What is steel fabrication and welding? Steel fabrication and welding are two essential processes in the construction industry. Steel fabrication is the process of shaping and forming steel into various components, while welding is the process of joining these components together. These processes are used to create a wide range of structures, from bridges and buildings to ships and airplanes.

Editor’s Notes: Steel fabrication and welding are important topics to understand for anyone working in the construction industry. These processes are essential for creating strong and durable structures. In this article, we will explore the basics of steel fabrication and welding, and provide some tips for getting started.

After doing some analysis and digging through a lot of information, we put together this steel fabrication and welding guide to help you make the right decision.

Key Differences

| Steel Fabrication | Welding |

|---|---|

| The process of shaping and forming steel into various components | The process of joining steel components together |

| Uses a variety of techniques, including cutting, bending, and forming | Uses a variety of welding techniques, including arc welding, MIG welding, and TIG welding |

| Requires specialized equipment and training | Requires specialized equipment and training |

Main Article Topics

- The benefits of steel fabrication and welding

- The different types of steel fabrication and welding

- The equipment and training required for steel fabrication and welding

- Tips for getting started with steel fabrication and welding

Steel Fabrication and Welding

Steel fabrication and welding are essential processes in the construction industry. They are used to create a wide range of structures, from bridges and buildings to ships and airplanes. Here are seven key aspects of steel fabrication and welding:

- Materials: Steel is a strong and durable material, making it ideal for a variety of applications. However, it is important to choose the right type of steel for the job. There are many different types of steel available, each with its own unique properties.

- Equipment: Steel fabrication and welding require a variety of specialized equipment. This equipment can be expensive, so it is important to invest in high-quality equipment that will last.

- Training: Steel fabrication and welding are skilled trades. It is important to receive proper training from a qualified instructor before attempting to perform these tasks.

- Safety: Steel fabrication and welding can be dangerous if proper safety precautions are not taken. Always wear appropriate safety gear and follow all safety regulations.

- Quality: The quality of steel fabrication and welding is essential for the safety and durability of the structure. Always inspect the work of steel fabricators and welders to ensure that it meets the required standards.

- Cost: Steel fabrication and welding can be expensive. However, the cost of these processes is often outweighed by the benefits they provide.

- Applications: Steel fabrication and welding are used in a wide range of applications, including construction, manufacturing, and transportation.

These seven key aspects provide a comprehensive overview of steel fabrication and welding. By understanding these aspects, you can make informed decisions about the use of these processes in your own projects.

Materials

The choice of steel for a particular fabrication or welding project depends on a number of factors, including the intended use of the structure, the environmental conditions to which it will be exposed, and the budget. Some of the most common types of steel used in fabrication and welding include:

- Carbon steel: Carbon steel is the most common type of steel used in fabrication and welding. It is strong and durable, and it is relatively inexpensive. However, it is also susceptible to corrosion, so it is not suitable for use in applications where it will be exposed to moisture or chemicals.

- Stainless steel: Stainless steel is a type of steel that contains chromium and nickel. This gives it a high resistance to corrosion, making it ideal for use in applications where it will be exposed to moisture or chemicals. However, stainless steel is more expensive than carbon steel.

- Alloy steel: Alloy steel is a type of steel that contains other elements, such as manganese, silicon, or nickel. This gives it specific properties, such as increased strength, hardness, or toughness. Alloy steel is more expensive than carbon steel, but it can be a good choice for applications where specific properties are required.

The choice of the right type of steel for a particular fabrication or welding project is essential for the safety and durability of the structure. By understanding the different types of steel available and their properties, you can make an informed decision about the best steel for your project.

Equipment

Steel fabrication and welding require a variety of specialized equipment, including cutting torches, welding machines, grinders, and bending machines. This equipment is essential for shaping and joining steel components to create a wide range of structures. Investing in high-quality equipment is important for several reasons.

- Safety: High-quality equipment is less likely to malfunction or break, which can help to prevent accidents.

- Efficiency: High-quality equipment is more efficient, which can save time and money.

- Accuracy: High-quality equipment is more accurate, which can help to ensure that the final product meets the required specifications.

- Durability: High-quality equipment is more durable, which means that it will last longer and require less maintenance.

