Wondering what SMK machines and fabrication can do for you? SMK machines and fabrication can provide you with the tools and expertise you need to create high-quality metal products.

Editor’s Notes: SMK machines and fabrication are essential for businesses that need to produce metal products. These machines can help you create a wide variety of products, from simple brackets to complex assemblies.

Our team has done the analysis, dug into the information, and put together this guide to help you make the right decision.

Key differences or Key takeaways:

| SMK Machine | Fabrication |

|---|---|

| A machine that can shape metal | The process of creating metal products |

Transition to main article topics:

- Types of SMK machines

- Benefits of using SMK machines

- How to choose the right SMK machine

- Tips for using SMK machines

SMK Machine & Fabrication

SMK machines and fabrication are essential for businesses that need to produce metal products. These machines can help you create a wide variety of products, from simple brackets to complex assemblies.

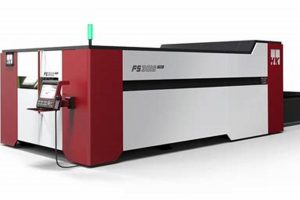

- Types: SMK machines come in a variety of types, including CNC machines, laser cutters, and press brakes.

- Benefits: SMK machines can offer a number of benefits, including increased productivity, precision, and quality.

- Applications: SMK machines are used in a wide range of applications, including automotive, aerospace, and medical.

- Materials: SMK machines can be used to fabricate a variety of materials, including steel, aluminum, and stainless steel.

- Processes: SMK machines can be used to perform a variety of processes, including cutting, bending, and welding.

- Industries: SMK machines are used in a variety of industries, including manufacturing, construction, and transportation.

- Equipment: SMK machines require a variety of equipment, including tooling, fixtures, and software.

- Maintenance: SMK machines require regular maintenance to ensure optimal performance.

These are just a few of the key aspects of SMK machines and fabrication. By understanding these aspects, you can make informed decisions about how to use these machines to improve your business.

Types

The type of SMK machine you choose will depend on the specific needs of your project. CNC machines are computer-controlled machines that can perform a variety of operations, including cutting, drilling, and milling. Laser cutters use a laser to cut metal, and press brakes are used to bend metal. By understanding the different types of SMK machines available, you can choose the right machine for your project.

For example, if you need to create a complex part with precise dimensions, a CNC machine would be a good choice. If you need to cut metal quickly and efficiently, a laser cutter would be a good choice. And if you need to bend metal, a press brake would be a good choice.

By understanding the different types of SMK machines available, you can choose the right machine for your project and improve your productivity and efficiency.

Table of SMK Machine Types

| Type | Description |

|---|---|

| CNC machines | Computer-controlled machines that can perform a variety of operations |

| Laser cutters | Use a laser to cut metal |

| Press brakes | Used to bend metal |

Benefits

SMK machines offer a number of benefits that can help businesses improve their productivity, precision, and quality. These benefits include:

- Increased Productivity: SMK machines can help businesses increase their productivity by automating tasks and reducing the need for manual labor. This can free up workers to focus on other tasks, such as product development and customer service.

- Improved Precision: SMK machines are highly precise, which can help businesses produce products that meet exact specifications. This can reduce the risk of defects and improve the overall quality of products.

- Enhanced Quality: SMK machines can help businesses improve the quality of their products by producing parts that are consistent and repeatable. This can reduce the risk of defects and improve the overall performance of products.

These are just a few of the benefits that SMK machines can offer businesses. By understanding these benefits, businesses can make informed decisions about how to use these machines to improve their operations.

Applications

SMK machines are used in a wide range of applications due to their versatility and precision. Some of the most common applications include:

- Automotive: SMK machines are used to manufacture a variety of automotive parts, including engine components, transmission components, and body panels.

- Aerospace: SMK machines are used to manufacture a variety of aerospace components, including aircraft parts, spacecraft parts, and rocket parts.

- Medical: SMK machines are used to manufacture a variety of medical devices, including surgical instruments, implants, and prosthetics.

These are just a few of the many applications for SMK machines. By understanding the versatility of these machines, businesses can explore new ways to use them to improve their operations and create new products.

Materials

SMK machines are versatile machines that can be used to fabricate a wide range of materials, including steel, aluminum, and stainless steel. This versatility makes SMK machines ideal for a variety of applications, from automotive to aerospace to medical.

