What is steel canopy fabrication? Steel canopy fabrication is the process of creating a canopy using steel. Canopies are typically used to provide shelter from the sun or rain, and they can be either attached to a building or freestanding.

Editor’s Notes: Steel canopy fabrication is an important topic for anyone considering adding a canopy to their home or business. By understanding the process of steel canopy fabrication, you can make informed decisions about the type of canopy that is right for you.

Our team has done extensive research and analysis to put together this comprehensive guide to steel canopy fabrication. We hope that this guide will help you make the right decision for your needs.

| Key Differences | Steel Canopy Fabrication |

|---|---|

| Material | Steel |

| Durability | Very durable |

| Cost | More expensive than other materials |

| Maintenance | Requires regular maintenance |

In this article, we will discuss the following topics:

- The benefits of steel canopy fabrication

- The different types of steel canopies

- The process of steel canopy fabrication

- The cost of steel canopy fabrication

- The maintenance of steel canopies

Steel Canopy Fabrication

Steel canopy fabrication is a versatile and durable construction method for creating canopies that provide shelter from the elements. Here are 10 key aspects to consider when exploring steel canopy fabrication:

- Material: Steel is a strong and durable material that is well-suited for canopy fabrication.

- Design: Steel canopies can be designed in a variety of shapes and sizes to meet specific needs.

- Fabrication: Steel canopy fabrication involves cutting, welding, and assembling steel components to create the desired canopy structure.

- Installation: Steel canopies can be installed on a variety of surfaces, including concrete, wood, and steel.

- Maintenance: Steel canopies require regular maintenance to keep them in good condition.

- Cost: Steel canopy fabrication is more expensive than other materials, but it is also more durable.

- Benefits: Steel canopies offer a number of benefits, including durability, strength, and versatility.

- Applications: Steel canopies are used in a variety of applications, including commercial, residential, and industrial.

- Codes and standards: Steel canopy fabrication must meet certain codes and standards to ensure safety and quality.

- Sustainability: Steel is a sustainable material that can be recycled at the end of its lifespan.

These key aspects provide a comprehensive overview of steel canopy fabrication. By understanding these aspects, you can make informed decisions about the design, fabrication, installation, and maintenance of steel canopies.

Material

Steel is a strong and durable material that is well-suited for canopy fabrication. This is because steel is:

- Strong: Steel has a high strength-to-weight ratio, which means that it can support a lot of weight without breaking.

- Durable: Steel is resistant to rust and corrosion, which means that it can last for many years without needing to be replaced.

- Versatile: Steel can be formed into a variety of shapes and sizes, which makes it suitable for a wide range of canopy applications.

As a result of these properties, steel is an excellent choice for canopy fabrication. Steel canopies are strong, durable, and versatile, and they can be used in a variety of applications.

Design

The design of a steel canopy is an important consideration, as it will affect the canopy’s appearance, functionality, and durability. Steel canopies can be designed in a variety of shapes and sizes to meet specific needs. Some of the most common canopy shapes include:

- Gable canopies: Gable canopies are the most common type of canopy. They have a simple, triangular design that is easy to install and maintain.

- Hip canopies: Hip canopies have four sloping sides that meet at a central point. They are more complex to design and install than gable canopies, but they offer better protection from the elements.

- Skillion canopies: Skillion canopies have a single sloping side. They are a good choice for areas with limited headroom.

- Curved canopies: Curved canopies have a curved roofline. They are more expensive to design and install than other types of canopies, but they offer a unique and stylish look.

In addition to the shape of the canopy, the size of the canopy is also an important consideration. The size of the canopy will depend on the intended use of the canopy. For example, a canopy that is used to cover a patio will need to be larger than a canopy that is used to cover a doorway.

When designing a steel canopy, it is important to consider the following factors:

- The intended use of the canopy

- The size of the area that needs to be covered

- The local climate

- The budget

By considering these factors, you can design a steel canopy that meets your specific needs.

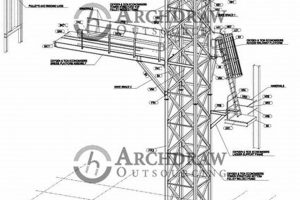

Fabrication

Steel canopy fabrication is a complex process that requires specialized skills and equipment. The fabrication process typically involves the following steps:

- Cutting: The first step is to cut the steel components to the desired size and shape. This can be done using a variety of cutting tools, such as saws, lasers, and water jets.

- Welding: Once the components are cut, they are welded together to create the desired canopy structure. Welding is a process that uses heat to fuse the metal components together.

