When it comes to your industry, is stainless steel pipe coil fabrication something you’re curious about?

Editor’s Notes: Stainless steel pipe coil fabrication is a crucial element of various industries, offering exceptional benefits that enhance performance and efficiency. Understanding its significance can empower businesses to make informed decisions and optimize their operations.

After extensive research and analysis, we’ve compiled this comprehensive guide to provide valuable insights into stainless steel pipe coil fabrication. Our goal is to equip our readers with the knowledge they need to navigate this topic confidently and make informed choices.

Key Differences or Key Takeaways:

Transition to main article topics:

Stainless Steel Pipe Coil Fabrication

In the realm of industrial applications, stainless steel pipe coil fabrication stands as a cornerstone, underpinning a multitude of critical processes. Delving into its intricacies, we uncover seven key aspects that define its significance:

- Durability: Stainless steel’s exceptional resistance to corrosion and wear ensures longevity in demanding environments.

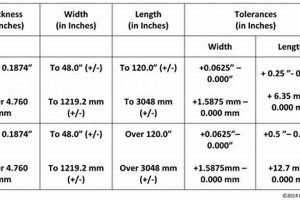

- Precision: Fabrication techniques enable precise shaping and bending, accommodating complex designs and tight tolerances.

- Hygiene: The non-porous surface of stainless steel inhibits bacterial growth, making it ideal for sanitary applications.

- Versatility: Pipe coils can be customized to suit diverse flow rates, pressures, and temperatures.

- Efficiency: Optimized designs minimize pressure drops and enhance heat transfer, maximizing energy efficiency.

- Cost-effectiveness: While stainless steel may have a higher initial cost, its durability and low maintenance requirements offer long-term savings.

- Sustainability: Stainless steel is recyclable, contributing to environmental conservation and reducing waste.

These key aspects intertwine to elevate stainless steel pipe coil fabrication beyond a mere manufacturing process. They represent a commitment to quality, efficiency, and sustainability, enabling industries to optimize their operations and achieve lasting success.

Durability

In the realm of stainless steel pipe coil fabrication, durability takes center stage. The exceptional resistance of stainless steel to corrosion and wear empowers these coils to withstand the rigors of demanding environments, ensuring longevity and uninterrupted performance.

- Resistance to Corrosion: Stainless steel’s composition, rich in chromium, forms a protective oxide layer that shields the metal from corrosion. This resistance is particularly crucial in applications involving exposure to moisture, acids, or corrosive chemicals, preventing premature degradation and maintaining structural integrity.

- Resistance to Wear: The inherent hardness and toughness of stainless steel endow pipe coils with exceptional resistance to wear and abrasion. This resilience is vital in applications involving high-velocity flows, abrasive particles, or frequent movement, preventing erosion and maintaining flow efficiency.

- Extended Lifespan: The combined resistance to corrosion and wear translates into an extended lifespan for stainless steel pipe coils. Unlike ordinary steel or other materials, stainless steel coils can endure harsh conditions without compromising their structural integrity or performance, minimizing maintenance requirements and maximizing operational uptime.

- Reliability in Extreme Environments: Stainless steel pipe coils excel in extreme environments, where other materials may falter. Their resistance to corrosion and wear ensures reliable performance in applications exposed to extreme temperatures, harsh chemicals, or abrasive conditions, reducing the risk of breakdowns and ensuring consistent operation.

In summary, the exceptional durability of stainless steel pipe coils, stemming from their resistance to corrosion and wear, is a key factor in their extensive adoption across various industries. This durability translates into longevity, reliability, and reduced maintenance requirements, making stainless steel pipe coils an investment in efficiency and long-term performance.

Precision

In the realm of stainless steel pipe coil fabrication, precision reigns supreme. Specialized fabrication techniques empower manufacturers to achieve precise shaping and bending, accommodating complex designs and adhering to stringent tolerances. This precision is of paramount importance, as it directly influences the performance, efficiency, and reliability of the final product.

The ability to shape and bend stainless steel pipes with precision enables the creation of intricate configurations, customized to meet specific application requirements. Complex geometries, such as spirals, helices, and serpentine coils, can be fabricated with accuracy, ensuring optimal flow dynamics and heat transfer efficiency. Moreover, tight tolerances ensure seamless integration with other system components, minimizing leaks and maximizing system integrity.

Precision in stainless steel pipe coil fabrication translates into tangible benefits:

- Enhanced Performance: Precisely shaped and bent coils optimize fluid flow, reduce pressure drops, and improve heat transfer efficiency, leading to enhanced overall system performance.

- Increased Efficiency: Minimized turbulence and optimized flow dynamics contribute to increased energy efficiency, reducing operational costs and environmental impact.

