Steel plays a crucial role in modern construction, and its design and fabrication are critical processes that ensure the structural integrity and aesthetic appeal of buildings and infrastructure. Steel design involves the calculation and detailing of steel elements, while steel fabrication transforms these designs into physical structures.

Editor’s Note: Steel design and fabrication are essential processes that require expertise and precision. Understanding these concepts can help individuals make informed decisions about steel structures and their applications.

Through extensive research and analysis, we have compiled this comprehensive guide to steel design and fabrication. Our aim is to provide valuable insights and practical information to assist our readers in understanding the intricacies of this field.

Key Differences: Steel Design vs. Steel Fabrication

| Steel Design | Steel Fabrication |

|---|---|

| Involves calculations and detailing of steel elements | Focuses on transforming designs into physical structures |

| Requires knowledge of structural engineering principles | Emphasizes precision and adherence to design specifications |

| Typically performed by engineers | Carried out by skilled fabricators |

Main Article Topics

- Importance of Steel Design and Fabrication

- Types of Steel Structures

- Materials Used in Steel Design

- Design Considerations

- Fabrication Techniques

- Quality Control and Inspection

- Applications of Steel Structures

Steel Design and Fabrication

Steel design and fabrication are crucial processes in construction, ensuring the integrity and aesthetics of steel structures. Here are ten key aspects that explore various dimensions of this field:

- Structural Analysis: Calculations to determine load-bearing capacities.

- Material Selection: Choosing the right steel grade for specific applications.

- Connection Design: Detailing how steel elements are joined.

- Fabrication Techniques: Processes used to transform designs into physical structures.

- Quality Control: Ensuring that fabricated structures meet design specifications.

- Code Compliance: Adhering to building codes and industry standards.

- Sustainability: Considering environmental impact in design and fabrication.

- Innovation: Exploring new technologies to improve efficiency and performance.

- Collaboration: Involving engineers, architects, and fabricators in the design-build process.

- Safety: Prioritizing worker safety throughout the design and fabrication stages.

These key aspects are interconnected and essential for successful steel design and fabrication. For instance, structural analysis informs material selection, which in turn influences connection design. Fabrication techniques must adhere to quality control measures and code compliance, while sustainability considerations can drive innovation. By understanding these aspects, stakeholders can make informed decisions, ensuring the safety, integrity, and longevity of steel structures.

Structural Analysis

Structural analysis is a crucial aspect of steel design and fabrication, providing the foundation for safe and efficient structures. It involves calculating the load-bearing capacities of steel elements to ensure they can withstand the forces acting upon them.

-

Facet 1: Determining Safe Load Limits

Structural analysis helps determine the maximum loads that a steel structure can safely without compromising its integrity. This is essential to prevent overloading and potential failures.

-

Facet 2: Optimizing Material Usage

By accurately calculating load-bearing capacities, engineers can optimize the use of steel materials. This can lead to cost savings and improved structural efficiency.

-

Facet 3: Ensuring Compliance with Codes

Structural analysis is vital for ensuring that steel structures comply with building codes and industry standards. These codes specify minimum load-bearing requirements to guarantee public safety.

-

Facet 4: Facilitating Design Innovation

Advanced structural analysis techniques enable engineers to explore innovative designs that push the boundaries of what is structurally possible. This can result in unique and awe-inspiring architectural creations.

In summary, structural analysis is an indispensable aspect of steel design and fabrication. It provides the necessary insights to ensure the safety, efficiency, and compliance of steel structures, while also facilitating design innovation. By understanding the intricate calculations and considerations involved in structural analysis, stakeholders can appreciate the critical role it plays in shaping the built environment.

Material Selection

Material selection is a critical aspect of steel design and fabrication, as the choice of steel grade can significantly impact the structural performance, cost, and durability of a project. Engineers must carefully consider various factors to ensure that the selected steel grade meets the specific requirements of the application.

-

Strength and Weight Considerations

The strength of the steel grade must be sufficient to withstand the anticipated loads and forces acting on the structure. However, it is also important to consider the weight implications of the steel grade, as heavier steel grades may require additional support and foundations.

-

Corrosion Resistance

If the steel structure will be exposed to corrosive environments, such as coastal areas or industrial settings, it is crucial to select a steel grade with high corrosion resistance. This can prevent premature deterioration and extend the lifespan of the structure.

-

Weldability

For structures that require welding, the weldability of the steel grade is a key consideration. Some steel grades are more difficult to weld than others, and using an incompatible grade can lead to welding defects and compromised joint strength.