- Assembly: The final step is to assemble the canopy structure. This involves bolting or riveting the components together.

The fabrication process is critical to the quality and durability of the steel canopy. A well-fabricated canopy will be strong, durable, and able to withstand the elements.

Steel canopy fabrication is a versatile process that can be used to create a wide variety of canopy structures. Steel canopies can be used for a variety of applications, including commercial, residential, and industrial.

Installation

The installation of steel canopies is an important step in the steel canopy fabrication process. The installation process involves attaching the canopy to a surface, such as concrete, wood, or steel. The type of surface will determine the type of fasteners that are used.

It is important to ensure that the canopy is installed securely, as a poorly installed canopy can be dangerous. A well-installed canopy will be able to withstand the elements and provide years of service.

Here are some of the benefits of installing a steel canopy:

- Protection from the elements: Steel canopies can provide protection from the sun, rain, snow, and wind.

- Increased curb appeal: Steel canopies can improve the appearance of a home or business.

- Added value: Steel canopies can add value to a home or business.

If you are considering installing a steel canopy, it is important to consult with a qualified contractor. A contractor can help you choose the right canopy for your needs and ensure that it is installed safely and securely.

| Surface | Fasteners |

|---|---|

| Concrete | Bolts or screws |

| Wood | Screws or nails |

| Steel | Welds or bolts |

Maintenance

Regular maintenance is crucial for ensuring the longevity and optimal performance of steel canopies. Neglecting maintenance can lead to deterioration, diminished structural integrity, and compromised aesthetics. Here are key facets to consider regarding the connection between maintenance and steel canopy fabrication:

- Preservation of Structural Integrity: Regular inspections and maintenance, including cleaning, repainting, and tightening of bolts, help prevent corrosion, rust, and other forms of degradation. This ensures the canopy’s structural soundness and stability, preventing potential safety hazards.

- Extending Lifespan: Proactive maintenance measures significantly extend the lifespan of steel canopies. By addressing minor issues promptly, such as repairing cracks or sealing leaks, major problems and costly repairs can be avoided, maximizing the canopy’s service life.

- Maintaining Aesthetic Appeal: Regular cleaning and repainting not only enhance the canopy’s appearance but also protect the underlying steel from the elements. This preserves the canopy’s visual appeal, ensuring it complements the surrounding environment and enhances the overall property aesthetics.

- Optimizing Performance: Proper maintenance ensures that all components of the steel canopy, such as drainage systems and support structures, function optimally. This prevents water accumulation, reduces the risk of leaks, and maintains the canopy’s intended functionality.

In conclusion, regular maintenance is an essential aspect of steel canopy fabrication. By incorporating these maintenance considerations into the fabrication process, manufacturers and installers can deliver high-quality canopies that stand the test of time and provide lasting value to property owners.

Cost

The cost of steel canopy fabrication is a significant factor to consider when choosing a canopy for your home or business. Steel canopies are more expensive than canopies made from other materials, such as aluminum or fabric. However, steel canopies are also more durable and long-lasting.

The durability of steel canopies makes them a good investment in the long run. Steel canopies can withstand high winds, heavy rains, and snow loads without sustaining damage. They are also resistant to rust and corrosion, which means that they will not need to be replaced as often as canopies made from other materials.

If you are looking for a canopy that will last for many years, then a steel canopy is a good option. Steel canopies are more expensive than other types of canopies, but they are also more durable and long-lasting.

Here is a table that compares the cost and durability of steel canopies to other types of canopies:

| Material | Cost | Durability |

|---|---|---|

| Steel | More expensive | More durable |

| Aluminum | Less expensive | Less durable |

| Fabric | Least expensive | Least durable |

Benefits

Steel canopy fabrication provides a range of advantages that contribute to the overall value and functionality of steel canopies. These benefits stem from the inherent properties of steel and the fabrication process itself.

Durability: Steel is renowned for its exceptional strength and resilience. Steel canopies can withstand harsh weather conditions, including strong winds, heavy rainfall, and snowfall, without compromising their structural integrity. This durability makes them a reliable choice for long-term use, even in demanding environments.

Strength: The robust nature of steel enables steel canopies to support significant weight loads. They can be engineered to accommodate heavy equipment, suspended structures, or even additional roofing materials, making them suitable for various industrial and commercial applications.

Versatility: Steel canopy fabrication allows for customization and adaptability to diverse architectural styles and functional requirements. Steel can be formed into various shapes and sizes, enabling the creation of canopies that seamlessly complement the aesthetics of any building or landscape. Their versatility also extends to integration with other building elements, such as walls, columns, or beams.