In addition to the benefits listed above, investing in high-quality equipment can also help to improve the overall quality of the finished product. By using the right tools for the job, fabricators and welders can create stronger, more durable, and more aesthetically pleasing structures.

Here are some examples of the types of equipment used in steel fabrication and welding:

- Cutting torches: Cutting torches are used to cut steel into various shapes and sizes. There are two main types of cutting torches: oxy-fuel torches and plasma cutters. Oxy-fuel torches use a mixture of oxygen and fuel gas to create a flame that can cut through steel. Plasma cutters use a plasma arc to cut through steel.

- Welding machines: Welding machines are used to join steel components together. There are two main types of welding machines: arc welders and MIG welders. Arc welders use an electric arc to create a weld between two pieces of steel. MIG welders use a continuous wire electrode to create a weld between two pieces of steel.

- Grinders: Grinders are used to smooth and finish welds. There are two main types of grinders: angle grinders and bench grinders. Angle grinders are handheld grinders that can be used to grind welds in a variety of locations. Bench grinders are stationary grinders that are used to grind welds on larger pieces of steel.

- Bending machines: Bending machines are used to bend steel into various shapes. There are two main types of bending machines: press brakes and rolling machines. Press brakes use a hydraulic ram to bend steel into a desired shape. Rolling machines use a series of rollers to bend steel into a desired shape.

The choice of the right equipment for a particular steel fabrication or welding project depends on a number of factors, including the type of steel being used, the thickness of the steel, and the desired shape of the finished product. By understanding the different types of equipment available and their capabilities, fabricators and welders can choose the right equipment for the job and create high-quality steel structures.

Training

Steel fabrication and welding are skilled trades that require specialized knowledge and training. This training is essential for ensuring the safety and quality of steel structures. Here are four key reasons why training is important for steel fabrication and welding:

- Safety: Steel fabrication and welding can be dangerous if proper safety precautions are not taken. Training helps to ensure that workers understand the hazards associated with these processes and how to protect themselves from injury.

- Quality: Proper training is essential for producing high-quality steel structures. Trained workers are more likely to produce welds that are strong, durable, and aesthetically pleasing.

- Efficiency: Trained workers are more efficient at performing steel fabrication and welding tasks. This can save time and money on construction projects.

- Code compliance: Steel fabrication and welding must be performed in accordance with building codes and standards. Training helps to ensure that workers are familiar with these codes and standards and that they are able to comply with them.

In addition to these four key reasons, training can also help to improve worker morale and job satisfaction. When workers feel confident in their abilities, they are more likely to be productive and take pride in their work.

If you are considering a career in steel fabrication or welding, it is important to receive proper training from a qualified instructor. This training will give you the skills and knowledge you need to perform these tasks safely and efficiently.

Safety

Steel fabrication and welding are essential processes in the construction industry. However, these processes can also be dangerous if proper safety precautions are not taken. Here are some of the hazards associated with steel fabrication and welding:

- Electrical hazards: Steel fabrication and welding often involve the use of electricity, which can pose a risk of electrical shock or electrocution.

- Fire hazards: Steel fabrication and welding can generate sparks and flames, which can ignite fires if proper precautions are not taken.

- Fumes and gases: Steel fabrication and welding can produce fumes and gases that can be harmful to health if inhaled.

- Noise hazards: Steel fabrication and welding can generate loud noise levels, which can damage hearing if proper hearing protection is not worn.

- Eye hazards: Steel fabrication and welding can generate bright light and sparks, which can damage eyes if proper eye protection is not worn.

To protect workers from these hazards, it is essential to wear appropriate safety gear and follow all safety regulations. Here are some of the most important safety precautions that should be taken when working with steel fabrication and welding:

- Wear appropriate clothing, including long sleeves, pants, and closed-toe shoes.

- Wear a welding helmet to protect your eyes and face from sparks and bright light.

- Wear earplugs or ear muffs to protect your hearing from loud noise.

- Use a respirator to protect your lungs from fumes and gases.

- Follow all safety regulations, including those to fire prevention, electrical safety, and hazardous materials handling.

