Looking for the best stainless steel fabrication services in the Bay Area? You’re in luck! We’ve done the research for you and compiled a list of the top stainless steel fabricators in the area. These companies have a proven track record of providing high-quality stainless steel fabrication services at competitive prices. Whether you need a custom stainless steel countertop, a new stainless steel railing, or any other type of stainless steel fabrication, these companies can help you get the job done right.

Editor’s Note: Stainless steel fabrication is an important process for a variety of industries. It is used to create everything from kitchen countertops to medical equipment. If you are looking for a stainless steel fabricator in the Bay Area, be sure to do your research and choose a company that has a good reputation for quality and customer service.

We’ve put together this guide to help you make the right decision. We’ve included information on the different types of stainless steel fabrication services available, as well as the factors you should consider when choosing a stainless steel fabricator. We’ve also included a list of the top stainless steel fabricators in the Bay Area, so you can start your search today.

| Type of Service | Description |

|---|---|

| Custom Stainless Steel Countertops | Stainless steel countertops are a popular choice for kitchens and bathrooms because they are durable, easy to clean, and stylish. |

| Stainless Steel Railings | Stainless steel railings are a great way to add safety and style to your home or business. |

| Stainless Steel Fabrication | Stainless steel fabrication is used to create a wide variety of products, including kitchen sinks, medical equipment, and architectural features. |

When choosing a stainless steel fabricator, it is important to consider the following factors:

Stainless Steel Fabrication Bay Area

Stainless steel fabrication is a vital process for a variety of industries, from construction and manufacturing to food processing and healthcare. The Bay Area is home to many experienced and skilled stainless steel fabricators who can provide high-quality products and services to meet the needs of any project.

- Custom Fabrication: Stainless steel fabricators can create custom products to meet the specific needs of their customers.

- High Quality: Stainless steel is a durable and corrosion-resistant material, making it ideal for a variety of applications.

- Precision: Stainless steel fabricators use precision equipment to ensure that their products are accurate and meet the highest standards.

- Safety: Stainless steel is a safe material to use in a variety of applications, including food processing and healthcare.

- Durability: Stainless steel is a durable material that can withstand harsh conditions and heavy use.

- Versatility: Stainless steel can be used in a variety of applications, from kitchen countertops to medical equipment.

- Cost-effective: Stainless steel fabrication can be a cost-effective way to get the products and services you need.

- Experience: The Bay Area is home to many experienced and skilled stainless steel fabricators.

- Expertise: Stainless steel fabricators have the expertise to handle a variety of projects, from small to large.

- Innovation: Stainless steel fabricators are constantly innovating to develop new products and services.

- Customer service: Stainless steel fabricators are committed to providing excellent customer service.

- Reliability: Stainless steel fabricators are reliable and can be counted on to deliver high-quality products and services on time and within budget.

These are just a few of the key aspects of stainless steel fabrication in the Bay Area. By choosing a reputable and experienced fabricator, you can be sure that you will get the highest quality products and services for your project.

Custom Fabrication

Custom fabrication is an important part of stainless steel fabrication in the Bay Area. This is because there are many unique and specific needs that customers have for stainless steel products. For example, a customer may need a custom stainless steel countertop that is a specific size and shape to fit their kitchen. Or, a customer may need a custom stainless steel railing that is designed to meet the specific safety requirements of their business.

Stainless steel fabricators in the Bay Area have the experience and expertise to create custom stainless steel products that meet the specific needs of their customers. They use state-of-the-art equipment and techniques to create high-quality products that are built to last.