These benefits collectively demonstrate the significance of steel canopy fabrication in delivering durable, strong, and versatile structures that meet the specific needs of various construction projects.

| Benefit | Significance in Steel Canopy Fabrication |

|---|---|

| Durability | Ensures longevity and resilience in challenging environments. |

| Strength | Provides support for heavy loads and demanding applications. |

| Versatility | Allows for customization and integration with diverse architectural styles. |

Applications

The diverse applications of steel canopies are a testament to the versatility and adaptability of steel canopy fabrication. Their inherent durability and strength make them suitable for a wide range of uses, from providing shelter and protection to enhancing aesthetics and functionality.

In commercial settings, steel canopies are commonly used over entrances, walkways, and loading areas. They provide protection from the elements for customers, employees, and goods, ensuring a safe and comfortable experience. Their robust construction can withstand heavy foot traffic and potential impact from vehicles.

Residential applications of steel canopies include patios, decks, and carports. They extend living spaces outdoors, creating shaded and sheltered areas for relaxation, dining, or parking. Steel canopies can be customized to complement the architectural style of the home, enhancing curb appeal and property value.

In industrial settings, steel canopies are used for various purposes, such as covering warehouses, factories, and machinery. They protect equipment and inventory from harsh weather conditions, ensuring the smooth operation of industrial processes. The strength of steel canopies allows them to support heavy loads, such as cranes and suspended platforms.

| Application | Benefits of Steel Canopy Fabrication |

|---|---|

| Commercial | Protection from elements, durability, aesthetic appeal |

| Residential | Extended living space, weather protection, curb appeal |

| Industrial | Protection of equipment and inventory, support for heavy loads |

Understanding the connection between steel canopy fabrication and its diverse applications is crucial for architects, engineers, and contractors. It enables them to select the most appropriate materials and fabrication techniques to meet specific project requirements. By harnessing the unique properties of steel, steel canopy fabrication contributes to the creation of versatile and durable structures that enhance functionality and aesthetics across a wide range of applications.

Codes and standards

Codes and standards play a crucial role in steel canopy fabrication, ensuring the safety and quality of these structures. By adhering to established guidelines, manufacturers and installers can guarantee that steel canopies meet specific performance requirements and industry best practices.

These codes and standards cover various aspects of steel canopy fabrication, including:

- Materials: Specifications for the type and quality of steel used in canopy construction.

- Design: Requirements for structural integrity, load-bearing capacity, and wind resistance.

- Fabrication: Guidelines for welding, bolting, and other fabrication techniques.

- Installation: Standards for proper installation, anchoring, and support systems.

- Maintenance: Recommendations for ongoing maintenance and inspection to ensure safety and longevity.

By meeting these codes and standards, steel canopy fabrication ensures:

- Public safety: Canopies are designed and built to withstand various loads and environmental conditions, minimizing the risk of collapse or failure.

- Structural integrity: Adherence to load-bearing and wind resistance standards ensures that canopies can safely support their intended use and withstand external forces.

- Durability: Proper materials and fabrication techniques enhance the longevity of steel canopies, reducing maintenance costs and extending their lifespan.

- Compliance: Meeting codes and standards demonstrates compliance with legal requirements and industry best practices, protecting stakeholders from liability.

| Code/Standard | Purpose |

|---|---|

| International Building Code (IBC) | Sets minimum requirements for building construction, including canopies. |

| American Institute of Steel Construction (AISC) Standards | Provides design and fabrication guidelines for steel structures. |

| American Welding Society (AWS) Standards | Establishes standards for welding procedures and qualifications. |

Understanding the connection between codes and standards and steel canopy fabrication is essential for architects, engineers, contractors, and building owners. By adhering to these guidelines, they can deliver safe, durable, and high-quality steel canopies that meet regulatory requirements and industry expectations.

Sustainability

The sustainability of steel is a key factor in its use for canopy fabrication. Steel is a durable and long-lasting material, but it is also recyclable. This means that at the end of its lifespan, a steel canopy can be recycled and used to create new products. This reduces the amount of waste going to landfills and helps to conserve natural resources.

In addition to being recyclable, steel is also a strong and durable material. This makes it an ideal choice for canopies, which are often exposed to harsh weather conditions. Steel canopies can withstand high winds, heavy rains, and snow loads without sustaining damage. They are also resistant to rust and corrosion, which means that they will not need to be replaced as often as canopies made from other materials.

The sustainability of steel canopy fabrication is a major benefit for businesses and homeowners alike. By choosing a steel canopy, you can help to reduce your environmental impact and save money in the long run.