-

Formability

For structures with complex shapes or intricate details, the formability of the steel grade is important. Certain steel grades are more ductile and can be easily bent or formed without compromising their strength.

By carefully considering these factors and selecting the appropriate steel grade, engineers can ensure that the fabricated steel structure meets the specific performance requirements of the project, while also optimizing cost and durability.

Connection Design

Connection design is a crucial aspect of steel design and fabrication, as it determines how individual steel elements are joined together to form a cohesive structure. Careful consideration of connection design is essential to ensure the strength, stability, and safety of the overall structure.

-

Facet 1: Transferring Loads Effectively

Connections play a critical role in transferring loads between steel elements. Proper connection design ensures that forces are distributed evenly throughout the structure, preventing localized failures and maintaining the integrity of the entire system.

-

Facet 2: Ensuring Structural Stability

Well-designed connections contribute to the overall stability of the steel structure. They resist lateral forces, such as wind and seismic loads, and prevent the structure from collapsing or swaying excessively.

-

Facet 3: Facilitating Construction and Assembly

Connection design considers the practicalities of construction and assembly. It aims to simplify the process, reduce the need for complex fabrication, and ensure that the structure can be erected efficiently and safely.

-

Facet 4: Accommodating Movement and Expansion

Steel structures are subject to movement and expansion due to temperature changes and other factors. Connection design incorporates measures to accommodate these movements, preventing undue stress and maintaining the structural integrity of the system.

In summary, connection design is an integral part of steel design and fabrication. It involves detailed planning and engineering calculations to ensure that steel elements are joined together in a manner that maximizes strength, stability, and safety, while also considering practical construction aspects. By understanding the principles of connection design, stakeholders can appreciate the critical role it plays in the successful realization of steel structures.

Fabrication Techniques

Fabrication techniques are the practical methods used to transform steel designs into tangible, physical structures. These techniques involve cutting, shaping, and joining steel elements to create the desired form and functionality. Understanding these techniques is crucial for realizing the full potential of steel design and fabrication.

-

Facet 1: Cutting and Shaping

Steel fabrication begins with cutting and shaping the steel elements to the specified dimensions and profiles. This can involve processes such as shearing, sawing, and plasma cutting. The accuracy and precision of these techniques ensure that the fabricated elements fit together seamlessly.

-

Facet 2: Bending and Forming

To achieve complex shapes and curves, bending and forming techniques are employed. These techniques use specialized machinery to apply controlled forces to the steel elements, shaping them into the desired configurations.

-

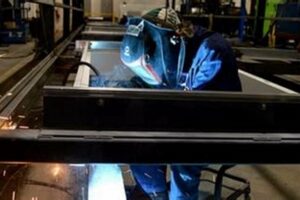

Facet 3: Welding and Joining

Welding and joining techniques are essential for connecting steel elements together. Various welding methods, such as arc welding and MIG welding, are used to create strong and durable joints. Other joining techniques, such as bolting and riveting, may also be employed.

-

Facet 4: Finishing and Treatment

Once the steel structure is fabricated, it may undergo additional finishing and treatment processes. This can include surface treatments to protect against corrosion, painting for aesthetic purposes, or heat treatment to enhance the material properties.

In summary, fabrication techniques are the backbone of steel design and fabrication. They enable the transformation of steel designs into tangible structures, ensuring that the desired form, functionality, and structural integrity are achieved. By understanding these techniques and their applications, stakeholders can appreciate the intricate processes involved in bringing steel designs to life.

Quality Control

Quality control is an essential component of steel design and fabrication, ensuring that the final product meets the intended design specifications and performance requirements. It involves a rigorous process of inspections, testing, and documentation to verify that the fabricated steel structure adheres to the approved design drawings and industry standards.

The importance of quality control in steel design and fabrication cannot be overstated. It helps to prevent structural failures, accidents, and costly repairs. By ensuring that the fabricated structure meets the design specifications, quality control contributes to the overall safety, reliability, and durability of the building or infrastructure.

For instance, in the construction of a steel bridge, quality control measures ensure that the fabricated steel components meet the specified strength and load-bearing capacities. This is achieved through rigorous inspections of welds, bolts, and other connections to identify and rectify any potential defects or weaknesses.

Quality control also involves testing the fabricated structure to verify its performance under simulated or actual load conditions. This may include load testing to assess the structural integrity and deflection characteristics, or fatigue testing to evaluate the durability of the structure under repeated loading.