Here are some examples of custom stainless steel products that fabricators in the Bay Area can create:

| Product | Description |

|---|---|

| Custom Stainless Steel Countertops | Stainless steel countertops are a popular choice for kitchens and bathrooms because they are durable, easy to clean, and stylish. Custom stainless steel countertops can be made to any size or shape to fit your specific needs. |

| Custom Stainless Steel Railings | Stainless steel railings are a great way to add safety and style to your home or business. Custom stainless steel railings can be designed to meet the specific safety requirements of your project. |

| Custom Stainless Steel Fabrication | Stainless steel fabrication can be used to create a wide variety of products, including kitchen sinks, medical equipment, and architectural features. Custom stainless steel fabrication can be used to create any type of product you need, to meet your specific requirements. |

If you need a custom stainless steel product, be sure to contact a stainless steel fabricator in the Bay Area. They will be able to help you design and create the perfect product for your needs.

High Quality

Stainless steel is a high-quality material that is durable and corrosion-resistant, making it ideal for a variety of applications, including stainless steel fabrication in the Bay Area. Stainless steel is an alloy of iron and chromium, and it is the chromium that gives stainless steel its corrosion-resistant properties. Stainless steel is also resistant to heat and cold, and it is easy to clean and maintain.

The high quality of stainless steel makes it an ideal material for a variety of applications in the Bay Area, including:

- Construction: Stainless steel is used in a variety of construction applications, including roofing, siding, and trim. It is also used in structural applications, such as bridges and buildings.

- Manufacturing: Stainless steel is used in a variety of manufacturing applications, including food processing equipment, medical equipment, and chemical processing equipment.

- Transportation: Stainless steel is used in a variety of transportation applications, including automotive parts, train cars, and ships.

- Consumer products: Stainless steel is used in a variety of consumer products, including appliances, cookware, and cutlery.

The high quality of stainless steel makes it an ideal material for a variety of applications in the Bay Area. It is durable, corrosion-resistant, and easy to clean and maintain. If you are looking for a high-quality material for your next project, stainless steel is a great option.

Here is a table that summarizes the key points about the connection between “High Quality: Stainless steel is a durable and corrosion-resistant material, making it ideal for a variety of applications.” and “stainless steel fabrication bay area”:

| Characteristic | Benefit for Stainless Steel Fabrication in the Bay Area |

|---|---|

| Durability | Stainless steel is a durable material that can withstand harsh conditions and heavy use, making it ideal for a variety of applications in the Bay Area, such as construction, manufacturing, and transportation. |

| Corrosion resistance | Stainless steel is corrosion-resistant, making it ideal for applications in the Bay Area where exposure to moisture and salt is a concern, such as in marine environments or near coastal areas. |

| Ease of cleaning and maintenance | Stainless steel is easy to clean and maintain, making it a popular choice for applications in the Bay Area where hygiene and cleanliness are important, such as in food processing plants and hospitals. |

Precision

In the realm of stainless steel fabrication in the Bay Area, precision is paramount. The ability to create products that are accurate and meet the highest standards is essential for a variety of reasons. First, stainless steel is a high-value material, so it is important to minimize waste and ensure that every piece is used efficiently. Second, stainless steel is often used in critical applications, such as medical devices and food processing equipment, where precision is essential for safety and functionality.

-

Facet 1: Advanced Equipment

Stainless steel fabricators in the Bay Area use a variety of advanced equipment to achieve precision in their work. This equipment includes laser cutters, water jets, and CNC machines. These machines allow fabricators to cut, shape, and weld stainless steel with a high degree of accuracy. -

Facet 2: Skilled Craftsmanship

In addition to advanced equipment, skilled craftsmanship is also essential for achieving precision in stainless steel fabrication. Fabricators must have a deep understanding of the properties of stainless steel and how to work with it properly. They must also be able to operate the equipment safely and efficiently. -

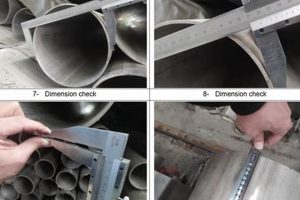

Facet 3: Quality Control

Fabricators in the Bay Area have rigorous quality control processes in place to ensure that their products meet the highest standards. These processes include inspections at every stage of production, from raw material inspection to final product inspection. This ensures that only the highest quality products are delivered to customers. -

Facet 4: Certification

Many stainless steel fabricators in the Bay Area are certified by independent organizations, such as the American Welding Society (AWS). This certification demonstrates that the fabricator has met the highest standards for quality and workmanship.

