.

- Verifying that preventive action plans are effective. This can be done by monitoring data and conducting audits.

By following these steps, steel fabricators can help to ensure that their products are safe, reliable, and durable.

Here is an example of how preventive action can be used in steel fabrication:

A steel fabricator is manufacturing a new type of steel beam. The fabricator is concerned that the beam may be susceptible to corrosion. To prevent this from happening, the fabricator conducts a risk assessment and develops a preventive action plan. The plan includes steps to ensure that the beam is properly coated with a corrosion-resistant material. By taking these steps, the fabricator can help to ensure that the beam is protected from corrosion and that it will last for many years to come.

Preventive action is an essential part of quality control in steel fabrication. By identifying and addressing potential problems before they occur, steel fabricators can help to ensure that their products are safe, reliable, and durable.

Training

Training is an essential part of quality control in steel fabrication. It ensures that all personnel involved in the process have the knowledge and skills necessary to perform their jobs safely and efficiently. This, in turn, helps to ensure that steel products are manufactured to the highest quality standards.

There are several key benefits to providing proper training to personnel involved in steel fabrication. These benefits include:

- Reduced errors and defects

- Improved safety

- Increased productivity

- Enhanced customer satisfaction

In addition to these benefits, proper training can also help to reduce costs associated with rework, scrap, and warranty claims.

There are several different types of training that may be provided to personnel involved in steel fabrication. This training may include:

- Safety training

- Equipment training

- Process training

- Quality control training

The type of training that is provided will vary depending on the specific job requirements. However, all training should be designed to provide personnel with the knowledge and skills necessary to perform their jobs safely and efficiently.

One of the most important aspects of training is ensuring that it is effective. This means that the training should be designed to meet the specific needs of the personnel involved in steel fabrication. It should also be delivered in a manner that is engaging and easy to understand.

By providing proper training to personnel involved in steel fabrication, companies can help to ensure that their products are manufactured to the highest quality standards. This, in turn, can help to improve customer satisfaction and reduce costs.

Here is an example of how training can be used to improve quality control in steel fabrication:

A steel fabrication company was experiencing a high number of defects in its products. The company decided to implement a new training program for its employees. The program covered a variety of topics, including safety, equipment operation, and quality control. After the program was implemented, the number of defects in the company’s products decreased significantly.

This example shows how training can be an effective way to improve quality control in steel fabrication. By providing employees with the knowledge and skills necessary to perform their jobs safely and efficiently, companies can help to ensure that their products are manufactured to the highest quality standards.

Table: Benefits of Training for Quality Control in Steel Fabrication

| Benefit | Description |

|---|---|

| Reduced errors and defects | Proper training can help to reduce errors and defects by providing personnel with the knowledge and skills necessary to perform their jobs correctly. |

| Improved safety | Proper training can help to improve safety by teaching personnel how to operate equipment safely and how to avoid hazards. |

| Increased productivity | Proper training can help to increase productivity by providing personnel with the knowledge and skills necessary to perform their jobs efficiently. |

| Enhanced customer satisfaction | Proper training can help to enhance customer satisfaction by ensuring that steel products are manufactured to the highest quality standards. |

Certification

Certification is an important aspect of quality control in steel fabrication. It provides independent verification that a steel fabricator has the systems and processes in place to produce high-quality steel products. This, in turn, can help to improve customer confidence and satisfaction.

-

ISO 9001:2015

ISO 9001:2015 is a quality management system standard that is recognized around the world. It sets out the requirements for a quality management system that can be used by any organization, regardless of its size or industry. Steel fabricators that are certified to ISO 9001:2015 have demonstrated that they have the systems and processes in place to produce high-quality steel products.

-

AWS D1.1

AWS D1.1 is a welding code that is developed by the American Welding Society (AWS). It sets out the requirements for welding steel structures. Steel fabricators that are certified to AWS D1.1 have demonstrated that they have the knowledge and skills necessary to weld steel structures safely and efficiently.