- Steel: Steel is a strong and durable material that is often used in construction and manufacturing. SMK machines can be used to cut, bend, and weld steel to create a variety of products, including beams, frames, and plates.

- Aluminum: Aluminum is a lightweight and corrosion-resistant material that is often used in aerospace and automotive applications. SMK machines can be used to cut, bend, and weld aluminum to create a variety of products, including aircraft parts, car bodies, and heat sinks.

- Stainless steel: Stainless steel is a corrosion-resistant material that is often used in medical and food processing applications. SMK machines can be used to cut, bend, and weld stainless steel to create a variety of products, including surgical instruments, food processing equipment, and architectural features.

The ability to fabricate a variety of materials makes SMK machines essential for a wide range of industries. By understanding the materials that SMK machines can fabricate, businesses can explore new ways to use these machines to improve their operations and create new products.

Processes

SMK machines are versatile machines that can be used to perform a variety of processes, including cutting, bending, and welding. These processes are essential for a wide range of applications, from automotive to aerospace to medical.

- Cutting is the process of removing material from a workpiece. SMK machines can be used to cut a variety of materials, including steel, aluminum, and stainless steel. Cutting processes include laser cutting, waterjet cutting, and plasma cutting.

- Bending is the process of deforming a workpiece by applying force. SMK machines can be used to bend a variety of materials, including steel, aluminum, and stainless steel. Bending processes include press braking, roll bending, and tube bending.

- Welding is the process of joining two or more pieces of metal together. SMK machines can be used to weld a variety of materials, including steel, aluminum, and stainless steel. Welding processes include arc welding, MIG welding, and TIG welding.

The ability to perform a variety of processes makes SMK machines essential for a wide range of industries. By understanding the processes that SMK machines can perform, businesses can explore new ways to use these machines to improve their operations and create new products.

Industries

The connection between “Industries: SMK machines are used in a variety of industries, including manufacturing, construction, and transportation.” and “smk machine & fabrication” is significant because it highlights the versatility and importance of SMK machines in various sectors of the economy.

SMK machines are essential for manufacturing because they can be used to create a wide range of metal products, from simple brackets to complex assemblies. In construction, SMK machines are used to fabricate structural components, such as beams and columns. In transportation, SMK machines are used to manufacture parts for cars, trucks, and airplanes.

The ability of SMK machines to perform a variety of processes, such as cutting, bending, and welding, makes them indispensable for these industries. By understanding the connection between “Industries: SMK machines are used in a variety of industries, including manufacturing, construction, and transportation.” and “smk machine & fabrication”, businesses can gain a deeper appreciation for the importance of these machines and how they can be used to improve productivity and efficiency.

Table of Industries that Use SMK Machines

| Industry | Applications |

|---|---|

| Manufacturing | Fabrication of metal parts, components, and assemblies |

| Construction | Fabrication of structural components, such as beams and columns |

| Transportation | Fabrication of parts for cars, trucks, and airplanes |

Equipment

The connection between “Equipment: SMK machines require a variety of equipment, including tooling, fixtures, and software.” and “smk machine & fabrication” is significant because it highlights the importance of having the right equipment to operate SMK machines effectively. Tooling, fixtures, and software are essential components of SMK machines, and they play a vital role in ensuring that these machines can perform their functions accurately and efficiently.

Tooling refers to the cutting tools and other accessories that are used with SMK machines. The type of tooling that is required will depend on the specific application. For example, a CNC machine that is used to cut metal will require different tooling than a laser cutter that is used to cut wood. Fixtures are used to hold the workpiece in place while it is being processed by the SMK machine. Fixtures are essential for ensuring that the workpiece is positioned correctly and that it is held securely during the machining process.

Software is used to control the operation of SMK machines. The software will typically include a CAD/CAM program that is used to create the design of the part that is to be produced. The software will also include a control program that is used to operate the machine. The control program will tell the machine how to move the cutting tool and how to perform the machining operations.

Having the right equipment is essential for getting the most out of SMK machines. By understanding the connection between “Equipment: SMK machines require a variety of equipment, including tooling, fixtures, and software.” and “smk machine & fabrication”, businesses can make informed decisions about the equipment that they need to purchase. This will help them to improve their productivity and efficiency, and it will also help them to produce higher-quality products.