By understanding the importance of quality control in steel design and fabrication, stakeholders can appreciate the critical role it plays in ensuring the safety and reliability of steel structures. It is a process that requires meticulous attention to detail, skilled professionals, and a commitment to meeting the highest standards of workmanship.

Code Compliance

In the realm of steel design and fabrication, code compliance is paramount, serving as the cornerstone for ensuring structural safety and integrity. Building codes and industry standards are established to regulate the design, construction, and maintenance of steel structures, providing a framework for quality and consistency.

Adherence to building codes and industry standards is not merely a legal obligation but a fundamental aspect of responsible steel design and fabrication. By complying with these regulations, engineers, architects, and fabricators demonstrate their commitment to public safety and structural reliability.

One of the critical aspects of code compliance is ensuring that steel structures can withstand the anticipated loads and forces acting upon them. Building codes specify minimum load requirements for different types of structures, considering factors such as dead loads (self-weight), live loads (occupancy and usage), and environmental loads (wind, snow, and seismic).

For instance, in regions prone to earthquakes, steel structures must be designed and fabricated to resist seismic forces. Building codes provide specific guidelines for the design of seismic-resistant steel structures, including requirements for moment-resisting frames, shear walls, and energy-dissipating devices.

Compliance with industry standards, such as those established by the American Institute of Steel Construction (AISC), further ensures the quality and reliability of steel structures. These standards provide detailed specifications for the fabrication, erection, and inspection of steel structures, covering aspects such as welding procedures, bolting techniques, and quality control measures.

Understanding the connection between code compliance and steel design and fabrication is crucial for all stakeholders involved in the construction process. By adhering to these regulations and standards, engineers, architects, and fabricators can create steel structures that are not only aesthetically pleasing but also safe and durable.

Benefits of Code Compliance in Steel Design and Fabrication

| Benefit | Description |

|---|---|

| Enhanced Safety | Code compliance ensures that steel structures are designed and fabricated to withstand anticipated loads and forces, minimizing the risk of structural failure and protecting public safety. |

| Improved Quality | Adherence to industry standards promotes consistent and high-quality fabrication practices, leading to durable and reliable steel structures. |

| Reduced Liability | Compliance with building codes and industry standards provides legal protection for engineers, architects, and fabricators, reducing the risk of liability in the event of structural failure. |

| Increased Sustainability | Code-compliant steel structures are designed and fabricated to be energy-efficient and environmentally friendly, contributing to sustainable building practices. |

Sustainability

Sustainability has become an increasingly important consideration in the construction industry, and steel design and fabrication are no exception. By adopting sustainable practices, engineers and fabricators can minimize the environmental impact of steel structures throughout their lifecycle.

-

Life Cycle Assessment:

Life cycle assessment (LCA) is a technique used to evaluate the environmental impact of a product or process over its entire life cycle, from raw material extraction to end-of-life disposal. LCA can be applied to steel structures to identify opportunities for reducing environmental impact at each stage.

-

Material Efficiency:

Material efficiency involves optimizing the use of steel materials to minimize waste and maximize structural performance. This can be achieved through design innovations, such as using high-strength steel grades or employing advanced fabrication techniques.

-

Recyclability:

Steel is a highly recyclable material, and can be recycled at the end of their service life. By designing for recyclability, engineers can reduce the environmental impact of steel structures and promote a circular economy.

-

Energy Efficiency:

Steel structures can be designed to be energy-efficient by incorporating features such as thermal insulation and natural lighting. This can reduce the operational energy consumption of buildings and contribute to overall sustainability goals.

By considering these facets of sustainability, engineers and fabricators can create steel structures that have a reduced environmental impact and contribute to a more sustainable built environment. Moreover, sustainable can also lead to cost savings and enhanced marketability, making them a smart choice for both environmental and economic reasons.

Innovation

In the realm of steel design and fabrication, innovation plays a pivotal role in driving progress and enhancing the efficiency and performance of steel structures. By embracing new technologies and exploring cutting-edge techniques, engineers and fabricators can push the boundaries of what is possible and create steel structures that are stronger, more sustainable, and more cost-effective.

-

Advanced Design Software:

Advancements in design software have revolutionized the way steel structures are designed and analyzed. These software programs enable engineers to create complex models, simulate real-world conditions, and optimize designs for strength, weight, and cost. This leads to more efficient and innovative steel structures that meet the demands of modern construction.

