What is steel fabrication? Steel fabrication is the process of shaping and assembling steel components to create structures and products. It is used in a wide range of industries, including construction, manufacturing, and transportation.

Editor’s Note: Steel fabrication is an important topic to understand because it is used in so many different industries. By learning more about steel fabrication, you can gain a better understanding of how the world around you is built.

We’ve done the research and put together this guide to help you learn more about steel fabrication. We’ll cover the basics of steel fabrication, including the different types of steel, the fabrication process, and the applications of steel fabrication.

Key Differences or Key Takeaways

| Characteristic | Steel Fabrication |

|---|---|

| Definition | The process of shaping and assembling steel components to create structures and products. |

| Industries | Construction, manufacturing, and transportation. |

Transition to main article topics

In this article, we will explore the following topics:

- The different types of steel

- The fabrication process

- The applications of steel fabrication

Steel Fabrication

Steel fabrication is a vital process in the construction, manufacturing, and transportation industries. It involves shaping and assembling steel components to create a wide range of structures and products. Here are seven key aspects of steel fabrication:

- Materials: Steel fabrication uses various types of steel, including carbon steel, stainless steel, and alloy steel.

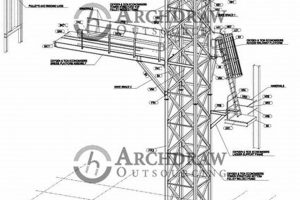

- Processes: Steel fabrication involves processes such as cutting, bending, welding, and assembling.

- Equipment: Steel fabrication requires specialized equipment, such as CNC machines, welding machines, and cranes.

- Industries: Steel fabrication is used in a variety of industries, including construction, manufacturing, and transportation.

- Products: Steel fabrication produces a wide range of products, including buildings, bridges, ships, and vehicles.

- Quality: Steel fabrication requires strict quality control to ensure the safety and durability of the finished products.

- Safety: Steel fabrication involves potential hazards, so safety precautions are essential.

These key aspects are all interconnected and essential to the steel fabrication process. For example, the type of steel used will determine the fabrication processes that are required. The equipment used will also impact the quality and safety of the finished products. By understanding these key aspects, you can gain a better understanding of steel fabrication and its importance in our world.

Materials

The type of steel used in steel fabrication has a significant impact on the properties and performance of the finished product. Carbon steel is the most common type of steel used in fabrication, offering a good balance of strength, durability, and cost. Stainless steel is more resistant to corrosion and is often used in applications where hygiene is important, such as food processing and medical equipment. Alloy steel is a type of steel that has been alloyed with other elements, such as chromium, nickel, or molybdenum, to improve its properties, such as strength, hardness, or wear resistance.

The choice of steel for a particular fabrication project will depend on the specific requirements of the application. For example, if the fabricated product will be used in a corrosive environment, then stainless steel would be a good choice. If the product will be subjected to high stresses, then alloy steel would be a good choice. By understanding the different types of steel available and their properties, fabricators can select the right steel for the job and ensure that the finished product meets the required specifications.

Here is a table summarizing the key differences between carbon steel, stainless steel, and alloy steel:

| Characteristic | Carbon Steel | Stainless Steel | Alloy Steel |

|---|---|---|---|

| Composition | Iron and carbon | Iron, chromium, and nickel | Iron and other alloying elements |

| Properties | Strong, durable, and cost-effective | Corrosion-resistant and hygienic | Strong, hard, and wear-resistant |

| Applications | Construction, manufacturing, and transportation | Food processing, medical equipment, and chemical processing | Automotive, aerospace, and mining |

By understanding the connection between the materials used in steel fabrication and the properties and performance of the finished product, fabricators can make informed decisions about the type of steel to use for a particular project. This understanding is essential for ensuring that the finished product meets the required specifications and performs as expected.

Processes

Steel fabrication processes are essential to the production of high-quality steel structures and products. These processes include cutting, bending, welding, and assembling. Each process plays a vital role in the overall fabrication process, and the quality of the finished product depends on the skill and expertise of the fabricators.

Cutting is the first step in the fabrication process. It involves cutting steel plates or bars to the desired shape and size. This can be done using a variety of methods, including plasma cutting, oxy-fuel cutting, and waterjet cutting. The choice of cutting method will depend on the thickness and type of steel being cut.

Bending is the process of shaping steel plates or bars into curved or angled shapes. This is done using a variety of bending machines, such as press brakes and roll benders. The type of bending machine used will depend on the size and shape of the steel being bent.