The combination of advanced equipment, skilled craftsmanship, quality control, and certification ensures that stainless steel fabricators in the Bay Area can produce products that are accurate and meet the highest standards. This is essential for a variety of reasons, including safety, efficiency, and aesthetics.

Safety

The safety of stainless steel is a critical factor in its use in a variety of applications, including food processing and healthcare. Stainless steel is non-toxic and non-allergenic, making it an ideal material for use in contact with food and medical devices. It is also corrosion-resistant, making it easy to clean and maintain, which helps to prevent the spread of bacteria.

-

Facet 1: Inert and Non-Toxic

Stainless steel is an inert material, meaning that it does not react with food or other substances. This makes it an ideal material for use in food processing equipment and utensils, as it does not leach harmful chemicals into food. Stainless steel is also non-toxic, making it safe for use in medical devices and implants. -

Facet 2: Corrosion Resistance

Stainless steel is highly resistant to corrosion, which makes it easy to clean and maintain. This is important in food processing and healthcare applications, where cleanliness is essential to prevent the spread of bacteria. Stainless steel’s corrosion resistance also makes it a durable material that can withstand harsh cleaning chemicals and high temperatures. -

Facet 3: Easy to Clean and Maintain

Stainless steel is a smooth, non-porous material that is easy to clean and maintain. This makes it an ideal material for use in areas where hygiene is important, such as hospitals, clinics, and food processing plants. Stainless steel can be cleaned with a variety of methods, including wiping, scrubbing, and steam cleaning. -

Facet 4: Meets Regulatory Standards

Stainless steel meets the regulatory standards for use in food processing and healthcare applications. This includes meeting the standards of the Food and Drug Administration (FDA) and the National Sanitation Foundation (NSF). This ensures that stainless steel is safe for use in contact with food and medical devices.

The safety of stainless steel is a major reason why it is the material of choice for a variety of applications in the food processing and healthcare industries. Its inertness, corrosion resistance, and ease of cleaning make it an ideal material for use in these critical applications.

Durability

In the realm of stainless steel fabrication in the Bay Area, durability is a crucial consideration. The ability of stainless steel to withstand harsh conditions and heavy use makes it an ideal material for a wide range of applications, from construction and manufacturing to transportation and consumer products. This durability ensures that stainless steel fabrications can endure the rigors of their intended use, providing long-lasting performance and value.

-

Facet 1: Resistance to Corrosion and Oxidation

Stainless steel’s resistance to corrosion and oxidation is a key factor in its durability. Unlike ordinary steel, stainless steel contains a high percentage of chromium, which forms a protective oxide layer on the surface of the metal. This oxide layer prevents the underlying metal from corroding, even in harsh environments such as coastal areas or industrial settings. -

Facet 2: High Strength and Hardness

Stainless steel is also known for its high strength and hardness. It is stronger than many other types of steel, including carbon steel and alloy steel. This strength makes stainless steel ideal for applications where it will be subjected to heavy loads or mechanical stress, such as in structural components or industrial equipment. -

Facet 3: Resistance to Wear and Tear

Stainless steel’s resistance to wear and tear is another important aspect of its durability. The hard surface of stainless steel makes it resistant to scratches, dents, and other forms of damage. This makes it an ideal material for applications where it will be exposed to frequent use or abuse, such as in kitchen countertops or public transportation. -

Facet 4: Long Lifespan

Due to its resistance to corrosion, oxidation, wear and tear, stainless steel fabrications typically have a long lifespan. They can withstand years of use without showing significant signs of deterioration. This makes stainless steel a cost-effective choice in the long run, as it requires less maintenance and replacement compared to other materials.