- Improved Reliability: Precision fabrication ensures proper alignment and leak-proof connections, minimizing downtime and maintenance requirements, thus enhancing system reliability.

- Design Flexibility: The ability to accommodate complex designs opens up a wide range of application possibilities, enabling engineers to tailor solutions to specific process requirements.

In summary, precision in stainless steel pipe coil fabrication is not merely a desirable attribute but a fundamental requirement for achieving optimal performance, efficiency, and reliability. The ability to precisely shape and bend stainless steel pipes empowers manufacturers to create customized solutions that meet the unique demands of diverse industrial applications.

Hygiene

In the realm of stainless steel pipe coil fabrication, hygiene takes center stage. The non-porous surface of stainless steel presents a formidable barrier against bacterial growth, rendering it an ideal material for sanitary applications where maintaining cleanliness is paramount.

The absence of pores on the surface of stainless steel prevents bacteria from adhering and forming colonies. This inherent resistance to bacterial growth is crucial in industries such as food processing, pharmaceuticals, and healthcare, where hygiene is of utmost importance. Stainless steel pipe coils ensure the purity and safety of products and processes, minimizing the risk of contamination and promoting public health.

The practical significance of hygiene in stainless steel pipe coil fabrication extends beyond its role in preventing bacterial growth. It also contributes to the overall efficiency and longevity of the system. By inhibiting the formation of biofilms and scale buildup, stainless steel coils maintain optimal flow rates and heat transfer capabilities, reducing maintenance requirements and downtime.

In summary, the non-porous surface of stainless steel, which inhibits bacterial growth, is a vital component of stainless steel pipe coil fabrication. It ensures hygiene, prevents contamination, and contributes to the overall efficiency and longevity of the system, making it an indispensable choice for sanitary applications.

Versatility

The versatility of stainless steel pipe coils is a cornerstone of their extensive adoption across various industries. This adaptability stems from the unique properties of stainless steel and the precision fabrication techniques employed in their . Pipe coils can be customized to meet specific requirements, accommodating diverse flow rates, pressures, and temperatures, making them a highly sought-after solution for a wide range of applications.

The ability to tailor pipe coils to specific flow rates is crucial in optimizing system performance. By carefully calculating the coil’s dimensions, the number of turns, and the pipe diameter, engineers can ensure that the coil provides the necessary pressure drop and flow rate to meet the demands of the process. This customization ensures efficient fluid flow, minimizes energy consumption, and optimizes overall system performance.

Similarly, the ability to withstand varying pressures is essential in many industrial applications. Stainless steel pipe coils can be fabricated to handle high pressures without compromising their structural integrity. The thickness of the pipe wall and the design of the coil can be adjusted to meet specific pressure requirements, ensuring safe and reliable operation even under demanding conditions.

Temperature resistance is another critical aspect of pipe coil versatility. Stainless steel exhibits excellent resistance to high temperatures, making it suitable for applications involving heat transfer or high-temperature fluids. The ability to customize the coil’s dimensions and materials allows engineers to design coils that can withstand extreme temperatures without losing their structural integrity or compromising their performance.

In summary, the versatility of stainless steel pipe coils, enabled by their customizable design and fabrication, makes them an indispensable component in a wide range of industrial applications. Their ability to adapt to diverse flow rates, pressures, and temperatures empowers engineers to design systems that are tailored to specific process requirements, maximizing performance, efficiency, and reliability.

Table: Practical Applications of Pipe Coil Versatility

| Industry | Application | Customization Requirements |

|---|---|---|

| Chemical Processing | Heat Exchangers | High-pressure, high-temperature coils with specific flow rates for efficient heat transfer |

| Power Generation | Boiler Coils | Coils designed to withstand high pressures and temperatures, while accommodating specific flow rates for optimal steam generation |

| HVAC | Condenser and Evaporator Coils | Coils customized to match the required cooling or heating capacity, flow rates, and pressure drops for efficient temperature control |

| Petrochemical | Reaction Vessels | Coils designed to handle corrosive fluids, withstand high pressures, and provide precise temperature control for chemical reactions |

| Food and Beverage | Pasteurizers and Sterilizers | Coils fabricated to meet sanitary standards, withstand high temperatures, and ensure precise temperature control for food preservation |

Efficiency

In the realm of stainless steel pipe coil fabrication, efficiency takes center stage. The inherent properties of stainless steel, coupled with optimized designs, enable the creation of pipe coils that minimize pressure drops and enhance heat transfer, leading to maximized energy efficiency.

- Reduced Pressure Drops: Optimized designs incorporate strategic coil configurations and sizing to minimize pressure drops as the fluid flows through the coil. This reduction in pressure drop translates into lower energy consumption by pumps or compressors, resulting in significant cost savings over the lifespan of the system.