Welding is the process of joining two or more pieces of steel together. This is done using a variety of welding methods, such as arc welding, MIG welding, and TIG welding. The choice of welding method will depend on the thickness and type of steel being welded.

Assembling is the final step in the fabrication process. It involves putting together the individual components of a steel structure or product. This is done using a variety of methods, such as bolting, riveting, and welding. The choice of assembly method will depend on the size and complexity of the structure or product being assembled.

The processes of cutting, bending, welding, and assembling are essential to the production of high-quality steel structures and products. By understanding these processes and how they are used in steel fabrication, you can gain a better appreciation for the skill and expertise of fabricators.

Table: Steel Fabrication Processes

| Process | Description | Importance |

|---|---|---|

| Cutting | Cutting steel plates or bars to the desired shape and size. | Ensures that the steel components fit together properly. |

| Bending | Shaping steel plates or bars into curved or angled shapes. | Creates the desired shape of the steel structure or product. |

| Welding | Joining two or more pieces of steel together. | Ensures that the steel structure or product is strong and durable. |

| Assembling | Putting together the individual components of a steel structure or product. | Completes the fabrication process and creates the finished product. |

By understanding the connection between steel fabrication processes and the production of high-quality steel structures and products, you can make informed decisions about the fabrication of steel components for your next project.

Equipment

Specialized equipment is essential to the steel fabrication process. Without the right equipment, it would be impossible to cut, bend, weld, and assemble steel components into the desired shapes and structures. CNC machines, welding machines, and cranes are just a few of the essential pieces of equipment used in steel fabrication.

CNC machines are used to cut and shape steel components with precision. They are computer-controlled, which allows them to produce complex shapes and cuts with a high degree of accuracy. Welding machines are used to join steel components together. There are many different types of welding machines, each with its own advantages and disadvantages. The type of welding machine used will depend on the thickness and type of steel being welded.

Cranes are used to lift and move heavy steel components. They are essential for assembling large steel structures, such as bridges and buildings. Cranes come in a variety of sizes and capacities. The type of crane used will depend on the size and weight of the steel components being lifted.

The use of specialized equipment in steel fabrication has a number of benefits. First, it allows fabricators to produce complex shapes and cuts with a high degree of accuracy. This is essential for ensuring that the finished product meets the required specifications. Second, the use of specialized equipment can improve productivity. By automating tasks, fabricators can reduce the time it takes to complete a project. Third, the use of specialized equipment can improve safety. By using machines to perform dangerous tasks, fabricators can reduce the risk of injury.

The connection between equipment and steel fabrication is essential to the production of high-quality steel structures and products. By understanding the importance of specialized equipment in steel fabrication, you can gain a better appreciation for the skill and expertise of fabricators.

| Equipment | Purpose | Importance |

|---|---|---|

| CNC machines | Cutting and shaping steel components with precision. | Ensures that the steel components fit together properly. |

| Welding machines | Joining two or more pieces of steel together. | Ensures that the steel structure or product is strong and durable. |

| Cranes | Lifting and moving heavy steel components. | Essential for assembling large steel structures. |

By understanding the connection between equipment and steel fabrication, you can make informed decisions about the fabrication of steel components for your next project.

Industries

Steel fabrication plays a vital role in a wide range of industries, including construction, manufacturing, and transportation. By understanding the connection between steel fabrication and these industries, we can gain a better appreciation for the importance of steel fabrication in our modern world.

- Construction: Steel fabrication is essential to the construction industry. Steel is used to build bridges, buildings, and other structures. Without steel fabrication, it would be impossible to build the modern world.

- Manufacturing: Steel fabrication is also used in the manufacturing industry. Steel is used to make a variety of products, including cars, appliances, and machinery. Without steel fabrication, it would be impossible to produce the goods that we rely on every day.

- Transportation: Steel fabrication is also used in the transportation industry. Steel is used to make ships, trains, and airplanes. Without steel fabrication, it would be impossible to transport people and goods around the world.

The connection between steel fabrication and these industries is essential to the functioning of our modern world. By understanding this connection, we can gain a better appreciation for the importance of steel fabrication in our lives.

Products

Steel fabrication plays a vital role in the production of a wide range of products, including buildings, bridges, ships, and vehicles. These products are essential to our modern world, and without steel fabrication, it would be impossible to build and maintain the infrastructure that we rely on every day.