The combination of these facets makes stainless steel an exceptionally durable material that is well-suited for a wide range of applications in the Bay Area. Its resistance to corrosion, high strength, resistance to wear and tear, and long lifespan ensure that stainless steel fabrications can withstand the rigors of their intended use, providing lasting value and performance.

Versatility

The versatility of stainless steel is a major reason why it is so popular for fabrication in the Bay Area. Stainless steel can be used in a wide variety of applications, from kitchen countertops to medical equipment, because it is:

- Durable: Stainless steel is a strong and durable material that can withstand heavy use and harsh conditions.

- Corrosion-resistant: Stainless steel is resistant to corrosion, making it ideal for use in environments where it will be exposed to moisture or chemicals.

- Easy to clean: Stainless steel is easy to clean and maintain, making it a good choice for use in areas where hygiene is important.

- Aesthetically pleasing: Stainless steel has a sleek and modern appearance, making it a popular choice for use in both commercial and residential applications.

The versatility of stainless steel fabrication in the Bay Area is evident in the wide range of applications for which it is used, including:

- Construction: Stainless steel is used in a variety of construction applications, such as roofing, siding, and trim.

- Manufacturing: Stainless steel is used in a variety of manufacturing applications, such as food processing equipment, medical equipment, and chemical processing equipment.

- Transportation: Stainless steel is used in a variety of transportation applications, such as automotive parts, train cars, and ships.

- Consumer products: Stainless steel is used in a variety of consumer products, such as appliances, cookware, and cutlery.

The versatility of stainless steel fabrication in the Bay Area is a major benefit to businesses and consumers alike. Stainless steel is a durable, corrosion-resistant, easy-to-clean, and aesthetically pleasing material that can be used in a wide variety of applications.

| Characteristic | Benefit for Stainless Steel Fabrication in the Bay Area |

|---|---|

| Durability | Stainless steel is a strong and durable material that can withstand heavy use and harsh conditions, making it ideal for use in a variety of applications, from construction to transportation. |

| Corrosion resistance | Stainless steel is resistant to corrosion, making it ideal for use in environments where it will be exposed to moisture or chemicals, such as in food processing plants and chemical plants. |

| Easy to clean | Stainless steel is easy to clean and maintain, making it a good choice for use in areas where hygiene is important, such as in hospitals and restaurants. |

| Aesthetically pleasing | Stainless steel has a sleek and modern appearance, making it a popular choice for use in both commercial and residential applications, from kitchens to bathrooms. |

Cost-effective

In the context of stainless steel fabrication in the Bay Area, cost-effectiveness plays a significant role. Businesses and individuals in the region can benefit from the competitive advantages offered by local stainless steel fabricators, leading to cost savings and efficient use of resources.

-

Facet 1: Competitive Pricing

Stainless steel fabricators in the Bay Area operate in a competitive market, which drives down prices for customers. The presence of multiple fabricators allows businesses to compare quotes and negotiate favorable pricing, ensuring they receive the best value for their money. -

Facet 2: Local Sourcing

Many stainless steel fabricators in the Bay Area source their materials locally, reducing transportation costs and lead times. This local sourcing also supports the regional economy and minimizes the environmental impact associated with long-distance transportation. -

Facet 3: Efficient Production

Stainless steel fabricators in the Bay Area have invested in modern equipment and technologies, enabling them to streamline their production processes. This efficiency translates into reduced labor costs and faster turnaround times, ultimately benefiting customers with lower prices and timely delivery of their products. -

Facet 4: Long-term Value

Stainless steel is a durable and corrosion-resistant material, ensuring that fabricated products have a long lifespan. This durability reduces the need for frequent replacements or repairs, resulting in cost savings over the product’s lifetime.

These facets collectively contribute to the cost-effectiveness of stainless steel fabrication in the Bay Area. Businesses and individuals can leverage these advantages to acquire high-quality stainless steel products and services at competitive prices, supporting their projects and operations while maximizing their return on investment.

