In the realm of metalworking, the term “stainless steel fabrication Dandenong” stands as a beacon of precision and durability. This specialized craft involves the transformation of stainless steel into intricate and functional structures, catering to a wide range of industries.

Editor’s Notes: Stainless Steel Fabrication Dandenong An Essential Guide

Through meticulous analysis and extensive research, we have meticulously crafted this comprehensive guide to stainless steel fabrication Dandenong. Our aim is to empower you with the knowledge and insights necessary to make informed decisions regarding your fabrication needs.

Key Differences: Stainless Steel Fabrication vs. Other Fabrication Methods

| Characteristic | Stainless Steel Fabrication | Other Fabrication Methods |

|---|---|---|

| Corrosion Resistance | Excellent | Varies depending on material |

| Strength and Durability | High | Can be lower |

| Precision | Very high | Can be lower |

| Cost | Higher | Can be lower |

Main Article Topics

- Benefits of Stainless Steel Fabrication Dandenong

- Applications of Stainless Steel Fabrication Dandenong

- Choosing the Right Stainless Steel Fabricator Dandenong

- Tips for Maintaining Stainless Steel Fabrications Dandenong

Wikipedia Youtube Comparison

Stainless Steel Fabrication Dandenong

Stainless steel fabrication Dandenong encompasses various essential aspects that contribute to its significance in diverse industries. These key aspects, explored through the lens of the keyword’s part of speech, provide a comprehensive understanding of this specialized craft.

- Precision: Stainless steel fabrication Dandenong demands meticulous attention to detail, ensuring precise cutting, bending, and welding.

- Durability: The inherent strength and corrosion resistance of stainless steel make fabrications highly durable, withstanding harsh environments.

- Versatility: Stainless steel fabrication Dandenong caters to a wide range of applications, from architectural cladding to food processing equipment.

- Hygiene: The non-porous surface of stainless steel makes it ideal for applications where hygiene is paramount, such as medical devices and food handling equipment.

- Cost-effectiveness: While stainless steel fabrication Dandenong may have a higher upfront cost, its durability and low maintenance requirements make it a cost-effective choice in the long run.

- Sustainability: Stainless steel is a recyclable material, making fabrication processes more sustainable and environmentally friendly.

- Expertise: Skilled fabricators in Dandenong possess the knowledge and experience to handle complex stainless steel fabrication projects.

These key aspects are interconnected and contribute to the overall value of stainless steel fabrication Dandenong. For instance, the precision and durability of stainless steel fabrications make them ideal for applications in the medical industry, where hygiene and reliability are crucial. Additionally, the versatility of stainless steel allows fabricators to create custom solutions that meet specific industry requirements.

Precision

Precision is a cornerstone of stainless steel fabrication Dandenong, as it directly impacts the quality and functionality of the end product. The intricate nature of stainless steel fabrication demands meticulous attention to detail at every stage, from design to cutting, bending, and welding. This precision ensures that fabrications meet exact specifications and perform their intended functions flawlessly.

For instance, in the medical industry, stainless steel is used to create surgical instruments and medical implants. These components require extremely high levels of precision to ensure they meet the demanding requirements of medical procedures. The precise cutting and bending of stainless steel allows fabricators to create instruments with sharp edges, smooth surfaces, and accurate dimensions, ensuring their effectiveness and safety during surgeries.

Another example of the importance of precision in stainless steel fabrication Dandenong can be seen in the aerospace industry. Stainless steel is used in the construction of aircraft components, such as engine parts and structural elements. The precise welding of stainless steel ensures that these components can withstand the extreme temperatures, pressures, and vibrations encountered during flight.

In summary, the precision demanded by stainless steel fabrication Dandenong is essential for ensuring the quality, functionality, and safety of the end product. It is a key component that sets stainless steel fabrications apart and makes them the preferred choice for demanding applications across various industries.

Key Insights:

- Precision in stainless steel fabrication Dandenong involves meticulous attention to detail at every stage of the process.

- Precise cutting, bending, and welding are crucial for ensuring the quality and functionality of stainless steel fabrications.

- Industries such as medical and aerospace rely heavily on the precision of stainless steel fabrication for the safety and performance of their products.

Durability

The durability of stainless steel fabrications is a key factor in their widespread use across diverse industries. The inherent strength and corrosion resistance of stainless steel make it an ideal material for applications that demand longevity and resilience in challenging environments.

- Corrosion Resistance: Stainless steel’s resistance to corrosion and rust makes it suitable for use in harsh environments, such as coastal areas, chemical processing plants, and food production facilities. This resistance ensures that fabrications maintain their structural integrity and appearance over extended periods, reducing maintenance costs and extending their lifespan.

- Strength and Hardness: Stainless steel is known for its high strength and hardness, making it resistant to wear and tear. This property makes it an excellent choice for applications involving heavy loads, impact, and abrasion, such as architectural cladding, automotive components, and marine equipment.