- Buildings: Steel is used to build a variety of buildings, including skyscrapers, office buildings, and warehouses. Steel buildings are strong, durable, and fire-resistant, making them ideal for a variety of applications.

- Bridges: Steel is also used to build bridges. Steel bridges are strong and durable, and they can be built to span long distances. Steel bridges are also relatively easy to maintain, making them a cost-effective option for many applications.

- Ships: Steel is used to build ships of all sizes, from small boats to large cargo ships. Steel ships are strong and durable, and they can withstand the harsh conditions of the open sea. Steel ships are also relatively easy to repair, making them a good choice for commercial and military applications.

- Vehicles: Steel is used to build a variety of vehicles, including cars, trucks, and buses. Steel vehicles are strong and durable, and they can withstand the rigors of daily use. Steel vehicles are also relatively easy to repair, making them a good choice for both personal and commercial use.

The connection between steel fabrication and the products that we use every day is essential to our modern world. By understanding this connection, we can gain a better appreciation for the importance of steel fabrication in our lives.

Quality

Strict quality control is essential to steel fabrication, as it ensures the safety and durability of the finished products. Samna Steel Fabrication is committed to maintaining the highest quality standards in all of its fabrication processes. This commitment to quality is evident in the company’s use of state-of-the-art equipment, highly trained personnel, and rigorous quality control procedures.

The use of state-of-the-art equipment allows Samna Steel Fabrication to produce steel components with precision and accuracy. The company’s highly trained personnel are experts in steel fabrication and welding, and they take pride in their work. Samna Steel Fabrication also has a rigorous quality control process in place to ensure that all of its products meet the highest standards of safety and durability.

As a result of its commitment to quality, Samna Steel Fabrication has a reputation for producing high-quality steel products that are used in a variety of applications, including construction, manufacturing, and transportation.

The importance of quality in steel fabrication cannot be overstated. Steel components are used in a wide variety of applications, and it is essential that they are safe and durable. Samna Steel Fabrication’s commitment to quality ensures that its products meet the highest standards of safety and durability, giving customers peace of mind.

Here is a table summarizing the key points discussed above:

| Characteristic | Importance |

|---|---|

| State-of-the-art equipment | Allows for precision and accuracy in steel fabrication. |

| Highly trained personnel | Experts in steel fabrication and welding. |

| Rigorous quality control process | Ensures that all products meet the highest standards of safety and durability. |

| Reputation for high-quality products | Samna Steel Fabrication’s products are used in a variety of applications, including construction, manufacturing, and transportation. |

Safety

Steel fabrication involves working with heavy machinery and materials, which can pose a number of potential hazards to workers. These hazards include:

- Cuts and lacerations

- Burns

- Eye injuries

- Hearing loss

- Respiratory problems

To protect workers from these hazards, it is essential to implement and follow proper safety precautions. These precautions include:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs

- Using machinery and equipment safely and properly

- Following established safety procedures

- Being aware of the potential hazards and taking steps to avoid them

Samna Steel Fabrication is committed to providing a safe and healthy work environment for all of its employees. The company has a comprehensive safety program in place that includes:

- Regular safety training for all employees

- Regular safety inspections of all equipment and machinery

- A system for identifying and correcting potential hazards

- A policy of continuous improvement in safety

As a result of its commitment to safety, Samna Steel Fabrication has a strong safety record. The company has been recognized for its safety performance by a number of organizations, including the National Safety Council and the Occupational Safety and Health Administration (OSHA).

The connection between safety and steel fabrication is essential to the well-being of workers and the success of the company. By understanding this connection, we can gain a better appreciation for the importance of safety in steel fabrication.

Here is a table summarizing the key points discussed above:

| Characteristic | Importance |

|---|---|

| Potential hazards in steel fabrication | Cuts and lacerations, burns, eye injuries, hearing loss, respiratory problems |

| Safety precautions in steel fabrication | Wearing PPE, using machinery and equipment safely, following safety procedures, being aware of hazards |

| Samna Steel Fabrication’s safety program | Regular safety training, regular safety inspections, identifying and correcting hazards, continuous improvement in safety |

| Benefits of a strong safety record | Improved worker safety, reduced costs, increased productivity, enhanced reputation |

By understanding the connection between safety and steel fabrication, we can make informed decisions about the fabrication of steel components for our next project.