By following these safety precautions, workers can help to reduce the risk of accidents and injuries when working with steel fabrication and welding.

Real-life examples

There are many real-life examples of the importance of safety in steel fabrication and welding. For example, in 2017, a worker was killed in a steel fabrication shop when he was struck by a piece of flying metal. The worker was not wearing a hard hat at the time of the accident. In another incident, a worker was seriously injured when he was exposed to toxic fumes while welding. The worker was not wearing a respirator at the time of the accident.

These are just two examples of the many accidents that can happen when proper safety precautions are not taken when working with steel fabrication and welding. By following the safety precautions outlined above, workers can help to reduce the risk of accidents and injuries.

Conclusion

Safety is of paramount importance in steel fabrication and welding. By following proper safety precautions, workers can help to reduce the risk of accidents and injuries. Employers have a responsibility to provide a safe work environment for their employees, and employees have a responsibility to follow safety regulations and wear appropriate safety gear.

Table

| Hazard | Safety precaution |

|---|---|

| Electrical hazards | Wear insulated gloves and clothing, use ground fault circuit interrupters (GFCIs), and follow electrical safety regulations. |

| Fire hazards | Keep work areas clean and free of flammable materials, have fire extinguishers readily available, and follow fire safety regulations. |

| Fumes and gases | Use ventilation systems to remove fumes and gases, wear respirators, and follow hazardous materials handling regulations. |

| Noise hazards | Wear earplugs or ear muffs, and follow noise exposure regulations. |

| Eye hazards | Wear welding helmets, safety glasses, and face shields, and follow eye protection regulations. |

Quality

The quality of steel fabrication and welding is one of the most important factors determining the safety and durability of a structure. Poor quality steel fabrication and welding can lead to structural failures, which can have catastrophic consequences. That is why it is essential to always inspect the work of steel fabricators and welders to ensure that it meets the required standards.

There are a number of factors that can affect the quality of steel fabrication and welding, including the skill and experience of the fabricators and welders, the quality of the materials used, and the welding equipment and techniques employed. It is important to choose a steel fabricator and welder who has a proven track record of producing high-quality work. You should also make sure that the fabricator and welder are using high-quality materials and welding equipment and techniques.

Once the steel fabrication and welding is complete, it is important to inspect the work to ensure that it meets the required standards. The inspector should check the welds for any defects, such as cracks, porosity, or undercutting. The inspector should also check the overall dimensions of the structure to ensure that it is within the specified tolerances.

By following these steps, you can help to ensure that the steel fabrication and welding on your project is of the highest quality. This will help to ensure the safety and durability of your structure for many years to come.

Real-life examples

There are many real-life examples of the importance of quality steel fabrication and welding. For example, the collapse of the World Trade Center towers on 9/11 was due in part to the failure of the steel welds that held the towers together. The welds were not strong enough to withstand the heat of the fire, which caused them to fail and the towers to collapse.

Another example of the importance of quality steel fabrication and welding is the collapse of the I-35W bridge in Minneapolis in 2007. The collapse was due to a design flaw in the bridge, which caused the steel gusset plates that connected the bridge’s deck to its supports to fail. The failure of the gusset plates caused the bridge to collapse, killing 13 people.

These are just two examples of the many real-life examples of the importance of quality steel fabrication and welding. By ensuring that the steel fabrication and welding on your project is of the highest quality, you can help to prevent accidents and injuries and ensure the safety and durability of your structure.

Conclusion

The quality of steel fabrication and welding is essential for the safety and durability of a structure. Always inspect the work of steel fabricators and welders to ensure that it meets the required standards. By following these steps, you can help to ensure that your structure is safe and durable for many years to come.

| Cause | Effect |

|---|---|

| Poor quality steel fabrication and welding | Structural failures |

| Failure of steel welds | Collapse of World Trade Center towers |

| Failure of steel gusset plates | Collapse of I-35W bridge |

Cost

Steel fabrication and welding are essential processes in the construction industry. They are used to create a wide range of structures, from bridges and buildings to ships and airplanes. While these processes can be expensive, the cost is often outweighed by the benefits they provide.

- Durability: Steel is a strong and durable material, and steel structures can last for many years with proper maintenance. This durability can save money in the long run, as it reduces the need for repairs and replacements.