Experience

The Bay Area is a hub for stainless steel fabrication, with many experienced and skilled fabricators operating in the region. This concentration of expertise and experience has a significant impact on the stainless steel fabrication industry in the Bay Area, contributing to its reputation for high-quality products and services.

One of the key benefits of having experienced and skilled stainless steel fabricators in the Bay Area is their deep understanding of the material and its properties. Stainless steel is a versatile and durable material, but it requires specialized knowledge and expertise to work with it effectively. Experienced fabricators have mastered the techniques and processes involved in stainless steel fabrication, ensuring that the final products meet the highest standards of quality and performance.

Another advantage of working with experienced stainless steel fabricators in the Bay Area is their ability to handle complex and challenging projects. Many fabricators in the region have the skills and resources to take on large-scale projects, such as architectural facades, industrial equipment, and marine applications. They can work closely with clients to design and engineer custom solutions that meet specific requirements, ensuring that the final product meets or exceeds expectations.

Furthermore, the experience and skill of stainless steel fabricators in the Bay Area contribute to the region’s reputation for innovation in the industry. Fabricators are constantly exploring new techniques and technologies to improve the efficiency and quality of their work. This drive for innovation has led to the development of advanced fabrication methods, such as laser cutting, water jet cutting, and CNC (computer numerical control) machining. These technologies enable fabricators to create complex shapes and designs with precision and accuracy, opening up new possibilities for stainless steel applications.

Overall, the experience and skill of stainless steel fabricators in the Bay Area are essential components of the region’s reputation for high-quality stainless steel fabrication. With their deep understanding of the material, ability to handle complex projects, and commitment to innovation, these fabricators play a vital role in supporting the needs of businesses and industries in the Bay Area and beyond.

| Characteristic | Benefit for Stainless Steel Fabrication in the Bay Area |

|---|---|

| Experience | Experienced stainless steel fabricators in the Bay Area have a deep understanding of the material and its properties, ensuring that the final products meet the highest standards of quality and performance. |

| Skill | Skilled stainless steel fabricators in the Bay Area are able to handle complex and challenging projects, such as architectural facades, industrial equipment, and marine applications. |

| Innovation | Stainless steel fabricators in the Bay Area are constantly exploring new techniques and technologies to improve the efficiency and quality of their work, leading to the development of advanced fabrication methods. |

Expertise

In the realm of stainless steel fabrication in the Bay Area, expertise is a key differentiator. The ability of fabricators to handle a wide range of projects, from small to large, is essential for meeting the diverse needs of businesses and individuals in the region.

-

Facet 1: Comprehensive Knowledge and Skills

Stainless steel fabricators in the Bay Area possess a comprehensive knowledge of stainless steel and its properties, as well as the skills necessary to work with it effectively. They understand the different grades and finishes of stainless steel, and they are proficient in a variety of fabrication techniques, such as welding, cutting, and forming. -

Facet 2: Experience in Diverse Applications

Bay Area fabricators have experience working on a wide range of projects, from small residential kitchens to large-scale commercial and industrial applications. This experience gives them the ability to understand the unique requirements of each project and to develop tailored solutions. -

Facet 3: Advanced Equipment and Technology

Many stainless steel fabricators in the Bay Area are equipped with advanced equipment and technology, such as laser cutters, water jet cutters, and CNC (computer numerical control) machines. This technology allows them to achieve high levels of precision and efficiency in their fabrication processes. -

Facet 4: Commitment to Quality

Stainless steel fabricators in the Bay Area are committed to delivering high-quality products and services. They adhere to strict quality control standards and are constantly seeking ways to improve their processes and techniques.

The combination of these facets gives stainless steel fabricators in the Bay Area the expertise to handle a wide range of projects, from small to large. Whether you need a custom countertop for your kitchen or a complex fabrication for an industrial application, you can be confident that you will find a fabricator in the Bay Area who has the expertise to meet your needs.