FAQs about Samna Steel Fabrication

This FAQ section provides answers to common questions and concerns about Samna Steel Fabrication. Whether you are a potential customer, a business partner, or simply curious about our company, we hope you find this information helpful.

Question 1: What sets Samna Steel Fabrication apart from other steel fabrication companies?

Answer: Samna Steel Fabrication is committed to providing high-quality steel fabrication services at competitive prices. We have a team of experienced and certified fabricators who use state-of-the-art equipment to produce precision steel components. We also have a strong commitment to safety and customer satisfaction.

Question 2: What types of steel fabrication services do you offer?

Answer: We offer a wide range of steel fabrication services, including cutting, bending, welding, and assembling. We can fabricate steel components for a variety of applications, including construction, manufacturing, and transportation.

Question 3: What is your quality control process?

Answer: We have a rigorous quality control process in place to ensure that all of our products meet the highest standards of quality and safety. Our quality control process includes regular inspections of all equipment and machinery, as well as a system for identifying and correcting potential hazards.

Question 4: What is your safety record?

Answer: We have a strong safety record and have been recognized for our safety performance by a number of organizations, including the National Safety Council and the Occupational Safety and Health Administration (OSHA).

Question 5: What is your turnaround time?

Answer: Our turnaround time varies depending on the complexity of the project. However, we are committed to providing our customers with the fastest possible turnaround time without sacrificing quality.

Question 6: What are your payment terms?

Answer: Our payment terms are flexible and can be tailored to meet the needs of our customers.

Summary of key takeaways or final thought:

We hope this FAQ section has been helpful. If you have any further questions, please do not hesitate to contact us.

Transition to the next article section:

Thank you for considering Samna Steel Fabrication for your steel fabrication needs. We look forward to working with you on your next project.

Tips from Samna Steel Fabrication

Samna Steel Fabrication is a leading provider of high-quality steel fabrication services. We have over 30 years of experience in the industry, and we have a team of highly skilled and experienced fabricators. We are committed to providing our customers with the highest quality products and services, and we are always looking for ways to improve our processes.

Here are a few tips from Samna Steel Fabrication:

Tip 1: Choose the right steel for your project.

There are many different types of steel available, and each type has its own unique properties. It is important to choose the right steel for your project based on the specific requirements of the application. For example, if you need a steel that is strong and durable, you may want to choose a high-strength steel. If you need a steel that is resistant to corrosion, you may want to choose a stainless steel.

Tip 2: Use the right fabrication techniques.

There are a variety of different steel fabrication techniques available, and each technique has its own advantages and disadvantages. It is important to choose the right fabrication technique for your project based on the specific requirements of the application. For example, if you need to create a complex shape, you may want to use a CNC plasma cutter. If you need to weld two pieces of steel together, you may want to use a MIG welder.

Tip 3: Follow proper safety procedures.

Steel fabrication can be a hazardous activity, so it is important to follow proper safety procedures. This includes wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs. It also includes following all of the manufacturer’s instructions for the equipment you are using.

Tip 4: Get professional help if needed.

If you are not sure how to complete a particular steel fabrication task, it is best to get professional help. A qualified steel fabricator can help you choose the right materials and techniques for your project, and they can ensure that the job is done safely and correctly.

Tip 5: Inspect your work regularly.

Once you have completed a steel fabrication project, it is important to inspect your work regularly to ensure that it is still in good condition. This includes checking for any signs of wear, tear, or damage. If you find any problems, it is important to repair them immediately.

Summary of key takeaways or benefits:

By following these tips from Samna Steel Fabrication, you can ensure that your steel fabrication projects are successful. We are committed to providing our customers with the highest quality products and services, and we are always looking for ways to improve our processes.

Transition to the article’s conclusion:

Thank you for choosing Samna Steel Fabrication. We look forward to working with you on your next project.

Conclusion

Steel fabrication is a vital process in the construction, manufacturing, and transportation industries. It involves shaping and assembling steel components to create a wide range of structures and products. Samna Steel Fabrication is a leading provider of high-quality steel fabrication services. We have over 30 years of experience in the industry, and we have a team of highly skilled and experienced fabricators. We are committed to providing our customers with the highest quality products and services, and we are always looking for ways to improve our processes.

We hope this article has given you a better understanding of steel fabrication and its importance in our modern world. If you have any questions or need assistance with your next steel fabrication project, please do not hesitate to contact us.