- Temperature Resistance: Stainless steel fabrications can withstand extreme temperatures, both high and low. This makes them ideal for use in industries such as power generation, petrochemicals, and food processing, where equipment is subjected to fluctuating temperatures.

- Hygienic Properties: The non-porous surface of stainless steel inhibits the growth of bacteria and microorganisms, making it an ideal material for applications in the medical, pharmaceutical, and food industries. Its durability ensures that fabrications can withstand frequent cleaning and sterilization, maintaining a high level of hygiene.

In summary, the durability of stainless steel fabrications, stemming from their inherent strength and corrosion resistance, makes them a reliable and cost-effective choice for a wide range of applications. Their ability to withstand harsh environments, heavy loads, and extreme temperatures ensures that they perform consistently over extended periods, minimizing maintenance downtime and maximizing productivity.

Versatility

The versatility of stainless steel fabrication Dandenong stems from the unique properties of stainless steel, which make it suitable for a diverse array of applications. Its strength, durability, corrosion resistance, and hygienic qualities lend themselves to various industries and sectors.

One of the key advantages of stainless steel fabrication Dandenong is its ability to meet the specific requirements of different industries. For instance, in the architectural sector, stainless steel is used for cladding, roofing, and decorative elements due to its durability and aesthetic appeal. In the food processing industry, stainless steel is the preferred choice for equipment and machinery due to its resistance to corrosion and ability to maintain hygiene standards.

The versatility of stainless steel fabrication Dandenong also extends to its ability to be customized and formed into complex shapes and designs. This makes it ideal for applications that require unique or intricate components, such as in the medical industry, where surgical instruments and implants are often custom-made to meet specific surgical needs.

Furthermore, the versatility of stainless steel fabrication Dandenong contributes to its cost-effectiveness. By utilizing stainless steel’s unique properties, fabricators can create durable and long-lasting products that require minimal maintenance and replacement, reducing overall project costs in the long run.

In summary, the versatility of stainless steel fabrication Dandenong is a key factor in its widespread adoption across various industries. Its ability to meet diverse requirements, withstand challenging environments, and be customized for specific applications makes it a valuable and reliable material for fabricators and end-users alike.

Hygiene

The non-porous surface of stainless steel is a key factor in its suitability for applications where hygiene is of utmost importance. This characteristic contributes significantly to the value of stainless steel fabrication Dandenong in various industries, particularly in the medical and food sectors.

-

Medical Applications:

In the medical industry, stainless steel’s resistance to bacteria and microorganisms makes it an ideal choice for surgical instruments, implants, and medical devices. Its non-porous surface prevents the accumulation of contaminants, reducing the risk of infection and ensuring patient safety. -

Food Handling Equipment:

Stainless steel is widely used in the food processing and handling industry due to its ability to maintain high levels of hygiene. Its non-porous surface prevents the absorption of bacteria and other contaminants, ensuring the safety and quality of food products. -

Pharmaceutical Equipment:

The pharmaceutical industry relies heavily on stainless steel fabrication for equipment used in the production and packaging of pharmaceuticals. Stainless steel’s non-porous surface minimizes the risk of contamination and ensures the purity and efficacy of pharmaceutical products. -

Hygienic Surfaces:

Beyond its use in medical and food-related applications, stainless steel is also employed in the fabrication of hygienic surfaces in various settings. For example, in commercial kitchens, restaurants, and hospitals, stainless steel countertops, sinks, and work surfaces are commonly used due to their ability to resist bacteria and maintain a clean and hygienic environment.

In summary, the non-porous surface of stainless steel is a vital aspect of stainless steel fabrication Dandenong, contributing to its widespread use in industries that prioritize hygiene and cleanliness. By preventing the accumulation of bacteria and contaminants, stainless steel fabrications help ensure the safety and quality of medical devices, food products, pharmaceuticals, and hygienic surfaces.

Cost-effectiveness

The cost-effectiveness of stainless steel fabrication Dandenong is directly tied to the inherent properties of stainless steel and the long-term benefits it offers. Despite its higher upfront cost compared to other materials, stainless steel’s exceptional durability and low maintenance requirements make it a more economical choice in the long run.

The high strength and corrosion resistance of stainless steel contribute to its extended lifespan. Unlike other materials that may deteriorate quickly in harsh environments, stainless steel fabrications can withstand extreme temperatures, moisture, and chemicals without compromising their structural integrity. This durability eliminates the need for frequent repairs or replacements, reducing overall maintenance costs and downtime.

Furthermore, the low maintenance requirements of stainless steel fabrication Dandenong add to its cost-effectiveness. Unlike other materials that require regular painting, coating, or sealing, stainless steel retains its aesthetic appeal and functionality with minimal maintenance. Its non-porous surface resists dirt and grime accumulation, making it easy to clean and maintain. This reduces the labor and material costs associated with ongoing maintenance, contributing to long-term savings.