- Strength: Steel is one of the strongest materials available, and steel structures can withstand high loads and forces. This strength makes steel structures ideal for use in areas where safety is a concern, such as in earthquake zones or in buildings that are subject to high winds.

- Versatility: Steel is a versatile material that can be used to create a wide range of shapes and sizes. This versatility makes steel structures ideal for use in a variety of applications, from small residential buildings to large commercial buildings.

- Fire resistance: Steel is a fire-resistant material, and steel structures can withstand high temperatures for extended periods of time. This fire resistance can help to protect people and property in the event of a fire.

While the cost of steel fabrication and welding can be a concern, the benefits these processes provide often outweigh the cost. Steel structures are durable, strong, versatile, and fire-resistant, making them an ideal choice for a wide range of applications.

Applications

Steel fabrication and welding are essential processes in the construction, manufacturing, and transportation industries. These processes are used to create a wide range of products, from bridges and buildings to cars and airplanes. The versatility of steel fabrication and welding makes them ideal for a variety of applications, each with its own unique set of challenges and requirements.

In the construction industry, steel fabrication and welding are used to create a variety of structures, including bridges, buildings, and skyscrapers. Steel is a strong and durable material, making it ideal for use in load-bearing structures. Steel structures are also relatively lightweight, which makes them easier to transport and erect. Steel fabrication and welding are also used in the manufacturing industry to create a variety of products, including cars, trucks, and airplanes. Steel is a strong and durable material, making it ideal for use in vehicles and aircraft. Steel is also relatively lightweight, which helps to improve fuel efficiency. In the transportation industry, steel fabrication and welding are used to create a variety of products, including ships, trains, and pipelines. Steel is a strong and durable material, making it ideal for use in transportation applications. Steel is also relatively lightweight, which helps to reduce the weight of vehicles and vessels.

The applications of steel fabrication and welding are vast and varied. These processes are essential for the construction, manufacturing, and transportation industries. The versatility of steel fabrication and welding makes them ideal for a wide range of applications, each with its own unique set of challenges and requirements.

Real-life examples

Here are some real-life examples of the applications of steel fabrication and welding:

- The Golden Gate Bridge in San Francisco is a suspension bridge made of steel. The bridge is 1.7 miles long and was completed in 1937. The Golden Gate Bridge is one of the most iconic landmarks in the United States.

- The Burj Khalifa in Dubai is the tallest building in the world. The building is made of steel and glass and was completed in 2010. The Burj Khalifa is a stunning example of modern architecture.

- The Boeing 747 is a wide-body airliner that is used by airlines around the world. The 747 is made of steel and aluminum and was first introduced in 1970. The 747 is one of the most recognizable airplanes in the world.

These are just a few examples of the many applications of steel fabrication and welding. These processes are essential for the construction, manufacturing, and transportation industries. The versatility of steel fabrication and welding makes them ideal for a wide range of applications, each with its own unique set of challenges and requirements.

Conclusion

Steel fabrication and welding are essential processes in the modern world. These processes are used to create a wide range of products, from bridges and buildings to cars and airplanes. The versatility of steel fabrication and welding makes them ideal for a variety of applications, each with its own unique set of challenges and requirements.

Table

| Industry | Applications |

|---|---|

| Construction | Bridges, buildings, skyscrapers |

| Manufacturing | Cars, trucks, airplanes |

| Transportation | Ships, trains, pipelines |

Frequently Asked Questions about Steel Fabrication and Welding

Steel fabrication and welding are essential processes in the construction, manufacturing, and transportation industries. These processes are used to create a wide range of products, from bridges and buildings to cars and airplanes. Here are some frequently asked questions about steel fabrication and welding:

Question 1: What is steel fabrication?

Steel fabrication is the process of shaping and forming steel into various components. This can be done using a variety of techniques, including cutting, bending, and welding.

Question 2: What is welding?

Welding is the process of joining two pieces of metal together by melting them at the point of contact. This can be done using a variety of welding techniques, including arc welding, MIG welding, and TIG welding.

Question 3: What are the different types of steel used in fabrication and welding?