- Enhanced Heat Transfer: The high thermal conductivity of stainless steel, combined with optimized coil geometry, facilitates efficient heat transfer. The increased surface area and optimized flow patterns promote greater heat exchange, leading to improved thermal performance and reduced energy consumption.

- Compact Designs: By leveraging the strength and flexibility of stainless steel, pipe coils can be designed in compact configurations without compromising performance. This compactness reduces the overall size and weight of the system, allowing for easier installation and space optimization.

- Corrosion Resistance: The exceptional corrosion resistance of stainless steel ensures that the optimized designs are not compromised over time. The absence of corrosion and fouling maintains the coil’s efficiency and performance, reducing maintenance costs and downtime.

The combination of these factors contributes to the overall energy efficiency of stainless steel pipe coil fabrication. By minimizing pressure drops, enhancing heat transfer, and employing compact and corrosion-resistant designs, these coils deliver optimal performance while reducing energy consumption and operating costs.

Cost-effectiveness

The cost-effectiveness of stainless steel pipe coil fabrication lies in the long-term savings it offers despite its potentially higher initial cost. This cost-effectiveness stems from the exceptional durability and low maintenance requirements of stainless steel.

The durability of stainless steel ensures that pipe coils can withstand harsh operating conditions and demanding environments without compromising their structural integrity. This durability translates into a longer lifespan for the coils, reducing the frequency of replacements and associated downtime costs.

Additionally, the low maintenance requirements of stainless steel further contribute to its cost-effectiveness. The corrosion resistance of stainless steel minimizes the need for regular maintenance, such as painting or protective coatings. Its smooth surface also prevents the accumulation of dirt and debris, reducing the need for frequent cleaning.

In practical terms, the cost-effectiveness of stainless steel pipe coil fabrication can be illustrated through real-life examples. In the chemical processing industry, stainless steel coils used in heat exchangers have demonstrated a lifespan of over 15 years, significantly longer than coils made from ordinary steel. This extended lifespan, combined with minimal maintenance requirements, has resulted in substantial cost savings over the system’s lifetime.

Furthermore, the use of stainless steel pipe coils in marine applications provides another testament to their cost-effectiveness. The resistance of stainless steel to corrosion and saltwater damage ensures that coils can withstand the harsh marine environment without requiring frequent replacements or repairs. This durability and low maintenance have contributed to the widespread adoption of stainless steel pipe coils in shipbuilding and offshore applications.

Understanding the cost-effectiveness of stainless steel pipe coil fabrication is crucial for businesses looking to optimize their operations and minimize long-term expenses. By considering the durability and low maintenance requirements of stainless steel, industries can make informed decisions that lead to significant cost savings and improved return on investment.

Table: Cost-Effectiveness Analysis of Stainless Steel Pipe Coil Fabrication

| Factor | Stainless Steel | Ordinary Steel |

|---|---|---|

| Initial Cost | Higher | Lower |

| Durability | Longer lifespan | Shorter lifespan |

| Maintenance Requirements | Low | High |

| Replacement Frequency | Less frequent | More frequent |

| Total Cost of Ownership | Lower (over the lifespan) | Higher (over the lifespan) |

Sustainability

The sustainability of stainless steel holds significant implications for stainless steel pipe coil fabrication, contributing to environmental conservation and waste reduction. Understanding this connection is crucial for businesses and industries seeking to align their operations with sustainable practices.

The recyclability of stainless steel is a key factor in its sustainability. Unlike many other materials, stainless steel can be recycled repeatedly without losing its inherent properties. This closed-loop recycling process significantly reduces the need for raw material extraction and minimizes the environmental impact associated with mining and processing.

By incorporating recycled stainless steel into pipe coil fabrication, manufacturers can reduce their environmental footprint and contribute to a more circular economy. The use of recycled stainless steel not only conserves natural resources but also reduces the amount of waste sent to landfills, promoting responsible waste management.

Real-life examples showcase the practical significance of stainless steel recyclability in pipe coil fabrication. In the construction industry, the use of recycled stainless steel in pipe coils for plumbing systems has gained traction. By diverting stainless steel from landfills and reintroducing it into the supply chain, construction companies can minimize their environmental impact while ensuring the durability and longevity of their projects.

In summary, the sustainability of stainless steel, driven by its recyclability, plays a vital role in stainless steel pipe coil fabrication. By embracing sustainable practices, businesses can not only reduce their environmental footprint but also contribute to a more circular economy, conserving natural resources, and reducing waste.