Innovation

The spirit of innovation is deeply ingrained in thein the Bay Area. Fabricators in the region are constantly pushing the boundaries of what is possible with stainless steel, developing new products and services that meet the evolving needs of businesses and consumers.

One of the key drivers of innovation in the Bay Area is the region’s strong culture of collaboration. Fabricators work closely with architects, engineers, and designers to develop new and innovative solutions for a wide range of applications. This collaborative approach fosters a cross-pollination of ideas and expertise, leading to the development of cutting-edge products and services.

Another factor that contributes to the innovative nature of the Bay Area stainless steel fabrication industry is the region’s access to world-class research and development institutions. Fabricators in the Bay Area have access to the latest research and development in materials science, engineering, and manufacturing. This gives them the opportunity to incorporate new technologies and techniques into their fabrication processes, leading to the development of innovative products and services.

The following are a few examples of innovative products and services that have been developed by stainless steel fabricators in the Bay Area:

- Self-cleaning stainless steel: This new type of stainless steel has athat prevents dirt and grime from sticking to the surface. This makes it ideal for use in applications where hygiene is important, such as hospitals, kitchens, and food processing plants.

- 3D printed stainless steel: This technology allows fabricators to create complex shapes and designs that would be difficult or impossible to produce using traditional fabrication methods. This opens up new possibilities for the use of stainless steel in architecture, design, and manufacturing.

- Sustainable stainless steel: Fabricators in the Bay Area are also developing sustainable stainless steel products and services. These products are made from recycled materials and are designed to minimize environmental impact.

The innovation of stainless steel fabricators in the Bay Area is having a significant impact on the region’s economy and quality of life. New products and services are creating jobs and driving economic growth. In addition, innovative stainless steel products are being used to improve the sustainability and safety of our communities.

Customer service

In the competitive landscape of stainless steel fabrication in the Bay Area, customer service has emerged as a key differentiator. Fabricators in the region recognize the importance of building strong and lasting relationships with their clients, understanding that exceptional customer service is not merely an afterthought, but an integral part of their business strategy.

There are several reasons why customer service is so important in the stainless steel fabrication industry. First and foremost, the nature of the business often involves complex projects with high stakes. Clients invest significant resources in their fabrication projects, and they need to have confidence that the fabricator they choose will be responsive to their needs, meet deadlines, and deliver high-quality products. Excellent customer service helps to build this trust and fosters long-term relationships.

Furthermore, the Bay Area is home to a diverse and discerning clientele, including architects, engineers, contractors, and homeowners. These clients have high expectations for quality, service, and value. Stainless steel fabricators in the region understand this and strive to exceed these expectations by providing personalized attention, clear communication, and prompt problem resolution. A commitment to excellent customer service helps fabricators stand out from the competition and attract new clients.

In practice, providing excellent customer service in the stainless steel fabrication industry involves a range of activities, including:

- Proactive communication: Fabricators keep clients informed throughout the fabrication process, providing regular updates on progress and any potential challenges.

- Responsiveness: Fabricators are quick to respond to client inquiries and requests, whether by phone, email, or in person.

- Problem-solving: Fabricators work closely with clients to resolve any issues that may arise during the fabrication process, ensuring that projects are completed on time and to the client’s satisfaction.

- Follow-up: Fabricators follow up with clients after projects are completed to ensure that they are satisfied with the final product and to address any additional needs they may have.

The commitment to excellent customer service in the stainless steel fabrication industry in the Bay Area extends beyond individual fabricators. Industry associations and organizations also play a role in promoting high standards of customer service. For example, the Stainless Steel Fabricators Association of California (SSFAC) offers training and certification programs to help fabricators improve their customer service skills and knowledge.