There are many different types of steel used in fabrication and welding, each with its own unique properties. Some of the most common types of steel include carbon steel, stainless steel, and alloy steel.

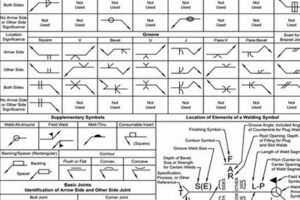

Question 4: What are the different welding techniques?

There are many different welding techniques, each with its own advantages and disadvantages. Some of the most common welding techniques include arc welding, MIG welding, and TIG welding.

Question 5: What are the safety precautions that should be taken when working with steel fabrication and welding?

Steel fabrication and welding can be dangerous if proper safety precautions are not taken. Some of the most important safety precautions include wearing appropriate safety gear, following all safety regulations, and being aware of the hazards associated with these processes.

Question 6: What are the applications of steel fabrication and welding?

Steel fabrication and welding are used in a wide range of applications, including construction, manufacturing, and transportation. Some of the most common applications include bridges, buildings, cars, and airplanes.

These are just a few of the most frequently asked questions about steel fabrication and welding. If you have any other questions, please do not hesitate to contact a qualified professional.

Summary

Steel fabrication and welding are essential processes in the modern world. These processes are used to create a wide range of products, from bridges and buildings to cars and airplanes. The versatility of steel fabrication and welding makes them ideal for a variety of applications, each with its own unique set of challenges and requirements.

Next Steps

If you are interested in learning more about steel fabrication and welding, there are a number of resources available online and in libraries. You can also find training courses and workshops that can teach you the skills you need to work with steel fabrication and welding.

Tips for Steel Fabrication and Welding

Steel fabrication and welding are essential processes in the construction, manufacturing, and transportation industries. These processes can be complex and dangerous, so it is important to follow proper safety procedures and use the right tools and techniques. Here are a few tips to help you get started:

Tip 1: Choose the Right Steel

There are many different types of steel available, each with its own unique properties. It is important to choose the right type of steel for the job. For example, if you are welding a structural component, you will need to use a steel that is strong and durable. If you are welding a decorative component, you may be able to use a less expensive type of steel.

Tip 2: Use the Right Welding Technique

There are many different welding techniques available, each with its own advantages and disadvantages. It is important to choose the right welding technique for the job. For example, if you are welding a thick piece of metal, you will need to use a welding technique that can generate a lot of heat. If you are welding a thin piece of metal, you may be able to use a welding technique that generates less heat.

Tip 3: Use the Right Safety Gear

Steel fabrication and welding can be dangerous, so it is important to wear the right safety gear. This includes a welding helmet, gloves, and safety glasses. It is also important to work in a well-ventilated area to avoid inhaling harmful fumes.

Tip 4: Follow Proper Safety Procedures

It is important to follow proper safety procedures when working with steel fabrication and welding. This includes keeping your work area clean and free of debris, and never welding near flammable materials. It is also important to be aware of the electrical hazards associated with welding and to take precautions to avoid electrical shock.

Tip 5: Get Training

If you are new to steel fabrication and welding, it is important to get training from a qualified professional. This will help you to learn the proper techniques and safety procedures.

By following these tips, you can help to ensure that your steel fabrication and welding projects are safe and successful.

Summary

Steel fabrication and welding are essential processes in the modern world. These processes are used to create a wide range of products, including bridges, buildings, cars, and airplanes. The tips provided in this article can help you to get started with steel fabrication and welding safely and successfully.

Next Steps

If you are interested in learning more about steel fabrication and welding, there are a number of resources available online and in libraries. You can also find training courses and workshops that can teach you the skills you need to work with steel fabrication and welding.

Conclusion

Steel fabrication and welding are essential processes in the construction, manufacturing, and transportation industries. These processes are used to create a wide range of products, from bridges and buildings to cars and airplanes. Steel fabrication and welding are complex processes that require specialized knowledge and training. However, by following proper safety procedures and using the right tools and techniques, you can safely and successfully complete your steel fabrication and welding projects.

The future of steel fabrication and welding is bright. As technology advances, new and innovative ways to use steel are being developed. This will lead to even more applications for steel fabrication and welding in the years to come.