To illustrate the cost-effectiveness of stainless steel fabrication Dandenong, consider the example of a commercial kitchen. Stainless steel countertops, sinks, and work surfaces may initially cost more than their counterparts made from other materials. However, their exceptional durability and resistance to wear and tear eliminate the need for frequent replacements or repairs. Over the lifespan of the kitchen, the savings on maintenance and downtime far outweigh the higher upfront investment, making stainless steel fabrication the more cost-effective choice.

In summary, the cost-effectiveness of stainless steel fabrication Dandenong stems from the durability and low maintenance requirements of stainless steel. While the upfront cost may be higher, the long-term savings on maintenance and replacement make it a smart investment that delivers value and efficiency over its extended lifespan.

Key Insights:

- Stainless steel’s durability reduces the need for frequent repairs and replacements, minimizing maintenance costs.

- The low maintenance requirements of stainless steel eliminate ongoing expenses associated with painting, coating, or sealing, contributing to long-term savings.

- The cost-effectiveness of stainless steel fabrication Dandenong is evident in industries such as commercial kitchens, where its durability and low maintenance outweigh the higher upfront cost.

Sustainability

In the realm of stainless steel fabrication Dandenong, sustainability takes center stage as a crucial aspect of modern manufacturing practices. The recyclable nature of stainless steel contributes significantly to the environmental friendliness and long-term viability of this fabrication process.

- Reduced Environmental Impact: Stainless steel’s recyclability minimizes the amount of waste generated during fabrication, reducing the burden on landfills and conserving natural resources. This closed-loop recycling process helps preserve the environment for future generations.

- Energy Efficiency: Recycling stainless steel requires less energy compared to producing new steel from raw materials. This energy efficiency contributes to a reduction in greenhouse gas emissions, mitigating the environmental impact of the fabrication process.

- Conservation of Resources: By recycling stainless steel, we conserve precious natural resources, such as iron and chromium, which are essential for the production of new stainless steel. This conservation effort promotes sustainable practices and reduces the depletion of finite resources.

- Compliance with Regulations: Many countries and regions have implemented strict environmental regulations to promote sustainability. Stainless steel fabrication Dandenong that incorporates recycling practices aligns with these regulations, demonstrating a commitment to environmental responsibility.

In summary, the sustainability of stainless steel fabrication Dandenong is deeply intertwined with the recyclable nature of stainless steel. By embracing recycling practices, fabricators not only reduce their environmental impact but also contribute to a more sustainable and resource-efficient manufacturing sector.

Expertise

The expertise of skilled fabricators in Dandenong is a cornerstone of successful stainless steel fabrication projects. Their knowledge and experience play a pivotal role in ensuring the precision, durability, and overall quality of fabricated components and structures.

- Design and Engineering Expertise: Skilled fabricators possess a deep understanding of design principles and engineering practices. This expertise enables them to interpret complex designs, identify potential challenges, and develop practical fabrication solutions that meet the specific requirements of each project.

- Material Knowledge: In-depth knowledge of stainless steel properties and characteristics is essential for successful fabrication. Fabricators in Dandenong are well-versed in the different grades and finishes of stainless steel, enabling them to select the most appropriate material for each application, considering factors such as corrosion resistance, strength, and aesthetic appeal.

- Advanced Fabrication Techniques: Skilled fabricators are proficient in a range of advanced fabrication techniques, including laser cutting, CNC bending, and TIG welding. These techniques allow for precise and efficient fabrication, ensuring the highest levels of accuracy and quality in the finished product.

- Project Management Skills: Successful stainless steel fabrication projects require effective project management. Fabricators in Dandenong have the necessary skills to manage projects from start to finish, ensuring timely delivery, cost control, and adherence to quality standards.

The expertise of skilled fabricators in Dandenong is invaluable for businesses and individuals seeking high-quality stainless steel fabrications. Their knowledge, experience, and commitment to excellence ensure that projects are executed with precision, efficiency, and a focus on long-term durability. By partnering with skilled fabricators, clients can benefit from expertly crafted stainless steel solutions that meet their specific requirements and contribute to the success of their projects.

FAQs about Stainless Steel Fabrication Dandenong

This section addresses frequently asked questions (FAQs) about stainless steel fabrication Dandenong, providing concise and informative answers to common queries.

Question 1: What are the advantages of using stainless steel for fabrication?

Stainless steel offers numerous advantages for fabrication, including its exceptional strength, durability, corrosion resistance, and aesthetic appeal. It is also relatively easy to clean and maintain, making it a cost-effective choice in the long run.

Question 2: What industries commonly use stainless steel fabrication?