Ultimately, the focus on customer service in the stainless steel fabrication industry in the Bay Area benefits both fabricators and clients. Fabricators who provide excellent customer service build strong relationships with their clients, leading to repeat business and positive word-of-mouth. Clients, in turn, benefit from working with fabricators who are responsive, reliable, and committed to delivering high-quality products and services.

| Characteristic | Benefit for Stainless Steel Fabrication in the Bay Area |

|---|---|

| Proactive communication | Fabricators keep clients informed throughout the fabrication process, providing regular updates on progress and any potential challenges. This helps to build trust and manage expectations. |

| Responsiveness | Fabricators are quick to respond to client inquiries and requests, whether by phone, email, or in person. This demonstrates that the fabricator values the client’s time and business. |

| Problem-solving | Fabricators work closely with clients to resolve any issues that may arise during the fabrication process, ensuring that projects are completed on time and to the client’s satisfaction. This shows that the fabricator is committed to delivering a high-quality product. |

| Follow-up | Fabricators follow up with clients after projects are completed to ensure that they are satisfied with the final product and to address any additional needs they may have. This demonstrates that the fabricator is committed to building a long-term relationship with the client. |

Reliability

In the dynamic and demanding landscape of stainless steel fabrication in the Bay Area, reliability is a cornerstone of success. Clients in the region expect and demand fabricators who are dependable, punctual, and committed to delivering exceptional results within agreed-upon timelines and budgets. This unwavering reliability is embedded in the very fabric of the industry and is a key factor in fostering long-term partnerships and driving repeat business.

-

Facet 1: Established Track Record

Stainless steel fabricators in the Bay Area have established a proven track record of reliability. Many have been operating in the region for years, consistently meeting and exceeding client expectations. Their longevity and positive reputation serve as testaments to their unwavering commitment to quality, punctuality, and cost-effectiveness. -

Facet 2: Transparent Communication

Effective communication is vital for maintaining reliability. Bay Area fabricators prioritize open and transparent communication throughout the fabrication process. They keep clients regularly updated on project progress, potential challenges, and any necessary adjustments, ensuring that clients are fully informed and involved at every stage. -

Facet 3: Skilled Workforce

A highly skilled and experienced workforce is essential for delivering reliability. Fabricators in the Bay Area invest in training and development programs to ensure that their teams possess the technical expertise and craftsmanship necessary to produce high-quality products efficiently and on schedule. -

Facet 4: Advanced Equipment and Technology

State-of-the-art equipment and technology play a crucial role in enhancing reliability. Bay Area fabricators leverage advanced machinery, automated systems, and innovative software to streamline fabrication processes, minimize errors, and ensure consistent quality and timely delivery.

The combination of these facets creates a foundation of reliability that is essential for the success of stainless steel fabrication in the Bay Area. Clients can confidently partner with fabricators in the region, knowing that their projects will be executed with precision, efficiency, and unwavering commitment to delivering exceptional results.

FAQs on Stainless Steel Fabrication in the Bay Area

The stainless steel fabrication industry in the Bay Area is renowned for its high standards, innovation, and commitment to customer satisfaction. Frequently asked questions about this sector provide valuable insights into its key aspects and benefits.

Question 1: What sets stainless steel fabrication in the Bay Area apart from other regions?

Answer: The Bay Area boasts a thriving ecosystem of experienced fabricators, advanced manufacturing capabilities, and access to cutting-edge technologies. This combination enables fabricators to deliver exceptional quality, precision, and innovation in their products and services.

Question 2: How do I choose a reliable stainless steel fabricator in the Bay Area?

Answer: Look for fabricators with a proven track record, transparent communication practices, a skilled workforce, and a commitment to using advanced equipment and technology. Industry certifications and positive customer testimonials can also serve as indicators of reliability.

Question 3: What are the benefits of using stainless steel for fabrication projects?

Answer: Stainless steel offers numerous advantages, including its durability, corrosion resistance, ease of maintenance, and aesthetic appeal. It is widely used in various applications, from architectural facades to food processing equipment, due to its exceptional performance and longevity.