-

Automated Fabrication Techniques:

Automation is transforming the steel fabrication process, improving accuracy, efficiency, and safety. Automated welding machines, laser cutters, and robotic systems can produce steel components with greater precision and consistency than manual methods. This results in higher quality steel structures that can be fabricated faster and at a lower cost.

-

High-Strength Steel Grades:

The development of new high-strength steel grades has allowed engineers to design steel structures that are stronger and lighter than ever before. These steels have a higher yield strength and tensile strength, enabling the use of thinner sections and more efficient designs. This can lead to significant savings in material costs and reduced structural weight.

-

Smart Steel Structures:

The integration of sensors and monitoring systems into steel structures is creating a new generation of smart structures. These structures can monitor their own performance, detect potential problems, and adapt to changing conditions. This can improve safety, reduce maintenance costs, and extend the lifespan of steel structures.

These are just a few examples of how innovation is driving progress in steel design and fabrication. By embracing new technologies and exploring cutting-edge techniques, engineers and fabricators can create steel structures that are stronger, more sustainable, and more cost-effective, shaping the future of the built environment.

Collaboration

Collaboration is essential to successful steel design and fabrication. It involves engineers, architects, and fabricators working together throughout the design-build process to ensure that the final product meets the intended design specifications and performance requirements.

-

Effective Communication:

Collaboration begins with effective communication among team members. Engineers, architects, and fabricators must clearly convey their ideas, concerns, and expectations to ensure that everyone is on the same page.

-

Shared Understanding of Design Intent:

All team members must have a shared understanding of the design intent. This includes the structural requirements, aesthetic considerations, and any other relevant factors. This shared understanding ensures that the final product aligns with the original vision.

-

Value Engineering and Cost Optimization:

Collaboration allows for value engineering and cost optimization. By working together, engineers, architects, and fabricators can identify areas where costs can be reduced without compromising the structural integrity or aesthetic appeal of the project.

-

Clash Detection and Resolution:

Collaboration facilitates clash detection and resolution. By reviewing the design together, the team can identify potential clashes between different components and find solutions to avoid costly rework during construction.

Effective collaboration among engineers, architects, and fabricators is crucial for the successful execution of steel design and fabrication projects. It ensures that the final product meets the intended design specifications, is cost-effective, and aligns with the original vision. By fostering a collaborative environment, stakeholders can deliver high-quality steel structures that meet the needs of clients and end-users.

Safety

In the realm of steel design and fabrication, safety takes paramount importance, serving as a cornerstone for protecting the well-being of workers involved in the construction process. By prioritizing safety throughout the design and fabrication stages, stakeholders can create a work environment that minimizes risks, promotes well-being, and ensures the timely completion of projects.

The connection between safety and steel design and fabrication is multifaceted. Firstly, it is a moral and ethical obligation to safeguard the health and safety of workers. Secondly, prioritizing safety can prevent accidents, injuries, and fatalities, reducing project delays and associated costs.

During the design stage, engineers must consider safety aspects such as access for construction and maintenance, fall protection systems, and the safe handling of heavy steel components. By incorporating safety features into the design, potential hazards can be identified and mitigated early on, reducing risks during fabrication and construction.

In the fabrication stage, safety measures focus on protecting workers from hazards associated with cutting, welding, and assembling steel components. Proper ventilation, protective equipment, and adherence to safety protocols are crucial to prevent accidents and exposure to harmful fumes and particles.

Real-life examples underscore the importance of safety in steel design and fabrication. The “Hard Hat” campaign in the construction industry has significantly reduced head injuries and fatalities by promoting the use of protective helmets. Similarly, the development of automated welding systems has reduced the risk of exposure to welding fumes and burns.

Understanding the connection between safety and steel design and fabrication is essential for all stakeholders involved in the construction process. By prioritizing safety, engineers, architects, fabricators, and construction workers can create a safe and productive work environment. This not only protects the well-being of workers but also contributes to the overall success and efficiency of steel construction projects.

| Key Insight | Practical Significance |

|---|---|

| Safety is a moral and ethical obligation. | Protects worker well-being and prevents human suffering. |

| Prioritizing safety reduces project delays and costs. | Prevents accidents, injuries, and fatalities, minimizing disruptions and financial losses. |

| Safety considerations in design and fabrication mitigate risks. | Identifies and addresses potential hazards early on, reducing dangers during construction and maintenance. |

| Safety measures protect workers from fabrication hazards. | Ensures proper ventilation, protective equipment, and adherence to safety protocols to prevent accidents and exposure to harmful substances. |

FAQs about Steel Design and Fabrication

This section addresses frequently asked questions about steel design and fabrication, providing clear and informative answers to common concerns and misconceptions.