-

CE Marking

CE Marking is a conformity mark that is required for products that are sold in the European Union. It indicates that a product meets the essential requirements of the relevant European Directives. Steel fabricators that are CE Marked have demonstrated that their products meet the safety, health, and environmental requirements of the European Union.

-

UL Listing

UL Listing is a safety certification that is provided by Underwriters Laboratories (UL). It indicates that a product has been tested and found to meet UL’s safety standards. Steel fabricators that are UL Listed have demonstrated that their products are safe for use in the United States.

These are just a few of the many certifications that are available to steel fabricators. By obtaining certification from a recognized quality control organization, steel fabricators can demonstrate their commitment to quality and improve customer confidence in their products.

Continuous improvement

Continuous improvement is an essential part of quality control in steel fabrication. It involves regularly reviewing and improving quality control processes to ensure that they are effective and efficient. This helps to ensure that steel products are manufactured to the highest quality standards.

- Plan: The first step in continuous improvement is to plan for it. This involves identifying areas for improvement and developing a plan to address them.

- Do: Once a plan has been developed, it is important to implement it. This involves making changes to quality control processes and monitoring the results.

- Check: Once changes have been implemented, it is important to check their effectiveness. This involves monitoring the results of the changes and making sure that they are achieving the desired outcomes.

- Act: If the changes are not achieving the desired outcomes, it is important to take action to correct them. This may involve making further changes to the quality control processes or developing new processes altogether.

By following these steps, steel fabricators can continuously improve their quality control processes and ensure that they are meeting the highest standards.

Customer satisfaction

Customer satisfaction is a key element of quality control in steel fabrication. When customers are satisfied with the quality of steel products, they are more likely to do business with the fabricator again and to recommend the fabricator to others. This can lead to increased sales and profits for the fabricator.

-

Facet 1: Meeting customer requirements

The first step to customer satisfaction is meeting customer requirements. This means understanding what the customer wants and needs, and then manufacturing steel products that meet those requirements. It is important to communicate with customers throughout the fabrication process to ensure that their needs are being met.

-

Facet 2: Providing high-quality products

Customers are more likely to be satisfied with steel products that are high quality. This means using high-quality materials, following proper manufacturing processes, and inspecting products carefully before they are shipped to customers.

-

Facet 3: Delivering products on time

Customers expect to receive their steel products on time. This means having efficient production processes in place and being able to meet customer deadlines. It is important to communicate with customers about any delays that may occur.

-

Facet 4: Providing good customer service

Good customer service is essential for customer satisfaction. This means being responsive to customer inquiries, resolving customer complaints quickly and efficiently, and providing ongoing support to customers.

By focusing on these four facets, steel fabricators can improve customer satisfaction and build lasting relationships with their customers.

Regulatory compliance

Regulatory compliance is an essential aspect of quality control in steel fabrication. It ensures that steel products meet all applicable safety, health, and environmental regulations. This is important for several reasons:

-

Facet 1: Ensures safety

Regulatory compliance helps to ensure that steel products are safe for use. This is important for protecting workers, consumers, and the general public.

-

Facet 2: Protects the environment

Regulatory compliance helps to protect the environment by ensuring that steel products are manufactured in a way that minimizes pollution and waste.

-

Facet 3: Avoids legal penalties

Regulatory compliance helps steel fabricators to avoid legal penalties. Steel fabricators who fail to comply with applicable regulations may be subject to fines, sanctions, or even criminal prosecution.

-

Facet 4: Maintains reputation

Regulatory compliance helps steel fabricators to maintain their reputation as responsible and ethical companies. This can lead to increased business opportunities and customer loyalty.

By meeting all applicable regulatory requirements, steel fabricators can help to ensure that their products are safe, environmentally friendly, and compliant with the law. This can help to protect workers, consumers, and the general public, while also avoiding legal penalties and maintaining a positive reputation.