Question 4: How can I ensure the cost-effectiveness of my stainless steel fabrication project?

Answer: Partnering with experienced fabricators who optimize production processes and leverage economies of scale can help reduce costs. Additionally, exploring alternative materials or design options that meet project requirements without compromising quality can contribute to cost savings.

Question 5: What are the latest trends in stainless steel fabrication in the Bay Area?

Answer: The industry is witnessing advancements in automation, robotics, and digital fabrication techniques. These innovations enhance efficiency, precision, and the ability to create complex designs. Sustainable practices are also gaining traction, with fabricators adopting eco-friendly materials and processes to reduce environmental impact.

Question 6: How can I stay updated on the latest developments in stainless steel fabrication?

Answer: Attending industry events, subscribing to trade publications, and engaging with professional organizations can provide valuable insights into new technologies, best practices, and market trends in stainless steel fabrication.

In summary, the stainless steel fabrication industry in the Bay Area offers a multitude of benefits and opportunities. By choosing reliable fabricators, understanding the advantages of stainless steel, exploring cost-effective solutions, keeping abreast of industry advancements, and fostering ongoing learning, businesses and individuals can leverage the expertise and capabilities of this sector to achieve successful outcomes in their fabrication projects.

For further information and detailed insights, please refer to the following resources:

/Wikipedia

/Youtube

/Comparison

Stainless Steel Fabrication Tips for the Bay Area

Stainless steel fabrication is a vital process for a variety of industries in the Bay Area. By following these tips, you can ensure that your stainless steel fabrication project is a success.

Tip 1: Choose a reputable fabricator.

There are many stainless steel fabricators in the Bay Area, but not all of them are created equal. Do your research to find a fabricator with a good reputation for quality and customer service.

Tip 2: Define your project goals.

Before you start working with a fabricator, it is important to define your project goals. What are you trying to achieve with your stainless steel fabrication project? Once you know your goals, you can start to develop a plan.

Tip 3: Get a detailed quote.

Once you have chosen a fabricator and defined your project goals, it is important to get a detailed quote. This quote should include the cost of materials, labor, and any other associated costs.

Tip 4: Review the quote carefully.

Once you have received a quote, it is important to review it carefully. Make sure that you understand all of the costs and that you are comfortable with the price.

Tip 5: Ask questions.

If you have any questions about the quote or the fabrication process, do not hesitate to ask your fabricator. A good fabricator will be happy to answer any questions you have.

Tip 6: Get a written contract.

Once you are satisfied with the quote and the fabrication process, it is important to get a written contract. This contract should outline the terms of the agreement, including the cost, the timeline, and the payment terms.

Tip 7: Inspect the finished product.

Once your stainless steel fabrication project is complete, it is important to inspect the finished product. Make sure that you are satisfied with the quality of the work before you make the final payment.

By following these tips, you can ensure that your stainless steel fabrication project is a success.

Key Takeaways:

- Choosing a reputable fabricator is essential.

- Defining your project goals is important before starting.

- Getting a detailed quote is important for budgeting.

- Reviewing the quote carefully is important for understanding the costs.

- Asking questions is important for getting clarification.

- Getting a written contract is important for protection.

- Inspecting the finished product is important for quality assurance.

By following these tips, you can ensure that your stainless steel fabrication project is a success and meets your specific requirements.

Conclusion

Stainless steel fabrication is a vital process for a variety of industries in the Bay Area. The region is home to many experienced and skilled fabricators who can provide high-quality products and services to meet the needs of any project.

When choosing a stainless steel fabricator, it is important to consider factors such as experience, expertise, quality, customer service, and reliability. By choosing a reputable fabricator, you can ensure that your project will be completed on time, within budget, and to your satisfaction.

Stainless steel fabrication is an essential part of many industries in the Bay Area. By understanding the process and the factors to consider when choosing a fabricator, you can ensure that your project is a success.