Question 1: What are the key considerations in steel design?

Answer: Steel design involves meticulous calculations and detailing to ensure the structural integrity of steel elements. It encompasses factors such as load-bearing capacities, material selection, connection design, and compliance with building codes and industry standards.

Question 2: How does fabrication transform steel designs into physical structures?

Answer: Fabrication involves cutting, shaping, and joining steel elements based on the design specifications. It utilizes techniques such as welding, bending, and forming to create the desired structural components.

Question 3: What is the significance of quality control in steel fabrication?

Answer: Quality control ensures that fabricated steel structures meet the intended design specifications and performance requirements. It involves rigorous inspections, testing, and documentation to verify the structural integrity and adherence to industry standards.

Question 4: How does sustainability play a role in steel design and fabrication?

Answer: Sustainability considerations focus on reducing the environmental impact of steel structures throughout their lifecycle. This includes optimizing material usage, promoting recyclability, incorporating energy-efficient features, and minimizing waste.

Question 5: What is the importance of collaboration in steel design and fabrication projects?

Answer: Collaboration among engineers, architects, and fabricators is crucial for successful project execution. It facilitates effective communication, shared understanding of design intent, value engineering, and clash detection resolution, ensuring that the final product aligns with the initial vision and requirements.

Question 6: Why is safety a top priority in steel design and fabrication?

Answer: Safety measures protect workers from hazards throughout the design and fabrication processes. It involves incorporating safety features into designs, implementing proper ventilation and protective equipment in fabrication facilities, and adhering to safety protocols to prevent accidents, injuries, and fatalities.

Summary: Steel design and fabrication encompass a range of complex processes that require expertise, precision, and adherence to industry standards. By understanding the key considerations, techniques, and importance of quality control, sustainability, collaboration, and safety, individuals can gain a comprehensive understanding of this critical field in construction.

Transition: To delve deeper into steel design and fabrication, let’s explore specific aspects such as structural analysis, material selection, connection design, and fabrication techniques in the following sections.

Tips for Optimizing Steel Design and Fabrication

Steel design and fabrication play a vital role in the construction industry, requiring careful planning, execution, and adherence to industry standards. Here are some valuable tips to optimize these processes:

Tip 1: Prioritize Structural Analysis

Conduct thorough structural analysis to determine load-bearing capacities and ensure the safety and integrity of steel structures. Consider factors such as dead loads, live loads, and environmental forces.

Tip 2: Select Materials Wisely

Choose the appropriate steel grades based on strength, corrosion resistance, weldability, and formability requirements. Consider the specific application and environmental conditions to optimize material selection.

Tip 3: Design Efficient Connections

Detail connections carefully to ensure proper load transfer, stability, and ease of construction. Consider factors such as bolt patterns, weld types, and gusset plates to optimize connection design.

Tip 4: Utilize Advanced Fabrication Techniques

Employ advanced fabrication techniques such as laser cutting, robotic welding, and automated assembly to enhance precision, efficiency, and quality control in steel fabrication.

Tip 5: Implement Quality Control Measures

Establish rigorous quality control processes to verify that fabricated steel structures meet design specifications and industry standards. This includes inspections, testing, and documentation.

Tip 6: Foster Collaboration

Facilitate effective collaboration among engineers, architects, and fabricators throughout the design and fabrication process. Encourage open communication, shared understanding of design intent, and value engineering.

Tip 7: Prioritize Safety

Implement comprehensive safety measures to protect workers during steel design and fabrication. This includes incorporating safety features into designs, providing proper ventilation and protective equipment, and adhering to safety protocols.

Tip 8: Consider Sustainability

Incorporate sustainable practices into steel design and fabrication. Optimize material usage, promote recyclability, and explore energy-efficient solutions to reduce environmental impact.

These tips can help optimize steel design and fabrication processes, leading to safe, efficient, and sustainable steel structures.

Steel Design and Fabrication

Steel design and fabrication are intricate processes that shape the built environment around us, from towering skyscrapers to resilient bridges. This article has explored the multifaceted aspects of this field, highlighting its importance in ensuring structural integrity, safety, and sustainability.

As we continue to push the boundaries of architectural design and engineering innovation, steel design and fabrication will undoubtedly play an increasingly critical role. By embracing new technologies, optimizing processes, and prioritizing sustainability, we can harness the full potential of steel to create structures that are not only aesthetically pleasing but also safe, durable, and environmentally responsible.