Here is a table that summarizes the key benefits of steel canopy fabrication:

| Benefit | Significance |

|---|---|

| Sustainability | Steel is a recyclable material, reducing waste and conserving resources. |

| Durability | Steel canopies can withstand harsh weather conditions and resist rust and corrosion. |

| Cost-effectiveness | Steel canopies are a durable and long-lasting investment, saving money on replacements and maintenance. |

Understanding the connection between sustainability and steel canopy fabrication is essential for making informed decisions about building materials. By choosing steel, you can help to create a more sustainable future.

Frequently Asked Questions about Steel Canopy Fabrication

This section addresses common inquiries and misconceptions surrounding steel canopy fabrication, providing concise and informative answers to guide your decision-making process.

Question 1: What are the advantages of choosing steel for canopy fabrication?

Steel canopies offer exceptional durability, strength, and versatility. They can withstand harsh weather conditions, support heavy loads, and be customized to complement diverse architectural styles.

Question 2: How does steel canopy fabrication contribute to sustainability?

Steel is a recyclable material, minimizing waste and conserving resources. Steel canopies are also durable and long-lasting, reducing the need for frequent replacements and maintenance, thus promoting sustainability.

Question 3: What factors influence the cost of steel canopy fabrication?

The cost of steel canopy fabrication is influenced by the size, complexity of design, material thickness, and any additional features or finishes required. It’s important to consult with fabricators to obtain accurate cost estimates.

Question 4: How does steel canopy fabrication ensure structural integrity?

Steel canopy fabrication adheres to strict codes and standards, which include guidelines for material selection, design calculations, and fabrication techniques. This ensures that steel canopies are structurally sound and can withstand the intended loads and environmental conditions.

Question 5: What maintenance is required for steel canopies?

Regular maintenance is crucial for preserving the longevity and appearance of steel canopies. This includes cleaning, repainting, and inspecting for any signs of corrosion or damage. Proper maintenance ensures that steel canopies remain safe and aesthetically pleasing.

Question 6: How can I find reputable steel canopy fabricators?

To find reputable steel canopy fabricators, consider seeking recommendations from architects or contractors, reviewing online reviews, and checking for industry certifications or affiliations. Reputable fabricators prioritize quality, safety, and customer satisfaction.

By addressing these frequently asked questions, we aim to provide a clearer understanding of steel canopy fabrication, empowering you to make informed decisions and choose the best canopy solution for your needs.

Feel free to explore our website or contact us for further information on steel canopy fabrication and its applications.

Tips for Steel Canopy Fabrication

Steel canopy fabrication involves meticulous planning and execution to ensure structural integrity, durability, and aesthetic appeal. Here are some valuable tips to guide your fabrication process:

Tip 1: Select High-Quality Materials

The choice of steel grade and thickness is crucial for the canopy’s strength and longevity. Opt for steel that meets industry standards and is suitable for the intended application.

Tip 2: Ensure Precise Design and Engineering

Proper design calculations and engineering drawings are essential to guarantee the canopy’s structural stability. Consult with experienced engineers to optimize the design for load-bearing capacity and wind resistance.

Tip 3: Employ Skilled Fabrication Techniques

Precision cutting, welding, and assembly techniques are paramount for creating a robust and durable canopy. Ensure that fabricators possess the necessary skills and certifications to deliver high-quality workmanship.

Tip 4: Consider Environmental Factors

Factors such as wind loads, snow loads, and UV exposure can impact the canopy’s design and material selection. Consult with local building codes and experts to determine the appropriate specifications for your location.

Tip 5: Prioritize Regular Maintenance

Regular cleaning, inspections, and repainting help maintain the canopy’s structural integrity and aesthetic appeal. Timely maintenance extends the canopy’s lifespan and ensures its continued functionality.

By adhering to these tips, you can enhance the quality, durability, and longevity of your steel canopy fabrication project. Remember to consult with reputable fabricators, engineers, and contractors to ensure a successful outcome.

Conclusion

Steel canopy fabrication stands as a testament to the strength, adaptability, and longevity of steel as a building material. Throughout this exploration, we have delved into the intricacies of fabrication, uncovering the advantages and applications of steel canopies. Their exceptional durability, strength, and versatility make them a prime choice for diverse architectural and engineering projects.

As we look towards the future, steel canopy fabrication will continue to play a pivotal role in shaping our built environment. Its sustainable qualities and cost-effectiveness make it an attractive option for eco-conscious and budget-minded projects alike. By embracing innovation and adhering to industry best practices, we can push the boundaries of steel canopy fabrication, creating structures that are not only functional but also aesthetically pleasing.