Table of Equipment for SMK Machines

| Equipment | Description |

|---|---|

| Tooling | Cutting tools and other accessories |

| Fixtures | Used to hold the workpiece in place |

| Software | Used to control the operation of the machine |

Maintenance

Regular maintenance is essential for ensuring that SMK machines perform at their best and produce high-quality products. Without proper maintenance, SMK machines may experience decreased accuracy, reduced productivity, and increased downtime.

- Regular cleaning is essential for removing metal chips, dust, and other debris from the machine. This will help to prevent the machine from becoming clogged or damaged.

- Lubrication is also important for keeping the machine running smoothly. The type of lubricant that is required will depend on the specific machine.

- Calibration is necessary to ensure that the machine is cutting and bending accurately. This should be done regularly, especially after the machine has been moved or repaired.

- Inspection is important for identifying any potential problems with the machine. This should be done regularly, and any problems should be addressed immediately.

By following these maintenance tips, businesses can help to ensure that their SMK machines perform at their best and produce high-quality products for many years to come.

FAQs

This FAQ section provides answers to common questions about SMK machine & fabrication. These questions are designed to help you better understand the capabilities and applications of SMK machines, as well as the benefits of using them in your business.

Question 1: What are SMK machines used for?

Answer: SMK machines are used for a wide range of applications, including cutting, bending, and welding metal. They are essential for manufacturing a variety of products, from simple brackets to complex assemblies.

Question 2: What materials can SMK machines fabricate?

Answer: SMK machines can fabricate a variety of materials, including steel, aluminum, and stainless steel. This versatility makes them ideal for a wide range of industries.

Question 3: What are the benefits of using SMK machines?

Answer: There are many benefits to using SMK machines, including increased productivity, precision, and quality. They can also help businesses reduce costs and improve their overall efficiency.

Question 4: What is the difference between a CNC machine and a laser cutter?

Answer: CNC machines are computer-controlled machines that can perform a variety of operations, including cutting, drilling, and milling. Laser cutters use a laser to cut metal. Both types of machines have their own advantages and disadvantages, depending on the specific application.

Question 5: How do I choose the right SMK machine for my business?

Answer: The best way to choose the right SMK machine for your business is to consult with a qualified dealer. They can help you assess your needs and recommend the best machine for your specific application.

Question 6: How do I maintain my SMK machine?

Answer: Regular maintenance is essential for keeping your SMK machine running at its best. This includes cleaning, lubricating, and calibrating the machine. It is also important to inspect the machine regularly for any potential problems.

These are just a few of the most common questions about SMK machine & fabrication. If you have any other questions, please feel free to contact us.

We hope this FAQ section has been helpful. For more information about SMK machines, please visit our website or contact us today.

SMK Machine & Fabrication Tips

SMK machines and fabrication techniques offer a wide range of possibilities for metalworking. Here are a few tips to help you get the most out of your SMK machine and fabrication processes:

Tip 1: Choose the Right Machine for the Job

There are many different types of SMK machines available, each with its own strengths and weaknesses. It is important to choose the right machine for the job at hand. Consider the type of material you will be working with, the size and complexity of the parts you need to produce, and your budget.

Tip 2: Use the Right Tools

The right tools can make all the difference in the quality of your work. Make sure you have the right tooling for the job, and that your tools are sharp and in good condition.

Tip 3: Follow the Manufacturer’s Instructions

Each SMK machine is different, so it is important to follow the manufacturer’s instructions carefully. This will help you to avoid accidents and ensure that your machine is operating properly.

Tip 4: Practice Makes Perfect

The more you use your SMK machine, the better you will become at using it. Take some time to practice on scrap material before you start working on your actual projects.

Tip 5: Safety First

SMK machines can be dangerous, so it is important to always put safety first. Wear appropriate safety gear, such as safety glasses, gloves, and a dust mask. Keep your work area clean and free of clutter.

Summary: By following these tips, you can get the most out of your SMK machine and fabrication processes. With a little practice, you can produce high-quality metal parts and products.

Conclusion

SMK machines and fabrication offer a wide range of possibilities for metalworking. These machines can be used to create a variety of products, from simple brackets to complex assemblies. They are essential for a wide range of industries, including manufacturing, construction, and transportation.

By understanding the capabilities of SMK machines and fabrication, businesses can explore new ways to improve their operations and create new products. These machines offer a number of benefits, including increased productivity, precision, and quality. By choosing the right machine for the job and following best practices, businesses can get the most out of their SMK machines and fabrication processes.