Cost control

In the context of quality control in steel fabrication, cost control is essential for ensuring that the cost of quality control activities is minimized without compromising the quality of the steel products. This can be achieved by implementing a number of strategies, including:

-

Facet 1: Preventive maintenance

Preventive maintenance involves regularly inspecting and servicing equipment to prevent breakdowns and costly repairs. This can help to reduce the cost of quality control activities by avoiding the need for emergency repairs and downtime.

-

Facet 2: Employee training

Well-trained employees are less likely to make mistakes, which can lead to reduced scrap and rework costs. This can help to reduce the cost of quality control activities by minimizing the amount of defective products that need to be scrapped or reworked.

-

Facet 3: Supplier management

Working with reliable suppliers who provide high-quality materials can help to reduce the cost of quality control activities by minimizing the amount of defective materials that need to be rejected.

-

Facet 4: Process optimization

Optimizing production processes can help to reduce the cost of quality control activities by eliminating waste and inefficiencies. This can be achieved by implementing lean manufacturing techniques, such as just-in-time inventory and Kanban.

By implementing these strategies, steel fabricators can minimize the cost of quality control activities without compromising the quality of their products. This can help to improve profitability and competitiveness.

Risk management

Risk management is an essential part of quality control in steel fabrication. It involves identifying and mitigating risks that could impact the quality of steel products, the safety of workers, or the environment. By proactively managing risks, steel fabricators can help to ensure that their products are safe, reliable, and durable.

-

Facet 1: Identifying risks

The first step in risk management is to identify potential risks. This can be done by conducting risk assessments, which involve examining all aspects of the steel fabrication process to identify potential hazards and risks. Risk assessments should be conducted regularly, especially when there are changes to the process or new materials are being used.

-

Facet 2: Assessing risks

Once risks have been identified, they need to be assessed to determine their likelihood and severity. This can be done using a variety of methods, such as qualitative risk analysis or quantitative risk analysis. Qualitative risk analysis involves using subjective judgment to assess the likelihood and severity of risks, while quantitative risk analysis uses data and statistical methods to assess risks.

-

Facet 3: Mitigating risks

Once risks have been assessed, they need to be mitigated to reduce their likelihood or severity. This can be done using a variety of methods, such as engineering controls, administrative controls, or personal protective equipment. Engineering controls are physical changes to the workplace or equipment that reduce the risk of accidents or injuries. Administrative controls are changes to work procedures or policies that reduce the risk of accidents or injuries. Personal protective equipment is equipment that workers wear to protect themselves from accidents or injuries.

-

Facet 4: Monitoring risks

Once risks have been mitigated, they need to be monitored to ensure that they are still being effectively controlled. This can be done by conducting regular inspections and audits, and by reviewing accident and injury data. If a risk is found to be no longer effectively controlled, it should be re-assessed and additional mitigation measures should be implemented.

By following these steps, steel fabricators can identify, assess, and mitigate risks associated with steel fabrication. This can help to ensure that their products are safe, reliable, and durable.

FAQs about Quality Control in Steel Fabrication

Quality control is a critical aspect of steel fabrication, ensuring the safety, reliability, and durability of steel products. Here are some frequently asked questions about quality control in steel fabrication:

Question 1: What are the key elements of quality control in steel fabrication?

Answer: Key elements of quality control in steel fabrication include inspection, testing, documentation, corrective action, preventive action, training, certification, continuous improvement, customer satisfaction, regulatory compliance, cost control, and risk management.

Question 2: Why is inspection important in quality control for steel fabrication?

Answer: Inspection is crucial to verify that steel products meet specifications and standards. It involves visual, dimensional, material, and non-destructive testing to identify any defects or non-conformances.

Question 3: What are the benefits of implementing a quality management system in steel fabrication?

Answer: Implementing a quality management system, such as ISO 9001:2015, provides a framework for steel fabricators to establish and maintain a comprehensive quality control system. It enhances customer satisfaction, improves efficiency, reduces costs, and ensures regulatory compliance.

Question 4: How can steel fabricators continuously improve their quality control processes?