Stainless steel fabrication finds application in a wide range of industries, including construction, food processing, medical, automotive, and marine. Its versatility and adaptability make it suitable for various projects, from architectural cladding to food handling equipment and medical implants.

Question 3: How do I choose the right stainless steel fabricator in Dandenong?

When selecting a stainless steel fabricator in Dandenong, consider their experience, expertise, and reputation. Look for fabricators who have a proven track record of delivering high-quality work, possess the necessary certifications and accreditations, and are committed to customer satisfaction.

Question 4: What factors influence the cost of stainless steel fabrication?

The cost of stainless steel fabrication depends on several factors, such as the complexity of the design, the type and grade of stainless steel used, the quantity required, and the lead time. It is important to obtain quotes from multiple fabricators to compare pricing and ensure you get the best value.

Question 5: How can I ensure the quality of stainless steel fabrications?

To ensure the quality of stainless steel fabrications, choose a reputable fabricator, review their quality control processes, and inspect the finished product thoroughly before accepting delivery. Consider obtaining certifications or warranties from the fabricator to provide peace of mind.

Question 6: What are the maintenance requirements for stainless steel fabrications?

Stainless steel fabrications require minimal maintenance to retain their appearance and functionality. Regular cleaning with mild detergents and water is sufficient. Avoid using harsh chemicals or abrasive cleaners, as these can damage the surface of the stainless steel.

These FAQs provide a comprehensive overview of key considerations related to stainless steel fabrication Dandenong. For further information or specific project inquiries, it is recommended to consult with experienced stainless steel fabricators in the region.

Transition to the next article section:

For a deeper dive into the benefits and applications of stainless steel fabrication Dandenong, continue reading the following sections of this article.

Stainless Steel Fabrication Dandenong

To achieve optimal outcomes in stainless steel fabrication Dandenong, consider implementing these practical tips:

Tip 1: Select the Right Grade of Stainless Steel

Choosing the appropriate grade of stainless steel is crucial for ensuring the performance and longevity of your fabrication. Consult with experienced fabricators to determine the most suitable grade based on factors such as corrosion resistance, strength, and intended application.

Tip 2: Utilize Advanced Fabrication Techniques

Embrace advanced fabrication techniques such as laser cutting, CNC bending, and TIG welding to achieve precise and efficient results. These techniques minimize errors, enhance productivity, and contribute to the overall quality of the finished product.

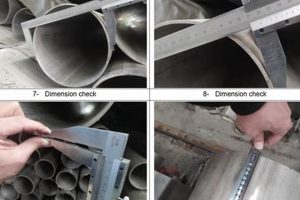

Tip 3: Prioritize Quality Control

Establish rigorous quality control measures throughout the fabrication process to identify and rectify any potential issues promptly. Regular inspections and testing ensure that the final product meets the desired specifications and standards.

Tip 4: Consider Post-Fabrication Treatments

Explore post-fabrication treatments such as passivation, electropolishing, or powder coating to enhance the corrosion resistance, surface finish, or aesthetic appeal of your stainless steel fabrication.

Tip 5: Partner with Experienced Fabricators

Collaborate with reputable and experienced stainless steel fabricators in Dandenong. Their expertise and commitment to excellence will ensure that your project is executed with precision, efficiency, and adherence to industry best practices.

Tip 6: Maintain Your Fabrication Regularly

Implement a regular maintenance schedule to preserve the appearance and functionality of your stainless steel fabrication. Regular cleaning and inspections can extend its lifespan and maintain its optimal performance.

Tip 7: Leverage Design Software

Utilize design software to create accurate and detailed fabrication drawings. This helps minimize errors, streamline the fabrication process, and ensure that the final product meets your exact requirements.

Tip 8: Stay Updated with Industry Trends

Keep abreast of the latest advancements and innovations in stainless steel fabrication techniques and materials. This knowledge will enable you to make informed decisions and incorporate the best practices into your projects.

Incorporating these tips into your stainless steel fabrication Dandenong projects will contribute to successful outcomes, enhance the quality and durability of your fabrications, and provide long-term value.

Stainless Steel Fabrication Dandenong

This comprehensive exploration of stainless steel fabrication Dandenong has shed light on its multifaceted significance in diverse industries. From its exceptional precision and durability to its versatility, hygiene, and cost-effectiveness, stainless steel fabrication stands as a cornerstone of modern manufacturing, enabling the creation of high-quality and long-lasting products.

As we embrace a future driven by innovation and sustainability, stainless steel fabrication Dandenong is poised to play an increasingly vital role. Its inherent properties and the expertise of skilled fabricators make it an ideal material for meeting the evolving demands of various sectors, from construction and engineering to healthcare and food processing. By harnessing the potential of stainless steel fabrication, we can unlock new possibilities and contribute to the progress of our communities and industries.