Table: Sustainability and Stainless Steel Pipe Coil Fabrication

| Aspect | Sustainability Impact |

|---|---|

| Recyclability | Reduces the need for raw material extraction and minimizes mining and processing impacts. |

| Closed-Loop Recycling | Preserves the inherent properties of stainless steel, allowing for repeated recycling without degradation. |

| Waste Reduction | Diverts stainless steel from landfills, promoting responsible waste management and conserving natural resources. |

| Environmental Footprint | Minimizes the environmental impact associated with pipe coil fabrication by reducing energy consumption and waste generation. |

FAQs on Stainless Steel Pipe Coil Fabrication

The intricate world of stainless steel pipe coil fabrication raises several common questions. Here, we present a series of FAQs to address these concerns and provide clarity on the subject.

Question 1: Why is stainless steel the preferred choice for pipe coil fabrication?

Answer: Stainless steel’s exceptional resistance to corrosion, heat, and wear make it an ideal material for pipe coil fabrication. Its durability and longevity ensure optimal performance in demanding environments.

Question 2: How does the fabrication process influence the quality of pipe coils?

Answer: Precision fabrication techniques are crucial for achieving the desired shape, dimensions, and tolerances. Advanced fabrication methods ensure the production of high-quality pipe coils that meet specific performance requirements.

Question 3: What are the key factors to consider when designing pipe coils?

Answer: Factors such as flow rate, pressure, temperature, and space constraints must be carefully evaluated during the design phase. Optimal coil design ensures efficient fluid flow, heat transfer, and overall system performance.

Question 4: How does stainless steel pipe coil fabrication contribute to sustainability?

Answer: Stainless steel’s recyclability and durability promote sustainability. Recycled stainless steel reduces the need for raw material extraction, and the longevity of pipe coils minimizes waste generation.

Question 5: What industries benefit the most from stainless steel pipe coil fabrication?

Answer: Industries involving fluid handling, heat transfer, and corrosive environments, such as chemical processing, power generation, and food and beverage, heavily rely on stainless steel pipe coils for their durability and efficiency.

Question 6: How can I ensure the longevity of stainless steel pipe coils?

Answer: Proper maintenance and regular cleaning are essential for extending the lifespan of pipe coils. Periodic inspections and timely repairs can prevent premature failure and maintain optimal performance.

Summary: Stainless steel pipe coil fabrication offers numerous advantages, including durability, corrosion resistance, and sustainability. Understanding the intricacies of the fabrication process and addressing common concerns can empower businesses to make informed decisions and optimize the performance of their pipe coil systems.

Transition to the next article section: To delve deeper into the world of stainless steel pipe coil fabrication, explore our comprehensive guide, which provides detailed insights and industry-specific applications.

Best Practices in Stainless Steel Pipe Coil Fabrication

Stainless steel pipe coil fabrication demands precision and attention to detail to ensure optimal performance and longevity. Here are several crucial tips to guide your fabrication process:

Tip 1: Material Selection

Choose the appropriate grade of stainless steel based on the specific application and environmental conditions. Consider factors such as corrosion resistance, temperature tolerance, and mechanical strength.

Tip 2: Precision Bending

Utilize specialized bending techniques to achieve accurate coil shapes and dimensions. Proper bending ensures optimal flow dynamics and heat transfer efficiency.

Tip 3: Welding Techniques

Employ high-quality welding methods to ensure strong and leak-proof joints. Proper welding techniques minimize the risk of corrosion and maintain structural integrity.

Tip 4: Surface Finishing

Apply appropriate surface treatments, such as passivation or electropolishing, to enhance corrosion resistance and improve the overall aesthetics of the pipe coils.

Tip 5: Quality Control

Implement rigorous quality control measures throughout the fabrication process. Conduct thorough inspections to verify dimensional accuracy, weld integrity, and surface finish.

Tip 6: Maintenance and Cleaning

Establish a regular maintenance and cleaning schedule to preserve the performance of pipe coils. Periodic cleaning removes deposits and contaminants, ensuring optimal flow rates and heat transfer.

Summary: By adhering to these best practices, manufacturers can produce high-quality stainless steel pipe coils that meet stringent industry standards and deliver exceptional performance in diverse applications.

Transition to the article’s conclusion: These tips empower businesses to optimize their pipe coil fabrication processes, maximizing efficiency, reliability, and longevity.

Conclusion

Stainless steel pipe coil fabrication stands as a cornerstone of industrial efficiency, offering an array of benefits that enhance performance, longevity, and sustainability. Its exceptional durability, precision, hygiene, versatility, efficiency, cost-effectiveness, and sustainability make stainless steel pipe coils indispensable components in a wide range of industries.

By embracing the best practices outlined in this article, manufacturers can optimize their fabrication processes to produce high-quality pipe coils that meet the demands of modern industrial applications. Investing in stainless steel pipe coil fabrication is an investment in long-term performance, reliability, and environmental consciousness, ultimately contributing to the success and sustainability of businesses.