Answer: Continuous improvement involves regularly reviewing and updating quality control processes. It includes planning, implementing, checking, and acting (PDCA) to identify areas for improvement, make necessary changes, and monitor their effectiveness.

Question 5: What are the consequences of poor quality control in steel fabrication?

Answer: Poor quality control can lead to defective products, safety hazards, customer dissatisfaction, legal liabilities, and reputational damage. It can also result in increased costs due to rework, scrap, and warranty claims.

Question 6: How can steel fabricators stay updated on the latest quality control standards and best practices?

Answer: Steel fabricators can stay informed by attending industry conferences, reading technical publications, participating in training programs, and collaborating with experts in the field. Regularly reviewing and adhering to industry standards and regulations is also essential.

In summary, quality control in steel fabrication encompasses various elements and processes to ensure the production of safe, reliable, and high-quality steel products. By implementing effective quality control measures, steel fabricators can enhance customer satisfaction, improve operational efficiency, and maintain a competitive edge in the industry.

Transition to the next article section:

Tips for Quality Control in Steel Fabrication

Maintaining high standards of quality control in steel fabrication is crucial for ensuring the safety, reliability, and durability of steel products. Here are some valuable tips to enhance quality control in your steel fabrication operations:

Tip 1: Establish Clear Specifications and Standards

Define clear and comprehensive specifications and standards for all aspects of steel fabrication, including materials, dimensions, tolerances, and performance requirements. Ensure that these specifications are communicated effectively to all relevant personnel.

Tip 2: Implement Rigorous Inspection and Testing Procedures

Establish a comprehensive inspection and testing plan that covers all stages of the fabrication process. Utilize a combination of visual, dimensional, material, and non-destructive testing methods to identify any defects or non-conformances promptly.

Tip 3: Maintain Traceability and Documentation

Implement a robust traceability system to track the history of each steel product throughout the fabrication process. Maintain accurate and detailed records of inspections, tests, and any corrective actions taken. This documentation is essential for quality control, product liability, and regulatory compliance.

Tip 4: Empower Employees with Training and Certification

Invest in training and certification programs for your employees to ensure they have the knowledge, skills, and expertise necessary to perform their tasks effectively. Encourage them to stay updated on the latest industry best practices and quality control techniques.

Tip 5: Encourage Continuous Improvement

Foster a culture of continuous improvement by regularly reviewing and updating your quality control processes. Seek feedback from customers, employees, and industry experts to identify areas for improvement and implement changes to enhance quality and efficiency.

Tip 6: Collaborate with Suppliers and Customers

Establish strong relationships with suppliers to ensure the quality of incoming materials and components. Collaborate with customers to understand their specific requirements and expectations to tailor your quality control measures accordingly.

Tip 7: Utilize Technology and Automation

Leverage advanced technologies, such as automated inspection systems and data analytics, to improve the accuracy, efficiency, and consistency of your quality control processes. Automation can reduce human error and provide real-time monitoring of product quality.

Summary:

By implementing these tips, steel fabricators can significantly enhance their quality control processes, ensuring the production of safe, reliable, and high-quality steel products. Continuous monitoring, improvement, and collaboration are key to maintaining the highest standards of quality in steel fabrication.

Conclusion

Quality control in steel fabrication is a multifaceted and critical process that ensures the safety, reliability, and durability of steel structures. Through rigorous inspections, testing, and documentation, steel fabricators can guarantee that their products meet the highest standards of quality.

The benefits of effective quality control in steel fabrication are numerous. It reduces the risk of product failure, enhances customer satisfaction, improves operational efficiency, and strengthens the reputation of steel fabricators. By embracing a culture of continuous improvement and collaboration, the steel fabrication industry can continue to deliver high-quality products that meet the evolving needs of the construction and manufacturing sectors.

As the demand for steel products continues to grow, the importance of quality control will only increase. By investing in state-of-the-art technologies, training their workforce, and implementing robust quality management systems, steel fabricators can position themselves as leaders in the industry and drive the future of steel construction.